Abstract

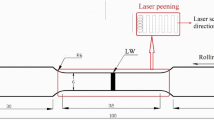

Laser peening without protective coating (LPwC) has been performed on austenitic stainless steel (SS304) with a power density of 9 GW cm−2 and peening passes of one, three and five. Effect of single and multiple laser peening on the residual stress distribution, work-hardening, surface roughness, phase transformation, and wettability has been studied using XRD, EBSD, surface profilometer and goniometer. A maximum compressive residual stress of - 581 MPa and work hardening depth that extended beyond 500 μm were observed with 5 peening passes. Further, an increase in austenite to martensite transformation (γ → α′) from 9.4 (unpeened) to 18.5% was observed for 5 peening passes. The average grain size reduced to 11.53% for five-time peened samples compared to single-time peened samples. Wettability studies revealed hydrophilic to hydrophobic transformation after laser peening.

Similar content being viewed by others

References

A.P. Mouritz, Steels for Aircraft Structures, Introduction to Aerospace Materials, Elsevier, 2012, p 232-250

Q. Lu, Q. Su, F. Wang, C. Zhang, Y. Lu, M. Nastasi and B. Cui, Influence of Laser Shock Peening on Irradiation Defects in Austenitic Stainless Steels, J. Nucl. Mater., 2017, 489, p 203-210. https://doi.org/10.1016/j.jnucmat.2017.03.046

P. Yella, P. Venkateswarlu, R.K. Buddu, N. Ravi, K.B.S. Rao, P.P. Kiran and K.V. Rajulapati, Role of Sacrificial Layers on Surface Characteristics of Laser Shock Peened SS304 Plates, Opt. Laser Technol., 2018, 107, p 142-149. https://doi.org/10.1016/j.optlastec.2018.05.018

R. Andersson, E. Schedin, C. Magnusson, J. Ocklund, and A. Persson, Stainless Steel Components in Automotive Vehicles, in Proceedings of the 4th Stainless Steel Science & Market Congress, 2002, 16(1), p 57. http://urn.kb.se/resolve?urn=urn:nbn:se:ltu:diva-6438

S. Bagheri and M. Guagliano, Review of Shot Peening Processes to Obtain Nanocrystalline Surfaces in Metal Alloys, Surf. Eng., 2009, 25(1), p 3-14.

L. Xie, Y. Wen, K. Zhan, L. Wang, C. Jiang and V. Ji, Characterization on Surface Mechanical Properties of Ti-6Al-4V after Shot Peening, J. Alloys Compd., 2016, 666, p 65-70.

S. Yang, W. Zeng and J. Yang, Characterization of Shot Peening Properties and Modelling on the Fatigue Performance of 304 Austenitic Stainless Steel, Int. J. Fatigue, 2020, 137, p 105621.

S. Pour-Ali, A.R. Kiani-Rashid and A. Babakhani, Surface Nanocrystallization and Gradient Microstructural Evolutions in the Surface Layers of 321 Stainless Steel Alloy Treated via Severe Shot Peening, Vacuum, 2017, 144, p 152-159. https://doi.org/10.1016/j.vacuum.2017.07.016

C.S. Montross, T. Wei, L. Ye, G. Clark and Y.W. Mai, Laser Shock Processing and Its Effects on Microstructure and Properties of Metal Alloys: A Review, Int. J. Fatigue, 2002, 24(10), p 1021-1036.

A.K. Gujba and M. Medraj, Laser Peening Process and Its Impact on Materials Properties in Comparison with Shot Peening and Ultrasonic Impact Peening, Materials, 2014, 7, p 7925-7974.

A.H. Clauer, Laser Shock Peening, the Path to Production, Metals (Basel), 2019, 9(6), p 626.

