Abstract

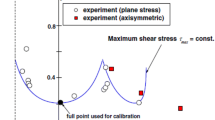

An accurate characterization of fracture behavior under pure shear, uniaxial tension, plane strain tension, and equi-biaxial tension plays a vital role in high-fidelity numerical simulation of the sheet metal forming. From a plastic deformation viewpoint, the non-directionality of the equi-biaxial tensile fracture is the inherent characteristic of sheet metal. However, little attention has been paid to modeling the non-directionality of the equi-biaxial fracture strain. This paper develops a new anisotropic ductile fracture model by including an empirical weight function into the DF2014-based fracture criterion to consider the non-directionality of the equi-biaxial tensile fracture. Then, the proposed model is utilized to depict the anisotropic ductile fracture behavior of DP980 steel, AA6082-T6 aluminum alloy, and Ti-6Al-4 V titanium alloy to verify its fracture predictability under various stress states. The prediction results are compared with the DF2014 and DF2016-based criteria. The results show that the proposed model correctly captures the non-directionality of equi-biaxial tensile fracture strain and depicts the anisotropic ductile behavior of these metals with high accuracy under proportional loading conditions. Meanwhile, the proposed model provided a similar fracture prediction accuracy to the DF2016-based criterion for different metal sheets, which indicated that the fracture predictability of this model had been successfully enhanced. In addition, finite element analysis for the square cup drawing test of AA6016-AC200 alloy is conducted in ABAQUS/Explicit to validate its performance under non-proportional loading conditions. The simulation results of the punch force–stroke curve and fracture shape in good agreement with the experimental measurements. The comparison study demonstrates that the proposed anisotropic ductile fracture model provides quite accurate predictability in depicting the anisotropic ductile fracture behavior of different metallic materials. Accordingly, the proposed model is recommended to be applied in FE simulation to improve the reliability and accuracy of numerical design and optimization of metal sheets product and forming process.

Similar content being viewed by others

References

K. Qvale, O.S. Hopperstad, O. Reiso, U.H. Tundal, C.D. Marioara, and T. Børvik, An Experimental Study on Pre-Stretched Double-Chamber 6000-Series Aluminium Profiles Subjected to Quasi-Static and Dynamic Axial Crushing, Thin Walled Struct., 2021, 158, p 107160.

M.B. Gorji, and D. Mohr, Predicting Shear Fracture of Aluminum 6016-T4 during DEEP DRAWING: COMBINING Yld-2000 Plasticity with Hosford Coulomb Fracture Model, Int. J. Mech. Sci., 2018, 137, p 105–120.

A. Pineau, A.A. Benzerga, and T. Pardoen, Failure of Metals I: Brittle and Ductile Fracture, Acta Mater., 2016, 107, p 424–483.

A.E. Tekkaya, P.O. Bouchard, S. Bruschi, and C.C. Tasan, Damage in Metal Forming, CIRP Ann., 2020, 69(2), p 600–623.

T. Xu, F. Li, X. Wang, and G. Zhang, Characterization of Anisotropic Fracture Behavior of 7075-T6 Aluminum Alloy Sheet under Various Stress States, J. Mater. Eng. Perform., 2022 https://doi.org/10.1007/s11665-022-07327-w

A.L. Gurson, Continuum Theory of Ductile Rupture by Void Nucleation and Growth: Part I—Yield Criteria and Flow Rules for Porous Ductile Media, J. Eng. Mater. Technol., 1977, 99(1), p 2–15.

C.C. Chu, and A. Needleman, Void Nucleation Effects in Biaxially Stretched Sheets, J. Eng. Mater. Technol., 1980, 102(3), p 249–256.

V. Tvergaard and A. Needleman, Analysis of the Cup-Cone Fracture in a Round Tensile Bar, Acta Metall., 1984, 32(1), p 157–169.

L. Xue, Constitutive Modeling of Void Shearing Effect in Ductile Fracture of Porous Materials, Eng. Fract. Mech., 2008, 75(11), p 3343–3366.

K. Nahshon and J.W. Hutchinson, Modification of the Gurson Model for Shear Failure, Eur. J. Mech. A. Solids, 2008, 27(1), p 1–17.

J. Lee, H. Jong Bong, H. Park, and D. Kim, Micromechanics-Based Modeling of Plastic and Ductile Fracture of Aluminum Alloy 2024-O, Eng. Fract. Mech., 2022, 261, p 108213.

