Abstract

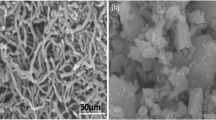

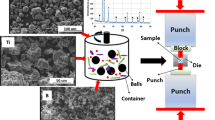

SiC reinforced tungsten matrix composites were fabricated via the spark plasma sintering process. In order to prevent an interfacial reaction between the SiC and tungsten during sintering, TiOx coated SiC particles were synthesized by a solution-based process. TiOx layer coated SiC particles were treated in high temperature nitriding conditions or annealed in a high temperature vacuum to form TiN or TiC coated SiC particles, respectively. The TiC layers coated on SiC particles successfully prevented tungsten from reacting with SiC; hence the proposed process resulted in successful fabrication of the SiC/W composites. The mechanical properties such as compressive strength and flexural strength of the composites were measured. Additionally, the effect of SiC on the high temperature oxidative ablation of tungsten was also investigated. The addition of SiC resulted in an improved oxidative ablation resistance of the tungsten-based composites.

Similar content being viewed by others

References

T. Hamacher and A. M. Bradshaw, 18th World Energy Congress, p.1, Buenos Aires (2001).

B. I. Khripunov, V. S. Koidan, A. I. Ryazanov, V. M. Gureev, S. N. Kornienko, S. T. Latushkin, A. S. Rupyshev, E. V. Semenov, V. S. Kulikauskas, and V. V. Zatekin, Phys. Procedia 71, 63 (2015).

ASM International, ASM International Engineering Materials Handbook, ASM International, Materials Park, OH (1991).

S. W. H. Yih and C. T. Wang, Tungsten-Sources, Metallurgy, Properties and Applications, pp. 266–271, Plenum Press, New York (1979).

E. Lassner and W. D. Schubert, Tungsten: Properties, Chemistry, Technology of the Element, Alloys, and Chemical Compounds, pp. 1–59, Plenum Publishers, New York (1999).

M. A. Yar, S. Wahlberg, H. Bergqvist, H. G. Salem, M. Johnsson, and M. Muhammed, J. Nucl. Mater. 408, 129 (2011).

M. Rieth, J. L. Boutard, S. L. Dudarev, T. Ahlgren, S. Antusch, and N. Baluc et al., J. Nucl. Mater. 417, 463 (2011).

M. A. Yar, S. Wahlberg, H. Bergqvist, H. G. Salem, M. Johnsson, and M. Muhammed, J. Nucl. Mater. 412, 227 (2011).

Z. Zhou, J. Tan, D. Qu, G. Pintsuk, M. Rödig, and J. Linke, J. Nucl. Mater. 431, 202 (2012).

M. Xia, Q. Yan, L. Xu, H. Guo, L. Zhu, and C. Ge, J. Nucl. Mater. 434, 85 (2013).

S. Wang, L.-M. Luo, X.-Y. Tan, G.-N. Luo, X. Zan, J.-G. Cheng, X.-Y. Zhu, and Y.-C. Wu, J. Nucl. Mater. 454, 114 (2014).

T. Palacios, A. Jiménez, A. Muñóz, M. A. Monge, C. Ballesteros, and J. Y. Pastor, J. Nucl. Mater. 454, 455 (2014).

J. Zhang, L.-M. Luo, X.-Y. Zhu, H.-Y. Chen, J.-L. Chen, X. Zan, J.-G. Cheng, and Y.-C. Wu, J. Nucl. Mater. 456, 316 (2015).

M. Zibrov, M. Mayer, L. Gao, S. Elgeti, H. Kurishita, Y. Gasparyan, and A. Pisarev, J. Nucl. Mater. 463, 1045 (2015).

H.-Y. Chen, L.-M. Luo, J.-B. Chen, P. Li, G.-N. Luo, J.-G. Cheng, and Y.-C. Wu, J. Nucl. Mater. 462, 496 (2015).

M. Xia, Q. Yan, L. Xu, L. Zhu, H. Guo, and C. Ge, J. Nucl. Mater. 430, 216 (2012).

W. D. Kloop, J. Less Common Met. 42, 261 (1975).

M. Rieth, S. L. Dudarev, S. M. Gonzalez de Vicente, J. Aktaa, T. Ahlgren, and S. Antusch et al., J. Nucl. Mater. 432, 482 (2013).

H. Kurishita, S. Matsuo, H. Arakawa, T. Sakamoto, S. Kobayashi, K. Nakai, T. Takida, M. Kato, M. Kawai, and N. Yoshida, J. Nucl. Mater. 398, 87 (2010).

D. Y. Park, Y. J. Oh, Y. S. Kwon, S. T. Lim, and S. J. Park, Int. J. Refract. Met. Hard 42, 205 (2014).

E. Y. Ivanov, C. Suryanarayana, and B. D. Bryskin, Mat. Sci. Eng. A-Struct. 251, 255 (1998).

Y. Song, Q. Li, J. Li, G. He, Y. Chen, and H. S. Kim, Met. Mater. Int. 20, 1145 (2014).

M. Muzyk, D. Nguyen-Manh, J. Wróbel, K. J. Kurzydlowski, N. L. Baluc, and S. L. Dudarev, J. Nucl. Mater. 442, 680 (2013).

A. Xu, C. Beck, D. E. J. Armstrong, K. Rajan, G. D.W. Smith, P. A. J. Bagot, and S. G. Roberts, Acta Mater. 87, 121 (2015).

A. Luo, D. L. Jacobson, and K. S. Shin, Scr. Metall. 23, 397 (1989).

Y. M. Kim, K. H. Lee, E.-P. Kim, D.-I. Cheong, and S. H. Hong, Int. J. Refract. Met. Hard 27, 842 (2009).

G.-M. Song, Y. Zhou, and Y.-J. Wang, Mater. Charact. 50, 293 (2003).

