Abstract

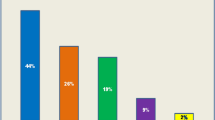

This study explored the feasibility of integrating an adsorption and solvent scrubbing process for post-combustion CO2 capture from a coal-fired power plant. This integrated process has two stages: the first is a vacuum swing adsorption (VSA) process using activated carbon as the adsorbent, and the second stage is a solvent scrubber/stripper system using monoethanolamine (30 wt-%) as the solvent. The results showed that the adsorption process could enrich CO2 in the flue gas from 12 to 50 mol-% with a CO2 recovery of > 90%, and the concentrated CO2 stream fed to the solvent scrubber had a significantly lower volumetric flowrate. The increased CO2 concentration and reduced feed flow to the absorption section resulted in significant reduction in the diameter of the solvent absorber, bringing the size of the absorber from uneconomically large to readily achievable domain. In addition, the VSA process could also remove most of the oxygen initially existed in the feed gas, alleviating the downstream corrosion and degradation problems in the absorption section. The findings in this work will reduce the technical risks associated with the state-of-the art solvent absorption technology for CO2 capture and thus accelerate the deployment of such technologies to reduce carbon emissions.

Similar content being viewed by others

References

Markewitz P, Kuckshinrichs W, Leitner W, Linssen J, Zapp P, Bongartz R, Schreiber A, Muller T E. Worldwide innovations in the development of carbon capture technologies and the utilization of CO2. Energy & Environmental Science, 2012, 5(6): 7281–7305

IEA. Transforming Industry through CCUS. 2019

Rochelle G T. Amine scrubbing for CO2 capture. Science, 2009, 325 (5948): 1652–1654

Ye B, Jiang J, Zhou Y, Liu J, Wang K. Technical and economic analysis of amine-based carbon capture and sequestration at coal-fired power plants. Journal of Cleaner Production, 2019, 222: 476–487

Oko E, Wang M, Joel A S. Current status and future development of solvent-based carbon capture. International Journal of Coal Science & Technology, 2017, 4(1): 5–14

Campbell K L S, Zhao Y, Hall J J, Williams D R. The effect of CO2-loaded amine solvents on the corrosion of a carbon steel stripper. International Journal of Greenhouse Gas Control, 2016, 47: 376–385

Krzemień A, Więckol-Ryk A, Smoliński A, Koteras A, Więcław-Solny L. Assessing the risk of corrosion in amine-based CO2 capture process. Journal of Loss Prevention in the Process Industries, 2016, 43: 189–197

Fredriksen S B, Jens K J. Oxidative degradation of aqueous amine solutions of MEA, AMP, MDEA, Pz: a review. Energy Procedia, 2013, 37: 1770–1777

Kimura H, Kubo T, Shimada M, Kitamura H, Fujita K, Suzuki K, Yamamoto K, Akai M. Environmental risk assessment of MEA and its degradation products from post-combustion CO2 capture pilot plant: drafting technical guidelines. Energy Procedia, 2017, 114: 6490–6500

Saiwan C, Supap T, Idem R O, Tontiwachwuthikul P. Part 3: corrosion and prevention in post-combustion CO2 capture systems. Carbon Management, 2011, 2(6): 659–675

Moser P, Wiechers G, Schmidt S, Garcia Moretz-Sohn Monteiro J, Charalambous C, Garcia S, Sanchez Fernandez E. Results of the 18-month test with MEA at the post-combustion capture pilot plant at Niederaussem—new impetus to solvent management, emissions and dynamic behaviour. International Journal of Greenhouse Gas Control, 2020, 95: 102945

Rezakazemi M, Heydari I, Zhang Z. Hybrid systems: combining membrane and absorption technologies leads to more efficient acid gases (CO2 and H2S) removal from natural gas. Journal of CO2 Utilization, 2017, 18: 362–369

Belaissaoui B, Le Moullec Y, Willson D, Favre E. Hybrid membrane cryogenic process for post-combustion CO2 capture. Journal of Membrane Science, 2012, 415–416: 424–434

Liu K, Neathery J K, Remias J E, Li X. Method for removing CO2 from coal-fired power plant flue gas using ammonia as the scrubbing solution, with a chemical additive for reducing NH3 losses, coupled with a membrane for concentrating the CO2 stream to the gas stripper. US Patent, 8328911, 2011

Webley P A, Qader A, Ntiamoah A, Ling J, Xiao P, Zhai Y. A new multi-bed vacuum swing adsorption cycle for CO2 capture from flue gas streams. Energy Procedia, 2017, 114(Suppl C): 2467–2480

Webley P A. Adsorption technology for CO2 separation and capture: a perspective. Adsorption, 2014, 20(2–3): 1–7

Saeed I M, Alaba P, Mazari S A, Basirun W J, Lee V S, Sabzoi N. Opportunities and challenges in the development of monoethanolamine and its blends for post-combustion CO2 capture. International Journal of Greenhouse Gas Control, 2018, 79: 212–233

Mazari S A, Alaba P, Saeed I M. Formation and elimination of nitrosamines and nitramines in freshwaters involved in postcombustion carbon capture process. Journal of Environmental Chemical Engineering, 2019, 7(3): 103111

