Abstract

The fabrication of packaged, flexible, and planar fractional-order capacitors (FOCs) using copper foil electrodes and thin films of PVDF polymer nanocomposite dielectric is presented in this paper. An extensive comparison of FOC properties is made by using two separate conductive fillers, i.e., graphene nanosheets (GNS) and reduced graphene oxide (rGO). Similar fractional-order is observed at a particular filler loading in both types of FOCs; however, differences in the pseudocapacitance values and width of the constant phase (CP) zone exists. Fractional order α (alpha) is reported to vary in the range 0.61–0.87 in impedance measurements made on individual samples of rGO/PVDF and GNS/PVDF FOCs and series/parallel connections of two identical-order FOCs. For series/parallel connection of arbitrary-order FOCs, α varies from 0.61 to 0.83. Phase angle variation ranges from − 56.2° to − 79° for standalone pure FOC samples, whereas, for series/parallel connection of identical or arbitrary order FOCs, phase ranges from − 54.94° to − 77.75°. Phase ripple varies between ± 1.1° and ± 4.8°, and a maximum CP zone of 4 decades (1 kHz to 10 MHz) for the fabricated samples is reported. Industrial manufacturing of large-value capacitors demands materials to be flexible to enable rolling of large-area electrodes into a miniature device. FOCs fabricated in this work match the design specifications of commercial standard thin film capacitors and show high-value capacitances as well as flexibility of materials and structure.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The industrial manufacturing of fractional-order capacitor (FOC) devices having similar predefined specifications as for integer-order capacitors has yet to be achieved. Many efforts to fabricate the same in either single/multi-component configurations or as emulated behavior in systems and networks have been carried out.1 To design an industry fit device, the requirements and limitations are regarding the size, dynamic tunability of the fractional order, bandwidth of constant phase (CP), lifetime of the device, etc. Over the past few decades, polymer nanocomposite (NC) FOC designs have been considered for industrial mass production. Polyvinyldene fluoride (PVDF) and its copolymers composited with nanofillers of highly conductive materials, like graphene structures (graphene nanosheets—GNS, carbon nanotubes—CNTs, reduced graphene oxide—rGO, etc.), transition metal dichalcogenides and other two-dimensional structures have been much researched.1 The reason for the increased interest in PVDF are its ferroelectric nature and the potential of replacing conventional materials used in industry for capacitor manufacturing. PVDF is lightweight, highly resistant to large electric fields, possesses low dielectric loss, and, more importantly, is highly flexible.2,3,4,5,6 However, the dielectric constant of PVDF is much less than that of the piezoelectric materials already being used for capacitor fabrication. One method of increasing the dielectric constant is to add a conductive phase, e.g., graphene, to form a composite.3,5,6 Doing so also introduces anomalous dielectric behavior which is evident beyond a certain concentration of conductive material. This concentration is called the percolation threshold,3 and the resulting system is now considered to be of fractional order, implying Debye relaxation phenomena at low frequency in such systems.2,3 The fractional-order α and phase angle Φ in such designs vary as per the weight loading percentage of the nanofiller.1,2,7,8,9,10,11,12,13,14,15,16 CP zones in the extent of five (~ 5) decades have been obtained,8,9,10 while the maximum phase angle variation for a particular weight percentage in its CP zone was recorded at ± 5°.11,12 Along with using different combinations of polymer matrix and nanofillers, various materials have been employed as electrodes. These FOCs also differ in design and configuration from each other. With miniaturization as the goal, most designs have used thin films of a NC dielectric on a conducting substrate with thermally evaporated top electrodes.8,13,14 However, some designs have also utilized conventional parallel plate configurations with copper electrodes, either flat (plate)8,9,15 or circular (cylindrical).12,16 To keep up with the industry standard, packaged flexible and large capacitance valued designs are sought. This is presently achieved by rolling two aluminum ribbons with a dielectric material separating them.7 Another emerging field is wearable electronics which has tremendous applications in health-monitoring systems. Such wearable devices demand flexible and robust circuits which are synthesized from appropriate components, e.g., flexible capacitors, batteries, displays, etc.

The contributions of this work are summarized as:

-

1.

