Abstract

Ru@MNP-MWCNT catalysts were obtained via functionalization of nanostructured carbon-based carriers (ie, MWCNT) with base molecules (ie, 2-aminophenol and ethylenediamine) followed by the complexation with RuCl3. These structures demonstrated a highly efficient behavior for the selective wet oxidation of levulinic acid and glucose to succinic acid. However, to ensure an easy recovery and high recyclability the MWCNTs nanotubes were modified by incorporation of super-paramagnetic Fe3O4 nanoparticles into porous structure. Besides the catalytic performances the resulted composites showed a good mechanical resistance.

Similar content being viewed by others

1 Introduction

The development of efficient catalytic methods for the biomass transformation to platform molecules is one of the most attractive and challenging subjects in green and sustainable chemistry [1]. In this context, a major topic of current research is the catalytic aerobic oxidation of renewable raw materials to valuable organic molecules [2]. Considering its economical importance, succinic acid (SA) is classified as one of the most important target products being included in the top 10 list of the interest platform molecules.

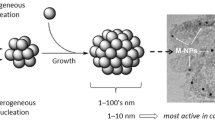

On the other side, magnetic nanoparticles (MNPs) have been gaining increasing interest in the last years due to their valuable properties such as high surface area, low toxicity and super-paramagnetic behavior [3]. This intrinsic property may allow a easier separation from reaction mixtures by the use of an external magnetic field. In addition, the presence of a large number of hydroxyl groups on the external surface affords both the deposition of inorganic shells containing different catalytic active phases or the direct immobilization of a variety of catalytic functionalities via covalent bonds [4]. Following these strategies, a significant number of MNPs-comprised catalysts have been developed for various catalytic reactions such as acylations [5], Michael additions [6], asymmetric hydrogenations [7], epoxidations [8], C–C coupling reactions [9], reduction of epoxy ketones [10] and hydroformylation [11].

For the efficient green chemical valorization of biomass, in which the solid raw material (e.g., cellulose, lignin, etc) is usually not completely converted to the end of reaction and, in addition, part of intermediates (e.g., 5-(hydroxymethyl)-2-furaldehyde (HMF)) is converted into humins as supplementary solid residues, the use of MNPs as carrier in core–shell nano-composites is also highly valuable. In this context, not long ago we reported an efficient Ru(4 wt%)@MNP-SiO2 catalyst for the oxidation of levulinic acid (LA) to SA (SSA = 96–98% for XLA = 59–79%) [12]. Moreover, by a simple addition of n-butylamine in the reaction medium, the catalyst afforded a more efficient Ru(IV)-bis-amine adduct (Ru(4 wt%)-bis-amine@MNP-SiO2) able to produce the one-pot catalytic wet oxidation (CWO) of glucose to SA (selectivity of 87.5%, for a > 99.9% conversion of glucose) [13]. The reaction occurs through a two steps mechanism involving both species from the homogeneous phase and the catalytic active sites from solid phase. Extremely important, the catalysts (ie, Ru(4 wt%)@MNP-SiO2 and Ru(4 wt%)-bis-amine@MNP-SiO2) were easily separated from the product mixture by an external magnetic force (e.g., generated by a commercial Nd-Fe-B permanent magnet), making possible its repeated use without any deactivation under hydrothermal or oxidation conditions. However, even not yet demonstrated, the SiO2 shell may be the subject of the hydrothermal degradation under the reactions conditions (i.e., in water, and at temperatures below 200 °C) while the presence of additives in the homogeneous phase (ie, n-butylamine) is not really in line with the green chemistry principles.

To overpass these drawbacks we explored novel heterogeneous catalytic systems, developed by functionalization of carriers with high mechanical strength properties (ie, graphene) and base sites directly inserted in the constitutive support. We have thus demonstrated that N-containing graphenes (Gs) act as catalysts for the selective CWO of glucose to SA, with selectivities over 60% for a complete conversion of glucose (160 °C, 18 atm O2 pressure for 20 h) [14]. This activity has been attributed to the presence of inserted graphenic-type N atoms. Further impregnation of these graphenes with RuCl3 led to small, well-dispersed ruthenium oxyhydroxide nanoparticles (particles size bellow 1 nm) that produced an increase of the selectivity to SA (87%) keeping the total conversion [15]. Very important, the best catalyst contained only a 1 wt% Ru loading and the graphene had a large population of graphenic N atoms. In this way, the continuous addition of an excess of amine to reach high SA selectivity and reusability was not anymore necessary. These findings constituted a step forward towards the development of a catalyst able to promote the selective one-pot conversion of glucose into SA. However, the separation and recovery of the catalyst needs a centrifugation step which may lead to their degradation, with a direct effect to the process effectiveness.

