Abstract

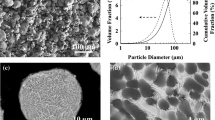

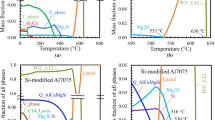

A key-factor for the industrial implementation of beam-based additive manufacturing technologies is the development of novel Al alloys characterized by enhanced hot-tearing resistance. Indeed, most of the standard Al alloys are susceptible to solidification cracking and can hardly be used to produce structural parts by laser-based additive manufacturing processes. In this study, we investigate the strategies to design high-strength Al alloys for Laser Powder Bed Fusion. The addition of Zr to the chemical composition of an Al–Mg–Si alloy (EN AW 6182) was carried out by following two different routes to promote the formation of equiaxed grains which are able to suppress hot cracking and enhance processability of the material. The first route is based on mechanical mixing of ZrH2 particles and gas-atomized Al alloy powder and on the in-situ reaction of the hydride to form Al3Zr nucleants. The second route relies on the use of pre-alloyed gas-atomized powders that feature Zr among the alloy elements. The specimens produced using pre-alloyed powder showed the best mechanical performance. After direct aging from the as-built condition, the alloy showed yield strength and ultimate tensile strength of 354 and 363 MPa, respectively, and elongation at fracture of 9.0 pct. The achieved properties are comparable to those of wrought 6182 alloy processed by conventional routes.

Graphical Abstract

Similar content being viewed by others

References

C.Y. Yap, C.K. Chua, Z.L. Dong, Z.H. Liu, D.Q. Zhang, L.E. Loh, and S.L. Sing: Appl. Phys. Rev., 2015, vol. 2, p. 041101.

M.N. Jahangir, M.A.H. Mamun, and M.P. Sealy: AIP Conf. Proc., https://doi.org/10.1063/1.5044305.

T. DebRoy, H.L. Wei, J.S. Zuback, T. Mukherjee, J.W. Elmer, J.O. Milewski, A.M. Beese, A. Wilson-Heid, A. De, and W. Zhang: Prog. Mater. Sci., 2018, vol. 92, pp. 112–224.

D. Koutny, D. Palousek, L. Pantelejev, C. Hoeller, R. Pichler, L. Tesicky, and J. Kaiser: Materials (Basel). https://doi.org/10.3390/ma11020298.

J.H. Martin, B.D. Yahata, J.M. Hundley, J.A. Mayer, T.A. Schaedler, and T.M. Pollock: Nature., 2017, vol. 549, pp. 365–9.

S. Kou: JOM., 2003, vol. 55, pp. 37–42.

S. Kou: in Welding Metallurgy, Second Edition, 2003.

F. Belelli, R. Casati, M. Riccio, A. Rizzi, M.Y. Kayacan, and M. Vedani: Metals (Basel), 2021, pp. 11, 35.

F. Belelli, R. Casati, F. Larini, M. Riccio, and M. Vedani: Mater. Sci. Eng. A, 2021, vol. 808, p. 140944.

F. Belelli, A. Cartapani, R. Casati, and M. Vedani: Submitt. to Philos. Mag. Lett., 2021, pp. 1–11.

M.L. Montero Sistiaga, R. Mertens, B. Vrancken, X. Wang, B. Van Hooreweder, J.P. Kruth, and J. Van Humbeeck: J. Mater. Process. Technol., 2016, vol. 238, pp. 437–45.

R. Casati, M. Coduri, M. Riccio, A. Rizzi, and M. Vedani: J. Alloys Compd.. https://doi.org/10.1016/j.jallcom.2019.06.123.

X.P. Li, G. Ji, Z. Chen, A. Addad, Y. Wu, H.W. Wang, J. Vleugels, J. Van Humbeeck, and J.P. Kruth: Acta Mater., 2017, vol. 129, pp. 183–93.

S.Y. Zhou, Y. Su, H. Wang, J. Enz, T. Ebel, and M. Yan: Addit. Manuf.. https://doi.org/10.1016/j.addma.2020.101458.

H. Zhang, H. Zhu, T. Qi, Z. Hu, and X. Zeng: Mater. Sci. Eng. A., 2016, vol. 656, pp. 47–54.

H. Zhang, H. Zhu, X. Nie, J. Yin, Z. Hu, and X. Zeng: Scr. Mater., 2017, vol. 134, pp. 6–10.

A.V. Koltygin, V.D. Belov, and V.E. Bazhenov: Russ. Metall., 2013, vol. 2013, pp. 66–70.

M. Andersson, J. Appelberg, A. Tilliander, K. Nakajima, H. Shibata, S.Y. Kitamura, L. Jonsson, and P. Jönsson: ISIJ Int., 2006, vol. 46, pp. 814–23.

BS EN ISO 11885:2007: 2009, p. 37.

ASTM Committee on Mechanical Testing: ASTM Int., 2013, vol. ASTM Stds., pp. 1–28.

ASTM International: 2020, pp. 1–27.

J.D. Robson and P.B. Prangnell: Acta Mater., 2001, vol. 49, pp. 599–613.

K.E. Knipling, D.C. Dunand, and D.N. Seidman: Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2007, vol. 38, pp. 2552–63.

K. Spierings, Adriaan Bernardus; Dawson, Karl; Kern, Kerstin; Palm, Frank; Wegener. https://doi.org/10.1016/j.msea.2017.06.089.

