Abstract

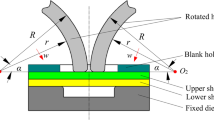

Clinching is a mechanical sheet metal joining technique, wherein the sheets are geometrically interlocked using a specially designed tool that does not require pre-hole or additional rivet material. In practical situations, the use of cross-tensile configuration is widespread, whose load-bearing capacity is found to be lower than that of lap shear configuration. Analytical models are easy to use and enable faster evaluation of joint strength. A novel analytical approach is proposed and validated experimentally. It is done on clinching joints made from Al 1100, because of low cost and good corrosion properties, sheets for various die flange diameters. Further, the experimental work carried out on various die flange diameters, varying from 0 to 12 mm at a step of 2 mm, showed that a different mode of failure could occur in which the interlock region fails by shear rather than button separation. The strength of joints in this proposed failure mode is consistent with the experimental data. The maximum strength of 2.15 kN was observed for a 6 mm diameter flange. Finite element simulations are performed to predict the occurrence of this mode of failure and its associated strength. Importantly, the critical interlock angle at which this mode of failure occurs is predicted. In the present study, this mode of failure is seen to occur when the angle of interlock exceeds 20°. The strength of the joints is higher during the button shear mode of failure when compared to the button separation mode. The critical angle thus commands the incurring mode of failure.

Similar content being viewed by others

Abbreviations

- X:

-

Plate thickness between die and punch

- Y:

-

Interlock length

- tU :

-

Undercut

- α:

-

Interlock angle

- tN :

-

Neck thickness

- Rp :

-

Punch radius

- RC :

-

Punch corner radius

- Rf :

-

Die flange radius

- Rd :

-

Die radius

- H:

-

Die depth

- Fb :

-

Button strength

- Fse :

-

Button separation strength

- µ:

-

Coefficient of friction

- σ:

-

Yield strength

- Fn :

-

Neck strength

- Fsh :

-

Button shear strength

- τT :

-

Top shear strength

- τB :

-

Bottom sheet base metal material

- CoF:

-

Coefficient of friction

- Vx :

-

Axisymmetric strained x-direction

- FD:

-

Die flange diameter

- αc :

-

Critical interlock angle

- SFTC:

-

Scientific forming technologies and corporation

- Fsh (T):

-

Button shear strength at the top

- Fsh (B):

-

Button shear strength at the bottom

References

Mucha, J. Clinching technology in the automotive industry. Arch. Mot. (2017). https://doi.org/10.14669/AM.VOL76.ART4

Madrid, J., Andersson, P., Söderberg, R., Wärmefjord, K., Kveselys, D., Lindkvist, L., Lööf, J.: Automated and interactive evaluation of welding producibility in an multidisciplinary design optimization environment for aircraft components. Int. J. Interact Design Manuf. 15(4), 463–479 (2021). https://doi.org/10.1007/s12008-021-00775-z

Yurdakul, M., Balci, A., Ic, Y.T.: A knowledge-based material selection system for interactive pressure vessel design. Int. J. Interact Design Manuf. 14(1), 323–343 (2020). https://doi.org/10.1007/s12008-020-00652-1

Azman, A.H., Hishamuddin, H., Daud, F., Baharom, N.A., Zan, M.A.M.: Interactive design and structural analysis of pit-opener DAG for airport oil tanks based on user-centered design and finite element analysis. Int. J. Interact Design Manuf. 15(4), 541–553 (2021). https://doi.org/10.1007/s12008-021-00780-2

Miller, W.S., Zhuang, L., Bottema, J., Wittebrood, A., De Smet, P., Haszler, A., Vieregge, A.J.M.S.: Recent development in aluminium alloys for the automotive industry. Mater. Sci. Eng. A 280, 37–49 (2000). https://doi.org/10.1016/S0921-5093(99)00653-X

Lambiase, F., Paoletti, A., Grossi, V., Genna, S.: Improving energy efficiency in friction assisted joining of metals and polymers. J. Mater. Process. Technol. 250, 379–389 (2017). https://doi.org/10.1016/j.jmatprotec.2017.08.005

Lüder, S., Härtel, S., Binotsch, C., Awiszus, B.: Influence of the moisture content on flat-clinch connection of wood materials and aluminium. J. Mater. Process. Technol. 214, 2069–2074 (2014). https://doi.org/10.1016/j.jmatprotec.2014.01.010

