Abstract

The present study concerns the cryogenic processing of metals with simultaneous analysis of x-ray diffraction in a synchrotron ring. The mechanical properties improvement related to cryogenic processing of metals is attributed to the partial suppression of dynamic recovery. Thus, commercially pure metals with different stacking fault energies (silver, copper and aluminum) were deformed by uniaxial tensile tests and characterized by in situ x-ray diffraction, at room (293 K) and cryogenic (77 K) temperatures. The cryogenic processing allows a simultaneous improvement in ductility and strength for silver and copper and an improvement in strength for aluminum. This difference in mechanical properties was investigated by means of variations in crystallite size, microstrain and also the amount and size of dimples on the fracture surface. The microstructural refinement at cryogenic temperatures shows a tendency related to the stacking fault energies.

Similar content being viewed by others

References

D.C.C. Magalhães, A.M. Kliauga, M. Ferrante, and V.L. Sordi, Plastic Deformation of FCC Alloys at Cryogenic Temperature: The Effect of Stacking-Fault Energy on Microstructure and Tensile Behaviour, J. Mater. Sci., 2017, 52, p 7466–7478. https://doi.org/10.1007/s10853-017-0979-8

D.C.C. Magalhães, M.F. Hupalo, and O.M. Cintho, Natural Aging Behavior of AA7050 Al Alloy After Cryogenic Rolling, Mater. Sci. Eng., A, 2014, 593, p 1–7. https://doi.org/10.1016/j.msea.2013.11.017

H. Bahmanpour, A. Kauffmann, M.S. Khoshkhoo, K.M. Youssef, S. Mula, J. Freudenberger, J. Eckert, R.O. Scattergood, and C.C. Koch, Effect of Stacking Fault Energy on Deformation Behavior of Cryo-rolled Copper and Copper Alloys, Mater. Sci. Eng., A, 2011, 529, p 230–236. https://doi.org/10.1016/j.msea.2011.09.022

S.K. Panigrahi, R. Jayaganthan, and V. Chawla, Effect of Cryorolling on Microstructure of Al–Mg–Si Alloy, Mater. Lett., 2008, 62, p 2626–2629. https://doi.org/10.1016/j.matlet.2008.01.003

Y. Wang, M. Chen, F. Zhou, and E. Ma, High Tensile Ductility in a Nanostructured Metal, Nature, 2002, 419, p 912. https://doi.org/10.1038/nature01133

V.S. Sarma, J. Wang, W.W. Jian, A. Kauffmann, H. Conrad, J. Freudenberger, and Y.T. Zhu, Role of Stacking Fault Energy in Strengthening Due to Cryo-deformation of FCC Metals, Mater. Sci. Eng., A, 2010, 527, p 7624–7630. https://doi.org/10.1016/j.msea.2010.08.015

Y.L. Gong, C.E. Wen, X.X. Wu, S.Y. Ren, L.P. Cheng, and X.K. Zhu, The Influence of Strain Rate, Deformation Temperature and Stacking Fault Energy on the Mechanical Properties of Cu Alloys, Mater. Sci. Eng., A, 2013, 583, p 199–204. https://doi.org/10.1016/j.msea.2013.07.001

G.H. Xiao, N.R. Tao, and K. Lu, Microstructures and Mechanical Properties of a Cu–Zn Alloy Subjected to Cryogenic Dynamic Plastic Deformation, Mater. Sci. Eng., A, 2009, 513, p 13–21. https://doi.org/10.1016/j.msea.2009.01.022

Y.S. Li, N.R. Tao, and K. Lu, Microstructural Evolution and Nanostructure Formation in Copper During Dynamic Plastic Deformation at Cryogenic Temperatures, Acta Mater., 2008, 56, p 230–241. https://doi.org/10.1016/j.actamat.2007.09.020

W.S. Zhao, N.R. Tao, J.Y. Guo, Q.H. Lu, and K. Lu, High-Density Nano-scale Twins in Cu Induced by Dynamic Plastic Deformation, Scr. Mater., 2005, 53, p 745–749. https://doi.org/10.1016/j.scriptamat.2005.05.022

F.J. Humphreys and M. Hatherly, Recrystallization and Related Annealing Phenomena, 2nd ed., Pergamon, Oxford, 2004

M.A. Meyers, O. Vöhringer, and V.A. Lubarda, The Onset of Twinning in Metals: A Constitutive Description, Acta Mater., 2001, 49, p 4025–4039. https://doi.org/10.1016/S1359-6454(01)00300-7

Y. Huang and P.B. Prangnell, The Effect of Cryogenic Temperature and Change in Deformation Mode on the Limiting Grain Size in a Severely Deformed Dilute Aluminium Alloy, Acta Mater., 2008, 56, p 1619–1632. https://doi.org/10.1016/j.scriptamat.2010.07.005

T. Konkova, S. Mironov, A. Korznikov, and S.L. Semiatin, Microstructural Response of Pure Copper to Cryogenic Rolling, Acta Mater., 2010, 58, p 5262–5273. https://doi.org/10.1016/j.actamat.2010.05.056