A planar miniaturized FOC device design utilizing ultrathin copper foil electrodes with polymer NC thin film dielectric sandwiched to form a parallel plate capacitor. Copper foil FOCs proposed here are compact, easy to fabricate, packaged, flexible, cost-effective, and similar in structure to industrially manufactured thin film capacitors. Planar copper foil FOCs have been fabricated using PVDF polymer and two types of nanofillers, i.e., GNS and rGO. A total of six samples (three samples for each type of filler) are fabricated, i.e., GNS—5%, 10%, and 15%, and rGO—5%, 10%, and 15%. The authors claim that this design is the best match to the industry standards for manufacturing thin film capacitors. The proposed FOC design could also be a fit for wearable electronics industry due to its flexibility.

-

2.

This work also focuses on the change in fabricated FOC properties (pseudocapacitance, phase angle, and bandwidth) of two devices having either identical or arbitrary order and connected in series/parallel configuration. The FOC characteristics have also been calculated theoretically using MATLAB open access source code presented in Ref. 16 (see supplementary material). Previously, impedance and pseudocapacitance change has been reported in series/parallel network configurations of FOCs.16

-

3.

In addition to having a good match with current manufacturing trends of film capacitors, the design proposed in this work also has compatibility with wearable electronics capacitive devices for wearable electronics, it is possible to obtain a wide tunable range of pseudocapacitance Cα and phase angle Φ values by designing a module compatible with PCB standards and consisting of just a few of such FOC samples. Tuning of these parameters can be carried out by connecting FOCs that provide the desired response in series/parallel configuration.

Materials and Methods

The polymer NC dielectric was synthesized using materials obtained from commercial vendors. All the materials were used as received. The properties mentioned in the datasheet were followed for predicting the properties of the NC. The values for most relevant properties as provided in the datasheet are shown in Table I.

PVDF has been used as the polymer matrix. The nanofillers and polymer were mixed using a solution-blending technique, which involves mixing of the filler and polymer solutions under shear stress. The dissolution and dispersion properties of solids in a solvent depend upon the matching Hildebrand and Hansen solubility parameters.17,18 A good match of these parameters ensures better dispersion. The electrodes were cut from copper foil tape obtained from commercial vendor (3M International). The bottom electrode on which the NC is pasted is 1 cm in length and 2.5 cm in width, and the top electrode has the same dimensions.

Preparation of PVDF Dispersion

The total NC weight was fixed at 1.2 g. To fabricate samples consisting of 5%, 10%, and 15% filler by weight, appropriate amounts of PVDF pellets were weighed. DMF (di-methyl formamide) solvent was added to the PVDF pellets in the required volume to yield 10 mg/mL concentration. Magnetic field-assisted stirring at 60–70°C was carried out to mix the PVDF solution for 1 h. Increasing the temperature accelerates the dissolution of PVDF pellets and also allows for the polymer chains to loosen up in the solvent, creating increased interchain distance for nanofiller intercalations. This was followed by stirring at 4500 rpm for 3 h at room temperature to yield a homogenous PVDF solution.

Preparation of GNS and RGO Dispersion

To fabricate six FOC samples, 60 mg, 120 mg, and 180 mg of each GNS rGO powder were weighed as per 5%, 10%, and 15% of the total NC sample weight (1.2 g). A mixture of N,N-dimethyl formamide and N-methyl 2-pyrolidone (DMF and NMP) in the ratio (2:1) was added in measured quantity to both the GNS and rGO powders to yield 5 mg/mL concentration. Both solvents have Hansen and Hildebrand solubility parameters matching to GNS and rGO. The GNS and rGO suspension was subject to ultrasonication in a DI water bath (at 400 W, 40 kHz, and 3 h) to obtain uniform homogenous GNS and rGO suspensions.

Preparation of NC Dielectric

To prepare NC of any of the two nanofillers and PVDF, the dispersions of the fillers were mixed with PVDF individually in a beaker. Ultrasonication was carried out using the same specifications as in the previous steps for 1 h. The sonicated solution was further stirred at 4000 rpm and 80–90°C until most of the solvent had evaporated. A highly viscous nanofiller/PVDF solution was obtained. The NC was now ready to be pasted on the copper foil electrodes, as in the next step.

