Abstract

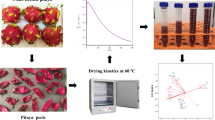

The present work proposes using microencapsulation, ethanol, ultrasound and convective drying to obtain iron fortified pineapple chips. Iron microparticles were produced by ferrous sulphate encapsulation with maltodextrin by spray drying. As a hydrophilic material, microparticles were dispersed in ethanol to be incorporated into the pineapple tissue, with or without the application of ultrasound. Then, the effect of different pre-treatment times with ethanol and ethanol + ultrasound was evaluated on pineapple drying. Finally, the residue of ethanol was evaluated in the final products. Pre-treatment with ethanol and ethanol + ultrasound allowed to increase significantly the iron content of pineapple chips (up to 1000% in comparison with control). In addition, the drying time decreased from 35.4 to 51.9% with the utilization of ethanol and ultrasound. Pre-treatment for 7.5 min allowed to reduce the drying time and to achieve negligible residual ethanol in the sample. The results demonstrated that the combination of the proposed technologies can be used to obtain pineapple chips enriched in iron, with reduced time of drying and a negligible residue of ethanol.

Similar content being viewed by others

References

Amanor-Atiemoh R, Zhou C, Abdullaleef Taiye M, Sarpong F, Wahia H, Amoa-Owusu A, Chen L (2019) Effect of ultrasound-ethanol pretreatment on drying kinetics, quality parameters, functional group, and amino acid profile of apple slices using pulsed vacuum drying. J Food Process Eng 43(2):e13347

Assis FR, Rodrigues LGG, Tribuzi G, de Souza PG, Carciofi BAM, Laurindo JB (2019) Fortified apple (Malus spp., var. Fuji) snacks by vacuum impregnation of calcium lactate and convective drying. LWT 113, 108298

Braga AMP, Pedroso MP, Augusto F, Silva MA (2009) Volatiles identification in pineapple submitted to drying in an ethanolic atmosphere. Drying Technol 27(2):248–257

Braga AM, Silva MA, Pedroso MP, Augusto F, Barata LE (2010) Volatile composition changes of pineapple during drying in modified and controlled atmosphere. Int J Food Eng 6(1)

Brasil (2005) O “regulamento técnico sobre a ingestão diária recomendada (IDR) de proteína, vitaminas e minerais” (Resolução RDC nº 269, de 22 de setembro de 2005). Diário Oficial da República Federativa do Brasil

Bryszewska MA, Tomás-Cobos L, Gallego E, Villalba M, Rivera D, Saa DLT, Gianotti A (2019) In vitro bioaccessibility and bioavailability of iron from breads fortified with microencapsulated iron. LWT 99:431–437

Cárcel JA, Benedito J, Rosselló C, Mulet A (2007) Influence of ultrasound intensity on mass transfer in apple immersed in a sucrose solution. J Food Eng 78(2):472–479

Corrêa JLG, Braga AMP, Hochheim M, Silva MA (2012) The influence of ethanol on the convective drying of unripe, ripe, and overripe bananas. Drying Technol 30(8):817–826

Corrêa JLG, Rasia MC, Mulet A, Cárcel JA (2017) Influence of ultrasound application on both the osmotic pretreatment and subsequent convective drying of pineapple (Ananas comosus). Innovative Food Science & Emerging Technologies 41:284–291

Gupta C, Chawla P, Arora S, Tomar SK, Singh AK (2015) Iron microencapsulation with blend of gum arabic, maltodextrin and modified starch using modified solvent evaporation method – milk fortification. Food Hydrocolloids 43:622–628

Kumar S, Anukiruthika T, Dutta S, Kashyap AV, Moses JA, Anandharamakrishnan C (2020) Iron deficiency anemia: A comprehensive review on iron absorption, bioavailability and emerging food fortification approaches. Trends Food Sci Technol 99:58–75