W.T. Li, Z.Y. Cai, H. Li, L.F. Peng, X.M. Lai, and M.W. Fu, The modified GTN-Thomason Criterion for Modelling of Ductile Fracture Considering Shear Factor and Size Effect in Micro-Scaled Plastic Deformation, Int. J. Mech. Sci., 2021, 204, p 106540.

Z. He, H. Zhu, and Y. Hu, An Improved Shear Modified GTN Model for Ductile Fracture of Aluminium Alloys under Different Stress States and its Parameters Identification, Int. J. Mech. Sci., 2021, 192, p 106081.

G. Li and S.S. Cui, A Review on Theory and Application of Plastic Meso-Damage Mechanics, Theor. Appl. Fract. Mech., 2020, 109, p 102686.

A.A. Benzerga, J.B. Leblond, A. Needleman, and V. Tvergaard, Ductile Failure Modeling, Int. J. Fract., 2016, 201(1), p 29–80.

G. Rousselier, Finite Deformation Constitutive Relations Including Ductile Fracture Damage, Three-Dimensional Constitutive Relations and Ductile Fracture Editioned., S. Nemat-Nasser, Ed., North Holland Publishing Company, 1981, p. 331–355

G. Rousselier, Porous Plasticity Revisited: Macroscopic and Multiscale Modeling, Int. J. Plast., 2021, 136, p 102881.

J. Lemaitre, A Continuous Damage Mechanics Model for Ductile Fracture, J. Eng. Mater. Technol., 1985, 107(1), p 83–89.

M. Brünig, S. Gerke, and M. Schmidt, Damage and Failure at Negative stress Triaxialities: Experiments, Modeling and Numerical Simulations, Int. J. Plast., 2018, 102, p 70–82.

T.S. Cao, J.M. Gachet, P. Montmitonnet, and P.O. Bouchard, A Lode-Dependent Enhanced Lemaitre Model for Ductile Fracture Prediction at Low Stress Triaxiality, Eng. Fract. Mech., 2014, 124–125, p 80–96.

M. Brünig, S. Gerke, and V. Hagenbrock, Stress-state-Dependence of Damage Strain Rate Tensors Caused by Growth and Coalescence of Micro-Defects, Int. J. Plast., 2014, 63, p 49–63.

Y.B. Bao and T. Wierzbicki, On Fracture Locus in the Equivalent Strain and Stress Triaxiality Space, Int. J. Mech. Sci., 2004, 46(1), p 81–98.

H. Zhang, M. Diehl, F. Roters, and D. Raabe, A Virtual Laboratory Using High Resolution Crystal Plasticity Simulations to Determine the Initial Yield Surface for Sheet Metal Forming Operations, Int. J. Plast., 2016, 80, p 111–138.

D. Li, H. Wu, X. Zhan, Z. Chang, and J. Chen, A New Ductile Fracture Model for Edge Cracking Prediction of Ultra-High Strength Steel Considering Damage Accumulation in Blanking Process, J. Mater. Eng. Perform., 2022, 31, p 6880–6890.

L. Dong, S.H. Li, and J. He, Ductile Fracture Initiation of Anisotropic Metal Sheets, J. Mater. Eng. Perform., 2017, 26(7), p 3285–3298.

Q. Hu, F.F. Zhang, X.F. Li, and J. Chen, Overview on the Prediction Models for Sheet Metal Forming Failure: Necking and Ductile Fracture, Acta Mech. Solida Sin., 2018, 31(3), p 259–289.

Y. Lou, H. Huh, S. Lim, and K. Pack, New Ductile Fracture Criterion for Prediction of Fracture Forming Limit Diagrams of Sheet Metals, Int. J. Solids Struct., 2012, 49(25), p 3605–3615.

Y. Lou, J.W. Yoon, and H. Huh, Modeling of Shear Ductile Fracture Considering a Changeable Cut-Off Value for Stress Triaxiality, Int. J. Plast., 2014, 54, p 56–80.

Y.S. Lou, L. Chen, T. Clausmeyer, A.E. Tekkaya, and J.W. Yoon, Modeling of Ductile Fracture from Shear to Balanced Biaxial Tension for Sheet Metals, Int. J. Solids Struct., 2017, 112, p 169–184.

