Abstract

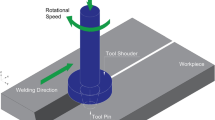

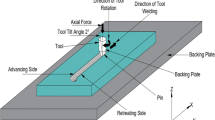

Physical simulation of friction stir welding (FSW) by means of hot torsion tests was performed on UNS S32205 duplex stainless steel. A thermomechanical simulator Gleeble 3800® with a custom-built liquid nitrogen cooling system was employed to reproduce the thermal cycle measured during FSW and carry out the torsion tests. Microstructures were compared by means of light optical microscopy and electron backscatter diffraction. True strain and strain rate were calculated by numerical simulation of the torsion tests. Thermomechanically affected zone (TMAZ) was reproduced at peak temperature of 1303 K (1030 °C), rotational speeds of 52.4 rad s−1 (500 rpm) and 74.5 rad s−1 (750 rpm), and 0.5 to 0.75 revolutions, which represent strain rate between 10 and 16 s−1 and true strain between 0.5 and 0.8. Strong grain refinement, similar to the one observed in the stir zone (SZ), was attained at peak temperature of 1403 K (1130 °C), rotational speed of 74.5 rad s−1 (750 rpm), and 1.2 revolution, which represent strain rate of 19 s−1 and true strain of 1.3. Continuous dynamic recrystallization in ferrite and dynamic recrystallization in austenite were observed in the TMAZ simulation. At higher temperature, dynamic recovery of austenite was also observed.

Similar content being viewed by others

References

R.S. Mishra and M.W. Mahoney: Friction Stir Welding and Processing, ASM International, Ohio, 2007.

M. Ghosh, K. Kumar, and R.S. Mishra: Scr. Mater., 2010, vol. 63, pp. 851-854.

Y.S. Sato, T.W. Nelson, C.J. Sterling, R.J. Steel, and C.-O. Petterson: Mater. Sci. Eng. A, 2005, vol. 397, pp. 376-384.

P. Edwards and M. Ramulu: Sci. Technol. Weld. Join., 2010, vol. 15, no. 6, pp. 468-472.

T.F.A. Santos, H.S. Idagawa, and A.J. Ramirez: Sci. Technol. Weld. Joining, 2014, vol. 19, no. 2, pp. 150-156.

K. Kuykendall, T. Nelson, and C. Sorensen: Int. J. Mach. Tool Manu., 2013, vol. 74, pp. 74-85.

H.W. Zhang, Z. Zhang, and J.T. Chen: Mater. Sci. Eng. A, 2005, vol. 403, pp. 340-348.

H. Schmidt and J. Hattel: Modell. Simul. Mater. Sci. Eng., 2005, vol. 13, pp. 77-93.

H.W. Zhang, Z. Zhang, and J.T. Chen: J. Mater. Process. Technol., 2007, vol. 183, pp. 62-70.

L. Fratini, G. Buffa, D. Palmeri: Comput. Struct., 2009, vol. 87, pp. 1166-1174.

R. Hamilton, D. MacKenzie, and H. Li: International Journal for Computer-Aided Engineering and Software, 2010, vol. 27, no. 8, pp. 967-985.

M. Assidi, L. Fourment, S. Guerdoux, and T. Nelson: International Journal of Machine Tools & Manufacture, 2010, vol. 50, pp. 143-155.

P. Heurtier, M.J. Jones, C. Desrayaud, J.H. Driver, F. Montheillet, and D. Allehaux: J. Mater. Process. Technol., 2006, vol. 171, pp. 348-357.

R. Nandan, G.G. Roy, T.J. Lienert, and T. DebRoy: Acta Mater., 2007, vol. 55, pp. 883-895.

A. Arora, Z. Zhang, A. De, and T. DebRoy: Scr. Mater., 2009, vol. 61, pp. 863-866.

D. Kim, H. Badarinarayan, J.H. Kim, C. Kim, K. Okamoto, R.H. Wagoner, and K. Chung: Eur. J. Mech. A Solids, 2010, vol. 29, pp. 204-215.

