Abstract

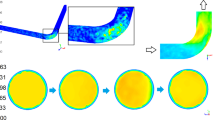

Pipeline hydraulic transport is a highly efficient and low energy-consumption method for transporting solids and is commonly used for tailing slurry transport in the mining industry. Erosion wear (EW) remains the main cause of failure in tailings slurry pipeline systems, particularly at bends. EW is a complex phenomenon influenced by numerous factors, but research in this area has been limited. This study performs numerical simulations of slurry transport at the bend by combining computational fluid dynamics and fluid particle tracking using a wear model. Based on the validation of the feasibility of the model, this work focuses on the effects of coupled inlet velocity (IV) ranging from 1.5 to 3.0 m·s−1, particle size (PS) ranging from 50 to 650 µm, and bend angle (BA) ranging from 45° to 90° on EW at the bend in terms of particle kinetic energy and incidence angle. The results show that the maximum EW rate of the slurry at the bend increases exponentially with IV and PS and first increases and then decreases with the increase in BA with the inflection point at 60° within these parameter ranges. Further comprehensive analysis reveals that the sensitivity level of the three factors to the maximum EW rate is PS > IV > BA, and when IV is 3.0 m/s, PS is 650 µm, and BA is 60°, the bend EW is the most severe, and the maximum EW rate is 5.68 × 10−6 kg·m−2·s−1. In addition, When PS is below or equal to 450 µm, the maximum EW position is mainly at the outlet of the bend. When PS is greater than 450 µm, the maximum EW position shifts toward the center of the bend with the increase in BA. Therefore, EW at the bend can be reduced in practice by reducing IV as much as possible and using small particles.

Similar content being viewed by others

References

Q.M. Nguyen, J. Abouezzi, and L. Ristroph, Early turbulence and pulsatile flows enhance diodicity of Tesla’s macrofluidic valve, Nat. Commun., 12(2021), No. 1, art. No. 2884.

R. Tarodiya and B.K. Gandhi, Hydraulic performance and erosive wear of centrifugal slurry pumps - A review, Powder Technol., 305(2017), p. 27.

Q.S. Chen, S.Y. Sun, Y.M. Wang, Q.L. Zhang, L.M. Zhu, and Y.K. Liu, In-situ remediation of phosphogypsum in a cement-free pathway: Utilization of ground granulated blast furnace slag and NaOH pretreatment, Chemosphere, 313(2023), art. No. 137412.

M.E. Ibrahim and M. Medraj, Prediction and experimental evaluation of the threshold velocity in water droplet erosion, Mater. Des., 213(2022), art. No. 110312.

I. Marusic, D. Chandran, A. Rouhi, et al., An energy-efficient pathway to turbulent drag reduction, Nat. Commun., 12(2021), art. No. 5805.

G. Singh, S. Kumar, and S.K. Mohapatra, Erosion wear in a slurry pipe with multisized coal and bottom-ash slurries, Mater. Today, 4(2017), No. 2, p. 3565.

A.X. Wu, Z. Ruan, and J.D. Wang, Rheological behavior of paste in metal mines, Int. J. Miner. Metall. Mater., 29(2022), No. 4, p. 717.

D.L. Wang, Q.L. Zhang, Q.S. Chen, C.C. Qi, Y. Feng, and C.C. Xiao, Temperature variation characteristics in flocculation settlement of tailings and its mechanism, Int. J. Miner. Metall. Mater., 27(2020), No. 11, p. 1438.

A. Uzi, Y. Ben Ami, and A. Levy, Erosion prediction of industrial conveying pipelines, Powder Technol., 309(2017), p. 49.

H.Z. Jiao, W.B. Yang, Z.E. Ruan, J.X. Yu, J.H. Liu, and Y.X. Yang, Microscale mechanism of tailing thickening in metal mines, Int. J. Miner. Metall. Mater., 30(2023), No. 8, p. 1538.

Q.S. Chen, L.M. Zhu, Y.M. Wang, J. Chen, and C.C. Qi, The carbon uptake and mechanical property of cemented paste backfill carbonation curing for low concentration of CO2, Sci. Total Environ., 852(2022), art. No. 158516.

R.K. Rathore, P.K. Gupta, and N. Kumar, Numerical investigation of zinc tailings slurry flow field in a horizontal pipeline, Mater. Today Proc., 45(2021), p. 2702.