Chen, C., Li, Y., Zhang, H., Li, Y., Pan, Q., Han, X.: Thin-walled structures Investigation of a renovating process for failure clinched joint to join thin-walled structures. Thin-Walled Struct. 151, 106686 (2020). https://doi.org/10.1016/j.tws.2020.106686

Series, IOPC; Science, M. FEM model and experimental measurement of clinched joint. In: Proceedings of the 4th International Conference Recent Trends in Structural Materials, Pilsen, Czech Republic, 9–11 November 2016

Series, IOPC; Science, M. Investigation of clinch joints made of similar and dissimilar materials. In: Proceedings of the 11th Hungarian Conference on Materials Science, Balatonkenese, Hungary, 15–17 October 2017

Hiller, M., Benkert, T., Vitzthum, S., Volk, W.: Influence of tool elasticity on process forces and joint properties during clinching with rotational tool movement influence of tool elasticity on process forces and joint properties during clinching with rotational tool movement. In: Proceedings of the 36th IDDRG Conference—Materials Modelling and Testing for Sheet Metal Forming Munich, Germany, 2–6 July 2017. https://doi.org/10.1088/1742-6596/896/1/012116

Coppieters, S., Lava, P., Baes, S., Sol, H., van Houtte, P., Debruyne, D.: Analytical method to predict the pull-out strength of clinched connections. Thin Walled Struct. 52, 42–52 (2012). https://doi.org/10.1016/j.tws.2011.12.002

Lee, C.J., Kim, J.Y., Lee, S.K., Ko, D.C., Kim, B.M.: Design of mechanical clinching tools for joining of aluminium alloy sheets. Mater. Des. 31, 1854–1861 (2010). https://doi.org/10.1016/j.matdes.2009.10.064

Qiu, R., Shi, H., Zhang, K., Tu, Y., Iwamoto, C., Satonaka, S.: Interfacial characterization of joint between mild steel and aluminum alloy welded by resistance spot welding. Mater. Charact. 61, 684–688 (2010). https://doi.org/10.1016/j.matchar.2010.03.015

Piccini, J.M., Svoboda, H.G.: Effect of the tool penetration depth in friction stir spot welding (FSSW) of dissimilar aluminum alloys. Procedia Mater. Sci. 8, 868–877 (2015). https://doi.org/10.1016/j.mspro.2015.04.147

Piccini, J.M., Svoboda, H.G.: Tool geometry optimization in friction stir spot welding of Al-steel joints. J. Manuf. Process. 26, 142–154 (2017). https://doi.org/10.1016/j.jmapro.2017.02.004

Rejek, M., Wróbel, N., Królczyk, J., Królczyk, G.: Designing and testing cold-formed rounded connections made on a prototype station. Materials 12, 1061 (2019). https://doi.org/10.3390/ma12071061

Kaščák, Ľ., Spišák, E., Majerníková, J.: Clinching and clinch-riveting as a green alternative to resistance spot welding. In: Proceedings of the 2019 International Council on Technologies of Environmental Protection (ICTEP), Starý Smokovec, Slovakia, 23–25 October 2019, pp. 138–142. https://doi.org/10.1109/ICTEP48662.2019.8968973

Kaščák, Ľ, Spišák, E., Majerníková, J., Kubík, R.: Clinching of dual-phase steels as an alternative to resistance spot welding. Mater. Sci. Forum 919, 68–77 (2018). https://doi.org/10.4028/www.scientific.net/MSF.919.68

Varis, J.: Economics of clinched joint compared to riveted joint and example of applying calculations to a volume product. J. Mater. Process. Technol. 172, 130–138 (2006). https://doi.org/10.1016/j.jmatprotec.2005.09.009

Mucha, J.: The analysis of lock forming mechanism in the clinching joint. Mater. Des. 32, 4943–4954 (2011). https://doi.org/10.1016/j.matdes.2011.05.045

Briskham, P., Blundell, N., Han, L., Hewitt, R., Young, K., Boomer, D.: Comparison of self-pierce riveting, resistance spot welding and spot friction joining for aluminium automotive sheet. SAE Technical Paper Serious 2006–01–0774 (2006). https://doi.org/10.4271/2006-01-0774