B. Dhakal and S. Swaroop, Review: Laser Shock Peening as Post Welding Treatment Technique, J. Manuf. Process., 2018, 32(April), p 721-733. https://doi.org/10.1016/j.jmapro.2018.04.006

W. Jia, Y. Zan, C. Mao, S. Li, W. Zhou, Q. Li, S. Zhang and V. Ji, Microstructure Evolution and Mechanical Properties of a Lamellar Near-α Titanium Alloy Treated by Laser Shock Peening, Vacuum, 2021, 184(Nonember 2020), p 109906. https://doi.org/10.1016/j.vacuum.2020.109906

I. Altenberger, R.K. Nalla, Y. Sano, L. Wagner and R.O. Ritchie, On the Effect of Deep-Rolling and Laser-Peening on the Stress-Controlled Low- and High-Cycle Fatigue Behavior of Ti-6Al-4V at Elevated Temperatures up to 550 °C, Int. J. Fatigue, 2012, 44, p 292-302.

E. Maawad, Y. Sano, L. Wagner, H.G. Brokmeier and C. Genzel, Investigation of Laser Shock Peening Effects on Residual Stress State and Fatigue Performance of Titanium Alloys, Mater. Sci. Eng. A, 2012, 536, p 82-91.

P.K. Rai, V. Pandey, K. Chattopadhyay, L.K. Singhal and V. Singh, Effect of Ultrasonic Shot Peening on Microstructure and Mechanical Properties of High-Nitrogen Austenitic Stainless Steel, J. Mater. Eng. Perform., 2014, 23(11), p 4055-4064.

Y. Feng, S. Hu, D. Wang and H. Zhang, Influence of Surface Topography and Needle Size on Surface Quality of Steel Plates Treated by Ultrasonic Peening, Vacuum, 2016, 132, p 22-30. https://doi.org/10.1016/j.vacuum.2016.07.021

J. Li, A. Feng, J. Zhou, H. Chen, Y. Sun, X. Tian, Y. Huang and S. Huang, Enhancement of Fatigue Properties of 2024-T351 Aluminum Alloy Processed by Cryogenic Laser Peening, Vacuum, 2019, 164(February), p 41-45. https://doi.org/10.1016/j.vacuum.2019.02.030

U. Trdan, M. Skarba and J. Grum, Laser Shock Peening Effect on the Dislocation Transitions and Grain Refinement of Al-Mg-Si Alloy, Mater. Charact., 2014, 97, p 57-68. https://doi.org/10.1016/j.matchar.2014.08.020

J.Z. Lu, K.Y. Luo, Y.K. Zhang, C.Y. Cui, G.F. Sun, J.Z. Zhou, L. Zhang, J. You, K.M. Chen and J.W. Zhong, Grain Refinement of LY2 Aluminum Alloy Induced by Ultra-High Plastic Strain during Multiple Laser Shock Processing Impacts, Acta Mater., 2010, 58(11), p 3984-3994.

C. Wang, L. Wang, C.L. Wang, K. Li and X.G. Wang, Dislocation Density-Based Study of Grain Refinement Induced by Laser Shock Peening, Opt. Laser Technol., 2020, 121, p 105827.

J.E. Masse and G. Barreau, Surface Modification by Laser Induced Shock Waves, Surf. Eng., 1995, 11(2), p 131-132.

L. Zhou, Y. Li, W. He, D. Chen and X. Nie, Effect of Multiple Laser Shock Processing on Microstructure and Mechanical Properties of Ti-5Al-4Mo-4Cr-2Sn-2Zr Titanium Alloy, Xiyou Jinshu Cailiao Yu Gongcheng/Rare Met. Mater. Eng., 2014, 43(5), p 1067-1072.

X. Shen, P. Shukla, S. Nath and J. Lawrence, Improvement in Mechanical Properties of Titanium Alloy (Ti-6Al-7Nb) Subject to Multiple Laser Shock Peening, Surf. Coat. Technol., 2017, 327, p 101-109.

R. Sundar, H. Kumar, R. Kaul, K. Ranganathan, P. Tiwari, L.M. Kukreja and S.M. Oak, Studies on Laser Peening Using Different Sacrificial Coatings, Surf. Eng., 2012, 28(8), p 564-568.