Preparation of FOC Sample

The copper foil was cut from the roll and adhered to a glass substrate with the aid of transparent tape. The NC sample was then pasted on the copper foil using a stainless steel spatula. The samples were left to dry for 24 h at room temperature (25°C). Afterwards, to remove all of the solvent from the NC film on the copper foil, the samples were dried in a hot-air oven at 60°C for 2 h. The whole process was carried out in a clean environment to prevent any particle adhesion to the NC film. The top copper foil electrode was then pasted on the top NC film surface to yield a parallel-plate FOC device. The device was then passivated using transparent tape to prevent electrode degradation due to corrosion, and also to prevent stray charges from affecting the measurement results. The sample design and schematics are shown in Fig. 1. Figure 2 shows an image of the FOC device.

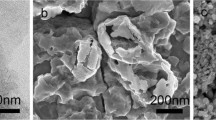

Characterization of Materials and the Fabricated Device

The crystallographic phase in the constituent materials, i.e., rGO and GNS powder, pristine PVDF thin film, and the rGO/PVDF and GNS/PVDF composites were determined by x-ray diffraction (XRD). The XRD patterns were acquired on a Rigaku D/max-rA x-ray diffractometer. The samples were scanned at 2° per minute using Cu-Kβ radiation (0.154 nm) at a filament voltage of 40 kV and current of 30 mA. XRD data for the constituent materials and final NC thin films are plotted in Fig. 4. The impedance magnitude, pseudocapacitance, and phase response for all the fabricated samples were recorded at room temperature using a Wayne Kerr precision impedance analyzer model 6500B in the frequency range 1 kHz to 10 MHz. A close match was observed with the theoretical values (values given in parentheses in Tables IV, V and VI) for magnitude and pseudocapacitance calculated using MATLAB open access source code.16 Figure 5 shows the Nyquist plots for all the six samples alongside a Z′′ versus Z′ plot for pristine PVDF. The equivalent circuit used to fit the Nyquist data is presented in Fig. 6.

Series/Parallel Connection of Identical/Arbitrary Order FOCS

The fabricated FOCs were connected in series and parallel networks to investigate the changes in Cα (fractance), Φ and the CP zone. Series and parallel connections of FOCs were tested previously by Kartci.16 For the n number of FOCs whose impedances are given as (1/sα1Cα1), (1/sα2Cα2)…(1/sαnCαn) for FOC1, FOC2…FOCn ,respectively, and connected in series or parallel configuration, the general form for the equivalent impedance of the circuit and its Φ, as cited in Ref. 16, are tabulated in Table II. In each configuration, two scenarios arise identified as:

Case I: where \({\alpha }_{1}={\alpha }_{2}=\dots ={\alpha }_{n}\) with \({C}_{{\alpha }_{1}}\ne {C}_{{\alpha }_{2}}\ne \dots {\ne C}_{{\alpha }_{n}}\).

Case II: where \({\alpha }_{1}={\alpha }_{2}=\dots ={\alpha }_{n}\) with \({C}_{{\alpha }_{1}}={C}_{{\alpha }_{2}}=\dots {=C}_{{\alpha }_{n}}\).

The equivalent Φ of the series network of identical-order FOCs remains identical to the individual FOCs. However, the magnitude of impedance |Z| is increased and, as such, the Cα values decrease. In parallel connections of FOCs, the phase response matches that of the individual FOCs in the circuit; however |Z| decreases and Cα increases.16

The FOCs fabricated in this work, having different combinations of filler materials and polymer matrices, have been categorized as per the filler weight percentage and named accordingly as 5G, 10G, and 15G for samples with 5%, 10%, and 15% of GNS filler and 5R, 10R, and 15R for samples with 5%, 10%, and 15% rGO filler, respectively. The FOCs were then connected on a bread board in series and parallel configurations, and the experimental workstation set-up is shown in Fig. 3. Series and parallel networks of two identical-order and arbitrary (non-identical)-order FOCs were designed to evaluate the resultant Ф and Cα variations. These methods were employed to achieve tunability of Ф and/or Cα, as per the system requirement. Connections to the impedance analyzer were made with connecting (male–male) wires. |Z|, Φ, and Cα versus frequency data were recorded for all combinations of identical-order FOCs (i.e., 5G + 5G, 10G + 10G, 15G + 15G, 5R + 5R, 10R + 10R, and 15R + 15R) both in series as well as in parallel configuration on a Precision Impedance Analyzer (Wayne Kerr 6500B). Prior to measurements the Impedance Analyzer was subject to standard calibration procedures (open circuit/short circuit/HF compensation). Measurements were made on the set-up with sinusoidal excitation (AC voltage—1 V, frequency—1 MHz) over the testing frequency range of 1 kHz to 10 MHz divided into 801 equally spaced points.

|Z|, Φ, and Cα have also been measured for each FOC individual sample. The graphs have then been plotted, as shown in Fig. 7a–f. The |Z|, Φ, and Cα of individual FOCs are plotted alongside corresponding plots obtained in series and parallel combinations with identical-order FOCs to indicate the change in impedance and capacitance characteristics. The data is numerically presented in Tables IV and V for reference.