Along graphene, in the last years, multi-wall carbon nanotubes (MWCNTs) have attracted an increasing attention as novel nanocarbon materials [16, 17]. This interest is directly related to several unique features of these materials, such as the high thermal/electrical conductivity, medium to high specific surface areas, excellent adsorptive resistance and high mechanical, chemical, and thermal stability. They make a full of promise as catalyst support, for metallic nanoparticles [18, 19], complexes [20, 21] or enzymes [22]. On the other side, carbon nanotubes filled with MNPs were reported as very interesting carriers for the enzymes immobilization [22] and for applications in biomedicine [23]. Based on these achievements, very recently we investigated and reported the synthesis of niobia-based magnetic carbon nanotubes (ie, MNP-MWCNT) catalysts [24], opening the way of the development of magnetic-based MWCNT catalysts with a high potential efficiency in the raw renewable materials valorization to platform molecules. By adjusting the preparation conditions of these composites (e.g., precursor nature, calcination temperature and loading of niobia) it was possible to produce an efficient catalyst for the synthesis of lactic acid through the direct hydrolysis of starch. The presence of the MNPs, a complete and simple catalyst recovery by means of an external magnetic field may be applied. However, the niobia-based MNP-MWCNT catalytic systems involved a difficult, long time consuming and expensive preparation method.

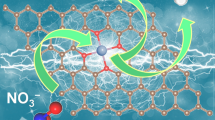

Thus, encouraged by these very promising results and with the aim to produce a more sustainable catalytic system, here we report the development of a recyclable and efficient magnetic recoverable catalyst based on Ru (IV) active species (Ru@MNP-MWCNT). The design strategy combined the most relevant elements of the previously reported catalysts. Accordingly, the novel heterogeneous catalytic system was developed via the functionalization of a carrier with a high mechanical strength (ie, MWCNT) with base species (ie, 2-aminophenol (AP) and ethylenediamine (EDA)). This functionalized MWCNT acted as a support for coordinated Ru(IV) complexes. Magnetic Fe3O4 nanoparticles were incorporated to allow easy recovery of mechanical stable MWCNTs. The new designed catalysts were tested in the oxidation of LA to SA, with molecular oxygen as oxidation agent and water as solvent. The optimized catalyst was further investigated for the one-pot CWO of glucose to SA.

2 Results and Discussion

The preparation steps of the Ru-based MNP-MWCNT catalysts are described in Schemes 1a and b. Details upon the procedure conditions are given in the Sect. 4.

In accordance to Wei et al. [23] the pre-treatment of the MWCNT with nitric acid is mandatory for a successful encapsulation of the MNPs into the nanotubes. It is proposed that this oxidative treatment makes their external surface to become slippery, preventing the adsorption of the iron solution which, in turn, discontinuously flows into the cavity of MWCNTs nanotubes through capillarity forces (Scheme 1a).

MNP-MWCNTs containing well-defined molecular Ru complexes produced via a –COCl anchoring group were forward synthesized (Scheme 1b). –COCl has been chosen because of its high chemical stability leading to strong covalent bonds with the MWCNT carrier and also to its high affinity for –NH2 groups leading to N-substituted amides. Anchoring of well-defined metal complexes instead of simply oxides has been decided due to the fact it presents a much higher potential to control stereospecific reactions through the ligand design tool kit.

XRD pattern of MWCNT (Fig. 1, pattern a) indicates specific diffraction lines at 2θ of around 25.9°, 42.7°, 44.4° and 53.8° (JCPDS file 75-1621) assigned to the (002), (100), (101) and (004) planes of the hexagonal graphite structure. The XRD of pure Fe3O4 nanoparticles (not shown in Fig. 1) showed diffraction lines at 2θ 30.1°, 35.6°, 37.5°, 44.1°, 55.4°, 58.5°, 64.1°, and 74.6° assigned to (220), (311), (222), (400), (422), (511), (440), and (533) planes corresponding to the cubic Fe3O4 phase of the inverse spinel (JCPDS file 19-0629) [25]. MWCNTs filled with Fe3O4 nanoparticles (Fig. 1, pattern b) shown characteristic planes of Fe3O4, but the 2θ values are shifted to lower angles than those found in pure Fe3O4 due to the interaction of Fe3O4 nanoparticles with MWCNTs. Moreover, the characteristic lines of the (002) and (100) diffraction planes of MWCNTs were also observed. The average crystallite size (Dc) of the encapsulated Fe3O4 nanoparticles, calculated by using the Sherrer equation, is about 8 nm, which fits with the size of the pore nanotube.

