Abstract

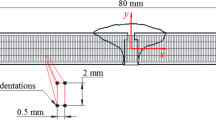

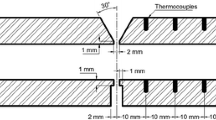

In this work, two different tests were done to establish the effect of heating cycles by welding in an AA7020-T6 aluminum alloy welded with ER5087 and ER5356 electrodes. During 10 months, welds were done to simulate in the laboratory several welding repairs (up to six repairs). Tensile and hardness measurements were done to evaluate the evolution of the properties against time. It was found that a single pass is enough to generate a heat-affected zone (HAZ) of 30 mm, and after four repairs the width of the HAZ exceeds 210 mm. In the HAZ, two regions were observed: the dissolution zone, which recovers a percentage of hardness by natural aging, and the over-aging zone, showing no increase in hardness. The results indicate that there is a maximum number of welding repairs that can be performed in a heat-treatable aluminum superstructure before it fails on the HAZ of the base material, since the tensile strength is reduced around 40 pct compared to the base metal.

Similar content being viewed by others

References

Tolga Dursun and Costas Soutis: Mater. Des., 2014, vol. 56, pp. 862–71.

L.J.R.Medina: PhD Thesis, Universidad de Coruña, 2010.

Gene Mathers: Welding of Aluminium and Its Alloys, CRC Press, Boca Raton, FL, 2002.

T Ma and G den Ouden: Mater. Sci. Eng. A, 1999, vol. 266, pp. 198–204.

Sindo Kou: JOM, 2003, vol. 55, pp. 37–42.

T. D. Burleigh: Corrosion, 1991, vol. 47, pp. 89–98.

A.K. Jha, K. Sreekumar, and P.P. Sinha: J. Fail. Anal. Prev., 2009, vol. 9, pp. 504–10.

J. R Davis: Corrosion of Aluminum and Aluminum Alloys, ASM International, Materials Park, OH, 1999.

ASTM International: Corrosion Tests And Standards: Application And Interpretation, 2 edition, ASTM International, West Conshohocken, PA, 2004.

I. J Polmear: Light Alloys: Metallurgy of the Light Metals, J. Wiley & Sons, New York, 1995.

C. Bloem, M. Salvador, V. Amig, and M. Vergar: in Alum. Alloys Theory Appl., Tibor Kvackaj, ed., InTech, 2011.

S. Esmaeili, X. Wang, D. J. Lloyd, and W. J. Poole: Metall. Mater. Trans. A, 2003, vol. 34, pp. 751–63.

Shahrzad Esmaeili and David J. Lloyd: Mater. Charact., 2005, vol. 55, pp. 307–19.

Marzena Lech-Grega, Sonia Hawryłkiewicz, Maria Richert, and Wojciech Szymański: Mater. Charact., 2001, vol. 46, pp. 251–57.

L. K Berg, J Gjønnes, V Hansen, X. Z Li, M Knutson-Wedel, G Waterloo, D Schryvers, and L. R Wallenberg: Acta Mater., 2001, vol. 49, pp. 3443–51.

C. A. Bloèm, M. D. Salvador, V. Amigó, and D. Busquets: Weld. Int., 2004, vol. 18, pp. 538–42.

Izabela Kalemba, Carter Hamilton, and Stanislaw Dymek: Mater. Des., 2014, vol. 60, pp. 295–301.

Y. Zhang, B. Milkereit, O. Kessler, C. Schick, and P. A. Rometsch: J. Alloys Compd., 2014, vol. 584, pp. 581–89.

Quentin Puydt, Sylvain Flouriot, Sylvain Ringeval, Frédéric De Geuser, Guillaume Parry, and Alexis Deschamps: Metall. Mater. Trans. A, 2014, vol. 45, pp. 6129–40.

Dongmei Liu, Baiqing Xiong, Fenggang Bian, Zhihui Li, Xiwu Li, Yongan Zhang, Feng Wang, and Hongwei Liu: Mater. Des., 2014, vol. 56, pp. 1020–24.

Y. E. Wu and Y. T. Wang: J. Mater. Eng. Perform., 2010, vol. 19, pp. 1362–69.

Acknowledgments

The authors acknowledge the Metro system of Medellín-Colombia for their support with the materials and funds for this study. We also acknowledge Materials Processing and Characterization Group at the Brazilian Nanotechnology National Laboratory (LNNano).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted November 7, 2014.

Rights and permissions

About this article

Cite this article

Maya-Johnson, S., Santa, J.F., Mejía, O.L. et al. Effect of the Number of Welding Repairs with GTAW on the Mechanical Behavior of AA7020 Aluminum Alloy Welded Joints. Metall Mater Trans B 46, 2332–2339 (2015). https://doi.org/10.1007/s11663-015-0416-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-015-0416-9