Abstract

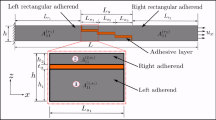

A brazed joint consists of a low-melting point and thin interlayer sandwiched between the high-melting-point base materials, in which the interlayer strength is typically lower than that of the base material. When this butt-joined composite is loaded uniaxially in the direction perpendicular to the plane of the brazing layer, the tensile strength is found to be much higher than that of the braze. This seems to violate the iso-stress condition in such a butt-joint serial configuration. The stress triaxiality has been usually ascribed, but without a quantitative rationalization, as being responsible for this tensile strength enhancement. Here a complete finite element simulation has been conducted to study the dependence of triaxiality and strength enhancement on geometric and material parameters. Two asymptotic limit solutions (based on Bridgman and Xia–Shih solutions, respectively) have been identified to understand the simulation results. The critical role of void evolution has been revealed when making a quantitative comparison to available experiments. In addition, ductility of the brazed joint, which has not been fully addressed in literature, is investigated by the Gurson–Tvergaard–Needleman model.

Similar content being viewed by others

Data Availability

Data contained in this paper are available upon request to the corresponding authors.

References

R.S. Rosen and M.E. Kassner: ASM Handbook, ASM International, Cleveland, 1993, vol. 6, pp. 165–172.

American Welding Society (AWS) (2007) Brazing Handbook, American Welding Society, Miami.

T. Lienert, T. Siewert, S. Babu, and V. Acoff: ASM Handbook, ASM International, 2011, vol. 6A Welding Fundamentals and Processes.

J.W. Lee, J.H. McMurray, and J.A. Miller: Welding J. 1985, vol. 64, pp. 18-21.

T. Zaharinie, R. Moshwan, F. Yusof, M. Hamdi, and T. Ariga: Mater. Des. 2014, vol. 54, pp. 375-381.

R.K. Shiue, S.K. Wu, and S.H. Yang: Metall. Mater. Trans. A 2017, vol. 48, pp. 735-744.

B.E. Riggs: Multi-scale computational modeling of Ni-base superalloy brazed joints for gas turbine applications. PhD Thesis, The Ohio State University, 2017.

M. Gao, B. Schneiderman, S.M. Gilbert, and Z. Yu: Metall. Mater. Trans. A 2019, vol. 50, pp. 5117-5127.

M. Way, J. Willingham, and R. Goodall: Int. Mater. Rev. 2020, vol. 65, pp. 257-285.

S.K. Tung, L.C. Lim, and M.O. Lai: Scripta Mater. 1995, vol. 33, pp. 1253-1259.

A. Elrefaey and W. Tillmann: J. Alloys Comp. 2009, vol. 487, pp. 639-645.

J. Ruiz-Vargas, N. Siredey-Schwaller, N. Gey, P. Bocher, and A. Hazotte: J. Mater. Process. Tech. 2013, vol. 213, pp. 20-29.

A.J. West, H.J. Saxton, A.S. Tetelman, and C.R. Barrett: Metall. Trans. 1971, vol. 2, pp. 1009-1017.

Y.H. Yu and M.O. Lai: J. Mater. Sci. 1995, vol. 30, pp. 2101-2107.

J. Mackerle: Modelling Simul. Mater. Sci. Eng. 1997, vol. 5, pp. 159-185.

Y.W. Lee, J.H. Kim, Y.S. Song, and C.S. Seok: Solid State Pheno. 2007, vols. 124-126, pp. 1673-1676.

M.K. Ghovanlou, H. Jahed, and A. Khajepour: Eng. Fract. Mech. 2014, vol. 120, pp. 43-59.

W. Jiang, W. Woo, and S.T. Tu: Mater. Des. 2015, vol. 72, pp. 63-71.

V. Tvergaard: Adv. Appl. Mech. 1990, vol. 27, pp. 83-151.

Z. Xue, M.G. Pontin, F.W. Zok, and J.W. Hutchinson: Eng. Frac. Mech. 2010, vol. 77, 492-509.

K.L. Nielsen and V. Tvergaard: Eng. Fract. Mech. 2010, vol. 77, 1031-1047.

A.A. Benzerga, J.-P. Leblond, A. Needleman, and V. Tvergaard: Int. J. Fract. 2016, vol. 201, pp. 29-80.

Y.F. Gao, Z. Xue, and Z. Yu: Ext. Mech. Lett. 2020, vol. 37, 100728.

K.M. Flores and R.H. Dauskardt: Acta Mater. 2001, vol. 49, pp. 2527–2537.

W.D. Li, H. Bei, and Y.F. Gao: Intermetallics 2016, vol. 79, pp. 12-19.

W.D. Li, Y.F. Gao, and H. Bei: Sci. Rep. 2016, vol. 6, 34878.

Y.C. Zhao and Y.F. Gao: JOM 2020, vol. 72, pp. 877-882.

L. Xia and C.F. Shih: J. Mech. Phys. Solids 1995, vol. 43, pp. 233-259.

Y. Cui, Y.F. Gao, and H.B. Chew: Int. J. Solids Struct. 2020, vols. 200-201, pp. 188-197.

Y.F. Gao, H.T. Xu, W.C. Oliver, and G.M. Pharr: J. Mech. Phys. Solids 2008, vol. 56, pp. 402-416.

Acknowledgments

This work has been supported by the China Scholarship Council (XC), the US National Science Foundation DMR-1809640 (YFG) and CMMI-1847630 (ZZY), the Center for Materials Processing at University of Tennessee (XW), and the US Department of Energy, Office of Vehicle Technology, under a prime contract with Oak Ridge National Laboratory (WZ and ZLF).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted March 12, 2020.

Rights and permissions

About this article

Cite this article

Cai, X., Gao, Y., Wang, X. et al. Triaxial Constraint and Tensile Strength Enhancement in Brazed Joints. Metall Mater Trans A 51, 5587–5596 (2020). https://doi.org/10.1007/s11661-020-05984-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-020-05984-x