K. Edalati and Z. Horita, High-Pressure Torsion of Pure Metals: Influence of Atomic Bond Parameters and Stacking Fault Energy on Grain Size and Correlation with Hardness, Acta Mater., 2011, 59, p 6831–6836. https://doi.org/10.1016/j.actamat.2011.07.046

T. Konkova, S. Mironov, A. Koznikov, and S.L. Semiatin, Microstructure Instability in Cryogenically Deformed Copper, Scr. Mater., 2010, 63, p 921–924. https://doi.org/10.1016/j.actamat.2011.07.046

H. Parvin and M. Kazeminezhad, Dependency Modeling of Steady-State Grain Size on the Stacking Fault Energy Through Severe Plastic Deformation, Mater. Lett., 2015, 159, p 410–412. https://doi.org/10.1016/j.matlet.2015.07.041

I.C. Dragomir, M. Gheorghe, N. Thadhani, and Rl Snyder, X-ray Peak Profile Analysis of Crystallite Size Distribution and Dislocation Type and Density Evolution in Nano-structured Cu Obtained by Deformation at Liquid Nitrogen Temperature, Mater. Sci. Eng., A, 2005, 402, p 158–162. https://doi.org/10.1016/j.msea.2005.04.028

C. Gauss, I.R. Souza Filho, M.J.R. Sandim, P.A. Suzuki, A.J. Ramirez, and H.R.Z. Sandim, In situ Synchrotron x-Ray Evaluation of Strain-Induced Martensite in AISI, 201 Austenitic Stainless Steel During Tensile Testing, Mater. Sci. Eng., A, 2016, 651, p 507–516. https://doi.org/10.1016/j.msea.2015.10.110

R.T. Smith, T. Lolla, D. Gandy, L. Wu, G. Faria, A.J. Ramirez, S.S. Babu, and P.M. Anderson, In Situ x-Ray Diffraction Analysis of Strain-Induced Transformations in Fe-and Co-base Hardfacing Alloys, Scr. Mater., 2015, 98, p 60–63. https://doi.org/10.1016/j.scriptamat.2014.11.003

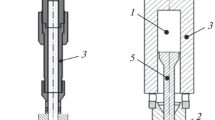

G. Faria, L. Wu, T. Alonso, A. Isaac, J. Piton, R. Neuenschwander, and A.J. Ramirez, Advanced Facility for Parallel Thermo-Mechanical Simulation and Synchrotron X-Ray Diffraction, In-situ Studies with Photons, Neutrons and Electrons Scattering II, T. Kannengiesser, S.S. Babu, Y. Komizu, and A.J. Ramirez, Ed., Springer, Berlin, 2014, p 245–259 https://doi.org/10.1007/978-3-319-06145-0_15

T. Ungár, Dislocation Densities, Arrangements and Character from X-ray Diffraction Experiments, Mater. Sci. Eng., A, 2001, 309, p 14–22. https://doi.org/10.1016/S0921-5093(00)01685-3

S.S. Babu, E.D. Specht, S.A. David, E. Karapetrova, P. Zschack, M. Peet, and H.K.D.H. Bhadeshia, In-Situ Observations of Lattice Parameter Fluctuations in Austenite and Transformation to Bainite, Metall. Mater. Trans. A, 2005, 36, p 3281–3289. https://doi.org/10.1007/s11661-005-0002-x

ASM. ASM Handbook Vol. 4, Heat Treating. ASM, 2004.

ASTM. ASTM E407-07: Standard Practice for Microetching Metals and Alloys. ASTM, 2015.

G. Faria. Exploring Metallic Materials Behavior Through In Situ Crystallographic Studies by Synchrotron Radiation. Magister Thesis in Mechanical Engineering, in the Materials And Fabrication Processes Area, University of Campinas, Campinas, 2014. http://repositorio.unicamp.br/handle/REPOSIP/265849

B.D. Cullity, Elements of X-ray Diffraction, 2nd ed., Prentice Hall, New Jersey, 2001

B.E. Warren, X-ray Diffraction, Dover Publisher, New York, 1990

A.R. Stokes and A.J.C. Wilson, Proc. Phys. Soc. London, 1944, 56, p 174–181

E. Wessel, Some Basic and Engineering Considerations Regarding the Fracture of Metals at Cryogenic Temperatures, in: Behavior of Materials at Cryogenic Temperatures—ASTM STP 387, ASTM International, 1966, p 32–59.

J. Weertman, Zener-Stroh Crack, Zener-Hollomon Parameter, and Other Topics, J. Appl. Phys., 1986, 60(6), p 1877–1887. https://doi.org/10.1063/1.337236

Acknowledgments

The authors acknowledge CAPES (PROAP) for financial support, LNNano/CNPEM for the technical support during the usage of the XTMS installation (especially to Mr. Leonardo Wu) and LNLS/CNPEM for the infrastructure present in the XRD1 beamline (Proposal 20160282). MTI, MYM and RSN acknowledge CAPES for their scholarships.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Izumi, M.T., Quintero, J.J.H., Crivoi, M.R. et al. In Situ X-Ray Diffraction Analysis of Face-Centered Cubic Metals Deformed at Room and Cryogenic Temperatures. J. of Materi Eng and Perform 28, 4658–4666 (2019). https://doi.org/10.1007/s11665-019-04226-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-04226-5