Abstract

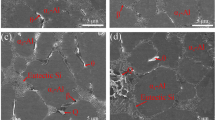

To develop a new compound heat treatment process for improving the mechanical properties of die-cast Al alloys, this study investigated the effects of cryogenic, solution and aging compound treatment on the microstructure and mechanical properties of die-cast Al alloys. The characterization methods used were optical microscopy (OM), scanning electron microscopy (SEM), transmission electron microscopy (TEM), electron backscatter diffraction (EBSD), and tensile tests; and the Image Pro Plus software was used for statistical analysis. The results indicated that compared with T6 heat treatment, the compound heat treatment process consisting of cryogenic treatment (−196 °C for 12 h), solid solution treatment (476 °C for 22 min), and aging (159 °C for 403 min) significantly enhanced the mechanical properties of the die-cast Al alloys. For instance, the tensile strength increased from 224.3 to 249.5 MPa; the hardness increased from HV 110.5 to HV 124.6, and the elongation increased from 6.28% to 7.72%, which in relative terms corresponds to 11.2%, 12.8% and 22.9%, respectively. The compound heat treatment process of the alloy led to significant refinement of its α-Al phases. In addition, Si phases tended to be more ellipsoidal or granular, while the tips of Fe-containing phases became rounded, which played a key role in enhancing the mechanical properties and microstructure stability of the alloys.

Graphical abstract

摘要

为寻求一种新型深冷复合热处理工艺方法, 借助光学显微镜 (OM), 扫插电子显微镜(SEM)、透射电子显微镜 (TEM), 电子背散射衍射 (EBSD), 拉伸试验等测试手段, 结合image pro plus 数据统计分析, 研究了深冷、 固溶、时效复合处理对压铸铝合金合金微观组织和力学性能的影响。结果表明:与T6 热处理相比, 深冷 (‒196 °C, 12 h) + 固溶 (476 °C, 22 min) + 时效 (159 °C, 403 min) 复合热处理能够显著提升压铸铝合金的力学性能, 抗拉强度由224.3 提升到249.5 MPa, 提高了11.2%, 硬度由HV 110.5 提升到HV 124.6, 提高了12.8%, 延伸 率由6.28%提升到7.72%, 提高了22.9%。经深冷复合处理工艺后, 合金的α-Al 相得到显著细化, Si 相趋于椭 圆状或颗粒状, 含铁相尖端变得圆整, 对提高合金的力学性能和组织的稳定性起到关键作用。

Similar content being viewed by others

References

Lewis GM, Buchanan CA, Jhaveri KD, Sullivan JL, Kelly JC, Das S, Taub AI, Keoleian GA. Green principles for vehicle lightweighting. Environ Sci Technol. 2019;53(8):4063. https://doi.org/10.1021/acs.est.8b05897.

Monteiro H, Alonso R, Goncalves M, Iten M, Caetano NS. Life cycle energy of vehicles on lightweighting and alternative powertrain strategies—a review. Energy Rep. 2022;8:241. https://doi.org/10.1016/j.egyr.2022.01.037.

Sato FEK, Nakata T. Analysis of the impact of vehicle lightweighting on recycling benefits considering life cycle energy reductions. Resour Conserv Recycl. 2021;164:105118. https://doi.org/10.1016/j.resconrec.2020.105118.

Burd JTJ, Moore EA, Ezzat H, Kirchain R, Roth R. Improvements in electric vehicle battery technology influence vehicle lightweighting and material substitution decisions. Appl Energy. 2021;283:116269. https://doi.org/10.1016/j.apenergy.2020.116269.

Kumar A, Maithani R, Kumar A, Kumar D, Sharma S. An all-aluminium vehicle’s design and feasibility analysis. Mater Today Proc. 2022;64:1244. https://doi.org/10.1016/j.matpr.2022.03.714.

Liu WP, Peng T, Kishita Y, Umeda Y, Tang RZ, Tang WC, Hu LK. Critical life cycle inventory for aluminum die casting: a lightweight-vehicle manufacturing enabling technology. Appl Energy. 2021;304:117814. https://doi.org/10.1016/j.apenergy.2021.117814.