Arbitrary order FOCs were connected in series and parallel configurations and analyzed for changes in the characteristics. The number of possible series/parallel combinations of arbitrary-ordered GNS/PVDF and rGO/PVDF FOCs are immensely large. Hence, a number of obtainable Cα ranges (five to be precise) were chosen and those series/parallel FOC combinations having equivalent Cα in that range are tabulated in Table VI. It is shown that, within a permissible range of Cα, it is possible to realize various Φ values using different combinations of arbitrary-order FOCs. The |Z| versus frequency, Cα versus frequency, and Φ versus frequency plots of all the chosen combinations (series/parallel) can be found in the supplementary online material (Figures S1–S5).

Results and Discussion

Structural Properties

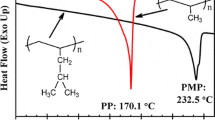

Figure 4 depicts the XRD patterns of rGO powder, GNS powder, and PVDF thin films. The XRD data for GNS/PVDF and rGO/PVDF NC thin film are also presented. XRD patterns are recorded in the range of 10°– 60°. The patterns show the increase of the β-phase and subsequent decrease of the α-phase PVDF due to incorporation of the fillers (i.e., rGO and GNS). Figure 4a shows the XRD data for pristine PVDF. The 2θ peaks at 18.67° and 20.46° correspond to the α (020) and β (002) phases. Similarly, peaks at 36.57° and 39.30° correspond to the β (020) and β (041) planes respectively. Figure 4b shows the XRD pattern for GNS powder, the diffraction peaks at 2θ values of 26.35°, 42.27°, and 54.24° correspond to the (002), (100) and (004) lattice planes, respectively, of the graphene structure. Figure 4d shows the diffraction peaks for the rGO powder. The 2θ peaks occur at angles resembling those of GNS, i.e., at 26.45°, 42.51°, and 54.47° corresponding to the (002), (100), and (004) lattice planes, respectively. Figure 4c and e shows the XRD patterns for GNS/PVDF and rGO/PVDF composite thin films ,respectively. It is evident that. with the addition of conductive fillers, i.e., GNS and rGO, the intensity of peaks corresponding to α-phase decreased, while the intensity increased for the corresponding β-phase percentage. The decrease in the intensity of the 2θ peak at 18.47° can be attributed to the fully stretched all trans planar zigzag confirmation that becomes apparent with the addition of the filler. It can be seen that the α-phase peak around 18.47° in pristine PVDF almost disappears in the rGO/PVDF composite, which indicates that the addition of rGO facilitates β-phase more than that achieved by the addition of pure GNS. Also, the increase in the weight loading of the conductive filler results in a gradual conversion of the α-phase to the β-phase in the PVDF. This in turn facilitates the increased ferroelectric behavior and as a result also increases fractional-order behavior.2,3

(a) XRD peaks for pristine PVDF indicating the presence of α and β polymorphs. (b) and (d) XRD data for pure GNS powder and rGO powder, respectively. The 2θ values and corresponding lattice planes are shown in the graph. (c) and (e) XRD data for GNS/PVDF and rGO/PVDF NC thin films, respectively. Note the decreased intensity of the α-PVDF peaks due to the addition of the conductive filler.