The CWO of LA to SA took place with an unexpectedly high catalytic efficiency, resulting in selectivities of > 98% to SA for conversions of LA in the range 91–100%, in only 4 h of reaction (Fig. 2a, b).

The catalysts were easily separated with an external magnet and the recovered catalysts were reused without a significant loss of the catalytic performance. Figure 3 illustrates the catalytic results for the recycling experiments with the Ru-AP@MNP-MWCNT catalyst.

The difference in selectivity (3–4%) till 100% in the second and third catalytic cycles is the effect of the production of acetic acid. It is the result of an alternative migration product in the Baeyer–Villiger oxidation of LA, to 3-hydroxypropanoic acid (HPA), in a good accordance to the previous report of Mascal et al. [26] (Scheme 2). HPA can then undergo a retro aldol cleavage to give acetic acid and formaldehyde, the latter ultimately being oxidized to formic acid. In contrast to acetic acid, formic acid is not stable in the investigated conditions and, in the presence of the Ru-based catalyst, is transformed into CO2 and H2O. The stability of this catalyst is quite similar to that of RuIII(4 wt%)-NH2@MNP-SiO2 [3] but its catalytic efficiency is superior. Accordingly, after 6 h, RuIII(4 wt%)-NH2@MNP-SiO2 afforded indeed a selectivity to SA of 96–98% but for a conversion of levulinic acid (XLA) of only 59–79% [12].

The UV–Vis time dependent analysis of the RuCl3 aqueous solution during the ruthenium impregnation has shown the formation of Ru(OH)xCl3−x species (bands located at 252 and 224 nm) that is in accordance with previous results [27]. It is also not excluded that in the presence of water, part of Ru species generated H+ and [Ru(H2O)5OH]2+ (ie, RuII–OH2 complex), as strong Brønsted acids (pKa = 2.9 at 298 K), via a similar mechanism to that reported by Sutin and co-workers for [Ru(H2O)6]3+ [28].

The new catalysts (Ru(4 wt%)-AP@MNP-MWCNT and Ru(4 wt%)-EDA@MNP-MWCNT) were investigated by XANES spectroscopy and compared to RuO2 as reference (spectra given in Fig. 4a, pre-edge is marked in dashed square). The corresponding first derivatives are given in Fig. 4b.

Getty et al. [29] assigned Ru K-edge pre-edge peaks to the centrosymmetric structure of Ru carbene complexes for olefin metathesis. By increasing the symmetry of the complexes, the pre-edge peaks become weaker which may correspond to a lowered Ru 4d–5p orbital mixing.

Accordingly, the very low-intensity of the Ru K-edge (Fig. 4a) implies a centrosymmetric coordination of the investigated Ru compounds, and can be assigned to Ru 4d←1s transitions in the six-coordinate pseudo-octahedral Ru-AP and Ru-EDA complexes. Also, the single pre-edge feature of these complexes can be associate to the absence of any splitting of the empty 4dσ* orbitals and, to a one available 2Eg ligand field excited state [30]. However, the values determined at the Ru K-edge (Fig. 4a, b) corresponds to a shift to lower photon energies in the following order: Ru-EDA < Ru-AP < RuO2. In accordance to Rompel et al. [31] an edge shift of about + 2 eV is characteristic for the couple Ru(II)/Ru(III), while within the same Ru oxidation state the edge energies increase with increasing the electronegativity of the first shell atoms. The edge energies observed in this study span a range of about 12 eV, with Ru-AP occupying a position in the middle. The bottom limit is marked by the Ru-EDA and the upper one by RuO2 with six O ligands and an oxidation state of + 4 (rutile type structure). On this basis one may assume that the catalytic species generated through the coordination of ruthenium with AP or EDA ligands correspond to six-coordinate pseudo-octahedral Ru-AP and Ru-EDA complexes with Ru(III) and mixed Cl/O/N first shell ligand atoms in different proportions.

