Abstract

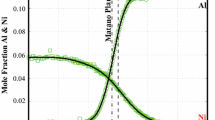

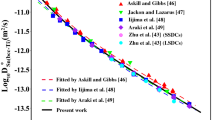

Diffusion behavior in the BCC Ti-Al-Zr ternary alloys was experimentally investigated at 1273 K (1000 °C) and 1473 K (1200 °C) by means of the diffusion-couple technique. Upon the Whittle-Green and generalized Hall methods, the inter- and impurity diffusion coefficients were respectively extracted from the composition profiles acquired by the electron microprobe analysis (EPMA) and subsequently represented by the error function expansion. The extracted main interdiffusion coefficient \(\tilde{D}_{\text{AlAl}}^{\text{Ti}}\) increases with increasing the content of either Al or Zr, and the increase is appearing more considerably at the higher temperature. However, \(\tilde{D}_{\text{ZrZr}}^{\text{Ti}}\) was noticed to decrease with the increase of Al and Zr contents at 1273 K (1000 °C) while there is an upward trend at 1473 K (1200 °C). The impurity diffusion coefficients of Al in Ti-Zr binary alloys, \(D_{{{\text{Al}}\left( {\text{Ti - Zr}} \right)}}^{*}\), and of Zr in Ti-Al binary alloys, \(D_{{{\text{Zr}}\left( {\text{Ti - Al}} \right)}}^{*}\), increase with increasing the Zr and Al contents respectively. A comparison of average main interdiffusion coefficient \(\overline{{\tilde{D}_{\text{XX}}^{\text{Ti}} }}\) made among ten Ti-Al-X ternary systems suggests that the Zr diffusion is most comparable to Cr and could operate via a vacancy-controlled mechanism.

Similar content being viewed by others

References

G. Lütjering and J.C. Williams, Titanium Based Intermetallics, Springer, Berlin, 2003

R.R. Boyer, Attributes, Characteristics, and Applications of Titanium and Its Alloys, JOM, 2010, 62(5), p 21-24

R.R. Boyer and R.D. Briggs, The Use of β Titanium Alloys in the Aerospace Industry, J. Mater. Eng. Perform., 2005, 14(6), p 681-685

J.H. Xiong, S.K. Li, F.Y. Gao, and J.X. Zhang, Microstructure and Mechanical Properties of Ti6321 Alloy Welded Joint by GTAW, Metall. Trans. A, 2015, 640, p 419-423

X. Zhang, H.C. Kou, J.S. Li, F.S. Zhang, and L. Zhou, Evolution of the Secondary α Phase Morphologies During Isothermal Heat Treatment in Ti-7333 Alloy, J. Alloys Compd., 2013, 577(2–3), p 516-522

Y.L. Wang, S.X. Hui, R. Liu, and W.J. Ye, Evaluation of dynamic performance and ballistic behavior of Ti-5Al-5Mo-5V-3Cr-1Zr alloy, Trans. Nonferrous Met. Soc., 2015, 25(2), p 429-436

H. Chang, E. Gautier, F. Bruneseaux, and L. Zhou, β → α+β Isothermal Phase Transformation Kinetics in Ti-B19 Metastable Titanium Alloy, Rare Metal Mat. Eng., 2006, 35(11), p 1696-1699

G.J. Fan, X.P. Song, M.X. Quan, and Z.Q. Hu, Mechanical Alloying and Thermal Stability of Al 67 Ti 25M 8 (M = Cr, Zr, Cu), Metall. Trans. A, 1997, 231(1–2), p 111-116

L. Feng, J.S. Li, Y.W. Cui, L. Huang, H.C. Kou, and L. Zhou, Research on Interdiffusion Behavior of Ti-Zr Binary Alloy in the β Phase, Rare Met. Mater. Eng., 2011, 40(04), p 610-614

Q. Chen, N. Ma, K.S. Wu, and Y.Z. Wang, Quantitative Phase Field Modeling of Diffusion-Controlled Precipitate Growth and Dissolution in Ti-Al-V, Scr. Mater., 2004, 50(4), p 471-476

H. Hu and S.A. Argyropoulos, Mathematical Modelling of Solidification and Melting: A Review, Model. Simul. Mater. Sci. Eng., 1996, 4, p 371-396

H. Araki, T. Yamane, Y. Minamino, S. Saji, Y. Hana, and S.B. Jung, Anomalous Diffusion of Aluminum in β-Titanium, Metall. Trans. A, 1994, 25(4), p 874-876

S.Y. Lee, O. Taguchi, and Y. Iijima, Diffusion of Alummum in β-Titanium, Mater. Trans., 2010, 51(10), p 1809-1813

I. Thibon, D. Ansel, and T. Gloriant, Interdiffusion in β-Ti-Zr Binary Alloys, J. Alloys Compd., 2009, 470(1–2), p 127-133

F. Yang, F.H. Xiao, S.G. Liu, S.S. Dong, L.H. Huang, Q. Chen, G.M. Cai, H.S. Liu, and Z.P. Jin, Isothermal Section of Al-Ti-Zr Ternary System at 1273K, J. Alloys Compd., 2014, 585, p 325-330

A.G. Nikitin, S.V. Spichak, S.V. Yu, and A.G. Naumovets, Symmetries and Modelling Functions for Diffusion Processes, J. Phys. D, 2009, 42, p 55301