Abe, Y., Kishimoto, M., Kato, T., Mori, K.: Joining of hot-dip coated steel sheets by mechanical clinching. Int. J. Mater. Form. 2(Suppl. 1), 291–294 (2009). https://doi.org/10.1007/s12289-009-0446-4

Israel, M., Mauermann, R., Schellnock, J.: Thick sheet clinching joining up to 20 mm total thickness. Adv. Shipp. Ocean Eng. 2, 1–10 (2013)

Li, X., Wang, X., Shen, Z., Ma, Y., Liu, H.: An experimental study on micro-shear clinching of metal foils by laser shock. Materials 12, 1422 (2019). https://doi.org/10.3390/ma12091422

Chen, C., Zhao, S., Cui, M., Han, X., Fan, S., Ishida, T.: An experimental study on the compressing process for joining Al6061 sheets. Thin Walled Struct. 108, 56–63 (2016). https://doi.org/10.1016/j.tws.2016.08.007

Alavinejad, S.A., Ghaderi, S.H.: Effect of tool geometry on the tensile strength of clinched joint and tool optimization using orthogonal experimental design method. MODARES Mech. Eng. 20, 1235–1243 (2020)

Abe, Y., Mori, K., Kato, T.: Joining of high strength steel and aluminium alloy sheets by mechanical clinching with dies for control of metal flow. J. Mater. Process. Technol. 212, 884–889 (2012). https://doi.org/10.1016/j.jmatprotec.2011.11.015

Abe, Y., Kato, T., Mori, K.I., Nishino, S.: Mechanical clinching of ultra-high strength steel sheets and strength of joints. J. Mater. Process. Technol. 214, 2112–2118 (2014). https://doi.org/10.1016/j.jmatprotec.2014.03.003

Lin, P.-C., Fang, J.-C., Lin, J.-W., Tran, X.V., Ching, Y.-C.: Preheated (heat-assisted) clinching process for Al/CFRP cross-tension specimens. Materials 13, 4170 (2020). https://doi.org/10.3390/ma13184170

Huang, Z., Yanagimoto, J.: Dissimilar joining of aluminum alloy and stainless steel thin sheets by thermally assisted plastic deformation. J. Mater. Process. Technol. 225, 393–404 (2015). https://doi.org/10.1016/j.jmatprotec.2015.06.023

Neugebauer, R., Kraus, C., Dietrich, S.: Advances in mechanical joining of magnesium. CIRP Ann. Manuf. Technol. 57, 283–286 (2008). https://doi.org/10.1016/j.cirp.2008.03.025

Lambiase, F.: Clinch joining of heat-treatable aluminum AA6082-T6 alloy under warm conditions. J. Mater. Process. Technol. 225, 421–432 (2015). https://doi.org/10.1016/j.jmatprotec.2015.06.022

Balawender, T., Sadowski, T., Golewski, P.: Numerical analysis and experiments of the clinch-bonded joint subjected to uniaxial tension. Comput. Mater. Sci. 64, 270–272 (2012). https://doi.org/10.1016/j.commatsci.2012.05.014

Ge, Y., Xia, Y.: Mechanical characterization of a steel-aluminum clinched joint under impact loading. Thin Walled Struct. 151, 106759 (2020). https://doi.org/10.1016/j.tws.2020.106759

Mucha, J.: The analysis of rectangular clinching joint in the shearing test. Eksploat. i Niezawodn. 51, 45–50 (2011)

Kaðèák, L., Spiðák, E., Kubík, R., Mucha, J.: Finite element calculation of clinching with rigid die of three steel sheets. Strength Mater. 49, 488–499 (2017). https://doi.org/10.1007/s11223-017-9892-2

Shi, C., Yi, R., Chen, C., Zhao, S.: Forming mechanism of the repairing process on clinched joint. J. Manuf. Process. 50, 329–335 (2020). https://doi.org/10.1016/j.jmapro.2019.12.025

Xing, B., He, X., Wang, Y., Yang, H., Deng, C.: Study of mechanical properties for copper alloy H62 sheets joined by self-piercing riveting and clinching. J. Mater. Process. Technol. 216, 28–36 (2015). https://doi.org/10.1016/j.jmatprotec.2014.08.030