EDA and AP act as bidentate ligands for the coordination of RuIII/RuII species produced in water. Such a coordination creates catalytic active sites with a different electronic density and different availability as compared to RuIII(4 wt%)-NH2@MNP-SiO2 catalyst (i.e., monodentate ligands). It also induces differences in the catalytic behavior demonstrating the sensitivity of this reaction to the electronic/coordination properties of the catalyst. Moreover, under the CWO conditions, RuIII-Cl(OH)/RuII-OH2 complex can easily generate higher RuIV=O oxidation state complexes through a sequential proton coupled electron transfer. Once generated, the RuIV=O complex becomes an oxidant able to afford a range of oxidative transformations including the olefin epoxidation [32].

However, as the previous results demonstrated, certain basicity is compulsory for this reaction. Indeed, the temperature-programmed desorption of carbon dioxide (CO2-TPD) measurements evidenced that Ru(IV)-bidentate complexes resulted via the complexation with grafted EDA or AP on the MNP-MWCNT carrier present a high density of strong base sites (Fig. 5; Table 1).

Compared to the RuIII(4 wt%)-NH2@MNP-SiO2 catalyst (Table 1, entries 5 and 6) [12] both Ru-AP@MNP-MWCNT and Ru-EDA@MNP-MWCNT display a higher density of base sites. Nevertheless, the basicity strength is quite similar to that determined for RuIII-NH2@MNP-SiO2 that may explain the similarity in selectivity. Thus, the catalytic efficiency of the MNP-MWCNT-derived catalyst should be also associated to the density of the basic sites.

Summarizing, the catalytic performances of the discussed Ru-based catalysts seem to be dictated by some essential factors as the geometry of the catalytic active sites, ie, mono- versus bi-dentate complexes, the Ru oxidation state, ie, Ru(III) versus Ru(IV), and the base density, ie, 0.42 mmol CO2/g versus 3.5–5.9 mmol CO2/g, for RuIII-NH2@MNP-SiO2 versus Ru-EDA@MNP-MWCNT and Ru-AP@MNP-MWCNT samples.

Obviously, along to these discussed properties, the availability of the substrates to the catalytic active sites is another essential factor for a good catalytic performance. Indeed, using micrometer-sized commercial silica powder, the catalyst (RuIII(4 wt%)@SiO2-NH2) prepared by combining propylamine functionalised silica with grafted cationic ruthenium afforded only a small conversion of LA (lower than 5%) with a selectivity to SA of 92% [12]. In line with the availability, the dispersability of the catalyst in the investigated solvent is also important. Figure 6 shows dynamic light scattering (DLS) measurements in water, ie the solvent in which the reactions were carried out. Differently to RuIII(4 wt%)@SiO2-NH2, which has a certain tendency for aggregation, the magnetic MNP-MWCNT nanoparticles confirmed a high dispersity in water. This fact minimizes the diffusion limitations and allows a better contact between the catalytic active surface and LA, also contributing to an increased reaction rate.

Thermal degradation (T = 180 °C) of glucose under oxidation conditions (10 atm of O2) and in the absence of the N-base took place with a moderate reaction rate (conversion of 12%) and non-selective, leading to a broad spectrum of products, the most important being glycolic acid, lactones, hexose and glucose isomers [13]. In the presence of free-metal AP@MNP-MWCNT or EDA@MNP-MWCNT (Scheme 1b) the conversion of glucose occurs in a large extent (Xglucose = 90–97%). SA is also present in the complex reaction mixture, but with an unsatisfactorily low selectivity (only 12–13% at 180 °C and 10 atm of O2, after 6 h of reaction).

The complexation of RuCl3 (Scheme 1b) with AP led to a strong synergic effect in the CWO of glucose. Thus, on Ru-AP@MNP-MWCNT, the CWO of glucose took place with a selectivity of 86.7% to SA for a conversion of glucose of 100%, in only 2 h. The difference till 100% was constituted from lower molecular mass carboxylic acids such as lactic, glycolic and glyceric acids.

After six cycles recycling tests shown almost no visible change in conversion and the selectivity to SA (Fig. 7).