F. Wang, D. Qiu, Z.L. Liu, J.A. Taylor, M.A. Easton, and M.X. Zhang: Acta Mater., 2013, vol. 61, pp. 5636–45.

N. Takata, H. Kodaira, K. Sekizawa, A. Suzuki, and M. Kobashi: Mater. Sci. Eng. A., 2017, vol. 704, pp. 218–28.

X. Liu, C. Zhao, X. Zhou, Z. Shen, and W. Liu: Mater. Des., 2019, vol. 168, p. 107677.

H. Qin, V. Fallah, Q. Dong, M. Brochu, M.R. Daymond, and M. Gallerneault: Mater. Charact., 2018, vol. 145, pp. 29–38.

Y.N. Wen and J.M. Zhang: Solid State Commun., 2007, vol. 144, pp. 163–7.

E. Clouet, J.M. Sanchez, and C. Sigli: Phys. Rev. B - Condens. Matter Mater. Phys., 2002, vol. 65, pp. 1–13.

J.J. Marattukalam, D. Karlsson, V. Pacheco, P. Beran, U. Wiklund, U. Jansson, B. Hjörvarsson, and M. Sahlberg: Mater. Des.. https://doi.org/10.1016/j.matdes.2020.108852.

P.A. Hooper: Addit. Manuf., 2018, vol. 22, pp. 548–59.

N. Kumar, S. Goel, R. Jayaganthan, and H.G. Brokmeier: Metallogr. Microstruct. Anal., 2015, vol. 4, pp. 411–22.

Y. li JI, F. an GUO, and Y. feng PAN: Trans. Nonferrous Met. Soc. China (English Ed., 2008, vol. 18, pp. 126–31.

N.C.W. Kuijpers, F.J. Vermolen, C. Vuik, P.T.G. Koenis, K.E. Nilsen, and S. van der Zwaag: Mater. Sci. Eng. A., 2005, vol. 394, pp. 9–19.

R. Casati, M.H. Nasab, M. Coduri, V. Tirelli, and M. Vedani: Metals (Basel)., 2018, vol. 8, p. 954.

R. Casati and M. Vedani: Adv. Eng. Mater., 2019, vol. 21, pp. 1–7.

W. Li, S. Li, J. Liu, A. Zhang, Y. Zhou, Q. Wei, C. Yan, and Y. Shi: Mater. Sci. Eng. A., 2016, vol. 663, pp. 116–25.

N.T. Aboulkhair, I. Maskery, C. Tuck, I. Ashcroft, and N.M. Everitt: Mater. Sci. Eng. A., 2016, vol. 667, pp. 139–46.

R. Casati, M. Coduri, S. Checchia, and M. Vedani: Mater. Charact., 2021, vol. 172, p. 110881.

B.E. 755-2:2016 BSI Standard: Br. Stand. Inst

F. Zupanič, M. Steinacher, S. Žist, and T. Bončina: Metals (Basel)., 2021, vol. 11, pp. 1–14.

L. Donati, A. Segatori, M. El Mehtedi, and L. Tomesani: Int. J. Plast., 2013, vol. 46, pp. 70–81.

K.L. Kendig and D.B. Miracle: Acta Mater., 2002, vol. 50, pp. 4165–75.

D.N. Seidman, E.A. Marquis, and D.C. Dunand: Acta Mater., 2002, vol. 50, pp. 4021–35.

B. Raeisinia, C.W. Sinclair, W.J. Poole, and C.N. Tomé: Model. Simul. Mater. Sci. Eng.. https://doi.org/10.1088/0965-0393/16/2/025001.

G.J. Fan, H. Choo, P.K. Liaw, and E.J. Lavernia: Acta Mater., 2006, vol. 54, pp. 1759–66.

H. Dierke, F. Krawehl, S. Graff, S. Forest, J. Šachl, and H. Neuhäuser: Comput. Mater. Sci., 2007, vol. 39, pp. 106–12.

R.C. Picu, G. Vincze, F. Ozturk, J.J. Gracio, F. Barlat, and A.M. Maniatty: Mater. Sci. Eng. A., 2005, vol. 390, pp. 334–43.

D.H. Johnson: 2012, pp. 50–57, 84–92.

D. Wongsawaeng and S. Jaiyen: J. Nucl. Mater., 2010, vol. 403, pp. 19–24.

W. Zhu, R. Wang, G. Shu, P. Wu, and H. Xiao: J. Phys. Chem. C., 2010, vol. 114, pp. 22361–8.

Y. Li and D. Gu: Mater. Des., 2014, vol. 63, pp. 856–67.

G. Lu and E. Kaxiras: Phys. Rev. Lett., 2005, vol. 94, pp. 1–4.

G. Lu, Q. Zhang, N. Kioussis, and E. Kaxiras: Phys. Rev. Lett., 2001, vol. 87, pp. 955011–4.

Acknowledgments

The present research was partially funded by the EIT Raw Materials project SAMOA (Sustainable Aluminum Additive Manufacturing for high-performance applications, no. 18079). The Italian Ministry of Education, University and Research is acknowledged for the support provided through the Project "Department of Excellence LIS4.0 - Lightweight and Smart Structures for Industry 4.0. The Authors also acknowledge Andrea Cartapani and Lorenzo Montin for their support to the experiments.

Author contributions

Conceptualization, MV, RC and JV.; Data curation, FB; Formal Analysis, FB; Funding Acquisition, RC and JV; Investigation, FB; Methodology, RC and FB; Project administration, RC and MV; Resources: FB; Software, FB; Supervision, MV and RC; Validation, RC, MV and JV; Visualization, FB; Writing—Original Draft Preparation, FB and RC; Writing—Review & Editing, MV, RC and JV.

Conflict of interest

The authors declare no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted August 4, 2021; accepted November 1, 2021.

Rights and permissions

About this article

Cite this article

Belelli, F., Casati, R., Vedani, M. et al. Design and Characterization of Al–Mg–Si–Zr Alloys with Improved Laser Powder Bed Fusion Processability. Metall Mater Trans A 53, 331–343 (2022). https://doi.org/10.1007/s11661-021-06531-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-021-06531-y