Abstract

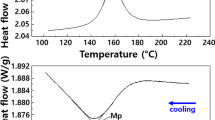

In this study, the effect of isothermal aging on the thermoelastic martensitic transformation and microstructure of the as-quenched Cu–12Al–3.5Ni–0.7Ti–0.05RE (RE = Ce, La) high temperature shape memory alloy was studied. The results showed that the alloy microstructure and martensitic transformation are strongly influenced by the aging temperature rather than aging time. During aging at 350 °C the alloy was prone to both the precipitation of the γ2 phase and the bainitic transformation, resulting in a loss of martensitic transformation and damping capacity. The prolonged aging at 350 °C caused a decomposition of parent phase into the equilibrium γ2 phase alongside the α phase which produced a significant hardness increment. On the other hand, aging at 250 °C affected the microstructure only slightly producing insignificant shift in the transformation temperatures. It was found that, the secondary phases including Ti-rich X-phase and the RE-rich phase were not influenced by the aging process. The results prescribe a high temperature order of the stability of martensitic transformation for this new alloy which is important for its high temperature shape memory applications.

Graphical Abstract

Similar content being viewed by others

References

V. Recarte, R.B. Pérez-Sáez, E.H. Bocanegra, M.L. Nó, J. San Juan, Influence of Al and Ni concentration on the martensitic transformation in Cu–Al–Ni shape-memory alloys. Metall. Mater. Trans. A 33, 2581–2591 (2002). https://doi.org/10.1007/s11661-002-0379-8

S.N. Saud, E. Hamzah, T. Abubakar, H.R. Bakhsheshi-Rad, Influence of silver nanoparticles addition on the phase transformation, mechanical properties and corrosion behaviour of Cu–Al–Ni shape memory alloys. J. Alloys Compd. 612, 471–478 (2014). https://doi.org/10.1016/j.jallcom.2014.05.173

U. Sari, Influences of 2.5 wt% Mn addition on the microstructure and mechanical properties of Cu–Al–Ni shape memory alloys. Int. J. Miner. Metall. Mater. 17(2), 192–198 (2010). https://doi.org/10.1007/s12613-010-0212-0

V. Recarte, R.B. Pérez-Sáez, E.H. Bocanegra, M.L. Nó, J. San Juan, Dependence of the martensitic transformation characteristics on concentration in Cu–Al–Ni shape memory alloys. Mater. Sci. Eng. A 273–275, 380–384 (1999). https://doi.org/10.1016/S0921-5093(99)00302-0

D. Fang, W. Lu, KCh. Hwang, Pseudoelastic behavior of CuAINi single crystal under biaxial loading. Met. Mater. Int. 4, 702–706 (1998). https://doi.org/10.1007/BF03026383

G.N. Sure, L.C. Brown, The fatigue properties of grain refined β–Cu–Al–Ni strain–memory alloys. Scr. Metall. 19, 401–404 (1985). https://doi.org/10.1016/0036-9748(85)90102-4

Z. Xiao, Z. Li, M. Fang, Sh Xiong, X. Sheng, M. Zhou, Effect of processing of mechanical alloying and powder metallurgy on microstructure and properties of Cu–Al–Ni–Mn alloy. Mater. Sci. Eng. A 488, 266–272 (2008). https://doi.org/10.1016/j.msea.2007.11.037

W.Y. Ci, T.A. Abubakar, E. Hamzah, S.N. Saud, Study of X-phase formation on Cu–Al–Ni shape memory alloys with Ti addition. J. Mech. Eng. Sci. 11, 2770–2779 (2017). https://doi.org/10.15282/jmes.11.2.2017.17.0251

S.N. Saud, E. Hamzah, T. Abubakar, M. Zamri, M. Tanemura, Influence of Ti additions on the martensitic phase transformation and mechanical properties of Cu–Al–Ni shape memory alloys. J. Therm. Anal. Calorim. 118, 111–122 (2014). https://doi.org/10.1007/s10973-014-3953-6