Yi H, Li F, Ning P, Tang X, Peng J, Li Y, Deng H. Adsorption separation of CO2,CH4 and N2 on microwave activated carbon. Chemical Engineering Journal, 2013, 215–216: 635–642

Vargas D, Giraldo L, Moreno-Piraján J C. Carbon dioxide and methane adsorption at high pressure on activated carbon materials. Adsorption, 2013, 19(6): 1075–1082

Idris I, Abdullah A, Shamsudin I K, Othman M R. Optimizing purity and recovery of hydrogen from syngas by equalized pressure swing adsorption using palm kernel shell activated carbon adsorbent. AIP Conference Proceedings, 2019, 2124(1): 020059

Zhang X X, Xiao P, Sun C Y, Luo G X, Ju J, Wang X R, Wang H X, Yang H. Optimal activated carbon for separation of CO2 from (H2 + CO2) gas mixture. Petroleum Science, 2018, 15(3): 625–633

Xu D, Xiao P, Zhang J, Li G, Xiao G, Webley P A, Zhai Y. Effects of water vapour on CO2 capture with vacuum swing adsorption using activated carbon. Chemical Engineering Journal, 2013, 230: 64–72

You Y Y, Liu X J. Modeling of CO2 adsorption and recovery from wet flue gas by using activated carbon. Chemical Engineering Journal, 2019, 369: 672–685

Raganati F, Chirone R, Ammendola P. CO2 capture by temperature swing adsorption: working capacity as affected by temperature and CO2 partial pressure. Industrial & Engineering Chemistry Research, 2020, 59(8): 3593–3605

The world biggest water ring vacuum pump is made by Huacheng. Zibo Water Ring Vacuum Pump Factory Co. Ltd. website, 2011

Xiao G, Saleman T L, Zou Y, Li G, May E F. Nitrogen rejection from methane using dual-reflux pressure swing adsorption with a kinetically-selective adsorbent. Chemical Engineering Journal, 2019, 372: 1038–1046

Zou Y, Xiao G, Li G, Lu W, May E F. Advanced non-isothermal dynamic simulations of dual reflux pressure swing adsorption cycles. Chemical Engineering Research & Design, 2017, 126: 76–88

May-Vázquez M M, Gómez-Castro F I, Rodríguez-Ángeles M A. Rate-based modelling and simulation of pilot scale distillation column. In: Kiss A A, Zondervan E, Lakerveld R, Özkan L, eds. Computer Aided Chemical Engineering. Amsterdam: Elsevier, 2019, 625–630

Zhang Y, Chen H, Chen C C, Plaza J M, Dugas R, Rochelle G T. Rate-based process modeling study of CO2 capture with aqueous monoethanolamine solution. Industrial & Engineering Chemistry Research, 2009, 48(20): 9233–9246

Lawal A, Wang M, Stephenson P, Obi O. Demonstrating full-scale post-combustion CO2 capture for coal-fired power plants through dynamic modelling and simulation. Fuel, 2012, 101: 115–128

Ramezan M, Skone T J, ya Nsakala N, Liljedahl G N. Carbon dioxide capture from existing coal-fired power plants. Report DOE/NETL-401/110907. 2007

Li L, Maeder M, Burns R, Puxty G, Clifford S, Yu H. The Henry coefficient of CO2 in the MEA-CO2-H2O system. Energy Procedia, 2017, 114: 1841–1847

Wu X, Wang M, Liao P, Shen J, Li Y. Solvent-based post-combustion CO2 capture for power plants: a critical review and perspective on dynamic modelling, system identification, process control and flexible operation. Applied Energy, 2020, 257: 113941

Li K, Leigh W, Feron P, Yu H, Tade M. Systematic study of aqueous monoethanolamine (MEA)-based CO2 capture process: technoeconomic assessment of the MEA process and its improvements. Applied Energy, 2016, 165: 648–659

Vega F, Sanna A, Maroto-Valer M M, Navarrete B, Abad-Correa D. Study of the MEA degradation in a CO2 capture process based on partial oxy-combustion approach. International Journal of Green-house Gas Control, 2016, 54: 160–167

Morken A K, Pedersen S, Nesse S O, Flø N E, Johnsen K, Feste J K, de Cazenove T, Faramarzi L, Vernstad K. CO2 capture with monoethanolamine: solvent management and environmental impacts during long term operation at the Technology Centre Mongstad (TCM). International Journal of Greenhouse Gas Control, 2019, 82: 175–183

Fang M, Yi N, Di W, Wang T, Wang Q. Emission and control of flue gas pollutants in CO2 chemical absorption system: a review. International Journal of Greenhouse Gas Control, 2020, 93: 102904

Hammond G P, Spargo J. The prospects for coal-fired power plants with carbon capture and storage: a UK perspective. Energy Conversion and Management, 2014, 86: 476–489

Acknowledgements

The authors wish to acknowledge financial assistance provided to the CO2CRC by the Australian Government through its CRC program and through Australian National Low Emissions Coal Research and Development (ANLEC R&D). ANLEC R&D is supported by Australian Coal Association Low Emissions Technology Limited and the Australian Government through the Clean Energy Initiative.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xiao, G., Xiao, P., Hoadley, A. et al. Integrated adsorption and absorption process for post-combustion CO2 capture. Front. Chem. Sci. Eng. 15, 483–492 (2021). https://doi.org/10.1007/s11705-020-1964-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11705-020-1964-3