Abstract

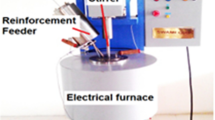

The disposal of waste granite marble powder (GMP) causes environmental problems. The present work reports the impact of waste GMP as a reinforcement to produce composites. The Al-4032/GMP composites with 0%, 4%, 6%, and 8% (by weight) GMP have been fabricated through stir casting. A maximum 0.63% increase in theoretical density while a maximum 5.65% decrease in experimental density has been recorded for 8% reinforcement. The microstructure of the as-cast samples has been analyzed using an optical microscope, x-ray diffraction, and scanning electron microscope equipped with energy-dispersive x-ray spectroscopy. Other properties, such as ultimate tensile strength, micro-hardness, and impact strength of the composites, were enhanced from 69.4 MPa to 115 MPa, 131.4 HV to 174.1 HV, and 22.4 J to 32 J, respectively, because of the addition of GMP particles. Among all, the Al-4032/6%GMP composite appears to possess the best combination of all mechanical properties.

Similar content being viewed by others

Abbreviations

- AMC:

-

Aluminum metal matrix composite

- ASTM:

-

American Society for Testing and Materials

- BHN:

-

Brinell hardness number

- EDS:

-

Energy-dispersive x-ray spectroscopy

- GMP:

-

Granite marble powder

- HV:

-

Vickers hardness

- J:

-

Joule

- MD:

-

Marble dust

- MMC:

-

Metal matrix composite

- MPa:

-

Mega pascal

- OM:

-

Optical microscope

- SEM:

-

Scanning electron microscope

- UTM:

-

Universal testing machine

- UTS:

-

Ultimate tensile strength

- WEDM:

-

Wire electric discharge machining

- XRD:

-

X-ray diffraction

- r :

-

Radius of the sample

- h :

-

Height of the sample

- \(\rho_{{{\text{exp}}}}\) :

-

Experimental density of the sample

- \(\rho_{{\text{m}}}\) :

-

Density of matrix

- \(\rho_{{\text{r}}}\) :

-

Density of reinforcement

- \(\rho_{{{\text{th}}}}\) :

-

Theoretical density of the sample

- \(W_{{\text{m}}}\) :

-

Weight fractions of the matrix

- \(W_{{\text{r}}}\) :

-

Weight fractions of the reinforcement

References

M.Y. Çelik and E. Sabah, J. Environ. Manage. 87, 106 (2008).

T. Uygunoğlu, I.B. Topçu, and A.G. Çelik, J. Clean. Prod. 84, 691 (2014).

J.A. Geiger and A.L. Walker, JOM. 43, 8 (1991).

N. Suresh, S. Venkateswaran, and S. Seetharamu, Int. J. Cast Met. Res. 24, 118 (2011).

Y. Sahin and M. Acilar, Part A Appl. Sci. Manuf. 34, 709 (2003).

V.K. Lindroos and M.J. Talvitie, J. Mater. Process. Tech. 53, 273 (1995).

H. Kala, K.K.S. Mer, and S. Kumar, Procedia Mater. Sci. 6, 1951 (2014).

C. Borsellino, L. Calabrese, and G. Di Bella, Constr. Build. Mater. 23, 1915 (2009).

G. Ahmetli, M. Dag, H. Deveci, and R. Kurbanli, J. Appl. Polym. Sci. 125, 24 (2012).

A.H. Awad and M.H. Abdellatif, Compos. Part B Eng. 173, 106948 (2019).

H. Hebhoub, H. Aoun, M. Belachia, H. Houari, and E. Ghorbel, Constr. Build. Mater. 25, 1167 (2011).

A.A. Aliabdo, A.E.M. Abd Elmoaty, and E.M. Auda, Constr. Build. Mater. 50, 28 (2014).

P.N. Raghunath, Sci. Iran. 26, 3159 (2019).

S.R. Kumar, A. Patnaik, and I.K. Bhat, J. Compos. Mater. 51, 1997 (2017).

A. Meena, H.S. Mali, A. Patnaik, and S.R. Kumar, Polym. Compos. 39, E321 (2018).

J. Hashim, L. Looney, and M.S.J. Hashmi, J. Mater. Process. Technol. 119, 329 (2001).

M.H. Lee, J.H. Kim, J.S. Park, W.T. Kim, and D.H. Kim, Mater. Sci. Forum. 475, 3427 (2005).

A. Sakthivel, R. Palaninathan, R. Velmurugan, and P. Raghothama Rao, J. Mater. Sci. 43, 7047 (2008).

M. Mahendra Boopathi, K.P. Arulshri, and N. Iyandurai, Am. J. Appl. Sci. 10, 219 (2013).

V. Gautam, A. Patnaik, and I.K. Bhat, SILICON 8, 133 (2016).

S. Gangwar, I.K. Bhat, and A. Patnaik, SILICON 9, 249 (2017).

S. Gangwar and V.K. Pathak, Mater. Today Commun. 25, 101615 (2020).

V.K. Sharma, S. Chaudhary, R.C. Singh, S. Vikas, and V. Goel, Mater. Res. Express. 6, 1265f6 (2020).

C.H. Gireesh, K.G. Durga Prasad, and K. Ramji, J. Compos. Sci. 2, 49 (2018).

D.M. Schuster, M.D. Skibo, R.S. Bruski, R. Provencher, and G. Riverin, JOM. 45, 26 (1993).

