Abstract

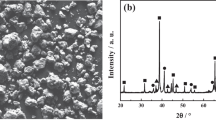

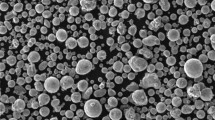

A powder injection molding (PIM) process was developed to prepare aluminum hybrid components incorporating low carbon steel, AlNiCo, or BaFeO magnetic inserts. The inserts were securely bound within the powder injection molded aluminum due to sintering shrinkage and physical reaction at the interface. The low sintering temperature of the aluminum alloy ensured a minimal level of interfacial reaction and limited the degradation of the properties of the inserts.

Similar content being viewed by others

Notes

JEOL is a trademark of Japan Electron Optics Ltd., Tokyo, Japan.

References

R.M. German and A. Bose: Injection Molding of Metals and Ceramics, Metal Powder Industries Federation, Princeton, NJ, 1997, pp. 1–413.

Z.Y. Liu, N.H. Loh, K.A. Khor, and S.B. Tor: Scripta Mater., 2001, vol. 44, pp. 1131–37.

T.Y. Chan and S.T. Lin: J. Am. Ceram. Soc., 1995, vol. 78, pp. 2746–52.

Z.Y. Liu, T.B. Sercombe, and G.B. Schaffer: Powder Metall., 2008, vol. 51, pp. 78–83.

Z.Y. Liu, D. Kent, and G.B. Schaffer: Mater. Sci. Eng. A, 2009, vols. 513–514, pp. 352–56.

D.F. Heaney, P. Suri, and R.M. German: J. Mater. Sci., 2003, vol. 38, pp. 4869–74.

P. Imgrund, A. Rota, F. Petzoldt, and A. Simchi: Int. J. Adv. Manuf. Technol., 2007, vol. 33, pp. 176–86.

J.C. Love and V. Goodship: Multi-Material Injection Moulding, iSmithers Rapra, Shropshire, UK, 2002, pp. 1–22.

C. von der Haar, L. Engelbrecht, O. Meier, A. Ostendorf, and H. Haferkamp: J. Laser Appl., 2008, vol. 20, pp. 224–29.

S. Mattei, A. Mathieu, A. Deschamps, B. Martin, and D. Grevey: NDT&E Int., 2006, vol. 39, pp. 272–76.

F.-W. Bach, A. Beniyash, K. Lau, and R. Versemann: Adv. Mater. Res., 2005, vols. 6–8, pp. 143–50.

Z. Lei, N. Yu, A. You, and S. Lin: Trans. China Weld. Inst., 2008, vol. 29, pp. 21–24 and 28.

B.-A. Behrens and F. Holz: Materialwiss. Werkstofftech., 2008, vol. 39, pp. 16–20.

A.D. Abbot and J.O. Allen: Met. Powder Rep., 1999, vol. 51, pp. 18–19.

B.E. Davies, R.S. Mottram, and I.R. Harris: Mater. Chem. Phys., 2001, vol. 67, pp. 272–81.

The authors thank the Australian Research Council, the Aluminium Powder Company, Cooltemp Pty Ltd., and The University of Queensland New Staff Research Start-Up Fund for financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted May 6, 2009.

Rights and permissions

About this article

Cite this article

Liu, Z., Kent, D. & Schaffer, G. Powder Injection Molding of Al-(Steel and Magnet) Hybrid Components. Metall Mater Trans A 40, 2785–2788 (2009). https://doi.org/10.1007/s11661-009-0012-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-009-0012-1