X. Liu, J. Chen, Y. Lian, J. Wu, Z. Xu, and N. Zhang et al., J. Nucl. Mater. 442, S309 (2013).

E. Y. Ivanov and B. D. Bryskin, Met. Powder Rep. 53, 39 (1998).

L. M. Huang, L. M. Luo, M. L. Zhao, G. N. Luo, X. Y. Zhu, and Y.-C. Wu et al., Mater. Design 81, 39 (2015).

K. Tokunaga, H. Kurishita, H. Arakawa, S. Matsuo, T. Hotta, K. Araki, Y. Miyamoto, T. Fujiwara, K. Nakamura, T. Takida, M. Kato, and A. Ikegaya, J. Nucl. Mater. 442, 297 (2013).

N. Jin, Y. Yang, X. Luo, J. Li, B. Huang, S. Liu, and Z. Xiao, Appl. Sur. Sci. 314, 896 (2014).

M. Hashemi, S. Mirdamadi, and H. R. Rezaie, Electrochim. Acta 138, 224 (2014).

D. Ding, Advances in Ceramic Matrix Composites, pp. 9–26, Woodhead Publishing Limited, Cambridge (2014).

L. L. Snead, T. Nozawa, Y. Katoh, T.-S. Byun, S. Kondo, and D. A. Petti, J. Nucl. Mater. 371, 329 (2007).

X. L. Shi, M. Wang, S. Zhang, and Q. Zhang, Int. J. Refract. Met. Hard 41, 60 (2013).

M. I. Chaudry, W. B. Berry, and M. V. Zeller, Mater. Res. Soc. Symp. Proc. 62, 507 (1990).

S. Kumar, A. Kumar, K. Sampath, V. V. B. Prasad, J. C. Chaudhary, A. K. Gupta, and G. Rohini Devi, J. Eur. Ceram. Soc. 31, 2425 (2011).

C. Thomas, T. Joseph, A. Peter, and M. James, Ceram. Eng. Sci. Proc. 03, 517 (2000).

H.-K. Kang, Scripta Mater. 51, 1051 (2004).

R.-J. Zhang, Y.-Q. Yang, W.-T. Shen, C. Wang, and X. Luo, J. Crys. Growth 313, 56 (2010).

T. T. Cheng, I. P. Jones, R. A. Shatwell, and P. Doorbar, Mat. Sci. Eng. A-Struct. 260, 139 (1999).

C. Guo, C. Zhang, L. He, B. Jin, and N. Shi, J. Mater. Sci. Technol. 23, 677 (2007).

W. F. Seng and P. A. Barnes, Mat. Sci. Eng. B-Solid 72, 13 (2000).

A. Yazdani and A. Zakeri, Powder Technol. 278, 196 (2015).

S. Coskun, M. L. Öveçoglu, B. Özkal, and M. Tanoglu, J. Alloy. Compd. 492, 576 (2010).

R. M. German, A. Bose, and S. S. Mani, Metall. Trans. A. 23, 211 (1992).

P. López-Ruiz, F. Koch, N. Ordás, S. Lindig, and C. García-Rosales, Fusion Eng. Des. 86, 1719 (2011).

M. Galatanu, B. Popescu, M. Enculescu, I. Tiseanu, T. Craciunescu, and A. Galatanu, Fusion Eng. Des. 88, 2598 (2013).

S. J. Son, K. H. Park, Y. Katoh, and A. Kohyama, J. Nucl. Mater. 329-333, 1549 (2004).

L. Baud, C. Jaussaud, R. Madar, C. Bernard, J. S. Chen, and M. A. Nicolet, Mat. Sci. Eng. B-Solid. 29, 126 (1995).

A. Nino, Y. Nakaibayashi, S. Sugiyama, and H. Taimatsu, Mater. Trans. 52, 1641 (2011).

Y. Lee, S. J Son, Y. Katoh, and A. Kohyama, J. Nucl. Mater. 329-333, 549 (2004).

D. J. Lee, H. S. Park, H. J. Ryu, S. W. Jeon, and S. H. Hong, J. Alloy. Compd. 509, 9060 (2011).

Kamiya, Kanichi, Yoko, Toshinobu, Bessho, and Masami, J. Mater. Sci. 22, 937 (1987).

W. W. Pultz and W. Hertl, Trans. Faraday Soc. 62, 2499 (1966).

G. D. Zhang and R. Chen, Compos. Interfaces 1, 337 (1993).

S. F. Peng and Metallurgy of Tungsten, pp. 168–172, Metallurgy Industry Press, Beijing, China (1981).

G.-M. Song, Y. Zhou, and Y.-J. Wang, Mater. Charact. 50, 293 (2003).

J. Y. Park, S. J. Yang, Y. G. Jin, C. R. Park, G. H. Kim, and H. N. Han, Met. Mater. Int. 20, 1037 (2014).

S. Rimza, K. Satpathy, S. Khirwadkar, and K. Velusamy, Fusion Eng. Des. 100, 581 (2015).

X. Zhang, Aerosp. Sci. Technol. 15, 402 (2011).

M. A. Umer, D. J. Lee, H. J. Ryu, and S. H. Hong, Int. J. Refract. Met. Hard 42, 17 (2014).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Umer, M.A., Lee, D., Waseem, O.A. et al. Fabrication of protective-coated SiC reinforced tungsten matrix composites with reduced reaction phases by spark plasma sintering. Met. Mater. Int. 22, 493–500 (2016). https://doi.org/10.1007/s12540-016-5700-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-016-5700-y