F.F. Li and G. Fang, Establishment and Verification of Two-Component Ductile Fracture Criteria with High Estimation Accuracy, Eng. Fract. Mech., 2018, 204, p 221–234.

X.Q. Shang, Z.S. Cui, and M.W. Fu, A Ductile Fracture Model Considering Stress State and Zener-Hollomon Parameter for hot Deformation of Metallic Materials, Int. J. Mech. Sci., 2018, 144, p 800–812.

J. Cao, Z. Sun, L. Huang, and Z. Yin, A Unified Model of Ductile Fracture Considering Strain Rate and Temperature under the Complex Stress States, J. Mater. Process. Technol., 2021, 297, p 117275.

Z. Zhang, Y. Wu, and F. Huang, Extension of a Shear-Controlled Ductile Fracture Criterion by Considering the Necking Coalescence of Voids, Int. J. Solids Struct., 2022, 236–237, p 111324.

A.A. Benzerga, J. Besson, and A. Pineau, Anisotropic Ductile Fracture Part I: Experiments, Acta Mater., 2004, 52(15), p 4623–4638.

A.A. Benzerga, J. Besson, and A. Pineau, Anisotropic Ductile Fracture Part II: Theory, Acta Mater., 2004, 52(15), p 4639–4650.

A.M. Beese, M. Luo, Y.N. Li, Y.L. Bai, and T. Wierzbicki, Partially Coupled Anisotropic Fracture Model for Aluminum Sheets, Eng. Fract. Mech., 2010, 77(7), p 1128–1152.

Y.L. Bai and T. Wierzbicki, Application of Extended Mohr-Coulomb Criterion to Ductile Fracture, Int. J. Fract., 2010, 161(1), p 1–20.

R. Hill, A Theory of the Yielding and Plastic Flow of Anisotropic Metals, Proc. Royal Soc. London Ser. A Math. Phys. Sci., 1948, 193(1033), p 281–297.

M. Luo, M. Dunand, and D. Mohr, Experiments and Modeling of Anisotropic Aluminum Extrusions under Multi-Axial Loading-Part II: Ductile Fracture, Int. J. Plast., 2012, 32–33, p 36–58.

Y.S. Lou and J.W. Yoon, Anisotropic Ductile Fracture Criterion Based on Linear Transformation, Int. J. Plast., 2017, 93, p 3–25.

F. Barlat and K.S. Chung, Anisotropic Potentials for Plastically Deforming Metals, Modell. Simul. Mater. Sci. Eng., 1993, 1(4), p 403–416.

B.T. Tang, Q.F. Wang, N. Guo, X.S. Li, Q.L. Wang, A. Ghiotti, S. Bruschi, and Z.G. Luo, Modeling Anisotropic Ductile Fracture Behavior of Ti-6Al-4V Titanium Alloy for Sheet Forming Applications at Room Temperature, Int. J. Solids Struct., 2020, 207, p 178–195.

G.Y. Gu and D. Mohr, Anisotropic Hosford-Coulomb fracture Initiation Model: Theory and application, Eng. Fract. Mech., 2015, 147, p 480–497.

Y.Q. Jia, and Y.L. Bai, Ductile Fracture Prediction for Metal Sheets Using All-Strain-Based Anisotropic eMMC Model, Int. J. Mech. Sci., 2016, 115, p 516–531.

N. Park, H. Huh, S.J. Lim, Y.S. Lou, Y.S. Kang and M.H. Seo, Fracture-Based Forming Limit Criteria for Anisotropic Materials in Sheet Metal Forming, Int. J. Plast., 2017, 96, p 1–35.

N. Park, H. Huh, and J.W. Yoon, Anisotropic Fracture Forming Limit Diagram Considering Non-Directionality of the Equi-Biaxial Fracture Strain, Int. J. Solids Struct., 2018, 151, p 181–194.

Y.S. Lou and J.W. Yoon, Alternative Approach to Model Ductile Fracture by Incorporating Anisotropic Yield Function, Int. J. Solids Struct., 2019, 164, p 12–24.

B. Gu, J. He, S.H. Li, and Z.Q. Lin, Anisotropic Fracture Modeling of Sheet Metals: From In-Plane to Out-of-Plane, Int. J. Solids Struct., 2020, 182, p 112–140.

N. Park, T.B. Stoughton, and J.W. Yoon, A New Approach for Fracture Prediction Considering General Anisotropy of Metal Sheets, Int. J. Plast., 2020, 124, p 199–225.