N. Mukai, N. Aoki, M. Obata, A. Ito, Y. Sano, and C. Konagai, Laser Processing for Underwater Maintenance in Nuclear Plants, in 3rd JSME/ASME Joint International Conference on Nuclear Engineering, 1995, p 1489-1494. https://inis.iaea.org/search/search.aspx?orig_q=RN:38008928. Accessed 11 March 2020

Y. Sano, K. Akita, K. Masaki, Y. Ochi, I. Altenberger and B. Scholtes, Laser Peening Without Coating as a Surface Enhancement Technology, J. Laser Micro Nanoeng., 2006, 1(3), p 161-166.

B. Sarre, S. Flouriot, G. Geandier, B. Panicaud and V. De Rancourt, Mechanical Behavior and Fracture Mechanisms of Titanium Alloy Welded Joints Made by Pulsed Laser Beam Welding, Proc. Struct. Integr., 2016, 2, p 3569-3576.

Y. Sano, K. Masaki, T. Gushi and T. Sano, Improvement in Fatigue Performance of Friction Stir Welded A6061-T6 Aluminum Alloy by Laser Peening Without Coating, Mater. Des., 2012, 36, p 809-814. https://doi.org/10.1016/j.matdes.2011.10.053

D. Kumar, S. Nadeem Akhtar, A. Kumar Patel, J. Ramkumar and K. Balani, Tribological Performance of Laser Peened Ti-6Al-4V, Wear, 2015, 322-323, p 203-217.

U. Trdan and J. Grum, SEM/EDS Characterization of Laser Shock Peening Effect on Localized Corrosion of Al Alloy in a Near Natural Chloride Environment, Corros. Sci., 2014, 82, p 328-338.

P. Peyre, R. Fabbro, P. Merrien and H.P. Lieurade, Laser Shock Processing of Aluminium Alloys. Application to High Cycle Fatigue Behaviour, Mater. Sci. Eng. A, 1996, 210(1-2), p 102-113.

A.H. Clauer and D.F. Lahrman, Laser Shock Processing as a Surface Enhancement Process, Key Eng. Mater., 2001, 197, p 121-142.

C. Wang, L. Wang, C.L. Wang, K. Li and X.G. Wang, Dislocation Density-Based Study of Grain Refinement Induced by Laser Shock Peening, Opt. Laser Technol., 2019, 2020, p 121.

H. Ding and Y.C. Shin, Dislocation Density-Based Modeling of Subsurface Grain Refinement with Laser-Induced Shock Compression, Comput. Mater. Sci., 2012, 53(1), p 79-88.

A. Umapathi and S. Swaroop, Residual Stress Distribution in a Laser Peened Ti-2.5Cu Alloy, Surf. Coat. Technol., 2016, 307, p 38-46. https://doi.org/10.1016/j.surfcoat.2016.08.053

D. Karthik, K.U. Yazar, A. Bisht, S. Swaroop, C. Srivastava and S. Suwas, Gradient Plastic Strain Accommodation and Nanotwinning in Multi-pass Laser Shock Peened 321 Steel, Appl. Surf. Sci., 2019, 487(May), p 426-432. https://doi.org/10.1016/j.apsusc.2019.05.130

O. Hatamleh and A. DeWald, An Investigation of the Peening Effects on the Residual Stresses in Friction Stir Welded 2195 and 7075 Aluminum Alloy Joints, J. Mater. Process. Technol., 2009, 209(10), p 4822-4829.

