Abstract

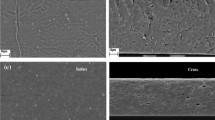

In this present study the biodegradable PLA/PBAT blend incorporated cardanol oil (CO) along with various nanoparticles (Nps) was fabricated by film casting technique. The primary goal of this work was to address and solve the incompatibility problem that exists between PLA and PBAT blending by introducing green chemical based natural additive cardanol oil as compatibilizer in PLA/PBAT biodegradable polymer blend. The packaging films were developed using various formulations of PLA/PBAT (90/10) biopolymer blend added with cardanol oil as compatibilizing agent and 1wt.% of ZnO, TiO2, and SiO2 as nanofiller. All of the developed PLA/PBAT blended biodegradable films were subjected to various characterizations such as fourier transform infrared spectroscopy, surface and inner morphology, X-ray diffraction, mechanical, thermal degradation, optical, surface hydrophobicity and antibacterial behaviour. The mechanical performance of the prepared film revealed that incorporating 1wt.% NPs (ZnO, TiO2, and SiO2) along with 5wt.% cardanol oil into the composite film improves tensile strength and percentage of elongation. The PLA/PBAT blended film containing both NPs and cardanol oil has a lower OTR and WVTR value and indicating that the flexible film has good barrier properties. The presence of both cardanol oil and NPs in the PLA/PBAT improved the optical properties and surface hydrophobicity. Finally, based on the experimental results obtained in this study, it is inferred that the PLA/PBAT/NPs/CO biodegradable films have high potential for the use in food packaging applications due to their improved packaging performances such as film flexibility, less water permeability, heat withstand ability, less water absorptiveness and good antimicrobial properties.

Similar content being viewed by others

Data Availability

No data available to deposit as private. There are no rights

References

Han Y, Shi J, Mao L, Wang Z, Zhang L (2020) Improvement of compatibility and mechanical performances of PLA/PBAT composites with epoxidized soybean oil as compatibilizer. Ind Eng Chem Res 59(50):21779–21790

Jaillet F, Darroman E, Boutevin B, Caillol S (2016) A chemical platform approach on cardanol oil: from the synthesis of building blocks to polymer synthesis. OCL - Oilseeds Fats Crops Lipids 23(5):511–518

Sharma S, Barkauskaite S, Duffy B, Jaiswal AK, Jaiswal S (2020) Characterization and antimicrobial activity of biodegradable active packaging enriched with clove and thyme essential oil for food packaging application. Foods 9(8):1117

Hernández-López M, Correa-Pacheco ZN, Bautista-Baños S, Zavaleta-Avejar L, Benítez-Jiménez JJ, Sabino-Gutiérrez MA, Ortega-Gudiño P (2019) Bio-based composite fibers from pine essential oil and PLA/PBAT polymer blend. Morphological, physicochemical, thermal and mechanical characterization. Mater Chem Phys 234:345–353

Raja V, Natesan R, Thendral Thiyagu P (2015) Preparation and mechanical properties of poly (butylene adipate-co-terephthalate) polyvinyl alcohol/SiO2 nanocomposite films for packaging applications. J Polym Mater 32(1):93–101

Correa-Pacheco ZN, Black-Solís JD, Ortega-Gudiño P, Sabino-Gutiérrez MA, Benítez-Jiménez JJ, Barajas-Cervantes A, Bautista-Baños S, Hurtado-Colmenares LB (2020) Preparation and characterization of bio-based PLA/PBAT and cinnamon essential oil polymer fibers and life-cycle assessment from hydrolytic degradation. Polymers 12(1):38

Sharma S, Jaiswal AK, Duffy B, Jaiswal S (2020) Ferulic acid incorporated active films based on poly (lactide)/poly (butylene adipate-co-terephthalate) blend for food packaging. Food Packag Shelf Life 24

Rigoussen A, Verge P, Raquez JM, Habibi Y, Dubois P (2017) In-depth investigation on the effect and role of cardanol in the compatibilization of PLA/ABS immiscible blends by reactive extrusion. Eur Polym J 93:272–283

Fu Y, Wu G, Bian X, Zeng J, Weng Y (2020) Biodegradation behavior of poly (Butylene Adipate-Co-Terephthalate)(PBAT), poly (Lactic Acid)(PLA), and Their blend in freshwater with sediment. Molecules 25(17):3946

Barbosa, Josiane Dantas Viana et al (2019). Bionanocomposites of PLA/PBAT/organophilic clay: preparation and characterization. Polímeros [online]. v. 29, n. 3, e2019045. Available from: . Epub 04 Nov 2019. ISSN 1678-5169.https://doi.org/10.1590/0104-1428.09018. [Accessed 1 December 2021]