Based on these catalytic and characterizations results we assume that the formation of SA occurs through a bifunctional mechanistic pathway involving a hydrogen transfer reaction catalyzed by Ru and an oxidative deoxygenation of tartaric acid into fumaric acid (Scheme 3). The presence of a base facilitates the alcohol group dehydrogenation by deprotonation and favors the desorption of produced carboxylic acids in a good accordance to the previous reports of Mallat and Baiker [33]. The role of oxygen is that to preserve the oxidation RuIV=O state species [13, 15]. The polyols present in the subjected substrates act as a source for the hydrogen transfer process. Separated control experiments confirmed indeed this approach demonstrating the investigated catalysts catalyze both the transfer hydrogenation of fumaric acid by polyols and deoxygenation of tartaric acid via an oxygen transfer to Ru.

3 Conclusions

This study presents an example of optimization of the Ru catalyst for the CWO of LA by using MWCNT as support, and selecting AP as complexating base. This strategy allowed, on one side, to tune the electronic properties and to stabilize the Ru(IV) species and, on the other side, to increase the density of the basic sites on the support. This optimization allowed a significant increase in the selectivity to SA (> 99.9% for a total conversion of LA) using LA as substrate, and of 86.7% using glucose as substrate (measured at total conversion of glucose). In addition, all these results evidenced several important advantages of the new bifunctional catalyst: (i) Ru-AP@MNP-MWCNT catalyst exhibits a high catalytic efficiency and stability to recycling, (ii) Ru-AP@MNP-MWCNT catalyst does not require any addition of a homogeneous base; (iii) compared to other reported heterogeneous catalysts the separation of Ru-AP@MNP-MWCNT catalyst is more efficient due to the incorporation of the MNPs inside the MWCNTs nanotubes.

4 Experimental

All the chemicals and reagents were of analytical purity grade, purchased from Sigma-Aldrich and used without any further purification. Multi-walled carbon nanotubes (MWCNTs) were purchased from Sigma-Aldrich with following features: armchair configuration; preparation method Catalytic Chemical Vapor Deposition (CVD) (CoMoCAT®), over 98% carbon, O.D.×L/6–9 nm × 5 µm.

4.1 Catalysts Preparation

4.1.1 Production of Magnetic MWCNTs (MNP-MWCNTs)

MWCNTs were filled with Fe3O4 using a simple method adapted from Goh et al. [22] and Esnaashari et al. [34]. Briefly, 5 g of MWCNT was oxidized under ultrasound at 50 °C for 3 h in 65% aqueous nitric acid solution. The oxidized MWCNT-COOH sample was filtered, and washed with water till the filtrate was neutral. In a 100 mL round-bottom flask equipped with a condenser and a magnetic stirrer bar, MWCNT-COOH (5 g), and SOCl2 (30 mL) were mixed and refluxed for 24 h under argon atmosphere. After that, the reaction mixture was cooled and SOCl2 was evaporated. The resulting precipitate was composed from chlorinated multi-wall carbon nanotubes, MWCNT-COCl.

Then, 0.15 g of ammonium iron(II) sulfate hexahydrate were dissolved in 5 mL of deionized (DI) water and hydrazine hydrate solution in a volume ratio of 3:1 to achieve a dark green solution. The chlorinated MWCNT-COCl was after that added to the solution. The mixture was sonicated and stirred vigorously for 12 h and the pH adjusted to 11–13 using ammonia solution to facilitate the uptake of the iron solution into the MWCNT. The surface of MWCNT was cleaned from iron oxide solution by reacting the tubes with diluted hydrochloric acid and then rinsing them with ethyl acetate and deionizated water (DI) while filtering. Lastly, the MWCNT were suspended in DI water and freeze–dried for 24 h to obtain MNP-MWCNT, as shown in Scheme 2a. The magnetic properties of MNP-MWCNT were checked by a simple magnet.

4.1.2 Preparation of AP@MNP-MWCNT and EDA@MNP-MWCNT

In a 100 mL round-bottom flask equipped with a magnetic stirring bar were added: dimethyl formamide (DMF) (50 mL), MNP-MWCNTs (2 g), AP or EDA (2 g) and Et3N (3 mL) and heated at 80 °C for 72 h. Then, the reaction mixture was filtered, washed with CH3CN and dried at 30–40 °C. The resulted samples were denoted AP@MNP-MWCNT and EDA@MNP-MWCNT, respectively.