H. Chen, A. Feng, J. Li, T. Jia and Y. Liu, Effects of Multiple Laser Peening Impacts on Mechanical Properties and Microstructure Evolution of 40CrNiMo Steel, J. Mater. Eng. Perform., 2019, 28(5), p 2522-2529. https://doi.org/10.1007/s11665-019-04034-x

X.C. Zhang, Y.K. Zhang, J.Z. Lu, F.Z. Xuan, Z.D. Wang and S.T. Tu, Improvement of Fatigue Life of Ti-6Al-4V Alloy by Laser Shock Peening, Mater. Sci. Eng. A, 2010, 527(15), p 3411-3415. https://doi.org/10.1016/j.msea.2010.01.076

J. Li, J. Zhou, A. Feng, S. Huang, X. Meng, Y. Sun, Y. Huang and X. Tian, Influence of Multiple Laser Peening on Vibration Fatigue Properties of TC6 Titanium Alloy, Opt. Laser Technol., 2019, 118, p 183-191.

J.Z. Lu, K.Y. Luo, Y.K. Zhang, G.F. Sun, Y.Y. Gu, J.Z. Zhou, X.D. Ren, X.C. Zhang, L.F. Zhang, K.M. Chen, C.Y. Cui, Y.F. Jiang, A.X. Feng and L. Zhang, Grain Refinement Mechanism of Multiple Laser Shock Processing Impacts on ANSI 304 Stainless Steel, Acta Mater., 2010, 58(16), p 5354-5362.

C. Ye, S. Suslov, D. Lin and G.J. Cheng, Deformation-Induced Martensite and Nanotwins by Cryogenic Laser Shock Peening of AISI 304 Stainless Steel and the Effects on Mechanical Properties, Philos. Mag., 2012, 92(11), p 1369-1389.

Y. Yang, X. Lian, K. Zhou and G. Li, Effects of Laser Shock Peening on Microstructures and Properties of 2195 Al-Li Alloy, J. Alloys Compd., 2019, 781, p 330-336. https://doi.org/10.1016/j.jallcom.2018.12.118

S. Sathyajith, S. Kalainathan and S. Swaroop, Laser Shot Peening of 304 Austenitic Stainless Steel Without Protective Coating, Mater. Sci. Forum, 2011, 699, p 131-140.

Y. Sano, M. Obata, T. Kubo, N. Mukai, M. Yoda, K. Masaki and Y. Ochi, Retardation of Crack Initiation and Growth in Austenitic Stainless Steels by Laser Peening Without Protective Coating, Mater. Sci. Eng. A, 2006, 417(1-2), p 334-340.

I. Nikitin, B. Scholtes, H.J. Maier and I. Altenberger, High Temperature Fatigue Behavior and Residual Stress Stability of Laser-Shock Peened and Deep Rolled Austenitic Steel AISI 304, Scr. Mater., 2004, 50(10), p 1345-1350.

Z. Lu, F. Xu, C. Tang, Y. Cui, H. Xu and J. Mao, Stress Corrosion Cracking Susceptibility of 304 Stainless Steel Subjected to Laser Shock Peening Without Coating, J. Mater. Eng. Perform., 2021 https://doi.org/10.1007/s11665-021-05898-8

A. Nakajima, K. Hashimoto and T. Watanabe, Recent Studies on Super-Hydrophobic Films, Monatshefte für Chemie/Chem. Mon., 2001, 132(1), p 31-41. https://doi.org/10.1007/s007060170142

Y.B. Wang, H.F. Li, Y.F. Zheng, S.C. Wei and M. Li, Correlation Between Corrosion Performance and Surface Wettability in ZrTiCuNiBe Bulk Metallic Glasses, Appl. Phys. Lett., 2010, 96(25), p 8-11.

T. Sasaki, M. Shin-ya, S. Mitsui, R. Nishimura, K. Yanagi, T. Miyoshi and Y. Arai, X-ray Tri-Axial Stress Analysis System Using Two Monolithic SOI Pixel Detectors, Nucl. Instrum. Methods Phys. Res. section A Accel. Spectrom. Detect. Assoc. Equip., 2020, 979, p 164426.

K.Y. Luo, J.Z. Lu, Y.K. Zhang, J.Z. Zhou, L.F. Zhang, F.Z. Dai, L. Zhang, J.W. Zhong and C.Y. Cui, Effects of Laser Shock Processing on Mechanical Properties and Micro-structure of ANSI 304 Austenitic Stainless Steel, Mater. Sci. Eng. A, 2011, 528(13-14), p 4783-4788.

