Abstract

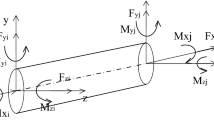

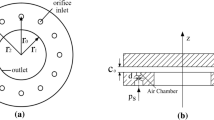

The purpose of the present study is to establish a mixed lubrication model for the journal-thrust coupled microgroove bearings (also referred as coupled bearings) used for the ship shaftless rim-driven thrusters. During the hydrodynamic modelling, the coupling hydrodynamic pressure between the journal bearing and the thrust bearing is considered. The mixed lubrication performances of the microgroove journal-thrust bearing with five different bottom shapes, including rectangle, semi-ellipse, right triangle, isosceles triangle and left triangle, are compared. Based on the numerical results, the optimal microgroove bottom shape of the journal bearing and tilting angle of the thrust pad are determined. Additionally, the comparative analysis shows that the coupled bearing with left triangle microgroove bottom shape exhibits the optimal mixed lubrication performance. The numerical result also indicates that the optimal inclination angle of the thrust bearing pad is 0.01° for the current simulation case.

摘要

本研究以船舶用无轴轮缘推进器中的一体式水润滑轴承为对象, 建立径推一体式微织构水润滑轴承的混合润滑分析模型. 在流体动力建模过程中, 考虑了径向轴承部分和推力轴承部分公共边界处的耦合流体动压力. 比较了矩形、半椭圆形、右三角形、等腰三角形和左三角形五种不同底形的微织构一体式水润滑轴承的混合润滑性能. 基于数值仿真结果, 确定了当前工况条件下的最优微织构底部形状以及最佳推力盘倾斜角. 对比分析表明, 左三角形底形的微织构一体式水润滑轴承表现出了最优的混合润滑性能, 最佳的推力盘倾斜角为0.01°.

Similar content being viewed by others

Abbreviations

- C :

-

Bearing clearance, mm

- ε :

-

Eccentricity ratio

- θ :

-

Circumferential direction

- ψ :

-

Attitude angle, rad

- φ :

-

Thrust pad angle, rad

- R j1 :

-

Inner radius of the journal bearing, mm

- R j2 :

-

Outer radius of the journal bearing, mm

- R t1 :

-

Inner radius of the thrust bearing, mm

- R t2 :

-

Outer radius of the thrust bearing, mm

- L :

-

Journal bearing width, mm

- h J :

-

Lubrication gap of the journal bearing, µm

- h t :

-

Lubrication gap of the thrust bearing, µm

- N g :

-

Groove number

- R g :

-

Groove ratio

- D g :

-

Maixmum groove depth, µm

- h p :

-

Geometry clearance, mm

- G j :

-

Journal bearing groove depth, µm

- G t :

-

Thrust bearing groove depth, µm

- δ j :

-

Journal bearing elastic deformation, µm

- δ t :

-

Thrust bearing elastic deformation, µm

- α t :

-

Tilting angle, rad

- T coat :

-

Coating thickness, mm

- p hj :

-

Hydrodynamic pressure of the Journal bearing, MPa

- p ht :

-

Hydrodynamic pressure of the thrust bearing, MPa

- ρ :

-

Density of the water, kg/m3

- η :

-

Viscosity of the water, Pa·s

- σ :

-

Composite roughness, µm

- ϕ η :

-

Flow factor in the circumferential direction

- ϕ r :

-

Flow factor in the radial direction

- ϕ s :

-

Shear factor

- ϕ c :

-

Contact factor

- ω :

-

Rotational speed, rad/s

- p c :

-

Contact pressure, MPa

- K :

-

Contact coefficient

- H dim :

-

Dimentionless lubrication gap

- β :

-

Asperity curvature

- D :

-

Asperity density

- θ t0 :

-

Cavitation position of thrust bearing

- θ j0 :

-

Cavitation position of journal bearing

- E j :

-

Elastic modulus of the journal bearing, GPa

- E s :

-

Elastic modulus of the shaft, GPa

- E t :

-

Elastic modulus of the thrust bearing, GPa

- ν j :

-

Poisson ratio of the journal bearing

- ν s :

-

Poisson ratio of the shaft

- σ s :

-

Surface roughness of the shaft, µm

- γ :

-

Surface orientation

References

YAN Xin-ping, LIANG Xing-xin, OUYANG Wu, et al. A review of progress and applications of ship shaft-less rim-driven thrusters [J]. Ocean Engineering, 2017, 144: 142–156. DOI: https://doi.org/10.1016/j.oceaneng.2017.08.045.