A. Uzi and A. Levy, Energy absorption by the particle and the surface during impact, Wear, 404–405(2018), p. 92.

R. Camassa, D.M. Harris, R. Hunt, Z. Kilic, and R.M. McLaughlin, A first-principle mechanism for particulate aggregation and self-assembly in stratified fluids, Nat. Commun., 10(2019), No. 1, art. No. 5804.

Q.L. Zhang, Y.T. Li, Q.S. Chen, Y.K. Liu, Y. Feng, and D.L. Wang, Effects of temperatures and pH values on rheological properties of cemented paste backfill, J. Cent. South Univ., 28(2021), No. 6, p. 1707.

S. Dhodapkar, P. Solt, and G. Klinzing, Understanding bends in pneumatic conveying systems, Chem. Eng., 116(2009), p. 53.

S.S. Rajahram, T.J. Harvey, and R.J.K. Wood, Erosion–corrosion resistance of engineering materials in various test conditions, Wear, 267(2009), No. 1–4, p. 244.

Y.F. Liu, Y.L. Zhao, and J. Yao, Synergistic erosion-corrosion behavior of X80 pipeline steel at various impingement angles in two-phase flow impingement, Wear, 466–467(2021), art. No. 203572.

H. Zhou, Q.F. Ji, W. Liu, H.Y. Ma, Y. Lei, and K.Q. Zhu, Experimental study on erosion-corrosion behavior of liquid–solid swirling flow in pipeline, Mater. Des., 214(2022), art. No. 110376.

J.H. Wang, T.F. Zhang, and S.G. Wang, Heterogeneous ice slurry flow and concentration distribution in horizontal pipes, Int. J. Heat Fluid Flow, 44(2013), p. 425.

H. Zhang, Y.Q. Tan, D.M. Yang, et al., Numerical investigation of the location of maximum erosive wear damage in elbow: Effect of slurry velocity, bend orientation and angle of elbow, Powder Technol., 217(2012), p. 467.

Y.Q. Tan, H. Zhang, D.M. Yang, S.Q. Jiang, J.H. Song, and Y. Sheng, Numerical simulation of concrete pumping process and investigation of wear mechanism of the piping wall, Tribol. Int., 46(2012), No. 1, p. 137.

B.Q. Wu, X.D. Wang, X.X. Liu, G.G. Xu, and S.B. Zhu, Numerical simulation of erosion and fatigue failure the coal gangue paste filling caused to pumping pipes, Eng. Fail. Anal., 134(2022), art. No. 106081.

V. Kannojiya, M. Deshwal, and D. Deshwal, Numerical analysis of solid particle erosion in pipe elbow, Mater. Today Proc., 5(2018), No. 2, p. 5021.

Q.C. Wang, Q.Y. Huang, N.R. Wang, et al., An experimental and numerical study of slurry erosion behavior in a horizontal elbow and elbows in series, Eng. Fail. Anal., 130(2021), art. No. 105779.

M.M. Zhou, S.B. Kuang, F. Xiao, K. Luo, and A.B. Yu, CFD-DEM analysis of hydraulic conveying bends: Interaction between pipe orientation and flow regime, Powder Technol., 392(2021), p. 619.

M. Parsi, M. Agrawal, V. Srinivasan, et al., CFD simulation of sand particle erosion in gas-dominant multiphase flow, J. Nat. Gas Sci. Eng., 27(2015), p. 706.

J.X. Zhang, J.A. Kang, J.C. Fan, and J.C. Gao, Study on erosion wear of fracturing pipeline under the action of multiphase flow in oil & gas industry, J. Nat. Gas Sci. Eng., 32(2016), p. 334.

M. Parsi, R.E. Vieira, N. Kesana, B.S. McLaury, and S.A. Shirazi, Ultrasonic measurements of sand particle erosion in gas dominant multiphase churn flow in vertical pipes, Wear, 328–329(2015), p. 401.

S.N. Shah and S. Jain, Coiled tubing erosion during hydraulic fracturing slurry flow, Wear, 264(2008), No. 3–4, p. 279.

N. Lin, H.Q. Lan, Y.G. Xu, S.H. Dong, and G. Barber, Effect of the gas-solid two-phase flow velocity on elbow erosion, J. Nat. Gas Sci. Eng., 26(2015), p. 581.

Q.B. Nguyen, V.B. Nguyen, C.Y.H. Lim, et al., Effect of impact angle and testing time on erosion of stainless steel at higher velocities, Wear, 321(2014), p. 87.