Dielectric Properties

Figure 5a and b shows the Z′′ versus Z′ (Nyquist) plot for the rGO samples (5R, 10R, and 15R) and the GNS samples (5G, 10G ,and 15G), respectively. The Z′′ versus Z′ curve for pristine PVDF has also been plotted in both graphs. The semi-circle and straight line curves can be seen indicating the presence of a capacitive C and a resistive R element in parallel.2,5,6 The equivalent circuit model fitting indicates Cole–Cole behavior. The single dispersion Cole–Cole circuit is shown in Fig. 6 along with the equivalent circuit parameters tabulated in Table III. As such, a constant-phase element represented by Cα, i.e., the fractance which is a factor of α (fractional-order) will be adopted instead of pure capacitance behavior. The Nyquist curve indicates a decreasing trend of dielectric constant with increasing frequency.5 It also indicates that Debye relaxation and dielectric loss phenomena at low frequencies are prominent due to decreased resistivity in the conductive filler-percolated NC dielectric.2,4,5 At low frequencies, all the four types (space charge, dipole, ionic, and electronic) of polarization contribute to the dielectric constant. At higher frequencies, the permanent dipoles cannot follow the fast switching polarity of the applied field, and thus the contribution of charge carriers towards the dielectric constant decreases (only ionic and electronic polarization are prominent). This phenomenon is also known as Maxwell–Sillars relaxation.

(a) Nyquist (Z′′ vs. Z′) plot for FOCs employing GNS as the conductive filler. The curves have been plotted for the 5G, 10G, and 15G samples. (b) Nyquist (Z′′ vs. Z′) plot for rGO/PVDF FOCs. The curves have been plotted for the 5R, 10R, and 15R samples. Z′′ versus Z′ curve for pristine PVDF has been plotted in both the graphs to provide estimates of the decrease of the |Z| with the increasing conductive filler percentage.

Impedance (|Z|) versus ω, pseudocapacitance (Cα) versus ω, and phase angle (Ф) versus ω plots (ω—frequency in Hz) for rGO/PVDF FOCs, i.e., 5R, 10R, and 15R, and their series and parallel combinations with identical-order FOCs are presented in Fig. 7a, c, and e, respectively. Similar plots have also been obtained for the GNS/PVDF FOCs, i.e., 5G, 10G, and 15G and their series and parallel combinations with identical-order FOCs and are presented in Fig. 7b, d, and f, respectively

The addition of two-dimensional (2D) (rGO and GNS) conductive fillers to the PVDF matrix creates a microscale network of resistors and capacitors within the dielectric material. The nanometer-sized 2D sheets of rGO and GNS intercalate within the PVDF polymer chains. Adjacent 2D filler sheets are either separated by PVDF (capacitive) or connected to each other (resistive). High-conductivity fillers also significantly increase the dielectric constant. This can be attributed to the considerably large specific surface area of graphene structures, i.e., rGO and GNS. As such, the effective electrode area of the FOC increases, and any two filler sheets which formed a microcapacitor are relatively very close to each other. This, in addition to the fact that the positive charge on the PVDF monomer –(CH2)– groups, which is considered responsible for the formation of the microstructure, allows for increased PVDF–2D filler interaction instead of filler–filler interaction.2,3,19,20,21 This leads to an increase in the effective Cα of FOC.

(a) |Z| versus ω, (c) Cα versus ω, and (e) Ф versus ω plots for individual RGO samples, i.e., 5R, 10R, and 15R, respectively, and series/parallel connection with identical-order FOCs. (b) |Z| versus ω, (d) Cα versus ω, and (f) Ф versus ω plots for individual GNS samples, i.e., 5G, 10G, and 15G, respectively, and series/parallel connections with identical-order FOCs.

Cα for rGO/PVDF FOC samples varies from 136 pF/s1−α for series combination of two identical-order (α = 0.84) FOCs, i.e., 5R(s) to 13.8 nF/s1−α obtained for parallel combination of two identical-order (α = 0.62) FOCs, i.e., 15R (p) at the center frequency (fc = 100 kHz). Ф varies in the range − 55.0° to − 77.1° for 5R (s) to 15R (p) combination, respectively, with a maximum phase ripple of ± 4.7°. The maximum CP zone of ~ 4 decades extends over the frequency range of 1300 Hz to 10 MHz. For the GNS/PVDF FOC samples, Cα varies in the range 94.6 pF/s1−α to 13.1 nF/s1−α (@fc = 100 kHz), and Ф varies in the range − 57.26° to − 77.75° for identical-order (0.86) FOCs in series, i.e., 5G (s), and identical-order (0.63) in parallel, i.e., 15G (p), combinations respectively, with the maximum CP zone (~ 3.4 decades) extending over 1000 Hz to 3.4 MHz. Cα remains fairly constant in the CP zone. The GNS/PVDF FOC samples exhibit smaller Cα values compared with the corresponding samples of the rGO-fabricated samples using similar weight loadings. The higher Cα values of the rGO samples can be attributed to the higher dispersibility of the rGO filler compared to GNS, as mentioned in Ref. 18. The presence of hydroxyl (–OH) groups on the carbon atoms increases the interlayer spacing and provides for better polymer chain intercalation during the composite synthesis process. This increases the dissipative properties and provides a more oriented network of micro-scale resistors and capacitors compared with that in a GNS/polymer composite.

