Abstract

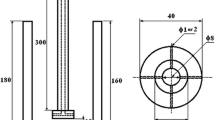

The effects of sample position and gas flow pattern on the sintering of a 7xxx aluminum alloy Al-7Zn-2.5Mg-1Cu in flowing nitrogen have been investigated both experimentally and numerically. The near-surface pore distribution and sintered density of the samples show a strong dependency on the sample separation distance over the range from 2 mm to 40 mm. The open porosity in each sample increases with increasing separation distance while the closed porosity remains essentially unchanged. A two-dimensional computational fluid dynamics (CFD) model has been developed to analyze the gas flow behavior near the sample surfaces during isothermal sintering. The streamlines, velocity profile, and volume flow rate in the cavity between each two samples are presented as a function of the sample separation distance at a fixed nitrogen flow rate of 6 L/min. The CFD modeling results provide essential details for understanding the near-surface pore distribution and density of the sintered samples. It is proposed that the different gas flow patterns near the sample surfaces result in variations of the oxygen content from the incoming nitrogen flow in the local sintering atmosphere, which affects the self-gettering process of the aluminum compacts during sintering. This leads to the development of different near-surface pore distributions and sintered densities.

Similar content being viewed by others

Abbreviations

- Aj :

-

bottom left corner of sample j

- Bj :

-

top left corner of sample j

- Cj :

-

top right corner of sample j

- Dj :

-

bottom right corner of sample j

- D :

-

diameter of the furnace, mm

- d :

-

separation distance between two samples, mm

- E:

-

cavity between sample 1 and sample 2

- F:

-

cavity between sample 2 and sample 3

- g:

-

gravitational acceleration, m/s2

- h :

-

height of the sample, mm

- H :

-

height of computational domain, mm

- L :

-

length of the furnace, mm

- l :

-

length of the furnace hot zone (computational domain), mm

- l 1 :

-

distance from sample 1 to the hot zone (computational domain) inlet, mm

- l 3 :

-

distance from Sample 3 to the hot zone (computational domain) outlet, mm

- n :

-

total number of elemental powders

- \( \vec{n} \) :

-

normal direction to the sample surface

- p :

-

pressure, Pa

- P :

-

nondimensional pressure

- Q c :

-

nitrogen volume flow rate through the cavity, L/min

- Q i :

-

nitrogen volume flow rate to the computational domain, L/min

- Q in :

-

nitrogen volume flow rate to the tubular furnace, L/min

- Re:

-

Reynolds number, = ρ 0 u i D/μ

- s :

-

length of samples, mm

- T :

-

temperature in sintering cycle, K

- t :

-

time in sintering cycle, min

- T i :

-

isothermal sintering temperature, K

- U :

-

nondimensional velocity component in X-direction

- u i :

-

inlet gas velocity to the computational domain, mm/s

- v :

-

velocity component in y-direction, mm/s

- V :

-

nondimensional velocity component in Y-direction

- \( \vec{V} \) :

-

velocity vector, mm/s

- w :

-

width of the sample, mm

- x :

-

horizontal coordinate distance, mm

- X :

-

nondimensional horizontal coordinate distance

- y :

-

vertical coordinate distance, mm

- Y :

-

nondimensional vertical coordinate distance

- ρ g :

-

green density of the compact, g/cm3

- ρ i :

-

density of elemental powder i, g/cm3

- ρ t :

-

theoretical density of the alloy, g/cm3

- ρ 0 :

-

density of nitrogen, g/cm3

- μ :

-

dynamic viscosity of nitrogen, Pa.s

- ψ :

-

stream function

References

M. Qian and G.B. Schaffer: Sintering of Advanced Materials, Woodhead Publishing Limited, Cambridge, U.K., 2010, pp. 289–322.

M. Vardavoulias, C. Jouanny-Tresy, and M. Jeandia: Wear, 1993, vol. 165, pp. 141–49.

K. Kondoh, J. Umeda, and R. Watanabe: Mater. Sci. Eng. A, 2009, vol. 499, nos. 1–2, pp. 440–44.

M.A. Islam and Z.N. Farhat: Trib. Int., 2011, vol. 44, no. 4, pp. 498–504.

G.N. Grayson, G.B. Schaffer, and J.R. Griffiths: Mater. Sci. Eng. A, 2006, vol. 434, nos. 1–2, pp. 1–6.

E. Crossin, J.Y. Yao, and G.B. Schaffer: Powder Metall., 2007, vol. 50, pp. 354–58.

R.N. Lumley and G.B. Schaffer: Scripta Mater., 2006, vol. 55, pp. 207–10.

