Abstract

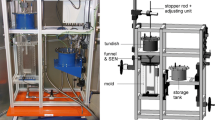

We present an experimental study on the formation and behavior of a liquid metal bubbly flow arising from a downward gas injection through a top submerged lance (TSL). A visualization of the bubble dynamics was achieved by the X-ray radiography combined with high-speed imaging. The experiments were carried out in a parallelepiped container (144 × 144 × 12 mm3) using GaInSn, a ternary alloy that is liquid at room temperature. The gas flow rate Qgas was adjusted in a range between 0.033 and 0.1 L/s. Three different injection positions were considered with respect to the submergence depth L. X-ray images allow for a characterization of the flow regimes and provide the properties of the individual bubbles such as size, shape, and trajectory. Formation and entrainment of smaller gas bubbles are observed at the free surface. These small bubbles can be trapped in the fluid for a long time by recirculation vortices. Bubble size distributions are determined for different Qgas. The bubble detachment frequency is measured as a function of Qgas and L. The results are compared with previously published data for water. The X-ray radiography offers an effective method for determining the local void fraction and allows for an estimation of the bubble volume.

Similar content being viewed by others

Reference

1 J.M. Floyd: Metall. Mater. Trans. B, 2005, vol. 36, pp. 557–75.

2 B.U.N. Igwe, S. Ramachandran, and J.C. Fulton: Metall. Trans., 1973, vol. 4, pp. 1887–94.

3 D. Mazumdar and R.I.L. Guthrie: Metall. Trans. B, 1985, vol. 16, pp. 83–90.

4 M. Iguchi, T. Uemura, H. Yamaguchi, T. Kuranaga, and Z. Morita: ISIJ Int., 1994, vol. 34, pp. 973–9.

5 J. Wang, H. Ooyabu, F. Wang, and M. Iguchi: ISIJ Int., 2011, vol. 51, pp. 1080–5.

A. Gosset, P. Rambaud, P. Planquart, J.-M. Buchlin, E. Robert, L. Guo, D.D. Joseph, Y. Matsumoto, Y. Sommerfeld, and Y. Wang: Xi’an, 2010, pp. 205–10.

7 T. Goda, M. Iguchi, Y. Sasaki, and H. Kiuchi: Mater. Trans., 2005, vol. 46, pp. 2461–6.

8 Y.S. Morsi, W. Yang, B.R. Clayton, and N.B. Gray: Can. Metall. Q., 2000, vol. 39, pp. 87–98.

9 C.B. Solnordal, F.R.A. Jorgensen, and R.N. Taylor: Metall. Mater. Trans. B, 1998, vol. 29, pp. 485–492.

10 Y. Pan and D. Langberg: J. Comput. Multiph. Flows, 2010, vol. 2, pp. 151–64.

11 P. Liovic, M. Rudman, and J.-L. Liow: Appl. Math. Model., 2002, vol. 26, pp. 113–40.

12 P. Liovic, J.-L. Liow, and M. Rudman: ISIJ Int., 2001, vol. 41, pp. 225–33.

13 N. Huda, J. Naser, G. Brooks, M.A. Reuter, and R.W. Matusewicz: Metall. Mater. Trans. B, 2010, vol. 41, pp. 35–50.

14 N. Huda, J. Naser, G. Brooks, M.A. Reuter, and R.W. Matusewicz: Metall. Mater. Trans. B, 2012, vol. 43, pp. 39–55.

15 S. Torres and M.A. Barron: Open J. Appl. Sci., 2016, vol. 06, pp. 860–7.

D. Obiso, S. Kriebitzsch, M. Reuter, and B. Meyer (2019) Metall. Mater. Trans. B, 5: 2. DOI: 10.1007/s11663-019-01630-z

17 O. Keplinger, N. Shevchenko, and S. Eckert: IOP Conf. Ser. Mater. Sci. Eng., 2017, vol. 228, pp. 012009-1–012009-9.

18 O. Keplinger, N. Shevchenko, and S. Eckert: Int. J. Multiph. Flow, 2018, vol. 105, pp. 159–69.

19 T. Vogt, S. Boden, A. Andruszkiewicz, K. Eckert, S. Eckert, and G. Gerbeth: Nucl. Eng. Des., 2015, vol. 294, pp. 16–23.