T. Xu, F. Li, X. Wang, and G. Zhang, Modeling Anisotropic Ductile Fracture of AA7075-T6 Sheet for Sheet Metal Forming Considering Anisotropic Stress State, Theor. Appl. Fract. Mech., 2022, 122, p 103610.

T. Xu, F. Li, and X. Wang, A User-Friendly Anisotropic Yield Function for Modeling Anisotropy of BCC and FCC Sheet Metals, J. Mater. Eng. Perform., 2022 https://doi.org/10.1007/s11665-022-07275-5

H. Quach and Y.-S. Kim, Effect of Non-Associated Flow Rule on Fracture Prediction of Metal Sheets Using a Novel Anisotropic Ductile Fracture Criterion, Int. J. Mech. Sci., 2021, 195, p 106224.

Y.S. Lou and J.W. Yoon, A User-Friendly Anisotropic Ductile Fracture Criterion for Sheet Metal under Proportional Loading, Int. J. Solids Struct., 2021, 217, p 48–59.

J.-Y. Lee, K.-J. Lee, M.-G. Lee, T. Kuwabara, and F. Barlat, Numerical Modeling for Accurate Prediction of Strain Localization in Hole Expansion of a Steel Sheet, Int. J. Solids Struct., 2019, 156–157, p 107–118.

D. Banabic, F. Barlat, O. Cazacu, and T. Kuwabara, Advances in Anisotropy of Plastic Behaviour and Formability of Sheet Metals, Int. J. Mater. Form., 2020, 13(5), p 749–787.

X.P. Zhan, Z.H. Wang, M. Li, Q. Hu, and J. Chen, Investigations on Failure-to-Fracture Mechanism and Prediction of Forming Limit for Aluminum Alloy Incremental Forming Process, J. Mater. Process. Technol., 2020, 282, p 116687.

F. Barlat and M.-G. Lee, Constitutive Description of Isotropic and Anisotropic Plasticity for Metals, Failure and Damage Analysis of Advanced Materialsed. H. Altenbach, T. Sadowski Ed., Springer, Vienna, 2015, p 67–118

D. Mohr and S.J. Marcadet, Micromechanically-Motivated Phenomenological Hosford-Coulomb Model for Predicting Ductile Fracture Initiation at Low Stress Triaxialities, Int. J. Solids Struct., 2015, 67–68, p 40–55.

Y. Bai and T. Wierzbicki, A Comparative Study of Three Groups of Ductile Fracture Loci in the 3D Space, Eng. Fract. Mech., 2015, 135, p 147–167.

C.C. Roth and D. Mohr, Ductile Fracture Experiments with Locally Proportional Loading Histories, Int. J. Plast., 2016, 79, p 328–354.

J. Lee, J. Ha, H.J. Bong, D. Kim, and M.-G. Lee, Evolutionary Anisotropy and Flow Stress in Advanced High Strength Steels under Loading Path Changes, Mater. Sci. Eng. A, 2016, 672, p 65–77.

L. Cortese, F. Nalli, and M. Rossi, A Nonlinear Model for Ductile Damage Accumulation under Multiaxial Non-Proportional Loading Conditions, Int. J. Plast., 2016, 85, p 77–92.

S. Basak and S.K. Panda, Implementation of Yld96 Anisotropy Plasticity Theory for Estimation of Polar Effective Plastic Strain Based Failure Limit of Pre-Strained thin Steels, Thin Walled Struct., 2018, 126, p 26–37.

M. Ganjiani and M. Homayounfard, Development of a Ductile Failure Model Sensitive to Stress Triaxiality and Lode Angle, Int. J. Solids Struct., 2021, 225, p 111066.

N. Hosseini, J.C. Nieto-Fuentes, M. Dakshinamurthy, J.A. Rodríguez-Martínez, and G. Vadillo, The Effect of Material Orientation on Void Growth, Int. J. Plast., 2022, 148, p 103149.

M. Dakshinamurthy, K. Kowalczyk-Gajewska, and G. Vadillo, Influence of Crystallographic Orientation on the Void Growth at the Grain Boundaries in bi-Crystals, Int. J. Solids Struct., 2021, 212, p 61–79.