For series combination of FOCs having identical-order α and matching Cα values, the equivalent Cα and |Z| follow laws of series connection for integer-order capacitors. The equivalent α is frequency-independent when α1 = α2, and frequency-dependent otherwise. This results in an extension of the CP zone as seen in the plots for series and parallel connected FOCs as compared to plots for the single FOC sample. The equivalent Cα value is almost halved for two identical FOCs connected in series, as a consequence of increased impedance |Z|. Ф shows a maximum deviation of ± 4.8° in the chosen CP zone for series/parallel networks and a maximum extension of 4 decades in the CP zone. For a parallel combination of two identical-order FOCs, the equivalent |Z| decreases accompanied by an increase in Cα. |Z| thus changes with frequency ω, the number of FOCs in the circuit n, and also their order α. The |Z|, Cα and Ф values for GNS/PVDF and rGO/PVDF and their series/parallel connections at center frequency (fc = 100 kHz) are tabulated in Tables IV and V, respectively. The CP zone, where Ф remains within the permissible error, is also shown for each sample. The theoretically calculated values at fc are tabulated alongside the measured values for |Z| and Cα, with the calculated values shown in parentheses following each value in the table. It is evident from the tables that the phase can be tuned using series and parallel combinations of FOCs. Also, for a given Ф range, a number of Cα values are possible.

For series connection of arbitrary-order FOCs, |Z| takes a value larger than |Z| for the FOC with lower α. The reason is the increase of dielectric disorder due to the increased physical separation between the input and output terminals. Similarly, Cα is reduced below Cα for the FOC with lower α. The phase angle takes an intermediate value between the Ф values for the two FOCs. It is observed in the series connection that the resultant Ф is closer to the FOC with lower α. For the parallel connection of arbitrary-order FOCs, |Z| reduces below |Z| of the FOC with larger α and, consequently, the Cα value increases beyond that of the FOC with larger α. This is assumed to happen due to the large increase in the effective electrode area, considering that the microscale network of resistors and capacitors within the dielectric of both FOCs are connected in parallel configuration, in addition to the copper foil electrodes which have doubled in area and the separation of the electrodes being the same. The CP zone increases in both the series and parallel connections of the FOCs, as mentioned earlier. However, the CP zone extension in the parallel-connected FOCs is larger than that for the series-connected FOCs. As mentioned earlier, this can be understood to be happening due to the increased dissipation in the series-connected FOCs owing to the increased path for charge within the dielectric.

The tunability of the fractional-order and Cα has been achieved by connecting FOCs in series and in parallel in tandem. Table VI shows the |Z|, Cα , and Ф values for series/parallel connections of two arbitrary-order FOCs yielding Cα in the range 138 pF/s1−α –10.3 nF/s1−α, along with the CP zone for each sample. It is evident from the table that different combinations can yield the same Cα with different Ф values and vice versa.

A comparison with previous works is presented in Table VII, highlighting the novelty of the proposed design. The FOCs proposed here provide fractional-order which matches closely with previous state-of-art FOCs. The bandwidth is also very large (4 decade), the maximum CP zone reported to date being 5 decades. The maximum phase angle variation reported is also close to the maximum allowable error. However, it is evident from Table VII that the FOC proposed in this work possesses features (flexible and packaged) comparable to commercial standard capacitors in addition to being PCB-compatible. Passivation is an important feature that can be seen in all types of commercial capacitors (ceramic, foil, and electrolytic).

Most of the previous designs, although fit for PCB integration, have not been passivated. On the other hand, tunability of fractional-order and pseudocapacitance has been achieved by altering the weight percentage of the filler, and also by synthesizing series/parallel networks of FOCs with the same or varying order. This approach provides a wider range of practically realizable Cα and Ф values within the working frequency range. As such, the authors report the features added to the FOC as a step towards defining a standard for FOC fabrication. The proposed FOC design is expected to have a large impact in the design of wearable flexible electronic devices, a field which is currently undergoing considerable development.