Irshad M, Subhani MA, Ali S, Hussain A (2020) Biological importance of essential oils. Essential Oils-Oils of Nature

da Silva JMF, Soares BG (2021) Epoxidized cardanol-based prepolymer as promising biobased compatibilizing agent for PLA/PBAT blends. Polym Test 93:106889

Wang B, Jin Y, Yang N, Weng Y, Huang Z, Men S (2020) Investigation on compatibility of PLA/PBAT blends modified by epoxy-terminated branched polymers through chemical micro-crosslinking. e-Polymers 20(1):39–54

Aliotta L, Gigante V, Acucella O, Signori F, Lazzeri A (2020) Thermal, mechanical and micromechanical analysis of PLA/PBAT/POE-g-GMA extruded ternary blends. Front Mater

Gan ZH, Kuwabara K, Yamamoto M, Abe H, Doi Y (2004) Solid-state structures and thermal properties of aliphatic-aromatic poly(butylene adipate-co-butylene terephthalate) copolyesters. Polym Degrad Stabil 83:289–300 (Search in Google Scholar)

Lin S, Guo W, Chen C, Ma J, Wang B (2012) Mechanical properties and morphology of biodegradable poly(lactic acid)/poly(butylene adipate-co-terephthalate) blends compatibilized by transesterification. Mater Des 36:604–608 (Search in Google Scholar)

Weng YX, Jin YJ, Meng QY, Wang L, Zhang M, Wang YZ (2013) Biodegradation behavior of poly(butylene adipate-co-terephthalate) (PBAT), poly(lactic acid) (PLA), and their blend under soil conditions. Polym Test 32:918–926

Al-Itry R, Lamnawar K, Maazouz A (2014) Rheological, morphological, and interfacial properties of compatibilized PLA/PBAT blends. Rheol Acta 53:501–517

Jaillet F, Darroman E, Boutevin B, Caillol S (2016) A chemical platform approach on cardanol oil: from the synthesis of building blocks to polymer synthesis. OCL Oilseeds Fats Crops Lipids 23(5):511–518

Noshirvani N, Ghanbarzadeh B, Gardrat C, Rezaei M, Hashemi M, Le Coz C, Coma V (2017) Cinnamon and ginger essential oils to improve antifungal, physical and mechanical properties of chitosan-carboxymethyl cellulose films. Food Hydrocoll 70:36–45

Khaleque M, Keya C, Hasan K, Hoque M, Inatsu Y, Bari M (2016) Use of cloves and cinnamon essential oil to inactivate Listeria monocytogenes in ground beef at freezing and refrigeration temperatures. LWT-Food Sci Technol 74:219–223

Marcet I, Weng S, Sáez-Orviz S, Rendueles M, Díaz M (2018) Production and characterisation of biodegradable PLA nanoparticles loaded with thymol to improve its antimicrobial e_ect. J Food Eng 239:26–32

Prakash VR, Arun, Viswanathan R (2019) Fabrication and characterization of silanized echinoidea fillers and kenaf fibre-reinforced Azadirachta-indica blended epoxy multi-hybrid biocomposite. Int J Plast Technol 23(2):207–217

Prakash VR, Arun J, Xavier F, Ramesh G, Maridurai T, Siva Kumar K, Blessing Sam Raj R (2020) Mechanical, thermal and fatigue behaviour of surface-treated novel Caryota urens fibre–reinforced epoxy composite. Biomass Convers Biorefin: 1–11

Rajadurai A (2016) Thermo-mechanical characterization of siliconized E-glass fiber/hematite particles reinforced epoxy resin hybrid composite. Appl Surf Sci 384:99–106

Ben Samuel J, Julyes Jaisingh S, Sivakumar K, Mayakannan AV, Arunprakash VR (2021) Visco-elastic, thermal, antimicrobial and dielectric behaviour of areca fibre-reinforced nano-silica and neem oil-toughened epoxy resin bio composite. Silicon 13(6):1703–1712

Greco A, Maffezzoli A (2018) Cardanol derivatives as innovative bio-plasticizers for poly (lactic acid). Polym Degrad Stabil 132:213–219. https://doi.org/10.1016/j.polymdegradstab.2016.02.020

Miele G, Bloise E, Cosemtino F, Lomonaco D, Avelino F, Marciano T, Massaro C, Mazzetto SE, Tammaro L, Scalone AG, Schioppa M, Terzi R (2019) Influence of cardanol oil on the properties of poly(lactic acid) films produced by melt extrusion. ACS Omega 4:718–726. https://doi.org/10.1021/acsomega.8b02880