4.1.3 Ru Deposition on MNP-MWCNT-OAP and MNP-MWCNT-EDA

Impregnation of the AP@MNP-MWCNT and EDA@MNP-MWCNT with an aqueous RuCl3 solution at a basic pH (pH 13) was made by adding 1.5 g of magnetically nanostructured material to 200 mg RuCl3 aqueous ruthenium(III) chloride (purchased from Aldrich) dissolved in 400 mL distilled water. The pH was adjusted at 13 with the aid of a NaOH aqueous solution (1 M). The mixture was maintained under stirring at 25 °C for 36 h. The solid was then magnetically collected from the solution, washed twice with distilled water and acetone and dried under vacuum. The loading of the ruthenium precursor corresponded to a concentration of 4 wt% Ru in the final catalyst. After the particles recovery, the supernatant solution was clear, the eventually remaining ruthenium species after impregnation being quantified with the UV–Vis spectroscopy. The last two preparation steps are summarized in Scheme 2b. The produced samples were denoted Ru-AP@MNP-MWCNT and Ru-EDA@MNP-MWCNT.

4.2 Catalysts Characterization

The obtained catalysts were exhaustively characterized using different techniques as powder X-ray diffraction (XRD), DLS, CO2-TPD, UV–Vis spectroscopy and X-ray absorption near edge spectroscopy (XANES).

Powder X-ray diffraction (XRD) patterns were recorded using a Shimadzu XRD-7000 diffractometer with Cu Kα radiation (λ = 1.5418 Å, 40 kV, 40 mA) at a step of 0.2θ and a scanning speed of 2° min−1 in the 5–90 degrees 2θ range.

DLS measurements were done by using a Mastersize 2000 apparatus from Malvern Instruments.

Temperature-programmed desorption of carbon dioxide (CO2-TPD) measurements were carried out using the AutoChem II 2920 station. The samples (30–50 mg) were placed in a U-shaped quartz reactor of an inner diameter of 0.5 cm and, then, they were pre-treated at 100 °C for 1 h with high purity He (Purity 5.0, from Linde), and then exposed to a flow of CO2 (from SIAD) for 1 h. After that, the samples were flushed with a flow of He (50 mL min−1) for 20 min at 25 °C in order to remove the weakly adsorbed CO2 species. TPD measurements were then carried out heating at a rate of 10 °C min−1 till 700 °C. The CO2 desorbed was quantified with a TC detector using a calibration curve. The results are expressed as mmoles of CO2 per gram of catalyst.

Optical spectra of the investigated catalysts were recorded in the UV–Vis region using the diffuse reflectance technique with a Specord 250 spectrometer from Analytik Jena.

Ru K-edge X-ray absorption near edge (XANES) spectra were recorded in transmission mode at the XAFS beamline of the Elettra synchrotron radiation facility in Trieste, Italy, by using a Si(311) double crystal monochromator and ionization chambers for recording the incident and the transmitted beam. The estimated resolving power is in the range of 20,000. Prior to the measurement, powder samples were grounded down to micrometer size and pressed into pellets together with cellulose after appropriate mixing.

4.3 Catalytic Tests

The activity tests in batch mode were carried out as follows: 50 mg of catalyst were added to a solution of 58 mg (0.5 mmoles) LA in 10 mL of water. After closing, the reactor was pressured at 5–14 bars with molecular oxygen and heated up to 100–180 °C, under stirring (1200 rpm), for 6–10 h. Additional catalytic tests were made in the same conditions using water as solvent and 90 mg (0.5 mmoles) of glucose as feedstock. After reaction, the oxygen was released and the catalyst was magnetically recovered by placing a permanent magnet on the reactor wall, and the products were separated by distillation under vacuum. The reaction mixture was silylated, diluted with 1 mL of toluene and analyzed by gas chromatography with flame-ionization detection (GC-FID, GC-Shimadzu apparatus). All samples were analyzed in triplicates and standard deviations of 5–8% were determined. The product identification was made by comparison with authentic samples and by using a GC–MS Carlo Erba Instruments QMD 1000 equipped with a Factor Four VF-5HT column.

The raw material conversion (X) and selectivity (S) to the reaction products were calculated from GC-FID chromatographic analysis by using the following equations:

where ni is the initial moles of substrate (ie, LA or glucose); nt is moles of untransformed substrate at time “t”, determined from GC-FID analysis:

The recovered catalyst was dispersed in distilled water and centrifuged six times, then, dried at ambient temperature and used in a consecutive reaction of LA or glucose.