Repeatability and Lifetime

Repeatability of the reported Cα values for all the six combinations has been established by carrying out a statistical study indicating the maximum deviation from the averaged value. A total of six samples were fabricated for each type of FOC (5G, 10G, 15G, 5R, 10R, and 15R). The statistical analysis is graphically represented in Fig. 8, showing that the deviation for Cα values obtained in all the samples fabricated using a particular filler loading in PVDF did not exceed ± 10%. It can be seen that the measured error in the samples reduces with the increase in the filler loading percentage in PVDF. This can be attributed to improved dispersion of the conductive filler sheets in the PVDF matrix at high filler loadings (10% and 15%) compared with filler loading of 5% in the FOC samples. Some deviation is also believed to be the outcome of environmental condition variations and human error during fabrication of separate batches of the samples. It is assumed that variations in the measured parameters can be reduced with optimization of the process and the fabrication environment factors.

Conclusions

A packaged, planar, and flexible design for FOC fabrication has been proposed. This design is very similar to the conventional integer-order capacitors available on the market. It utilizes thin copper foil electrodes to sandwich a thin film of polymer NC dielectric. The structure is passivated using transparent tape to prevent deterioration, as well as to prevent external charges affecting the measurements. A total of six FOC samples have been fabricated using two combinations of filler/polymer, i.e., three for the GNS/PVDF NC and three for the rGO/PVDF NC. The FOCs have been assembled on a breadboard, to facilitate the series/parallel and individual testing. The individual response and the series/parallel responses for |Z|, Cα and Ф were recorded. Ф varied from − 55.0° to − 77.75° for individual FOC samples, while Cα varied from 94.6 pF/s1−α to 13.8 nF/s1−α at fc = 100 kHz signal frequency. The maximum CP zone obtained for individual samples was ~ 4 decades (1300 Hz to 10 MHz). In series/parallel configuration, the Cα and Ф can be tuned in the range − 54.94° to − 75.34° and 138 pF/s1−α to 10.3 nF/s1−α at fc. The measured values show acceptable closeness with the calculated values. The CP zone was observed to extend when connecting two FOCs in series or in parallel configuration. This behavior can be utilized to realize tunability of Cα and Ф by choosing the appropriate combination of FOCs. The proposed design is similar to the current industry manufactured capacitor standard. Despite providing similar results in terms of the obtainable CP zone, Cα , and Ф, it also has additional features like flexiblity and planar structure. The lifetime of the device is being researched. However, the authors expect the impedance analysis results to remain similar over time due to the solid-state nature of the device and the passivated structure, which prevents electrode degradation.

Improvements to the current FOC design can be carried out to further miniaturize the device which may also increase the equivalent capacitance values. A single module containing various FOC samples, and able to provide Ф and Cα values in a pre-defined range by merely changing the terminals, is being worked on. Such a module should have immense applications in designing fractional-order systems. It can also be a candidate to replace CMOS FOCs in systems like an FO proportional–integral–differential controller, FO oscillator, and filter circuits, etc.

References

Z.M. Shah, M.Y. Kathjoo, F.A. Khanday, K. Biswas, and C. Psychalinos, A survey of single and multi-component fractional-order elements (FOEs) and their applications. Microelectron. J. 84, 9 (2019).

Z.M. Shah, and F.A. Khanday, Analysis of disordered dynamics in polymer nanocomposite dielectrics for the realization of fractional-order capacitor. IEEE Trans. Dielectr. Electr. Insul. 28, 266 (2021).

H. Ait Laasri, D. Fasquelle, A. Tachafine, J.C. Carru, M. Rguiti, and M. Elaatmani, Ferroelectric BT–PVDF composite thick films for electrical energy storage. J. Electron. Mater. 50, 1132 (2021).

J. Tang, J. Liu, and H. Huang, Dielectric, piezoelectric and ferroelectric properties of flexible 0–3 type PZT/PVDF composites doped with graphene. J. Electron. Mater. 48, 4033 (2019).