N. Hosseini and J.A. Rodríguez-Martínez, A Simple and Computationally Efficient Stress Integration Scheme Based on Numerical Approximation of the Yield Function Gradients: Application to Advanced Yield Criteria, Finite Elem. Anal. Des., 2021, 192, p 103538.

H. Quach, J.J. Kim, J.H. Sung, and Y.S. Kim, A Novel Uncoupled Ductile Fracture Criterion for Prediction of Failure in Sheet Metal Forming, IOP Conf. Ser. Mater. Sci. Eng., 2020, 967(1), p 012032.

N. Park, H. Huh, and J.W. Yoon, Prediction of Fracture Initiation in Square Cup Drawing of DP980 Using an Anisotropic Ductile fracture Criterion, J. Phys. Conf. Ser., 2017, 896, p 012111.

Acknowledgments

The authors express sincere gratitude to Dr. Navab Hosseini (University Carlos III of Madrid) for helpful discussions on implementing the constitutive model in ABAQUS. The authors are very grateful for the support received from the National Natural Science Foundation of China (Grant No. 51275414, No.51605387), the Fundamental Research Funds for the Central Universities with Grant No. 3102015BJ (II) ZS007, the Research Fund of the State Key Laboratory of Solidification Processing (NWPU), China (Grant No.130-QP-2015), and the Key Research and Development Program of Shaanxi Province (No. 2020ZDLGY12-07).

Author information

Authors and Affiliations

Contributions

TX involved in conceptualization, investigation, numerical simulation, visualization, and writing—original draft. FL involved in review and editing and supervision. XW involved in investigation and visualization.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix A: Calibrated Parameters of Lou and Yoon's (2021) Model for Different metal Sheets

Appendix A: Calibrated Parameters of Lou and Yoon's (2021) Model for Different metal Sheets

Lou and Yoon (Ref 53) suggested a user-friendly anisotropic ductile fracture defined below:

with

where Ci(θ) (i = 1, 2 , 3, 4) is the interpolated fracture parameters along the arbitrary loading direction, for instance, the interpolated fracture parameters are expressed as:

where \(C_{i}^{0}\), \(C_{i}^{45}\), and \(C_{i}^{90}\) (i = 1, …, 4) are calibrated fracture parameters along RD, DD, and TD, respectively.

In order to calibrate the fracture parameters in the above Lou and Yoon’s model, it is generally required three steps as follows:

-

(1)

Fracture experiments are performed to determine the fracture strains along different loading directions under various stress states of in-plane shear, uniaxial tension, plane strain tension, and balanced biaxial tension.

-

(2)

Based on measured fracture strains in Step 1, the fracture parameters in the above Lou and Yoon’s model are identified along specific loading directions, e.g., \(C_{i}^{0}\) for RD, \(C_{i}^{45}\) for DD, and \(C_{i}^{90}\) for TD by minimizing the error equation defined in Eq A4.

$$\begin{array}{*{20}c} {{\text{err}} = \mathop \sum \limits_{i = 1}^{N} \left( {\frac{{\overline{\varepsilon }_{f}^{{{\text{pred}}.}} }}{{\overline{\varepsilon }_{f}^{{{\text{exp}}.}} }} - 1} \right)^{2} \times 100\% } \\ \end{array}$$(A4)where the superscript exp. and pred. denote whether the data are obtained from the experiments or predictions.

-

(3)

Substituting the identified fracture parameters along specific loading directions in Step 2 into Eq A3, after simple linear operations, the interpolation coefficients, viz., Ai, Bi, and Di, are finally identified.

Furthermore, to take into account the non-directionality of the balanced biaxial tension fracture strain, C3(θ) in Eq A1 is set as identical to equi-biaxial fracture strain, viz., \(C_{3} \left( \theta \right) = \overline{\varepsilon }_{{\text{f}}}^{{\text{b}}}\).

Accordingly, based on the experimental data provided in Table 1 for DP980 steel, Table 6 for AA6082-T6 alloy, and Table 8 for Ti-6Al-4 V alloy, the corresponding identified fracture parameters of the Lou and Yoon's model are briefly summarized below.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xu, T., Li, F. & Wang, X. Modeling Anisotropic Ductile Fracture Behavior of Sheet Metals Considering Non-directionality of Equi-Biaxial Tensile Fracture. J. of Materi Eng and Perform 33, 1092–1113 (2024). https://doi.org/10.1007/s11665-023-08072-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-08072-4