S. Bhattacharya, A. Bhuniya, M.K. Banerjee, Influence of minor additions on characteristics of Cu–AI–Ni alloy. J. Mater. Sci. Technol. 9, 654–658 (1993). https://doi.org/10.1179/mst.1993.9.8.654

J.S. Lee, C.M. Wayman, Grain refinement of a Cu–Al–Ni shape memory alloy by Ti and Zr additions. Trans. Jpn. Inst. Met. 27(8), 584–591 (1986). https://doi.org/10.2320/matertrans1960.27.584

Sh Yang, F. Zhang, J. Wu, Y. Lu, Z. Shi, C. Wang, X. Liu, Superelasticity and shape memory effect in Cu–Al–Mn–V shape memory alloys. Mater. Des. 115, 17–25 (2017). https://doi.org/10.1016/j.matdes.2016.11.035

X. Zhang, Q. Liu, Cu–Al–Ni–V high-temperature shape memory alloys. Intermetallics 92, 108–112 (2018). https://doi.org/10.1016/j.intermet.2017.10.001

M.A. Morris, Influence of boron additions on ductility and microstructure of shape memory Cu–Al–Ni alloys. Scr. Metall. Mater. 25, 2541–2546 (1991). https://doi.org/10.1016/0956-716X(91)90065-9

G.S. Yang, J.K. Lee, W.Y. Jang, Effect of grain refinement on phase transformation behavior and mechanical properties of Cu–based alloy. T. Nonferr. Met. Soc. 19, 979–983 (2009). https://doi.org/10.1016/S1003-6326(08)60390-8

N.F. Kennon, D.P. Dunne, L. Middleton, Aging effects in copper-based shape memory alloys. Metall. Trans. A 13, 551–555 (1982). https://doi.org/10.1007/bf02644418

C.W.H. Lam, C.Y. Chung, Study of anisothermai ageing of CANTiM shape memory alloys by positron annihilation. Met. Mater. Int. 2, 75–80 (1996). https://doi.org/10.1007/bf03025949

K. Otsuka, C.M. Wayman, Shape Memory Materials (Cambridge University Press, Cambridge, 1999), pp. 97–116

K. Shimizu, Ageing and thermal cycling effects in shape memory alloys. J. Electron Microsc. 34(4), 277–288 (1985). https://doi.org/10.1093/oxfordjournals.jmicro.a050520

U. Sari, T. Kirindi, F. Ozcan, M. Dikici, Effects of aging on the microstructure of a Cu–Al–Ni–Mn shape memory alloy. Int. J. Miner. Metall. Mater. 18(4), 430–436 (2011). https://doi.org/10.1007/s12613-011-0458-1

N. El-Bagoury, M.M. Hessien, Z.I. Zaki, Influence of aging on microstructure, martensitic transformation and mechanical properties of NiTiRe shape memory alloy. Met. Mater. Int. 20, 997–1002 (2014). https://doi.org/10.1007/s12540-014-5003-0

V. Recarte, R.B. Pérez-Sáez, M.L. Nó, J. San Juan, Ordering kinetics in Cu–Al–Ni shape memory alloys. J. Appl. Phys. 86, 5467–5473 (1999). https://doi.org/10.1063/1.371547

V. Recarte, O.A. Lambri, R.B. Pérez-Sáez, M.L. Nó, J. San Juan, Ordering temperatures in Cu–Al–Ni shape memory alloys. Appl. Phys. Lett. 70, 3513–3515 (1997). https://doi.org/10.1063/1.119217

J.I. Pérez-Landazábal, V. Recarte, V. Sánchez-Alarcos, M.L. Nó, J. San Juan, Study of the stability and decomposition process of the β phase in Cu–Al–Ni shape memory alloys. Mater. Sci. Eng. A 438–440, 734–737 (2006). https://doi.org/10.1016/j.msea.2005.12.066

