Abstract

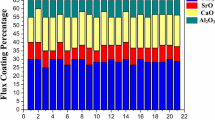

The SMAW electrode coating fluxes are formulated for the pipeline steels. The contact angle, spread area, work of adhesion, and floatation coefficient at 1573 K are investigated for the \(\text{CaF}_{2}\text{-CaO-Al}_{2}\text{O}_{3}\text{-BaO-SiO}_{2}\text{-TiO}_{2}\) fluxes. The 27 flux compositions are generated by extreme vertices design approach. The surface tension and corrected optical basicity of the fluxes are calculated. The regression analysis is used to estimate the effect of individuals and the interaction of constituents. The ANN models are prepared and compared with regression analysis for prediction accuracy. The phases present in the fluxes are characterized by the XRD and FTIR analysis. The structural analysis of the melt is performed by analyzing the powder of quenched slag. The structural analysis of the as-quenched slag is done by XRD, and FTIR which indicates the network formation of \({{[\text{AlO}}_{4}]}^{5-}\) tetrahedral and \({{[\text{SiO}}_{4}]}^{4-}\) tetrahedral unit. The UV–Vis analysis of the as-quenched slag shows the redshift with lower corrected optical basicity. The corrected optical basicity is a global measure of oxygen species in the melt. The \(\text{CaO and BaO}\) act as network breaker and releases non-bridging oxygen \({\text{O}}^{-}\) at the expense of bridging oxygen \({\text{O}}^{0}\). The contact angle decreases with the increase of \(\text{CaO and BaO}\). The increase in individual constituents \({\text{Al}}_{2}{\text{O}}_{3}\) and \({\text{CaF}}_{2}\) increases the contact angle. The \({\text{Al}}_{2}{\text{O}}_{3}\) acts as network former in the melts. The \({\text{CaF}}_{2}\) present in the melt as \({\text{Ca}}^{2+}\) and \({\text{F}}^{-}\) due to higher \({\text{CaF}}_{2}\) concentration \((\sim \) 35 pct) which has positively affected the contact angle. The increase of individual constituents such as \(\text{CaO and BaO}\) has an increasing effect on the work of adhesion and decreasing effect on the floatation coefficient. The increase of \({\text{Al}}_{2}{\text{O}}_{3}\) and \({\text{CaF}}_{2}\) has a decreasing effect on the work of adhesion and an increasing effect on the floatation coefficient. The \({\text{Al}}_{2}{\text{O}}_{3}\) is generally considered as network former, which influences the wetting properties. The binary interaction of \(\text{CaO}\)·\(\text{BaO, and {CaF}}_{2}\)·\(\text{CaO}\) has a decreasing effect on the contact angle, and floatation coefficient, and an increasing effect on the work of adhesion. The binary interaction of the \({\text{CaF}}_{2}\cdot \text{CaO, CaF}_{2} \cdot {\text{Al}_{2}\text{O}_{3}, {\text{CaF}}_{2} \cdot \text{BaO, and CaO}} \cdot {{\text{Al}}_{2}\text{O}}_{3}\) has a decreasing effect on the spread area, whereas the ternary interaction of \({\text{CaF}}_{2} \cdot \text{CaO} \cdot {{\text{Al}}_{2}\text{O}}_{3}, \text{and}\) \({\text{CaF}}_{2} \cdot \text{CaO} \cdot \text{BaO}\) has an increasing effect on the spread area.

Similar content being viewed by others

References

Energy Agency International: World Energy Outlook, 2021.

A.K. Das: Mater. Manuf. Processes, 2010, vol. 25, pp. 14–19.

Annual report 2018–19: Energizing and Empowering India, 2018.

M. Witek: J. Nat. Gas Sci. Eng., 2015, vol. 27, pp. 374–84.

H. Hillenbrand and C. Kalwa: World Pipelines, 2002, vol. 2, pp. 57–61.

S.K. Sharma and S. Maheshwari: J. Nat. Gas Sci. Eng., 2017, vol. 38, pp. 203–17.

S. Felber: Weld. World., 2008, vol. 52, pp. 19–41.

S.Y. Shin, K. Oh, K.B. Kang, and S. Lee: ISIJ Int., 2009, vol. 49, pp. 1191–99.

D.I. Pantelis and T.E. Tsiourva: Trends in oil and gas corrosion research and technologies: production and transmission, Elsevier Inc., Amsterdam, 2017, pp. 249–70.

R. Pourazizi, M.A. Mohtadi-Bonab, and J.A. Szpunar: Mater. Charact., 2020, vol. 164, p. 110330.

A. Talebi Hanzaei, S.P.H. Marashi, and E. Ranjbarnodeh: Int. J. Hydrog. Energy, 2018, vol. 43, pp. 9399–407.

C. Liu and S.D. Bhole: Sci. Technol. Weld. Join., 2013, vol. 18, pp. 169–81.

R. Pouriamanesh, K. Dehghani, R. Vallant, and N. Enzinger: J. Mater. Eng. Perform., 2018, vol. 27, pp. 6058–68.

S.S. Babu: Curr. Opin. Solid State Mater. Sci., 2004, vol. 8, pp. 267–78.

H. Alipooramirabad, A. Paradowska, R. Ghomashchi, and M. Reid: J. Manuf. Process., 2017, vol. 28, pp. 70–81.

U. Mitra and T.W. Eagar: Metall. Trans. B, 1991, vol. 22, pp. 65–71.

S. Liu and D.L. Olson: Weld. J., 1986, vol. 65, pp. 139s-s149.

M. Matsushita and S. Liu: Weld. J., 1993, vol. 79, pp. 295s–303s.

J. du Plessis, M. du Toit, and P. Pistorius: Weld. J., 2007, vol. 86, pp. 273–80.

H. Wang, R. Qin, and G. He: Metall. Mater. Trans. A, 2016, vol. 47, pp. 4530–42.

S. Chung and I. Sohn: Int. J. Hydrog. Energy, 2014, vol. 39, pp. 18490–7.

C.M. Chang, S.H. Wu, C. Fan, M.C. Chen, and W. Wu: Mater. Chem. Phys., 2008, vol. 112, pp. 783–8.