Wang F, Sun SJ, Wang Z, Yu B, Mao PL, Liu Z. Microstructure, mechanical properties and first-principle analysis of vacuum die-cast Mg–7Al alloy with Sn addition. Rare Met. 2022;41(6):1961. https://doi.org/10.1007/s12598-015-0585-3.

Honarmand M, Salehi M, Shabestari SG, Saghafian H. Impact strength and structural refinement of A380 aluminum alloy produced through gas-induced semi-solid process and Sr addition. Trans Nonferrous Met Soc China. 2022;32(5):1405. https://doi.org/10.1016/S1003-6326(22)65882-5.

Taher M, Mao F, Berastegui P, Andersson AM, Jansson U. The influence of chemical and phase composition on mechanical, tribological and electrical properties of silver–aluminum alloys. Tribol Int. 2018;119:680. https://doi.org/10.1016/j.triboint.2017.11.026.

Liu Y, Liu YL, Peng HP, Tu H, Wang JH, Su XP. Al-3B modification on microstructure and mechanical properties of Al–10Si alloy. Chin J Rare Met. 2021;45(2):154. https://doi.org/10.13373/j.cnki.cjrm.XY19030026.

Huang B, Liu YZ, Zhou ZG, Cheng W, Liu XH. Selective laser melting of 7075 aluminum alloy inoculated by Al–Ti–B: grain refinement and superior mechanical properties. Vacuum. 2022;200:111030. https://doi.org/10.1016/j.vacuum.2022.111030.

Immanuel RJ, Panigrahi SK. Influence of cryorolling on microstructure and mechanical properties of a cast hypoeutectic Al–Si alloy. Mater Sci Eng A. 2015;640:424. https://doi.org/10.1016/j.msea.2015.06.019.

Eidhed K, Muangnoy P. Grain refinement and eutectic modification of A356 casting alloy by adding Al–B–Sr master alloys and its effect on tensile properties. Mater Res Express. 2022;9(10):106518. https://doi.org/10.1088/2053-1591/ac99c1.

Ding WW, Gou LM, Hu LW, Zhang HX, Zhao WJ, Ma JY, Qiao JS, Li XC. Modification of eutectic Si in hypoeutectic Al–Si alloy with novel Al–3Ti–4.35La master alloy. J Alloys Compd. 2022;929:167350. https://doi.org/10.1016/j.jallcom.2022.167350.

Qin PF, Yang Q, He YY, Zhang JH, Xie JS, Hua XR, Guan K, Meng J. Microstructure and mechanical properties of high-strength high-pressure die-cast Mg–4Al–3La–1Ca–0.3Mn alloy. Rare Met. 2021;40(10):2956. https://doi.org/10.1007/s12598-020-01661-5.

Wei JX, He CS, Qie MF, Li Y, Zhao Y, Qin GW, Zuo L. Microstructure refinement and mechanical properties enhancement of wire-arc additive manufactured 2219 aluminum alloy assisted by interlayer friction stir processing. Vacuum. 2022;203:111264. https://doi.org/10.1016/j.vacuum.2022.111264.

Li XP, Wang BW, Xu DH, Wang B, Dong WP, Li MJ. Super-high bonding strength of polyphenylene sulfide-aluminum alloy compound structure achieved by facile molding methods. Compd Part B Eng. 2021;224:109204. https://doi.org/10.1016/j.compositesb.2021.109204.

Gu C, Moodispaw MP, Luo AA. Cellular automaton simulation and experimental validation of eutectic transformation during solidification of Al–Si alloys. NPJ Comput Mater. 2022;8(1):134. https://doi.org/10.1038/s41524-022-00824-5.

Gu YF, Liu WP, Huang ZH, Zhang CX, Luo JT. 5083 aluminum alloy sheet with excellent mechanical properties fabricated by constrained ring groove pressing based on a cyclic stress state. J Mater Process Technol. 2021;295:117174. https://doi.org/10.1016/j.jmatprotec.2021.117174.