P.R. Smith, M.J. Shepard, P.S. Prevéy and A.H. Clauer, Effect of Power Density and Pulse Repetition on Laser Shock Peening of Ti-6Al-4V, J. Mater. Eng. Perform., 2000, 9(1), p 33-37.

Z. Tong, X. Ren, Y. Ren, F. Dai, Y. Ye, W. Zhou, L. Chen and Z. Ye, Effect of Laser Shock Peening on Microstructure and Hot Corrosion of TC11 Alloy, Surf. Coat. Technol., 2018, 335, p 32-40.

D. Karthik and S. Swaroop, Laser Peening without Coating Induced Phase Transformation and Thermal Relaxation of Residual Stresses in AISI 321 Steel, Surf. Coat. Technol., 2016, 291, p 161-171. https://doi.org/10.1016/j.surfcoat.2016.02.038

B.D. Cullity, Elements of X-ray Diffraction, Addison Wesley Publishing, Reading, MA, 1956, p 99

E. Nagy, V. Mertinger, F. Tranta and J. Sólyom, Deformation Induced Martensitic Transformation in Stainless Steels, Mater. Sci. Eng. A, 2004, 378(1-2 SPEC. ISS.), p 308-313.

A.K. De, D.C. Murdock, M.C. Mataya, J.G. Speer and D.K. Matlock, Quantitative Measurement of Deformation-Induced Martensite in 304 Stainless Steel by X-ray Diffraction, Scr. Mater., 2004, 50(12), p 1445-1449.

Y.F. Shen, X.X. Li, X. Sun, Y.D. Wang and L. Zuo, Twinning and Martensite in a 304 Austenitic Stainless Steel, Mater. Sci. Eng. A, 2012, 552, p 514-522.

M. Turski, S. Clitheroe, A.D. Evans, C. Rodopoulos, D.J. Hughes and P.J. Withers, Engineering the Residual Stress State and Microstructure of Stainless Steel with Mechanical Surface Treatments, Appl. Phys. A Mater. Sci. Process., 2010, 99(3), p 549-556.

M. Gerland and M. Hallouin, Effect of Pressure on the Microstructure of an Austenitic Stainless Steel Shock-Loaded by Very Short Laser Pulses, J. Mater. Sci., 1994, 29(2), p 345-351.

I. Nikitin and I. Altenberger, Comparison of the Fatigue Behavior and Residual Stress Stability of Laser-Shock Peened and Deep Rolled Austenitic Stainless Steel AISI 304 in the Temperature Range 25-600 °C, Mater. Sci. Eng. A, 2007, 465(1-2), p 176-182.

B.N. Mordyuk, Y.V. Milman, M.O. Iefimov, G.I. Prokopenko, V.V. Silberschmidt, M.I. Danylenko and A.V. Kotko, Characterization of Ultrasonically Peened and Laser-Shock Peened Surface Layers of AISI 321 Stainless Steel, Surf. Coat. Technol., 2008, 202(19), p 4875-4883.

S. Kalainathan, S. Sathyajith and S. Swaroop, Effect of Laser Shot Peening Without Coating on the Surface Properties and Corrosion Behavior of 316L Steel, Opt. Lasers Eng., 2012, 50(12), p 1740-1745. https://doi.org/10.1016/j.optlaseng.2012.07.007

P. Peyre, X. Scherpereel, L. Berthe, C. Carboni, R. Fabbro, G. Béranger and C. Lemaitre, Surface Modifications Induced in 316L Steel by Laser Peening and Shot-Peening. Influence on Pitting Corrosion Resistance, Mater. Sci. Eng. A, 2000, 280(2), p 294-302.

B. Dhakal and S. Swaroop, Effect of Laser Shock Peening on Mechanical and Microstructural Aspects of 6061-T6 Aluminum Alloy, J. Mater. Process. Technol., 2020, 282, p 116640.

