Abstract

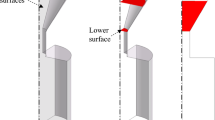

The blast furnace dripping zone is of great importance to the mass transfer of elements such as sulfur, carbon, and silicon, to and from the liquid metal phase. To understand mass transfer in the dripping zone, not only mass-transfer reactions and kinetics should be known, but the flow phenomena and process dynamics should be understood as well. The flow of hot metal and slag in the dripping zone was studied in experiments, in which liquid slag and metal trickled through a packed coke bed at 1500 °C to 1600 °C. The results indicate that slag and iron flow concurrently in a funicular type of flow. The iron flows through the core of the voids in the bed and is enveloped by slag, which flows filmwise in between the coke and the iron. This mode of flow allows for a large contact area between slag and iron, through which mass can be transferred. While flowing, the liquid can only pass and access a void, if and when the fluid capillary pressure at the void neck can be overcome. As a result, liquid droplets collect into rivulets. These rivulets flow down, along the accessible voids, using only a part of the available volume. The residence times of the fluids in the bed depend partly on the length of the pathway and are a function of the bed structure, the void neck distribution, and the stochastics of the flow. During flow, slag may react with coke, thus changing the distribution of the slag composition, and its sulfur capacity. In addition, the residence time distribution of the slag and the liquid holdup change as a result of these reactions. Holdup and residence time distribution of the liquids as measured in the experimental setup could not be modeled quantitatively, most likely due to the doubly distributed nature (in space and in time) of the model parameters, induced by reactions between slag, coke, and liquid metal.

Similar content being viewed by others

Abbreviations

- a … h :

-

constants in dimensionless equations (—)

- A n :

-

\(\frac{1}{{\tau _n }}.\exp \left[ {\frac{{ - 1}}{{\tau _n }}\left( {t - \frac{{V_P }}{{v_0 }}} \right)} \right]n = 1,2(S^{ - 1} )\)

- C 0 :

-

initial concentration (mol m−3)

- C 6 :

-

concentration of outflow (mol m−3)

- Cp s :

-

\(\frac{{\rho _f \cdot g \cdot (\phi \cdot d_p )^2 }}{{(1 - \varepsilon )^2 \cdot \sigma }}\) modified capillary number (—)

- Cp m :

-

\(\frac{{\rho _f \cdot g \cdot (\phi \cdot d_p )^2 }}{{(1 - \varepsilon )^2 \cdot \sigma \cdot (1 + \cos (\theta ))}} = \frac{{Cp_s }}{{Nc}}\) capillary number (—)

- ε :

-

voidage fraction (—)

- g :

-

9.8 (m s−2)

- Ga m :

-

\(\frac{{\rho _l^2 \cdot g \cdot (\phi \cdot d_p )^3 }}{{(1 - \varepsilon )^3 \cdot \mu ^2 }}\) modified Galileo number (—)

- ϕ :

-

shape factor (—)

- H D :

-

dynamic holdup (—)

- H S :

-

static holdup (—)

- H T :

-

total holdup (—)

- h f :

-

height of a fluid column (m)

- μ :

-

viscosity (Pa s)

- Nc:

-

(1+cos (θ) dimensionless contact angle term (—)

- r :

-

radius (m)

- Re:

-

\(\frac{{\rho _f \cdot v_f \cdot d_p }}{{\mu _f }}( - )\)

- Re m :

-

\(\frac{{\rho _f \cdot v_f \cdot \phi \cdot d_p }}{{(1 - \varepsilon ) \cdot \mu _f }}( - )\)

- t :

-

time (s)

- V D :

-

dead volume (m3)

- V M1 :

-

semibatch reactor type 1 volume (m3)

- V M2 :

-

semibatch reactor type 2 volume (m3)

- V NU :

-

unused volume (m3)

- V P :

-

plug flow volume (m3)

- v 0 :

-

initial volumetric velocity (m3 s−1)

- v a…e :

-

volumetric velocities (m3 s−1)

- θ :

-

contact angle (—)

- ρ f :

-

density of a fluid (kg m−3)

- σ f :

-

surface tension of fluid (N m−1)

References

A.S. Mehta, V. Sahajwalla, and J.J. Poveromo: 56th Ironmaking Conf. Proc., Mar. 1997, ISS, Warrendale, PA, 1997, pp. 217–27.

N. Siddiqi, V. Sahajwalla, O. Ostrovski, and G.R. Belton: High Temp. Mater. Processes, 1997, vol. 16 (4), pp. 213–25.

N. Siddiqi, B. Bhoi, R.K. Paramguru, V. Sahajwalla, and O. Ostrovski: 57th Ironmaking Conf. Proc., Mar. 1998, ISS, Warrendale, PA, 1998, pp. 1901–12.

A.S. Mehta, V. Sahajwalla, J.J. Poveromo, and T.F. Wall: 57th Ironmaking Conf. Proc., Mar. 1998, ISS, Warrendale, PA, 1998, pp. 1459–70.

A.S. Mehta, V. Sahajwalla, and T.F. Wall: 57th Ironmaking Conf. Proc., Mar. 1998, ISS, Warrendale, PA, 1998, pp. 1867–79.