Y. Nakata, Y. Iizuka, T. Ono, The effects of aging on the degree of order in Cu–Al–Ni shape memory alloys. Mater. Trans. 57, 257–262 (2016). https://doi.org/10.2320/matertrans.MB201511

H. Morawiec, M. Gigla, Effect of ageing on shape recovery in Cu–Al–Ni alloy with Ti + B addition. Acta Metall. Mater. 42, 2683–2686 (1994). https://doi.org/10.1016/0956-7151(94)90209-7

W. Zou, J. Gui, R. Wang, C. Tang, M. Xiang, D. Zhang, Bainitic precipitation and its effect on the martensitic transformation in the Cu–Al–Ni–Mn–Ti shape-memory alloy. J. Mater. Sci. 32, 5279–5286 (1997). https://doi.org/10.1023/A:1018606609313

U. Sari, İ. Aksoy, Electron microscopy study of 2H and 18R martensites in Cu-11.92 wt% Al-3.78 wt% Ni shape memory alloy. Alloys Compd. 417, 138–142 (2006). https://doi.org/10.1016/j.jallcom.2005.09.049

M.K. Lee, S.M. Hong, G.H. Kim, K.H. Kim, W.W. Kim, Structural properties in flame quenched Cu-9Al-4.5Ni-4.5Fe alloy. Met. Mater. Int. 10, 313–319 (2004). https://doi.org/10.1007/BF03185979

K. Adachi, K. Shoji, Y. Hamada, Formation of X phase and origin of grain refinement effect in Cu–Al–Ni shape memory alloys added with titanium. ISIJ Int. 29(5), 378–387 (1989). https://doi.org/10.2355/isijinternational.29.378

I. Hurtado, J. Van Humbeek, P. Ratchev, L. Delaey, Effect of X phase precipitation on elastic modulus of Cu–Al–Ni–Ti–Mn shape memory alloys. Mater. Trans. JIM 37(7), 1371–1378 (1996). https://doi.org/10.2320/matertrans1989.37.1371

H. Cheniti, M. Bouabdallah, E. Patoor, High temperature decomposition of the β1 phase in a Cu–Al–Ni shape memory alloy. Alloys Compd. 476, 420–424 (2009). https://doi.org/10.1016/j.jallcom.2008.09.003

P. Rodriguez, G. Guenin, Thermal aging behaviour and origin of a Cu-Al-Ni shape memory alloy. Mater. Sci. Eng. A 129, 273–277 (1990). https://doi.org/10.1016/0921-5093(90)90274-7

J.I. Pérez-Landazábal, V. Recarte, J. Campo, M.L. Nó, J. San Juan, Neutron diffraction analysis of the β decomposition process in a texture free Cu–Al–Ni shape memory alloy. Physica B 350, 1007–1009 (2004). https://doi.org/10.1016/j.physb.2004.03.277

V. Recarte, J.I. Pérez-Landazábal, A. Ibarra, M.L. Nó, J. San Juan, High temperature β phase decomposition process in a Cu–Al–Ni shape memory alloy. Mater. Sci. Eng. A 378, 238–242 (2004). https://doi.org/10.1016/j.msea.2003.09.111

M. Benke, V. Mertinger, L. Daróczi, High-temperature transformation processes in Cu–13.4Al–5Ni shape memory alloy single crystals. J. Mater. Eng. Perform. 18, 496–499 (2009). https://doi.org/10.1007/s11665-009-9397-7

Z.G. Wei, H.Y. Peng, W.H. Zou, D.Z. Yang, Aging effects in a Cu–12Al–5Ni–2Mn–1Ti shape memory alloy. Metall. Mater. Trans. A 29, 955–967 (1997). https://doi.org/10.1007/s11661-997-0226-z