HSIEH M F, CHEN J H, YEH Y H, et al. Integrated design and realization of a hubless rim-driven thruster [C]// IECON 2007-33rd Annual Conference of the IEEE Industrial Electronics Society. Taipei, Taiwan, China: IEEE, 2007: 3033–3038. DOI: https://doi.org/10.1109/IECON.2007.4460298.

SHEN Yang, HU Peng-fei, JIN Shuan-bao, et al. Design of novel shaftless pump-jet propulsor for multi-purpose long-range and high-speed autonomous underwater vehicle [J]. IEEE Transactions on Magnetics, 2016, 52(7): 1–4. DOI: https://doi.org/10.1109/tmag.2016.2522822.

XIANG Guo, HAN Yan-feng, HE Tao, et al. Transient tribo-dynamic model for journal bearings during start-up considering 3D thermal characteristic [J]. Tribology International, 2020, 144: 106123. DOI: https://doi.org/10.1016/j.triboint.2019.106123.

WANG Y S, WANG Q J, LIN C. Mixed lubrication of coupled journal-thrust bearing systems [J]. CMES: Computer Modeling in Engineering & Sciences, 2002, 3(4): 517–530. DOI: https://doi.org/10.3970/cmes.2002.003.517.

WANG Y S, WANG Q J, LIN C. Mixed lubrication of coupled journal-thrust-bearing systems including mass conserving cavitation [J]. Journal of Tribology, 2003, 125(4): 747–755. DOI: https://doi.org/10.1115/1.1574519.

WANG Y S, WANG Q J, LIN C. A mixed-EHL analysis of effects of misalignments and elastic deformations on the performance of a coupled journal-thrust bearing system [J]. Tribology International, 2006, 39(4): 281–289. DOI: https://doi.org/10.1016/j.triboint.2005.01.033.

RONEN A, ETSION I, KLIGERMAN Y. Friction-reducing surface-texturing in reciprocating automotive components [J]. Tribology Transactions, 2001, 44(3): 359–366. DOI: https://doi.org/10.1080/10402000108982468.

ETSION I, HALPERIN G, BRIZMER V, et al. Experimental investigation of laser surface textured parallel thrust bearings [J]. Tribology Letters, 2004, 17(2): 295–300. DOI: https://doi.org/10.1023/b:tril.0000032467.88800.59.

ETSION I. Improving tribological performance of mechanical components by laser surface texturing [J]. Tribology Letters, 2004, 17(4): 733–737. DOI: https://doi.org/10.1007/s11249-004-8081-1.

DOBRICA M B, FILLON M, PASCOVICI M D, et al. Texturing effects in plane-inclined slider bearings [C]//Proceedings of ASME/STLE 2007 International Joint Tribology Conference. San Diego, California, USA, 2009: 269–271. DOI: https://doi.org/10.1115/IJTC2007-44258.

YU Hai-wu, WANG Xiao-lei, ZHOU Fei. Geometric shape effects of surface texture on the generation of hydrodynamic pressure between conformal contacting surfaces [J]. Tribology Letters, 2010, 37(2): 123–130. DOI: https://doi.org/10.1007/s11249-009-9497-4.

FOWELL M T, MEDINA S, OLVER A V, et al. Parametric study of texturing in convergent bearings [J]. Tribology International, 2012, 52: 7–16. DOI: https://doi.org/10.1016/j.triboint.2012.02.013.

MENG Fan-ming, ZHOU Rui, DAVIS T, et al. Study on effect of dimples on friction of parallel surfaces under different sliding conditions [J]. Applied Surface Science, 2010, 256(9): 2863–2875. DOI: https://doi.org/10.1016/j.apsusc.2009.11.041.

MENG F M. On influence of cavitation in lubricant upon tribological performances of textured surfaces [J]. Optics & Laser Technology, 2013, 48: 422–431. DOI: https://doi.org/10.1016/j.optlastec.2012.10.020.

MENG F M, ZHANG L, LIU Y, et al. Effect of compound dimple on tribological performances of journal bearing [J]. Tribology International, 2015, 91: 99–110. DOI: https://doi.org/10.1016/j.triboint.2015.06.030.

UDDIN M S, IBATAN T, SHANKAR S. Influence of surface texture shape, geometry and orientation on hydrodynamic lubrication performance of plane-to-plane slider surfaces [J]. Lubrication Science, 2017, 29(3): 153–181. DOI: https://doi.org/10.1002/ls.1362.

GROPPER D, WANG Ling, HARVEY T J. Hydrodynamic lubrication of textured surfaces: A review of modeling techniques and key findings [J]. Tribology International, 2016, 94: 509–529. DOI: https://doi.org/10.1016/j.triboint.2015.10.009.