A.S. Mehta, V. Sahajwalla, and T.F. Wall: 58th Ironmaking Conf. Proc., Mar. 1999, ISS, Warrendale, PA, 1999, pp. 445–454.

A.S. Mehta and V. Sahajwalla: Scand. J. Metall., 2000, pp. 17–29.

A.S. Mehta and V. Sahajwalla: Proc. 6th Int. Conf. on Molten Slags, Fluxes and Salts, Helsinki/Stockholm, June 2000, paper no. 26 on CD-rom.

F. McCarthy, V. Sahajwalla, and J. Hart: 61st Ironmaking Conf. Proc., Mar. 2002, ISS, Warrendale, PA, 2002, ISS, Warrendale, PA, 2002, pp. 313–24.

C. Wu and V. Sahajwalla: Metall. Mater. Trans. B, 1998, vol. 29B, pp. 471–77.

C. Wu and V. Sahajwalla: Metall. Mater. Trans. B, 2000, vol. 31B, pp. 243–51.

C. Wu, R. Wiblen, and V. Sahajwalla: Metall. Mater. Trans. B, 2000, vol. 31B, pp. 1099–104.

T. Fukutake and V. Rajakumar: Trans. Iron Steel Inst. Jpn., 1982, vol. 22, pp. 355–64.

T. Sugiyama, T. Nakagawa, and H. Sibaike: Trans. Iron Steel Inst. Jpn., 1987, vol. 73, pp. 2044–51.

Y. Niwa, T. Sumigama and A. Maki: Tetsu-to-Hagané, 1990, vol. 76, pp. 337–44.

S.J. Chew, P. Zulli, P.R. Austin, J.G. Mathieson, and A. Yu: Ironmaking Conf. Proc., 2001, ISS, Warrendale, PA, 2001, vol. 60, pp. 241–52.

G.S. Gupta, J.D. Litster, E.T. White, and V.R. Rudolph: Metall. Mater. Trans. B, 1997, vol. 28B, pp. 597–604.

G.C. Gardner: Chem. Eng. Sci., 1956, vol. 5, pp. 101–14.

N.A. Warner: Chem. Eng. Sci., 1959, vol. 11, pp. 149–60.

N. Standish: Chem. Eng. Sci., 1968, vol. 23, pp. 51–56.

J. Szekely and J. Mendrykowski: Chem. Eng. Sci., 1972, vol. 27, pp. 959–63.

J. Wang, R. Takahashi, and J.-I. Yagi: Tetsu-to-Hagané, 1991, pp. 1585–92.

T. Usui, K. Masamori, H. Kawabata, and Z.-I. Morita: Iron Steel Inst. Jpn. Int., 1993, vol. 33, pp. 687–96

M. Li, Y. Bando, T. Tsuge, K. Yasuda, and M. Nakamura: Chem. Eng. Sci., 2001, vol. 56, pp. 5969–76.

G.X. Wang, S.J. Chew, A.B. Ya, and P. Zulli: Iron Steel Inst. Jpn. Int., 1997, vol. 37 (6), pp. 573–82.

M. Matsu-Ura and Y. Ohno: Tetsu-to-Hagané, 1994, vol. 80 (12), pp. 884–89.

Y. Ohno and M. Schneider: Tetsu-to-Hagané, 1998, vol. 74 (10), pp. 1923–30.

W.M. Husslage, A.G.S. Steeghs, T. Bakker, R.H. Heerema, and M.A. Reuter: Ironmaking Conf. Proc., 2001, ISS, Warrendale, PA, 2001, vol. 60, pp. 323–35

W.M. Husslage, R.H. Heerema, M.A. Reuter, A.G.S. Steeghs, and T. Bakker: Proc. 6th World Conf. on Chemical Engineering, Melbourne, 2001, paper no. 1634.

J.R. Post, W.M. Husslage, Y. Yang, and M.A. Reuter: Int. Blast Furnace Lower Zone Symp., Wollongong, 2002.

Y. Sassa: Tetsu-to-Hagané, 1984, p. S842.

Takatade: Tetsu-to-Hagané, 1984, pp. A25–A28.

F.A.L. Dullien: Porous Media, Fluid Transport and Pore Structure, 2nd ed., Academic Press Inc., San Diego, CA, 1992, pp. 161 and 334–36.

D.E. Hartley and W. Murgatroyd: Int. J. Heat Mass Transfer, 1964, vol. 7, pp. 1003–15.

T. Bakker, W.M. Husslage, M.A. Reuter, P. den Exter, and A.G.S. Steeghs: Proc. Ironmaking Conf., 2002, ISS, Warrendale, PA, 2002, vol. 61, pp. 241–54.

G. Stephanopoulos: Chemical Process Control: an Introduction to Theory and Practice, Prentice-Hall Inc., Englewood Cliffs, NJ, 1984.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Husslage, W.M., Bakker, T., Steeghs, A.G.S. et al. Flow of molten slag and iron at 1500 °C to 1600 °C through packed coke beds. Metall Mater Trans B 36, 765–776 (2005). https://doi.org/10.1007/s11663-005-0080-6

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11663-005-0080-6