Abstract

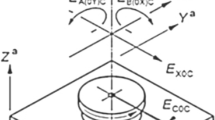

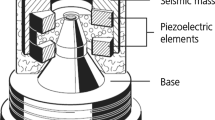

Static, quasi-static and dynamic displacements influence the accuracy of machine tool results. The low-frequency parts of these displacements can, on the one hand, be traced back to static stresses resulting from gravity as well as process loads and, on the other hand, to geometrical machine errors and the faulty positioning in the working area resulting from this. Dynamic loads, however, are characterised by the distribution of masses and stiffnesses. This paper aims to present an approach to adaptronically compensate for static and quasi-static displacements while, at the same time, showing how a component can fulfill the functions of a sensor and an actuator. In order to achieve this, an intelligent adaptronical strut was designed for which the piezoelectric transducer can fulfill actuated as well as sensoric tasks at the same time. Based on the principle of vibrating strings, a vibrating string is used to induce vibrations which allow for the static, quasi-static and dynamic machine displacements to be recorded using the developed integrated sensors and actuators. A first prototype was integrated into a machine tool to verify the concept. Static and dynamic measurements endorse the functionality of this approach. Machining trial runs show the effectiveness of this approach in a parallel kinematic machine tool with regards to adaptronically compensating for geometrical machine errors.

Similar content being viewed by others

References

Mussa S (2002) Aktive Korrektur von Verlagerungsfehlern in Werkzeugmaschinen. Universität Karlsruhe (TH), Karlsruhe. ISSN 0724-4967

Janocha H (1999) Adaptronics and smart structures. Springer. ISBN 3-540-61484-2

Munzinger C (2007) Adaptronische Strebe zur Steifigkeitssteigerung von Werkzeugmaschinen. Universität Karlsruhe (TH), Karlsruhe. ISBN 978-3-8322-5871-9

Weck M, Brecher C (2006) Werkzeugmaschinen 5 Messtechnische Untersuchung und Beurteilung, dynamische Stabilität. 7. neu bearbeitete Auflage, Springer Verlag, 2006, S. 79f. ISBN 13 978-3-540-22505-8

Munzinger C, Weis M, Herder S (2009) Adaptronic hydrostatic guiding system for intelligent level control of machine tool slides. Smart structures and materials and nondestructive evaluation and health monitoring 2009, 8.–12.3.2009, San Diego, CA, USA, Verlag SPIE, Herausgeber/Veranstalter SPIE, band smart structures and materials and nondestructive evaluation and health monitoring 2009, Bellingham, WA, S. 72881P-1–72881P-10

Thomsen B (1969) Ein Beitrag zur Präzisionskraftmessung nach dem Prinzip der schwingenden Saite. TU Berlin

Munzinger C, Herder S, Weis M, Broos A (2009) Einsatz einer intelligenten Strebe zur Kompensation geo-metrischer Maschinenfehler in einer Werkzeugmaschine. Mechatronik-Konferenz, 12.–13.05.2009, Wiesloch, Deutschland, Herausgeber/Veranstalter VDI EKV/GMA, Band Mechatronik, S. 367–377

Munzinger C, Weis M, Seemann W, Kern D (2010) SPP 1156, Shaker Verlag, Herausgeber Hoffmeister/Gerdes, Braunschweig 2010 (Buchbeitrag bislang noch nicht erschienen)

Acknowledgments

The research work presented herein was funded by the German Research Foundation (DFG) as part of the Priority Programme 1156, “Adaptronics for machine tools”. We would like to thank the DFG for their support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fleischer, J., Munzinger, C., Herder, S. et al. Adaptronical compensation of geometrical machine errors. Prod. Eng. Res. Devel. 6, 303–309 (2012). https://doi.org/10.1007/s11740-012-0381-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-012-0381-y