Llavata B, García-Pérez JV, Simal S, Cárcel JA (2020) Innovative pre-treatments to enhance food drying: a current review. Current Opinion in Food Science 35:20–26

Lobo MG, Paull RE (Eds) (2017) Handbook of pineapple technology: production, postharvest science, processing and nutrition. Chinchester:John Wiley & Sons

Maleki M, Shahidi F, Varidi MJ, Azarpazhooh E (2019) Hot air drying kinetics of novel functional carrot snack: Impregnated using polyphenolic rich osmotic solution with ultrasound pretreatment. J Food Process Eng 43:e13331

Mashkour M, Maghsoudlou Y, Kashaninejad M, Aalami M (2018) Effect of ultrasound pretreatment on iron fortification of potato using vacuum impregnation. J Food Process Preserv 42(5):e13590

Mészáros C, Farkas I, Gottschalk K, Bálint Á (2017) Mathematical modeling of the simultaneous convection–anomalous diffusion processes in porous media. Drying Technol 35(8):994–998

Miano AC, Augusto PED (2018) The ultrasound assisted hydration as an opportunity to incorporate nutrients into grains. Food Res Int 106:928–935

Miano AC, Ibarz A, Augusto PED (2016) Mechanisms for improving mass transfer in food with ultrasound technology: Describing the phenomena in two model cases. Ultrason Sonochem 29:413–419

Orikasa T, Koide S, Sugawara H, Yoshida M, Kato K, Matsushima U, Tagawa A (2018) Applicability of vacuum-microwave drying for tomato fruit based on evaluations of energy cost, color, functional components, and sensory qualities. J Food Process Preserv 42(6):e13625

Page GE (1949) Factors influencing the maximum rates of air drying shelled corn in thin layers. MSc. Thesis. West Lafayette, IN, USA: Department of Mechanical Engineering, Purdue University

Paltridge NG, Milham PJ, Ortiz-Monasterio JI, Velu G, Yasmin Z, Palmer LJ, Stangoulis JC (2012) Energy-dispersive X-ray fluorescence spectrometry as a tool for zinc, iron and selenium analysis in whole grain wheat. Plant Soil 361(1–2):261–269

Quyen DTM, Joomwong A, Rachtanapun P (2013) Influence of storage temperature on ethanol content, microbial growth and other properties of queen pineapple fruit. International Journal of Agriculture & Biology 15(2):207–214

Rojas ML, Augusto PE (2018a) Ethanol and ultrasound pre-treatments to improve infrared drying of potato slices. Innovative food science & emerging technologies 49:65–75

Rojas ML, Augusto PE (2018b) Ethanol pre-treatment improves vegetable drying and rehydration: kinetics, mechanisms and impact on viscoelastic properties. J Food Eng 233:17–27

Rojas ML, Alvim ID, Augusto PED (2019) Incorporation of microencapsulated hydrophilic and lipophilic nutrients into foods by using ultrasound as a pre-treatment for drying: a prospective study. Ultrason Sonochem 54:153–161

Rojas ML, Silveira I, Augusto PE (2019) Improving the infrared drying and rehydration of potato slices using simple approaches: Perforations and ethanol. J Food Process Eng 42(5):e13089

Rojas ML, Augusto PED, Cárcel JA (2020a) Ethanol pre-treatment to ultrasound-assisted convective drying of apple. Innov Food Sci Emerg Technol 102328

Rojas ML, Silveira I, Augusto PED (2020b) Ultrasound and ethanol pre-treatments to improve convective drying: drying, rehydration and carotenoid content of pumpkin. Food Bioprod Process 119:20–30

Sangsuwan J, Rattanapanone N, Rachtanapun P (2008) Effect of chitosan/methyl cellulose films on microbial and quality characteristics of fresh-cut cantaloupe and pineapple. Postharvest Biol Technol 49(3):403–410

Silva MA, Braga AMP, Santos PHS (2012) Enhancement of fruit drying: the ethanol effect. In: 18th International Drying Symposium, Xiamen (Vol. 11, pp. 11–15)