References

Kamm B (2007) Production of platform chemicals and synthesis gas from biomass. Angew Chem Int Ed 46:5056–5058

Corma A, Iborra S, Velty A (2007) Chemical routes for the transformation of biomass into chemicals. Chem Rev 107(6):2411–2502

Shylesh S, Schünemann V, Thiel WR (2010) Magnetically separable nanocatalysts: bridges between homogeneous and heterogeneous catalysis. Angew Chem Int Ed 49:3428–3459

McCafferty E, Wightman JP (1998) Determination of the concentration of surface hydroxyl groups on metal oxide films by a quantitative XPS method. Surf Interface Anal 26:549–564

Gleeson O, Tekoriute R, Gun’Ko YK, Connon SJ (2009) The first magnetic nanoparticle-supported chiral DMAP analogue: highly enantioselective acylation and excellent recyclability. Chem A 15:5669–5673

Wang BG, Ma BC, Wang Q, Wang W (2010) Superparamagnetic nanoparticle-supported (S)-diphenyl-prolinol trimethylsilyl ether as a recyclable catalyst for asymmetric Michael addition in water. Adv Synth Catal 352:2923–2928

Hu A, Liu S, Lin W (2012) Immobilization of chiral catalysts on magnetite nanoparticles for highly enantioselective asymmetric hydrogenation of aromatic ketones. RSC Adv 2:2576–2580

Shokouhimehr M, Piao Y, Kim J, Jang Y, Hyeon T (2007) A magnetically recyclable nanocomposite catalyst for olefin epoxidation. Angew Chem Int Ed 46:7039–7043

Jin M-J, Lee D-H (2010) A practical heterogeneous catalyst for the Suzuki, Sonogashira, and Stille coupling reactions of unreactive aryl chlorides. Angew Chem Int Ed 49:1119–1122

Xu H-J, Wan X, Shen Y-Y, Xu S, Feng Y-S (2012) Magnetic nano-Fe3O4-supported 1-benzyl-1,4-dihydronicotinamide (BNAH): synthesis and application in the catalytic reduction of α, β-epoxy ketones. Org Lett 14:1210–1213

Yoon T-J, Lee W, Oh Y-S, Lee J-K (2003) Magnetic nanoparticles as a catalyst vehicle for simple and easy recycling. New J Chem 27:227–229

Podolean I, Kuncser V, Gheorghe N, Macovei D, Parvulescu VI, Coman SM (2013) Ru-based magnetic nanoparticles (MNP) for succinic acid synthesis from levulinic acid. Green Chem 15(11):3077–3082

Podolean I, Rizescu C, Bala C, Rotariu L, Parvulescu VI, Coman SM, Garcia H (2016) Unprecedented catalytic wet oxidation of glucose to succinic acid induced by the addition of n-butylamine to a RuIII catalyst. ChemSusChem 9(17):2307–2311

Rizescu C, Podolean I, Albero J, Parvulescu VI, Coman SM, Bucur C, Puche M, Garcia H (2017) N-doped graphene as a metal-free catalyst for glucose oxidation to succinic acid. Green Chem 19:1999–2005

Rizescu C, Podolean I, Cojocaru B, Parvulescu VI, Coman SM, Albero J, Garcia H (2017) RuCl3 supported on N-doped graphene as a reusable catalyst for the one-step glucose oxidation to succinic acid. ChemCatChem 9(17):3314–3321

Tasis D, Tagmatarchis N, Bianco A, Prato M (2006) Chemistry of carbon nanotubes. Chem Rev 106:1105–1136

Coleman JN, Khan U, Balu WJ, Gunko YK (2006) Small but strong: a review of the mechanical properties of carbon nanotube–polymer composites. Carbon 44:1624–1652

Chen J, Wang M, Liu B, Fan Z, Cui K, Kuang Y (2006) Platinum catalysts prepared with functional carbon nanotube defects and its improved catalytic performance for methanol oxidation. J Phys Chem B 110:11775–11779

Domínguez-Domínguez S, Berenguer-Murcia A, Pradhan BK, Linares-Solano A, Cazorla-Amorós D (2008) Semihydrogenation of phenylacetylene catalyzed by palladium nanoparticles supported on carbon materials. J Phys Chem C 112:3827–3834

Baleizão C, Gigante B, García H, Corma A (2004) Chiral vanadyl salen complex anchored on supports as recoverable catalysts for the enantioselective cyanosilylation of aldehydes. Comparison among silica, single wall carbon nanotube, activated carbon and imidazolium ion as support. Tetrahedron 60:10461–10468