G.E. Dieter, Mechanical Metallurgy, McGRAW-Hill Book Company, New York, 1961, p 447-459

L. Zhou, W. He, S. Luo, C. Long, C. Wang, X. Nie, G. He, X. Shen and Y. Li, Laser Shock Peening Induced Surface Nanocrystallization and Martensite Transformation in Austenitic Stainless Steel, J. Alloys Compd., 2016, 655, p 66-70. https://doi.org/10.1016/j.jallcom.2015.06.268

K.Y. Luo, H.X. Yao, F.Z. Dai and J.Z. Lu, Surface Textural Features and Its Formation Process of AISI 304 Stainless Steel Subjected to Massive LSP Impacts, Opt. Lasers Eng., 2014, 55, p 136-142.

M.J.J.P.T. NovelliFundenbergerBocherGrosdidier, On the Effectiveness of Surface Severe Plastic Deformation by Shot Peening at Cryogenic Temperature, Appl. Surf. Sci., 2016, 389, p 1169-1174.

Y. Zou, Z. Sang, Q. Wang, T. Li, D. Li and Y. Li, Improving the Mechanical Properties of 304 Stainless Steel Using Waterjet Peening, Medziagotyra, 2020, 26(2), p 161-167.

S. Prabhakaran, A. Kulkarni, G. Vasanth, S. Kalainathan, P. Shukla and V.K. Vasudevan, Laser Shock Peening Without Coating Induced Residual Stress Distribution, Wettability Characteristics and Enhanced Pitting Corrosion Resistance of Austenitic Stainless Steel, Appl. Surf. Sci., 2018, 428, p 17-30. https://doi.org/10.1016/j.apsusc.2017.09.138

B.S. Yilbas, H. Ali, A. Al-Sharafi and H. Al-Qahtani, Laser Processing of Ti6Al4V Alloy: Wetting State of Surface and Environmental Dust Effects, Heliyon, 2019, 5(2), p e01211.

P. Peyre, C. Carboni, A. Sollier, L. Berthe, C. Richard, E. de Los Rios and R. Fabbro, New Trends in Laser Shock Wave Physics and Applications, High-Power Laser Ablation IV, 2002, 4760, p 654-666.

P. Peyre, C. Carboni, P. Forget, G. Beranger, C. Lemaitre and D. Stuart, Influence of Thermal and Mechanical Surface Modifications Induced by Laser Shock Processing on the Initiation of Corrosion Pits in 316L Stainless Steel, J. Mater. Sci., 2007, 42(16), p 6866-6877.

D. Karthik and S. Swaroop, Laser Shock Peening Enhanced Corrosion Properties in a Nickel Based Inconel 600 Superalloy, J. Alloys Compd., 2017, 694, p 1309-1319.

M.A. Meyers, Microstructural Evolution in Adiabatic Shear Localization in Stainless Steel, Acta Mater., 2003, 571, p 571-574.

V.K. Caralapatti and S. Narayanswamy, Analyzing the Effect of High Repetition Laser Shock Peening on Dynamic Corrosion Rate of Magnesium, Opt. Laser Technol., 2017, 93, p 165-174. https://doi.org/10.1016/j.optlastec.2017.02.010

Acknowledgments

We thank Aeronautics R&D Board, India for the financial support (Grant No. ARDB/GTMAP/01/2031839/M/I), Vellore Institute of Technology (VIT), Vellore for the infrastructure and constant support throughout the project and Sophisticated Analytical Instrument Facility (SAIF) at IIT-Bombay for EBSD measurements.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Praveenkumar, K., Swaroop, S. & Manivasagam, G. Residual Stress Distribution, Phase Transformation, and Wettability Characteristics of Laser Peened Austenitic Stainless Steel. J. of Materi Eng and Perform 31, 6846–6857 (2022). https://doi.org/10.1007/s11665-022-06748-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-06748-x