K.C. Mills and B.J. Keene: Int. Met. Rev., 1981, vol. 26, pp. 21–69.

J.B. Kim, J.K. Choi, I.W. Han, and I. Sohn: J. Non Cryst. Solids, 2016, vol. 432, pp. 218–26.

R. Zhang, Y. Meng, Z. Wang, S. Jiao, J. Jia, Y. Min, and C. Liu: Metall. Mater. Trans. B, 2022, vol. 53, pp. 571–83.

L. Sharma, J. Kumar, and R. Chhibber: Ceram. Int., 2020, vol. 46, pp. 8111–21.

L. Sharma, J. Kumar, and R. Chhibber: Ceram. Int., 2020, vol. 46, pp. 5649–57.

W. Lin Wang, E. Zhuo Gao, L. Jun Zhou, L. Zhang, and H. Li: J. Iron Steel Res. Int., 2019, vol. 26, pp. 355–64.

R. Joshi and R. Chhibber: Renew. Energy, 2018, vol. 119, pp. 282–9.

W.N. Khan, J. Kumar, and R. Chhibber: Proc. Inst. Mech. Eng. L: J. Mater.: Des. Appl., 2020, vol. 234, pp. 622–36.

K.C. Mills: ISIJ Int., 1993, vol. 33, pp. 148–55.

J.B. Kim, T.H. Lee, and I. Sohn: Metall. Mater. Trans. A, 2018, vol. 49, pp. 2705–20.

H. Tian, Z. Wang, T. Zhao, and C. Wang: Metall. Mater. Trans. B, 2022, vol. 53, pp. 232–41.

Z. Wang and I. Sohn: J. Am. Ceram. Soc., 2018, vol. 101, pp. 4285–96.

J.S. Choi, Y. Park, S. Lee, and D.J. Min: J. Am. Ceram. Soc., 2018, vol. 101, pp. 2856–67.

Z. Wang, J. Zhang, M. Zhong, and C. Wang: Metall. Mater. Trans. B, 2022, vol. 53, pp. 1364–70.

V. Kumar and R. Chhibber: Ceram. Int., 2022, vol. 48, pp. 17412–24.

S. Mahajan and R. Chhibber: Ceram. Int., 2019, vol. 45, pp. 24154–67.

W.N. Khan and R. Chhibber: Ceram. Int., 2020, vol. 46, pp. 8601–14.

L. Peng, Z. Jiang, and X. Geng: Metals, 2019, vol. 9, p. 1300.

S. Mahajan, J. Kumar, and R. Chhibber: Silicon, 2020, vol. 12, pp. 2741–53.

V. Kumar, J. Kumar, R. Chhibber, and L. Sharma: Silicon, 2022, pp. 1–3.

R.A. McLean and V.L. Anderson: Technometrics, 1966, vol. 8, pp. 447–54.

R.E. Boni and G. Derge: J. Met., 1956, vol. 8, pp. 53–9.

K. Nakashima and K. Mori: ISIJ Int., 1992, vol. 32, pp. 11–8.

K.C. Mills, L. Yuan, Z. Li, G.H. Zhang, and K.C. Chou: High. Temp. Mater. Process., 2012, vol. 31, pp. 301–21.

J.A. Duffy and M.D. Ingram: J. Non Cryst. Solids, 1976, vol. 21, pp. 373–410.

K.C. Mills and S. Sridhar: Ironmak. Steelmak., 1999, vol. 26, pp. 262–8.

S. Hara and K. Ogino: ISIJ Int., 1989, vol. 29, pp. 477–85.

Y. Liu, X. Lv, C. Bai, and B. Yu: ISIJ Int., 2014, vol. 54, pp. 2154–61.

K.C. Mills and Y.C. Su: Int. Mater. Rev., 2006, vol. 51, pp. 329–51.

Y. Chen, A. Furmann, M. Mastalerz, and A. Schimmelmann: Fuel, 2014, vol. 116, pp. 538–49.

Z. Wang, X.T. Zu, X. Xiang, J. Lian, and L. Wang: J. Mater. Sci., 2006, vol. 41, pp. 1973–8.

Y. Zhang, T. Coetsee, H. Yang, T. Zhao, and C. Wang: Metall. Mater. Trans. B, 2020, vol. 51, pp. 1947–52.

J.S. Choi, T.J. Park, and D.J. Min: J. Am. Ceram. Soc., 2021, vol. 104, pp. 140–56.

J.H. Park, D.J. Min, and H.S. Song: ISIJ Int., 2002, vol. 42, pp. 38–43.

Y. Li, B. Yu, B. Wang, T.H. Lee, and M. Banu: Mater. Des., 2020, vol. 194, p. 108912.

Z. Tian: J. Intell. Manuf., 2012, vol. 23, pp. 227–37.

J. Freiesleben, J. Keim, and M. Grutsch: Qual. Reliab. Eng. Int., 2020, vol. 36, pp. 1837–48.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kumar, A., Chhibber, R. Investigation of the Wetting Behavior of Formulated SMAW Electrode Coating Fluxes With Regression and ANN Model. Metall Mater Trans B 54, 287–302 (2023). https://doi.org/10.1007/s11663-022-02689-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-022-02689-x