Baleizão C, Gigante B, García H, Corma A (2004) Vanadyl salen complexes covalently anchored to single-wall carbon nanotubes as heterogeneous catalysts for the cyanosilylation of aldehydes. J Catal 221:77–84

Goh WJ, Makam VS, Hu J, Kang L, Zheng M, Yoong SL, Udalagama CNB, Pastorin G (2012) Iron oxide filled magnetic carbon nanotube–enzyme conjugates for recycling of amyloglucosidase: toward useful applications in biofuel production process. Langmuir 28:16864–16873

Li JH, Hong RY, Luo GH, Zheng Y, Li HZ, Wei DG (2010) An easy approach to encapsulating Fe3O4 nanoparticles in multiwalled carbon nanotubes. New Carbon Mater 25:192–198

Podolean I, Anita F, Garcia H, Parvulescu VI, Coman SM (2017) Efficient magnetic recoverable acid-functionalized-carbon catalysts for starch valorization to multiple bio-chemicals. Catal Today 279:45–55

Chen Y, Gu H (2012) Microwave assisted fast fabrication of Fe3O4-MWCNTs nanocomposites and their application as MRI contrast agents. Mater Lett 67:49–51

Wu L, Dutta S, Mascal M (2015) Efficient, chemical-catalytic approach to the production of 3-hydroxypropanoic acid by oxidation of biomass-derived levulinic acid with hydrogen peroxide. ChemSusChem 8(7):1167–1169

Parvulescu VI, Coman S, Palade P, Macovei D, Teodorescu CM, Filoti G, Molina R, Poncelet G, Wagner FE (1999) Reducibility of ruthenium in relation with zeolite structure. Appl Surf Sci 141:164–176

Böttcher W, Brown GM, Sutin N (1979) Electron-transfer reactions involving the aquoruthenium(II)-aquoruthenium(III) couple. Inorg Chem 18:1447–1451

Getty K, Delgado-Jaime MU, Kennepohl P (2008) Assignment of pre-edge features in the Ru K-edge X-ray absorption spectra of organometallic ruthenium complexes. Inorg Chim Acta 361:1059–1065

Westre TE, Kennepohl P, DeWitt JG, Hedman B, Hodgson KO, Solomon EI (1997) A multiplet analysis of Fe K-edge 1 s → 3d pre-edge features of iron complexes. J Am Chem Soc 119:6297–6314

Hummer AA, Heffeter P, Berger W, Filipits M, Batchelor D, Büchel GE, Jakupec MA, Keppler BK, Rompel A (2013) X-ray absorption near edge structure spectroscopy to resolve the in vivo chemistry of the redox-active indazolium trans-[tetrachlorobis(1H-indazole)ruthenate(III)] (KP1019). J Med Chem 56:1182–1196

Dakkach M, López MI, Romero I, Rodríguez M, Atlamsani A, Parella T, Fontrodona X, Llobet A (2010) New Ru(II) complexes with anionic and neutral N-donor ligands as epoxidation catalysts: an evaluation of geometrical and electronic effects. Inorg Chem 49:7072–7079

Mallat T, Baiker A (2004) Oxidation of alcohols with molecular oxygen on solid catalysts. Chem Rev 104:3037–3058

Esnaashari F, Moghadam M, Mirkhani V, Tangestaninejad S, Mohammadpoor-Baltork I, Reza Khosropour A, Zakeri M (2012) Multi-wall carbon nanotubes supported molybdenyl acetylacetonate: efficient and highly reusable catalysts for epoxidation of alkenes with tert-butyl hydroperoxide. Mater Chem Phys 137:69–75

Acknowledgements

Authors are gratefully to Giuliana Aquilanti and Luca Olivi, Elettra Sincrotrone Trieste, S.S. 14 km 163,5, Area Science Park, 34149 Basovizza-Trieste, Italy for XANES measurements. Vasile I. Parvulescu kindly acknowledges UEFISCDI for financial support (project PN-III-P4-ID-PCE-2016-0146, Nr. 121/2017).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Podolean, I., Cojocaru, B., Garcia, H. et al. From Glucose Direct to Succinic Acid: an Optimized Recyclable Bi-functional Ru@MNP-MWCNT Catalyst. Top Catal 61, 1866–1876 (2018). https://doi.org/10.1007/s11244-018-1012-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11244-018-1012-4