J.K. Chen, Y.S. Wang, X.F. Li, R.Y. He, S. Han, and Y.L. Chen, Erosion prediction of liquid-particle two-phase flow in pipeline elbows via CFD–DEM coupling method, Powder Technol., 275(2015), p. 182.

M. Tiberga, A. Hennink, J.L. Kloosterman, and D. Lathouwers, A high-order discontinuous Galerkin solver for the incompressible RANS equations coupled to the k−ϵ, Comput. Fluids, 212(2020), art. No. 104710.

B.E. Launder and B.I. Sharma, Application of the energy-dissipation model of turbulence to the calculation of flow near a spinning disc, Lett. Heat Mass Transf., 1(1974), No. 2, p. 131.

Y. Sun, M.L. Liu, Y. Xiao, and Y.F. Chen, A novel molecular communication inspired detection method for the evolution of atherosclerosis, Comput. Meth. Programs Biomed., 219(2022), art. No. 106756.

M. Rafiee, M.J.H. Simmons, A. Ingram, and E.H. Stitt, Development of positron emission particle tracking for studying laminar mixing in Kenics static mixer, Chem. Eng. Res. Des., 91(2013), No. 11, p. 2106.

A. Mansouri, Development of Erosion Equations for Slurry Flows, Advis. Board Rep. Erosion/Corrosion Res. Center, Univ. Tulsa, Tulsa, 2015, p. 48.

L. Zeng, G.A. Zhang, and X.P. Guo, Erosion-corrosion at different locations of X65 carbon steel elbow, Corros. Sci., 85(2014), p. 318.

M.H. Zolfagharnasab, M. Salimi, H. Zolfagharnasab, H. Alimoradi, M. Shams, and C. Aghanajafi, A novel numerical investigation of erosion wear over various 90-degree elbow duct sections, Powder Technol., 380(2021), p. 1.

M.A. Al-Bukhaiti, S.M. Ahmed, F.M.F. Badran, and K.M. Emara, Effect of impingement angle on slurry erosion behaviour and mechanisms of 1017 steel and high-chromium white cast iron, Wear, 262(2007), No. 9–10, p. 1187.

R.E. Vieira, A. Mansouri, B.S. McLaury, and S.A. Shirazi, Experimental and computational study of erosion in elbows due to sand particles in air flow, Powder Technol., 288(2016), p. 339.

X.H. Chen, B.S. McLaury, and S.A. Shirazi, Numerical and experimental investigation of the relative erosion severity between plugged Tees and elbows in dilute gas/solid two-phase flow, Wear, 261(2006), No. 7–8, p. 715.

D.J. Blanchard, P. Griffith, and E. Rabinowicz, Erosion of a pipe bend by solid particles entrained in water, J. Manuf. Sci. Eng., 106(1984), No. 3, p. 213.

P.C. Kang, Q.Q. Zhao, S.Q. Guo, et al., Optimisation of the spark plasma sintering process for high volume fraction SiCp/Al composites by orthogonal experimental design, Ceram. Int., 47(2021), No. 3, p. 3816.

Q. Li, Z.Y. Peng, W.B. Jiang, et al., Optimization of Ti−Zr−Cr−Fe alloys for 45 MPa metal hydride hydrogen compressors using orthogonal analysis, J. Alloys Compd., 889(2021), art. No. 161629.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Nos. 52104156, 52074351 and 52004330) and the Science and Technology Innovation Program of Hunan Province, China (No. 2021RC3125).

Author information

Authors and Affiliations

Corresponding author

Additional information

Conflict of Interest

Qiusong Chen is an editorial board member and Yikai Liu is a youth editorial board member for this journal; they were not involved in the editorial review or the decision to publish this article. All authors declare that there are no competing interests.

Supplementary Information

12613_2023_2672_MOESM1_ESM.docx

Erosion wear at the bend of pipe during tailings slurry transportation: Numerical study considering inlet velocity, particle size and bend angle, approximately 28 KB.

Rights and permissions

About this article

Cite this article

Chen, Q., Zhou, H., Wang, Y. et al. Erosion wear at the bend of pipe during tailings slurry transportation: Numerical study considering inlet velocity, particle size and bend angle. Int J Miner Metall Mater 30, 1608–1620 (2023). https://doi.org/10.1007/s12613-023-2672-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-023-2672-z