Y. Nishida, N. Izawa, and Y. Kuramasu, Metall. Mater. Trans. A. 30, 839 (1999).

P.S. Ling and M. Gupta, Mater. Sci. Technol. 16, 568 (2000).

J.B. Fogagnolo, E.M. Ruiz-Navas, M.A. Simón, and M.A. Martinez, J. Mater. Process. Technol. 143, 792 (2003).

Y. Yang, R. Boom, B. Irion, D.J. Van Heerden, P. Kuiper, and H. De Wit, Chem. Eng. Process.: Process Intensif. 51, 53 (2012).

K.K. Chawla, In Compos. Mater. Springer, Cham, 517 (2019).

N.A. Shuaib, S.O. Ismail, A.A. Samat, A.I. Azmi, and P.T. Mativenga, In Adv. in Mach. of Compos. Mater. Springer, Cham, 527 (2021).

V.S. Aigbodion and S.B. Hassan, Mater. Sci. Eng. A. 447, 355 (2007).

M. Agarwal and R. Srivastava, Trans. Indian Ceram. Soc. 78, 94 (2019).

R. Manikandan, T.V. Arjunan, and A.R. Akhil, Compos. Part B Eng. 183, 107668 (2020).

S. Kumar, R.S. Panwar, and O.P. Pandey, Ceram. Int. 39, 6333 (2013).

B. Gobalakrishnan, C. Rajaravi, G. Udhayakumar, and P.R. Lakshminarayanan, Met. Mater. Int. 12, 1 (2020).

A. Bhowmik, D. Dey, and A. Biswas, SILICON 15, 1 (2020).

N. Pandey, S.C. Ram, I. Chakrabarty, and M.R. Majhi, Trans. Indian Ceram. Soc. 79, 188 (2020).

S.O. Akinwamide, B.T. Abe, O.J. Akinribide, B.A. Obadele, and P.A. Olubambi, Int. J. Adv. Manuf. Technol. 109, 975 (2020).

K. Raja, V.S. Chandra Sekar, V. Vignesh Kumar, T. Ramkumar, and P. Ganeshan, Arab. J. Sci. Eng. 45, 9481 (2020).

J. Hashim, L. Looney, and M.S.J. Hashmi, J. Mater. Process. Technol. 123, 251 (2002).

J. Hashim, L. Looney, and M.S.J. Hashmi, J. Mater. Process. Technol. 123, 258 (2002).

N. Ahamad, A. Mohammad, K.K. Sadasivuni, and P. Gupta, J. Compos. Mater. 54, 2985 (2020).

S.N. Ahmad, J. Hashim, and M.I. Ghazali, J. Compos. Mater. 39, 451 (2005).

M.A. Chaudhry, L. Ali, K.M. Ghauri, and J. Iqbal, Mater. Res. Express. 6, 095032 (2019).

M.E. Glicksman, Mater. Sci. Eng. 65, 45 (1984).

W. Zhou and Z.M. Xu, J. Mater. Process. Technol. 63, 358 (1997).

P. Rohatgi, B. Schultz, and W. Milwaukee, Casting. 15, 390 (2018).

P.K. Swain, K. Das Mohapatra, R. Das, A.K. Sahoo, and A. Panda, Mech. Ind. 21, 307 (2020).

A.M. Rajesh, M. Kaleemulla, S. Doddamani, and B. KN, Adv. Compos. Lett. 28, 1 (2019).

P. Suresh, K. Marimuthu, S. Ranganathan, and T. Rajmohan, Trans. Nonferrous Met. Soc. China. 24, 2805 (2014).

S. Mohammed and A.K. Birru, Trans. Indian Ceram. Soc. 78, 137 (2019).

S. Ouyang, Y. Li, S. Li, D. Ouyang, R. Xiang, and N. Xu, Trans. Indian Ceram. Soc. 79, 182 (2020).

B.C. Pai, G. Ramani, R.M. Pillai, and K.G. Satyanarayana, J. Mater. Sci. 30, 1903 (1995).

L. Poovazhagan, K. Kalaichelvan, A. Rajadurai, and V. Senthilvelan, Procedia Eng. 64, 681 (2013).

G. Singh and S. Goyal, Part. Sci. Technol. 36, 154 (2018).

A. Seshappa and B. Anjaneya Prasad, SILICON 9, 1 (2020).

N. Parvin, R. Assadifard, P. Safarzadeh, S. Sheibani, and P. Marashi, Mater. Sci. Eng. A. 492, 134 (2008).

Acknowledgments

The authors grateful to Prof. N M Suri, Department of Production & Industrial Engineering, Punjab Engineering College, Chandigarh for permitting fabrication of composite materials. The authors also wishes to acknowledge the expert guidance by Retired Prof. S K Nath, IIT, Roorkee and Prof. Harpreet Singh, IIT, Ropar for analysis of research. Thanks are also due to anonymous expert reviewers for making useful comments to improve the manuscript. The microstructure and micro hardness testing have been conducted at Department of Mechanical Engineering, SLIET, Longowal.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Saini, P., Singh, P.K. Physical, Morphological, and Mechanical Characterization of Al-4032/GMP Composite Fabricated Through Stir Casting. JOM 74, 1340–1349 (2022). https://doi.org/10.1007/s11837-022-05159-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-022-05159-6