20 G.N. Oryall and J.K. Brimacombe: Metall. Trans. B, 1976, vol. 7, pp. 391–403.

21 K.G. Davis, G.A. Irons, and R.I.L. Guthrie: Metall. Trans. B, 1978, vol. 9, pp. 721–2.

22 Mukai K., Nakamura T., and Terashima H.: Tetsu–Hagane, 1992, vol. 78, pp. 1682–9.

23 P.K. Iwamasa and R.J. Fruehan: ISIJ Int., 1996, vol. 36, pp. 1319–27.

24 M.C. Baker and R. Bonazza: Exp. Fluids, 1998, vol. 25, pp. 61–8.

25 V.F. Chevrier and A.W. Cramb: Metall. Mater. Trans. B, 2000, vol. 31, pp. 537–40.

26 Z. Han and L. Holappa: ISIJ Int., 2003, vol. 43, pp. 292–7.

27 Z. Han and L. Holappa: Metall. Mater. Trans. B, 2003, vol. 34, pp. 525–32.

28 S.V. Gnyloskurenko and T. Nakamura: Mater. Trans., 2003, vol. 44, pp. 2298–302.

29 Y. Plevachuk, V. Sklyarchuk, S. Eckert, G. Gerbeth, and R. Novakovic: J. Chem. Eng. Data, 2014, vol. 59, pp. 757–63.

30 K. Timmel, N. Shevchenko, M. Röder, M. Anderhuber, P. Gardin, S. Eckert, and G. Gerbeth: Metall. Mater. Trans. B, 2015, vol. 46, pp. 700–710.

C. Tomasi and R. Manduchi: in Sixth International Conference on Computer Vision (IEEE Cat. No.98CH36271), Narosa Publishing House, Bombay, India, 1998, pp. 839–46.

32 D. Bradley and G. Roth: J. Graph. Tools, 2007, vol. 12, pp. 13–21.

33 J. Serra: Signal Process. 1994, vol. 38, pp. 3–11.

34 E. Delnoij, J. Westerweel, N.G. Deen, J.A.M. Kuipers, and W.P.M. van Swaaij: Chem. Eng. Sci., 1999, vol. 54, pp. 5159–71.

35 T. Sanada, M. Watanabe, T. Fukano, and A. Kariyasaki: Chem. Eng. Sci., 2005, vol. 60, pp. 4886–900.

36 L. Liu, O. Keplinger, T. Ma, T. Ziegenhein, N. Shevchenko, S. Eckert, H. Yan, and D. Lucas: Chem. Eng. Sci., 2018, vol. 192, pp. 288–305.

37 L. Liu, O. Keplinger, T. Ziegenhein, N. Shevchenko, S. Eckert, H. Yan, and D. Lucas: Int. J. Multiph. Flow, 2019, vol. 110, pp. 218–37.

38 M.P. Schwartz: Chem. Eng. Sci., 1990, vol. 45, pp. 1765–77.

39 I. Leibson, E.G. Holcomb, A.G. Cacoso, and J.J. Jacmic: AIChE J., 1956, vol. 2, pp. 300–6.

40 B. Krull, E. Strumpf, O. Keplinger, N. Shevchenko, J. Fröhlich, S. Eckert, and G. Gerbeth: IOP Conf. Ser. Mater. Sci. Eng., 2017, vol. 228, pp. 012006-1–012006-16.

41 N. Shevchenko, S. Boden, S. Eckert, D. Borin, M. Heinze, and S. Odenbach: Eur. Phys. J. Spec. Top., 2013, vol. 220, pp. 63–77.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted April 15, 2019.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Akashi, M., Keplinger, O., Shevchenko, N. et al. X-ray Radioscopic Visualization of Bubbly Flows Injected Through a Top Submerged Lance into a Liquid Metal. Metall Mater Trans B 51, 124–139 (2020). https://doi.org/10.1007/s11663-019-01720-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-019-01720-y