Zhang L, Zheng ZQ, Li JF, Tan CY, Chen YL, Zhang XH. Microstructural evolution and mechanical properties of a new Al–Cu–Li–X alloy at different solution temperatures. Rare Met. 2021;40(3):635. https://doi.org/10.1007/s12598-016-0763-y.

Cai Q, Mendis CL, Chang ITH, Fan ZY. Effect of short T6 heat treatment on the microstructure and the mechanical properties of newly developed die-cast Al–Si–Mg–Mn alloys. Mater Sci Eng A. 2020;788:139610. https://doi.org/10.1016/j.msea.2020.139610.

Tang P, Yu FY, Liu QN, Xie YL, Peng LX, Mo ZQ. Microstructure and properties of Al-11.5Si-9.5Mg alloy with Sb addition and heat treatment. Chin J Rare Met. 2022;46(4):428. https://doi.org/10.13373/j.cnki.cjrm.XY20070015.

Kang HJ, Park JY, Choi YS, Cho DH. Influence of the solution and artificial aging treatments on the microstructure and mechanical properties of die-cast Al–Si–Mg alloys. Metals. 2022;12(1):71. https://doi.org/10.3390/met12010071.

Villa M, Somers MAJ. Cryogenic treatment of an AISI D2 steel: the role of isothermal martensite formation and “martensite conditioning”. Cryogenics. 2020;110:103131. https://doi.org/10.1016/j.cryogenics.2020.103131.

Jovičević-Klug P, Jenko M, Jovičević-Klug M, Batic BS, Kovac J, Podgornik B. Effect of deep cryogenic treatment on surface chemistry and microstructure of selected high-speed steels. Appl Surf Sci. 2021;548:149257. https://doi.org/10.1016/j.apsusc.2021.149257.

Madhloom MA, Ataiwi AH, Dawood JJ. Influence of cryogenic treatment on hardness, tensile properties, and microstructure of aluminum alloy AA6061. Mater Today Proc. 2022;60:2157. https://doi.org/10.1016/j.matpr.2022.02.131.

Volokitin A, Naizabekov A, Volokitina I, Lezhnev S, Panin E. Thermomechanical treatment of steel using severe plastic deformation and cryogenic cooling. Mater Lett. 2021;304:130598. https://doi.org/10.1016/j.matlet.2021.130598.

Chen D, Li WX. Cryogenic treatment of Al and Al alloys. Chin J Nonferrous Met. 2000;10(6):891. https://doi.org/10.19476/j.ysxb.1004.0609.2000.06.026.

Shi HF, Zhao ZW, Wang YL, Sun W. Effect of cryogenic treatment order and frequency on rapidly solidified high-silicon aluminum alloy. Ordnance Mater Sci Eng. 2012;35(02):47. https://doi.org/10.14024/j.cnki.1004-244x.2012.02.023.

Li MJ, Liu GL, Jiang WH, Zhao L, Zhu LJ, Gu L. Effect of cryogenic + solid solution + ageing composite treatment on microstructure and mechanical properties of A356 alloy. Chin J Rare Met. 2020;44(1):101. https://doi.org/10.13373/j.cnki.cjrm.xy18080042.

Acknowledgements

This study was financially supported by the National Natural Science Foundation of China-Youth Project (No. 51801076), the Provincial Colleges and Universities Natural Science Research Project of Jiangsu Province (No. 18KJB430009), the Postdoctoral Research Support Project of Jiangsu Province (No. 1601055C) and the Senior Talents Research Startup of Jiangsu University (No. 14JDG126).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tao, C., Cheng, XN., Li, ZQ. et al. Mechanism of cryogenic, solid solution and aging compound heat treatment of die-cast Al alloys considering microstructure variation. Rare Met. 42, 3130–3138 (2023). https://doi.org/10.1007/s12598-023-02341-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-023-02341-w