D. Forrest, J. Nguyen, M. Posada, J. DeLoach, D. Boyce, J. Cho, and P. Dawson: Proceedings of the 7th International Conference on Trends in Welding Research, S.A. David, ed., ASM International, 2006, pp. 279–86.

S.J. Norton: Ph.D. Thesis, The Ohio State University, Columbus, 2006.

M.F. Sinfield: M.Sc. Thesis, The Ohio State University, Columbus, 2007.

D.M. Failla: M.Sc. Thesis, The Ohio State University, Columbus, 2009.

M.J. Rubal: M.Sc. Thesis, The Ohio State University, Columbus, 2009.

J.R. Rule and J.C. Lippold: Metall. Mater. Trans. A, 2013, vol. 44, pp. 3649-3663.

T. Saeid, A. Abdollah-zadeh, H. Assadi, and F. Malek Ghaini: Mater. Sci. Eng. A, 2008, vol. 496, pp. 262-268.

T.F.A. Santos, R.R. Marinho, M.T.P. Paes, A.J. Ramirez: REM, 2013, vol. 66, no. 2, pp. 187-191.

R.N. Gunn: Duplex Stainless Steels: microstructure, properties and applications, Abington Publishing, Cambridge, 2003.

I. Alvarez-Armas and S. Degallaix-Moreuil, eds: Duplex Stainless Steel, ISTE, London, 2009.

A. Iza-Mendia, A. Pinol-Juez, J.J. Urcola, and I. Gutierrez: Metall. Mater. Trans. A, 1998, vol. 29, pp. 2975-2986.

H. Farnoush, A. Momeni, K. Dehghani, J. AghazadehMohandesi, and H. Keshmiri: Mater. Des. 2010, vol. 31, pp. 220-226.

P. Cizek: Acta Mater., 2016, vol. 106, pp. 129-143.

E. Evangelista, H.J. McQueen, M. Niewczas and M. Cabibbo: Can. Metall. Q., 2004, vol. 43, no. 3, pp. 339-354.

P. Cizek, B.P. Wynne: Mater. Sci. Eng. A, 1997, vol. 230, pp. 88-94.

F.J. Humphreys and M. Hatherly: Recrystallization and related annealing phenomena, Elsevier, Oxford, 2004.

T.F.A. Santos, E.A.T. Lopez, E.B. Fonseca, A.J. Ramirez: Mater. Res., 2016, vol. 19(1), pp. 117-131.

T.F.A. Santos: Ph.D. Thesis, University of Campinas, Campinas, 2012 (in Portuguese).

A. Hansel, T. Spittel, Kraft- und Arbeitsbedarf bildsamer. Formgeburgsverfahren, VEB DeutscherVerlag fur Grundstoffindustrie, Leipzig, 1978

T. Saeid, A. Abdollah-zadeh, T. Shibayanagi, K. Ikeuchi, and H. Assadi: Mater. Sci. Eng. A, 2010, vol. 527, pp. 6484-6488.

J.C. Lippold and J.J. Livingston: Metall. Mater. Trans. A, 2013, vol. 44, pp. 3815-3825.

S.S. Babu, J. Livingston, and J.C. Lippold: Metall. Mater. Trans. A, 2013, vol. 44, pp. 3577-3591.

Acknowledgments

The authors would like to acknowledge FAPESP and CNPq for scholarships and Aperam for material donation. Research supported by Petrobras and ANP.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted February 5, 2015.

Rights and permissions

About this article

Cite this article

da Fonseca, E.B., Santos, T.F.A., Button, S.T. et al. Physical Simulation of a Duplex Stainless Steel Friction Stir Welding by the Numerical and Experimental Analysis of Hot Torsion Tests. Metall Mater Trans A 47, 4543–4552 (2016). https://doi.org/10.1007/s11661-016-3631-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-016-3631-3