Silva MG, Celeghini RMS, Silva, MA (2018) Effect of ethanol on the drying characteristics and on the coumarin yield of dried guaco leaves (Mikania laevigata Schultz Bip. ex baker). Braz J Chem Eng 35(3):1095–1104

Simpson R, Ramírez C, Nuñez H, Jaques A, Almonacid S (2017) Understanding the success of Page’s model and related empirical equations in fitting experimental data of diffusion phenomena in food matrices. Trends Food Sci Technol 62:194–201

Soria AC, Villamiel M (2010) Effect of ultrasound on the technological properties and bioactivity of food: a review. Trends Food Sci Technol 21(7):323–331

Stewart RJ, Smialowska A, Pedley KC, Carr AJ (2018) Ascorbic acid-enriched goat milk may be a suitable vehicle for iron fortification. LWT 97:491–495

TACO (2011) Tabela brasileira de composição de alimentos. Revista Ampliada NEPA. Campinas: UNICAMP

Tamilmani P, Pandey MC (2016) Iron binding efficiency of polyphenols: comparison of effect of ascorbic acid and ethylenediaminetetraacetic acid on catechol and galloyl groups. Food Chem 197:1275–1279

Tapiero H, Gate L, Tew KD (2001) Iron: deficiencies and requirements. Biomed Pharmacother 55(6):324–332

Tatemoto Y, Mizukoshi R, Ehara W, Ishikawa E (2015) Drying characteristics of food materials injected with organic solvents in a fluidized bed of inert particles under reduced pressure. J Food Eng 158:80–85

Tezotto T, Favarin JL, Paula Neto A, Gratão PL, Azevedo RA, Mazzafera P (2013) Simple procedure for nutrient analysis of coffee plant with energy dispersive X-ray fluorescence spectrometry (EDXRF). Scientia Agricola 70(4):263–267

Wang X, Feng Y, Zhou C, Sun Y, Wu B, Yagoub AEA, Aboagarib EAA (2019) Effect of vacuum and ethanol pretreatment on infrared-hot air drying of scallion (Allium fistulosum). Food Chem 295:432–440

World Health Organization (2004) Vitamin and mineral requirements in human nutrition. 2 ed. World Health Organization

Chen XD, Patel KC (2008) Biological change during food drying processes. Chen XD, Mujumdar AS (Eds), Drying technology in food processing, Blackwell Publishing Ltd (pp. 90–109), Oxford: Blackwell Publishing.

Zhao H, Fang X, Wang J, Ju H, Zhang Y, Chen X, Xiao H (2016) Effect of ethanol dipping pretreatment on drying characteristics and quality of eggplant slices. Transactions of the Chinese Society of Agricultural Engineering 32(9):233–240

Zubernik J, Dadan, M, Cichowska J, Witrowa-Rajchert, D. The impact of the pre-treatment in ethanol solution on the drying kinetics and selected properties of convective dried apples. Int J Food Eng, 16(1–2)

Acknowledgments

The authors are grateful to the valuable help and discussion by/with Eng. Karoline Costa dos Santos and Prof. Dr. Severino Matias de Alencar.

Funding

The present work was funded by the São Paulo Research Foundation (FAPESP, Brazil) for funding the project n° 2019/05043-6 and the GR Carvalho postdoctoral fellowship (2018/17844-0), the National Council for Scientific and Technological Development (CNPq, Brazil) for funding the productivity grant of P.E.D. Augusto (306557/2017-7) and the LNNano (CNPEM, Brazil) for technical support and facilities during electron microscopy work (Project SEM-24192).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflicts of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Carvalho, G.R., Massarioli, A.P., Alvim, I.D. et al. Iron-Fortified Pineapple Chips Produced Using Microencapsulation, Ethanol, Ultrasound and Convective Drying. Food Eng Rev 13, 726–739 (2021). https://doi.org/10.1007/s12393-020-09259-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12393-020-09259-4