Hang H, Li Y, Gong M, Guo Y, Guo Z, Fang Q, Li X (2018) An environmentally sustainable plasticizer toughned polylactide. RSC Adv 8:116–143. https://doi.org/10.1039/c7ra13448g

Gu W, Liu X, Li F, Shi SQ, Xia C, Zhou W, … Li J (2019) Tough, strong,and biodegradable composite film with excellent UV barrier performance comprising soy protein isolate, hyperbranched polyester, and cardanol derivative. Green Chem 21(13):3651-3665

Lee S, Park MS, Shin J, Kim YW (2018) Effect of the individual and combined use of cardanol-based plasticizers and epoxidized soybean oil on the properties of PVC. Polym Degrad Stabil 147:1–11. https://doi.org/10.1016/j.polymdegradstab.2017.11.002

Greco A, Ferrari F, Maffezzoli A (2019) Mechanical properties of poly (lactid acid) plasticized by cardanol derivatives. Polym Degrad Stab 159:199–204

Cranston E, Kawada J, Raymond S, Morin FG, Marchessault RH (2003) Cocrystallization Model For Synthetic Biodegradable Poly(Butylene Adipate-Co-Butylene Terephthalate). Biomacromolecules 4:995–999. https://doi.org/10.1021/bm034089n

Wang X, Huang L, Zhang C, Deng Y, Xie P, Liu L, Cheng J (2020) Research advances in chemical modifications of starch for hydrophobicity and its applications: A review. Carbohydr Polym 240:116292

Seong DM, Lee H, Kim J, Jeong Ho C (2020) High oxygen and water-vapor transmission rate and in vitro cytotoxicity assessment with illite-polyethylene packaging films. Materials 13(10):2382

Lian S, Jintong Z, Jiangyong W, Xu C, Swart HC, Terblans JJ (2021) A Model for adsorption and diffusion in water vapor barrier films. Phys Status Solidi (B) 258(6):2000609

Ma J, Cahill DG, Miljkovic N (2020) Condensation induced blistering as a measurement technique for the adhesion energy of nanoscale polymer films. Nano Lett 20(5):3918–3924

Chavoshizadeh S, Pirsa S, Mohtarami F (2020) Conducting/smart color film based on wheat gluten/chlorophyll/polypyrrole nanocomposite. Food Packag Shelf Life 24:100501

Soliman TS, Sergey AV, Elkalashy SI (2020) Structural, thermal, and linear optical properties of SiO2 nanoparticles dispersed in polyvinyl alcohol nanocomposite films. Polym Compos 41(8):3340–3350

Thendral TT, Sai Prasanna Kumar JV, Sathiyamoorthy V, Arun Prakash VR (2021) Effect of cashew shell biomass synthesized cardanol oil green compatibilizer on flexibility, barrier, thermal, and wettability of PLA/PBAT biocomposite films. Biomass Convers Biorefin: 1–11

Mizielińska M, Kowalska U, Jarosz M, Sumińska P, Landercy N, Duquesne E (2018) The effect of UV aging on antimicrobial and mechanical properties of PLA films with incorporated zinc oxide nanoparticles. Int J Environ Res Public Health 15(4):794

Hasheminya S-M, Mokarram RR, Ghanbarzadeh B, Hamishekar H (2018) Physicochemical, mechanical, optical, microstructural and antimicrobial properties of novel kefiran-carboxymethyl cellulose biocomposite films as influenced by copper oxide nanoparticles (CuONPs). Food Packag Shelf Life 17:196–204

Atarés L, Chiralt A (2016) Essential oils as additives in biodegradable films and coatings for active food packaging. Trends Food Sci Technol 48:51–62

Author information

Authors and Affiliations

Contributions

All have done equal contribution.

Corresponding author

Ethics declarations

Yes this article compliance with ethical standards of journal

Conflicts of Interest/Competing Interests

There is no conflict of interest by any form for this manuscript

Consent to Participate

Yes. All permission granted

Consent for Publication

Yes. All permission granted

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Thiyagu, T.T., Gokilakrishnan, G., Uvaraja, V.C. et al. Effect of SiO2/TiO2 and ZnO Nanoparticle on Cardanol Oil Compatibilized PLA/PBAT Biocomposite Packaging Film. Silicon 14, 3795–3808 (2022). https://doi.org/10.1007/s12633-021-01577-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-021-01577-4