A. Wang, C. Chen, J. Qian, F. Yang, L. Wang, and M. Zhang, Enhanced electrical properties of PVDF thin film by addition of NaCl by near-electric-field 3D printing. J. Electron. Mater. 50, 4781 (2021).

Y. Li, Q. Fu, L. Lili, and W. Li, Electrical and mechanical properties of the dielectric capacitor film based on polyvinylidene fluoride and aromatic polythiourea. J. Electron. Mater. 45, 5152 (2016).

M. Zulkarnain, M. Husaini, M. Jaafar, and I. Abdul Azid, Particle arrangement design for predicting the percolation threshold of silver/epoxy composite for electrically conductive adhesive application. J. Electron. Mater. 44, 4525 (2015).

A. Agambayev, M. Farhat, S.P. Patole, A.H. Hassan, H. Bagci, and K.N. Salama, An ultrabroadband single-component fractional-order capacitor using MoS2-ferroelectric polymer composite. Appl. Phys. Lett. 113, 093505 (2018).

D.A. John, S. Banerjee, G.W. Bohannan, and K. Biswas, Solid-state fractional-order capacitor using MWCNT-epoxy nanocomposite. Appl. Phys. Lett. 110, 163504 (2017).

A. Adhikary, M. Khanra, S. Sen and K. Biswas, Realization of a carbon nanotube based electrochemical fractor, in IEEE International Symposium on Circuits and Systems (ISCAS) (2015), p. 2329.

T.C. Haba, G. Ablart, T. Camps, and F. Olivie, Influence of the electrical parameters on the input impedance of a fractal structure realised on silicon. Chaos Solitons Fractals 24, 479 (2005).

G.W. Bohannan, Application of fractional calculus to polarization dynamics in solid dielectric materials. PhD Dissertation, Montana State University Bozeman, Montana (2000).

M. Elshurafa, N. Almadhoun, K. Salama, and H. Alshareef, Microscale electrostatic fractional-order capacitors using reduced graphene oxide percolated polymer composites. Appl. Phys. Lett. 102, 232901 (2013).

S. Tu, Q. Jiang, X. Zhang, and H.N. Alshareef, Solid state MXene based eletrostatic fractional capacitors. Appl. Phys. Lett. 114, 232903 (2019).

A. Buscarino, R. Caponetto, G. Di Pasquale, L. Fortuna, S. Graziani, and A. Pollicino, Carbon black based capacitive fractional-order element towards a new electronic device. AEU-Int. J. Electr. Comm. 84, 307 (2018).

A. Kartci, A. Agambayev, N. Herencsar, and K.N. Salama, Series-, parallel-, and inter-connection of solid-state arbitrary fractional-order capacitors: theoretical study and experimental verification. IEEE Access 6, 10933 (2018).

M.H.F. Taha, H. Ashraf, and W. Caesarendra, A brief description of cyclic voltammetry transducer-based non-ezymatic glucose biosensor using synthesized grapheme electrodes. Appl. Syst. Innov. 3, 32 (2020).

Y. Hernandez, Y. Lotya, D. Rickard, S.D. Bergin, and J.N. Coleman, Measurement of multi component solubility parameters for graphene facilities solvent discovery. Langmiur 26, 3208 (2010).

M.A. Bissett, S. Worrall, I. Kinloch, and R. Dryfe, Comparison of two-dimensional transition metal dichalcogenides for electrochemical supercapacitors. Electrochim. Acta 201, 30 (2016).

D. Konios, M.M. Stylianakis, E. Stratakis, and E. Kymakis, Dispersion behavior of graphene oxide and reduced graphene oxide. J. Colloid and Interface Sci. 430, 108 (2014).

J. Widakdo, Y.H. Chiao, Y.L. Lai, A.C. Imawan, F.M. Wang, and W.S. Hung, Mechanism of a self-assembling smart and electrically responsive PVDF-Graphene membrane for controlled gas separation. ACS Appl. Mater. Interfaces 12(27), 30915 (2020).

Funding

This funded was provided by Department of Science and Technology, Government of India (EMR/2016/007125).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shah, Z.M., Khanday, F.A. & Jhat, Z.A. Packaged Flexible Planar Copper Foil Fractional-Order ‘0.61–0.87’ Capacitors: Series/Parallel Combinations. J. Electron. Mater. 52, 1829–1839 (2023). https://doi.org/10.1007/s11664-022-10171-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-022-10171-2