GROPPER D, HARVEY T J, WANG Ling. Numerical analysis and optimization of surface textures for a tilting pad thrust bearing [J]. Tribology International, 2018, 124: 134–144. DOI: https://doi.org/10.1016/j.triboint.2018.03.034.

GUI Chao, MENG Fan-ming. Comparative study of spherical dimple and bump effects on the tribological performances of journal bearing [J]. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology, 2019, 233(1): 139–157. DOI: https://doi.org/10.1177/1350650118770355.

XIANG Guo, HAN Yan-feng, CHEN Ren-xiang, et al. A hydrodynamic lubrication model and comparative analysis for coupled microgroove journal-thrust bearings lubricated with water [J]. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology, 2020, 234(11): 1755–1770. DOI: https://doi.org/10.1177/1350650119884798.

BRAUN D, GREINER C, SCHNEIDER J, et al. Efficiency of laser surface texturing in the reduction of friction under mixed lubrication [J]. Tribology International, 2014, 77: 142–147. DOI: https://doi.org/10.1016/j.triboint.2014.04.012.

GREINER C, MERZ T, BRAUN D, et al. Optimum dimple diameter for friction reduction with laser surface texturing: The effect of velocity gradient [J]. Surface Topography: Metrology and Properties, 2015, 3(4): 044001. DOI: https://doi.org/10.1088/2051-672x/3/4/044001.

SCHNEIDER J, BRAUN D, GREINER C. Laser textured surfaces for mixed lubrication: Influence of aspect ratio, textured area and dimple arrangement [J]. Lubricants, 2017, 5(3): 32. DOI: https://doi.org/10.3390/lubricants5030032.

MENG Xiang-hui, GU Chun-xing, XIE You-bai. Elasto-plastic contact of rough surfaces: A mixed-lubrication model for the textured surface analysis [J]. Meccanica, 2017, 52(7): 1541–1559. DOI: https://doi.org/10.1007/s11012-016-0492-1.

PATIR N, CHENG H S. An average flow model for determining effects of three-dimensional roughness on partial hydrodynamic lubrication [J]. Journal of Lubrication Technology, 1978, 100(1): 12–17. DOI: https://doi.org/10.1115/1.3453103.

SHI Fang-hui, WANG Q J. A mixed-TEHD model for journal-bearing conformal contacts—Part I: Model formulation and approximation of heat transfer considering asperity contact [J]. Journal of Tribology, 1998, 120(2): 198–205. DOI: https://doi.org/10.1115/1.2834410.

GREENWOOD J A, TRIPP J H. The contact of two nominally flat rough surfaces [J]. Proceedings of the Institution of Mechanical Engineers, 1970, 185(1): 625–633. DOI: https://doi.org/10.1243/pime_proc_1970_185_069_02.

CHUN S M, KHONSARI M M. Wear simulation for the journal bearings operating under aligned shaft and steady load during start-up and coast-down conditions [J]. Tribology International, 2016, 97: 440–466. DOI: https://doi.org/10.1016/j.triboint.2016.01.042.

GONG Jia-yu, JIN Yong, LIU Zheng-lin, et al. Study on influencing factors of lubrication performance of water-lubricated micro-groove bearing [J]. Tribology International, 2019, 129: 390–397. DOI: https://doi.org/10.1016/j.triboint.2018.08.035.

XIONG Shang-wu, WANG Q J. Steady-state hydrodynamic lubrication modeled with the payvar-salant mass conservation model [J]. Journal of Tribology, 2012, 134(3): 031703. DOI: https://doi.org/10.1115/1.4006615.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Foundation item

Project(51975064) supported by the National Natural Science Foundation of China; Project(cstc2018jcyjAX0442) supported by the General Projects of Basic Science and Frontier Technology Research of Chongqing, China; Projects (2018M631059, 2019T120805) supported by the Postdoctoral Science Foundation of China; Project(cstc2017zdcyzdzxX0001) supported by the Major Research and Development Program of China; Project supported by the Innovation Program on the Common and Key Technologise of Key Industries, China

Contributors

WANG Jia-xu provided the idea of this research. TANG Dong-xing built the model, analyzed the results and wrote the fist draft of the manuscript. YIN Lei and XIAO Bin participated in data processing. HAN Yan-feng and XIANG Guo provided assistance on modeling and theoretical analysis. All authors participated in responding to the reviewers and revised the final version of the manuscript.

Conflict of interest

All authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Tang, Dx., Yin, L., Xiao, B. et al. Numerical analysis on mixed lubrication performance of journal-thrust coupled microgroove bearings with different bottom shapes. J. Cent. South Univ. 29, 1197–1212 (2022). https://doi.org/10.1007/s11771-022-4985-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-022-4985-x