He, X., Zhang, Y., Xing, B., Gu, F., Ball, A.: Mechanical properties of extensible die clinched joints in titanium sheet materials. Mater. Des. 71, 26–35 (2015). https://doi.org/10.1016/j.matdes.2015.01.005

Haque, R.: Quality of self-piercing riveting (SPR) joints from cross-sectional perspective: a review. Arch. Civ. Mech. Eng. 18(1), 83–93 (2018). https://doi.org/10.1016/j.acme.2017.06.003

Mucha, J., Kaščák, Ľ, Witkowski, W.: Research on the influence of the AW 5754 aluminum alloy state condition and sheet arrangements with AW 6082 aluminum alloy on the forming process and strength of the ClinchRivet joints. Materials 14(11), 2980 (2021). https://doi.org/10.3390/ma14112980

Lambiase, F., Derazkola, H.A., Simchi, A.: Friction stir welding and friction spot stir welding processes of polymers—state of the art. Materials 13, 2291 (2020). https://doi.org/10.3390/ma13102291

Lambiase, F., di Ilio, A.: Mechanical clinching of metal-polymer joints. J. Mater. Process. Technol. 215, 12–19 (2015). https://doi.org/10.1016/j.jmatprotec.2014.08.006

Lambiase, F., Ko, D.C.: Two-steps clinching of aluminum and carbon fiber reinforced polymer sheets. Compos. Struct. 164, 180–188 (2017). https://doi.org/10.1016/j.compstruct.2016.12.072

Lambiase, F.: Ko, DC Feasibility of mechanical clinching for joining aluminum AA6082-T6 and carbon fiber reinforced polymer sheets. Mater. Des. 107, 341–352 (2016). https://doi.org/10.1016/j.matdes.2016.06.061

Abe, Y., Maeda, T., Yoshioka, D., Mori, K.: Mechanical clinching and self-pierce riveting of thin three sheets of 5000 series aluminium alloy and 980 MPa grade cold rolled ultra-high strength steel. Materials 13, 4741 (2020). https://doi.org/10.3390/ma13214741

Mucha, J.: The failure mechanics analysis of the solid self-piercing riveting joints. Eng. Fail. Anal. 47, 77–88 (2015). https://doi.org/10.1016/j.engfailanal.2014.10.008

Kaščák, L., Mucha, J., Spišák, E., Kubík, R.: Wear study of mechanical clinching dies during joining of advanced high-strength steel sheets. Strength Mater. 49, 726–737 (2017). https://doi.org/10.1007/s11223-017-9918-9

Kaðèák, L., Spiðák, E., Kubik, R., Jacek, M.: Fem analysis of clinching tool load in a joint of dual-phase steels. Strength Mater. 48, 74–80 (2016). https://doi.org/10.1007/s11223-016-9795-7

Wang, C.C., Kam, H.K., Cheong, W.C.: Effect of tool eccentricity on the joint strength in mechanical clinching process. Procedia Eng. 81, 2062–2067 (2014). https://doi.org/10.1016/j.proeng.2014.10.286

Kumar, S., Edachery, V., Velpula, S., Govindaraju, A., Choudhury, S.K., Kailas, S.V.: Influence of surface roughness, friction coefficient, and wrap angle on clinching joint strength and its correlation with belt friction phenomenon. P. I. Mech. Eng. J-J Eng. (2021). 10.1177%2F13506501211025362

Kumar, S., Avinash, G., Vimal, E.: Ductility effect on clinching joint strength in lap-shear configuration loading. Mater. Today Proc. 39, 1667–1672 (2020). https://doi.org/10.1016/j.matpr.2020.06.144

Menezes, P.L., Kishore; Kailas, SV,: Effect of roughness parameter and grinding angle on coefficient of friction when sliding of Al–Mg alloy over EN8 steel. J. Tribol. 128, 697 (2006). https://doi.org/10.1115/1.2345401

Zhang, P., Li, S.X., Zhang, Z.F.: General relationship between strength and hardness. Mater. Sci. Eng., A 529, 62–73 (2011). https://doi.org/10.1016/j.msea.2011.08.061

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kumar, S., Lakshmikanthan, A., Selvan, C.P. et al. Effect of interlock angle and bottom die flange diameter on clinching joint load bearing capacity in cross-tensile loading. Int J Interact Des Manuf 17, 2209–2220 (2023). https://doi.org/10.1007/s12008-022-00955-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12008-022-00955-5