W.M. Bai, Y.Y. Tian, G.L. Xu, Z.J. Yang, L.B. Liu, P.J. Masset, and L.G. Zhang, Diffusivities and Atomic Mobilities in bcc Ti-Zr-Nb Alloys, Calphad, 2019, 62, p 160-174

Q.J. Wu, J.Y. Wang, Y.Y. Gu, Y.H. Guo, G.L. Xu, and Y.W. Cui, Experimental Diffusion Research on BCC Ti-Al-Sn Ternary Alloys, J. Phase Equilib. Diff., 2018, 39(5), p 724-730

X. Huang, Y.J. Tan, Y.H. Guo, G.L. Xu, and Y.W. Cui, Experimental Diffusion Research on BCC Ti-Mn Binary and Ti-Al-Mn Ternary Alloys, J. Phase Equilib. Diffus., 2018, 39(5), p 702-713

J.S. Kirkaldy, Diffusion in Multicomponent Metallic Systems, Can. J. Phys., 1957, 35(4), p 435-440

D.P. Whittle and A. Green, The Measurement of Diffusion Coefficients in Ternary Systems, Scr. Mater., 1974, 8(7), p 883-884

C.Y. Wang, G.L. Xu, and Y.W. Cui, Mapping of Diffusion and Nanohardness Properties of Fcc Co-Al-V Alloys Using Ternary Diffusion Couples, Metall. Trans. A, 2017, 48(9), p 4286-4296

L.D. Hall, An Analytical Method of Calculating Variable Diffusion Coefficients, J. Chem. Phys., 1953, 21, p 87-89

Y. Chen, B. Tang, G.L. Xu, C.Y. Wang, H.C. Kou, J.S. Li, and Y.W. Cui, Diffusion Research in BCC Ti-Al-Mo Ternary Alloys, Metall. Mater. Trans. A, 2014, 45A(4), p 1647-1652

Y. Chen, J.S. Li, B. Tang, G.L. Xu, H.C. Kou, and Y.W. Cui, Interdiffusion in FCC Co-Al-Ti Ternary Alloys, J. Phase Equilib. Diff., 2015, 36(2), p 127-135

J.S. Kirkaldy, D. Weichert, and Z.U. Haq, Diffusion in Multicomponent Metallic Systems: VI. Some Thermodynamic Properties of the D Matrix and the Corresponding Solutions of the Diffusion Equations, Can. J. Phys., 1963, 41(12), p 2166-2173

F.O. Shuck and H.L. Toor, Diffusion in the Three Component Liquid System Methyl Alcohol-n-Propyl Alcohol-Isobutyl Alcohol, J. Phys. Chem., 1963, 67(3), p 540-545

Y.Y. Gu, F.J. Fan, Y.H. Guo, G.L. Xu, H. Chang, L. Zhou, and Y.W. Cui, Diffusion and Atomic Mobility of BCC Ti-Al-Nb Alloys: Experimental Determination and Computational Modeling, Calphad, 2018, 62, p 83-91

B. Gao, Y.Y. Gu, Q.J. Wu, Y.H. Guo, and Y.W. Cui, Diffusion Research in BCC Ti-Al-Ni Ternary Alloys, J. Phase Equilib. Diff., 2017, 38(4), p 502-508

T. Takahashi, Ternary Diffusion and Thermodynamic Interaction in the β Solid Solutions of Ti-Al-Co Alloys, J. Jpn. Inst. Met., 2009, 59(8), p 432-438

T. Takahashi and Y. Minamino, Ternary Diffusion and Thermodynamic Interaction in the β Solid Solutions of Ti-Al-Fe Alloys at 1423 K, J. Alloys Compd., 2012, 545, p 168-175

W.B. Li, B. Tang, Y.W. Cui, R. Hu, H. Chang, J.S. Li, and L. Zhou, Assessment of Diffusion Mobility for the bcc Phase of the Ti-Al-Cr System, Calphad, 2011, 35, p 384-390

L. Huang, Y.W. Cui, H. Chang, H. Zhong, J.S. Li, and L. Zhou, Assessment of Atomic Mobilities for bcc Phase of Ti-Al-V System, J. Phase Equilib. Diff., 2010, 31(2), p 135-143

G.M. Hood and R.J. Schultz, Ultra-fast Solute Diffusion in α-Ti and α-Zr, Philos. Mag., 1972, 26(2), p 329-336

Acknowledgments

This research was funded by the Defense Industrial Technology Development Program of China [No. JCKY2018414C020]. YC acknowledges the support from the Natural Science Funds of China [Grant No. 51571113]. GX was funded by the Natural Science Funds of China [Grant No. 51701094] and the Natural Science Funds of Jiangsu Province [Grant No. BK20171014]. FF and YG would like to thank the support from the Synergetic Innovation Center for Advanced Materials, Jiangsu Collaborative Innovation Center for Advanced Inorganic Function Composites, Nanjing Tech University.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Fan, F., Gu, Y., Xu, G. et al. Diffusion Research in BCC Ti-Al-Zr Ternary Alloys. J. Phase Equilib. Diffus. 40, 686–696 (2019). https://doi.org/10.1007/s11669-019-00755-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11669-019-00755-7