T. Norton and D.W. Sun: Trends Food Sci. Tech., 2006, vol. 17, no. 11, pp. 600–20.

P. Verboven, N. Scheerlinck, J. De Baerdemaeker, and B.M. Nicolai: J. Food Eng., 2000, vol. 43, no. 2, pp. 61–73.

A.A. Osma, D. Kocaefe, and Y.S. Kocaefe: Can. J. Chem., 2008, vol. 86, no. 4, pp. 693–99.

T.J. Young and K. Vafai: Int. J. Heat Mass Trans., 1998, vol. 41, no. 21, pp. 3279–98.

M.H. Yang, R.H. Yeh, and J.J. Hwang: Int. J. Heat Mass. Trans., 2010, vol. 53, no. 4, pp. 760–71.

S.M. Aminossadati and K. Hooman: 12th U.S./North American Mine Ventilation Symposium, Reno, NV, 2008.

S.M. Aminossadati and B. Ghasemi: Eur. J. Mech. B/Fluids, 2009, vol. 28, no. 4, pp. 590–98.

T. Philips, N. Saxena, H. Nayar, and M. Kirschner: Adv. Powder Metall. Part. Meter., 1994, vol. 7, pp. 143–51.

N. Saxena, M. Kirschner, H. Nayar, and T. Philips: Adv. Powder Metall. Part. Meter., 1995, vol. 1, no. 1, pp. 429–40.

J.W. Kang and Y.M. Rong: J. Mater. Process. Technol., 2006, vol. 174, nos. 1–3, pp. 109–14.

N. Saxena, J. Dwyer, N. Haring, M, Kirschner, and H. Nayar: Adv. Powder Metall. Part. Mater., 1996, vol. 3, pp. 12.43–12.55.

P.F. Stratton and N. Saxena: The 1st International Automotive Heat Treating Conf., Puerto Vallarta, Mexico, 1999.

G.B. Schaffer, B.J. Hall, S.J. Bonner, S.H. Huo, and T.B. Sercombe: Acta Mater., 2006, vol. 54, no. 1, pp. 131–38.

T. Pieczonka, T. Schubert, S. Baunack, and B. Kieback: Mater. Sci. Eng. A, 2008, vol. 478, nos. 1–2, pp. 251–56.

G.B. Schaffer, J.Y. Yao, S.J. Bonner, S.J. Pas, and A.J. Hill: Acta Mater., 2008, vol. 56, no. 11, pp. 2615–24.

M. Yan, P. Yu, G.B. Schaffer, and M. Qian: Acta Mater., 2010, vol. 58, no. 17, pp. 5667–74.

P. Yu, M. Yan, G.B. Schaffer, and M. Qian: Metall. Mater. Trans. A, 2011, vol. 42A, pp. 2040–47.

F.P. Incropera, D.P. Dewitt, T.L. Bergman, and A.S. Lavine: Fundamentals of Heat and Mass Transfer, 6th ed. Wiley, New York, NY, 2007, p. 944.

S.V. Patankar: Numerical Heat Transfer and Fluid Flow, Hemisphere Publishing Corporation, New York, NY, 1980, pp. 126–31.

Ansys Fluent 12.0 Users’ guide, 2009, pp. 26.11–12.

F.M. White: Fluid Mechanics, 6th ed., McGraw-Hill, New York, NY, 2008, pp. 40–42, 249–52.

G.B. Schaffer and B.J. Hall: Metall. Mater. Trans. A, 2002, vol. 33A, pp. 3279–84.

T.B. Sercombe and G.B. Schaffer: Acta Mater., 2004, vol. 52, no. 10, pp. 3019–25.

Acknowledgments

This work was supported by Ampal Inc., a member of the United States Metal Powders Group, through the CAST CRC, a Cooperative Research Center established by the Australian Commonwealth Government. Helpful discussions with Dr. K. Hooman about CFD modeling are gratefully acknowledged. X.N.Y. further acknowledges the support of a CAST-CRC Scholarship and a University of Queensland International Research Tuition Award (UQIRTA). In-depth constructive comments from the Key Reader and reviewer are acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted August 8, 2011.

Rights and permissions

About this article

Cite this article

Yuan, X.N., Aminossadati, S.M., Huo, S.H. et al. The Effects of Sample Position and Gas Flow Pattern on the Sintering of a 7xxx Aluminum Alloy. Metall Mater Trans A 43, 4345–4355 (2012). https://doi.org/10.1007/s11661-012-1227-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-012-1227-0