C. Tatar, Gamma irradiation-induced evolution of the transformation temperatures and thermodynamic parameters in a CuZnAl shape memory alloy. Thermochim. Acta 437, 121–125 (2005). https://doi.org/10.1016/j.tca.2005.06.030

J. Ortin, A. Planes, Thermodynamics of thermoelastic martensittc transformations. Acta Metall. 37, 1433–1441 (1989). https://doi.org/10.1016/0001-6160(89)90175-2

F. Dagdelen, M. Kok, I.N. Qader, Effects of Ta content on thermodynamic properties and transformation temperatures of shape memory NiTi alloy. Met. Mater. Int. (2019). https://doi.org/10.1007/s12540-019-00298-z

J. Ortin, A. Planes, Thermodynamic analysis of thermal measurements in thermoelastic martensitic transformations. Acta Metall. 36(8), 1873–1889 (1988). https://doi.org/10.1016/0001-6160(88)90291-X

E.M. Mazzer, C.S. Kiminami, C. Bolfarini, R.D. Cava, W.J. Botta, P. Gargarella, Thermodynamic analysis of the effect of annealing on the thermal stability of a Cu–Al–Ni–Mn shape memory alloy. Thermochim. Acta 608, 1–6 (2015). https://doi.org/10.1016/j.tca.2015.03.024

W.H. Zou, H.Y. Peng, R. Wang, J. Gui, D.Z. Yang, heating effects on fine structure of a Cu–Al–Ni–Mn–Ti shape memory alloy. Acta Metall. Mater. 43, 3009–3016 (1995). https://doi.org/10.1016/0956-7151(95)00016-O

J.M. Guilemany, J. Fernández, Relationships between structure and hardness developed during the high temperature ageing of a smart Cu–based alloy. J. Mater. Sci. 31, 4981–4984 (1996). https://doi.org/10.1007/BF00355890

N. Suresh, U. Ramamurty, Aging response and its effect on the functional properties of Cu–Al–Ni shape memory alloys. J. Alloys Compd. 449, 113–118 (2008). https://doi.org/10.1016/j.jallcom.2006.02.094

ShK Wu, W.J. Chan, ShH Chang, Damping characteristics of inherent and intrinsic internal friction of Cu–Zn–Al shape memory alloys. Metals 7(10), 397–406 (2017). https://doi.org/10.3390/met7100397

J. Yang, Q.Z. Wang, F.X. Yin, C.X. Cui, P.G. Ji, B. Li, Effects of grain refinement on the structure and properties of a CuAlMn shape memory alloy. Mater. Sci. Eng. A 664, 214–220 (2016). https://doi.org/10.1016/j.msea.2016.04.009

J.M. Jani, M. Leary, A. Subic, M.A. Gibson, A review of shape memory alloy research, applications and opportunities. Mater. Des. 56, 1078–1113 (2014). https://doi.org/10.1016/j.matdes.2013.11.084

A. Pérez-Checa, J. Feuchtwanger, J.M. Barandiaran, V.A. Chernenko, Ni–Mn–Ga high temperature shape memory alloys: Function stability in β and β + γ regions. J. Alloys Compd. 741, 148–154 (2018). https://doi.org/10.1016/j.jallcom.2018.01.068

Acknowledgements

The authors from University of Tehran acknowledge the financial support provided by the office of international affairs and the office for research affairs, college of engineering for the project number 8107009/6/39. Funding from Spanish Ministry of Economy and Competitiveness (project MAT2014-56116-C4-1-3-4-R) is acknowledged. Authors are also grateful to the technical support provided by SGIker (UPV/EHU, MINECO, GV/EJ, ERDF and ESF).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dalvand, P., Raygan, S., López, G.A. et al. Effect of Aging on the Structure and Transformation Behavior of Cu–12Al–3.5Ni–0.7Ti–0.05RE High Temperature Shape Memory Alloy. Met. Mater. Int. 26, 1354–1365 (2020). https://doi.org/10.1007/s12540-019-00376-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-019-00376-2