Abstract

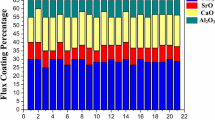

The present paper aims to study the thermophysical and physicochemical properties of CaO-CaF2-SiO2-22.5% TiO2 based electrode coating for welding the components of advanced ultra-supercritical power plants. The mixture design methodology was used to formulate thirteen coating mixtures to explore the effect of flux coating properties, i.e., density, change in enthalpy, weight loss, thermal conductivity, specific heat, and thermal diffusivity. Flux coating properties play an essential role in achieving better weldments. Fourier transformation and X-ray diffraction were used to analyze electrode coating composition structural behavior. The coating composition was also characterized by using a thermogravimetric analyzer and hot disc apparatus, and after that, a regression model analysis was carried out to study individual, and their interaction effects on the thermophysical and physicochemical properties. CaO.CaF2, CaO.SiO2, and CaF2.SiO2 is the most effective binary mixture which has an increasing effect on density. The weight loss of coating observed during thermogravimetric analysis is affected by individual constituents significantly. The binary interaction of SiO2.CaO and CaF2.SiO2 is the most favorable and has an increasing effect on weight loss. Individual components affect change in enthalpy significantly. The binary interaction of CaO.SiO2 and CaF2.SiO2 is the most effective and has an increasing effect on change in enthalpy. The thermal properties of coating composition observed during hot disc are affected by individual and binary mixture constituents. Binary mixture CaF2.CaO and CaF2.SiO2 is having an increasing effect on thermal conductivity. Binary mixture SiO2.CaO shows a decreasing impact on thermal diffusivity. Binary mixture constituents CaF2.CaO, SiO2.CaO is the most effective and has an increasing effect on specific heat.

Similar content being viewed by others

Data Availability

I Vijay Kumar (Corresponding Author) certified that data & material will be available on author’s request.

References

Pavan AHV, Vikrant KSN, Ravibharath R, Singh K (2015) Development and evaluation of SUS304H-IN 617 welds for advanced ultra super-critical boiler applications. Mater Sci Eng A 642:32–41

Shah Hosseini H, Shamanian M, Kermanpur A (2011) Characterization of microstructures and mechanical properties of Inconel 617/310 stainless steel dissimilar welds. Mater Charact 62(4):425–431

Dupont JN (2012) Microstructural evolution and high-temperature failure of ferritic to austenitic dissimilar welds. Int Mater Rev 57(4):208–234

Fuchs R, Heuser H, Hahn B (2010) Welding of dissimilar materials. Mater High Temp 27(3):183–190

Akram J, Kalvala PR, Chalavadi P, Misra M (2018) Dissimilar metal weld joints of P91/Nimicrostructural characterization of HAZ of P91 and stress analysis at the weld interfaces. J Mater Eng Perform 27(8):4115–4128

Kumar V, Chhibber R (2022) Experimental investigation on SMAW electrode coatings developed using CaO–SiO2–CaF2–SrO based coating system. Ceram Int. https://doi.org/10.1016/j.ceramint.2022.06.187

Bhandari D, Chhibber R, Arora N, Mehta R (2019) Investigations on weld metal chemistry and mechanical behaviour of bimetallic welds using CaO-CaF2-SiO2-Ni based electrode coatings. Proceedings of the Institution of Mechanical Engineers, Part L, Journal of Materials: Design and Applications 233(4):563–579

Mahajan S, Chhibber R (2019) Design and development of shielded metal arc welding (SMAW) electrode coatings using a CaO-CaF2-SiO2 and CaO-SiO2-Al2O3 flux system. JOM 71(7):2435–2444

Khan WN, Chhibber R (2020) Physicochemical and thermophysical characterization of CaO-CaF2-SiO2 and CaO-TiO2-SiO2 based electrode coating for offshore welds. Ceram Int 46(7):8601–8614

North TH, Bell HB, Nowicki A, Craig I (1978) Slag/metal interaction, oxygen and toughness in submerged arc welding. Weld J (Miami, Fla). 57(3):63–75

Mitra U, Eagar TW (1984) Slag metal reactions during submerged arc welding of alloy steels. Metall Trans A, Phys Metall Mater Sci 15 A(1):217–227

Bhandari D, Chhibber R, Arora N, Mehta R (2016) Investigation of TiO2-SiO2-CaO-CaF2based electrode coatings on weld metal chemistry and mechanical behaviour of bimetallic welds. J Manuf Process 23:61–74

Kumar V, Chhibber R (2022) Physicochemical and thermophysical properties of CaO–TiO2–SiO2–Na3AlF6 system based electrode coating for AUSC power plant. Ceram Int. https://doi.org/10.1016/j.ceramint.2022.03.005

Khan WN, Chhibber R (2021) Investigations on the effect of CaO-CaF2-TiO2-SiO2 based electrode coating constituents and their interactions on weld chemistry. Ceram Int 47(9):12483–12493

Jindal S, Chhibber R, Mehta NP (2013) Investigation on flux design for submerged arc welding of high-strength low-alloy steel. Proc Inst Mech Eng Part B J Eng Manuf 227(3):383–395

Sharma L, Chhibber R (2019) Design and development of submerged arc welding fluxes using TiO2-SiO2-CaO and SiO2-CaO-Al2O3 flux system. Proc Inst Mech Eng Part E J Process Mech Eng 233(4):739–762

Natalie CA, Olson DL (1986) Physical and chemical behaviour of welding fluxes. Ann RevMaterialScience:389–413

Mitra U, Eagar TW (1991) Slag-metal reactions during welding: part III. Verification of the theory. Metall Trans B 22(1):83–100

Qin R, He G (2013) Mass transfer of nickel-base alloy covered electrode during shielded metal arc welding. Metall Mater Trans A Phys Metall Mater Sci 44(3):1475–1484

Eriksson G, Pelton AD (1993) Critical evaluation and optimization of the thermodynamic properties and phase diagrams of the CaO-Al2O3, Al2O3-SiO2, and CaO-Al2O3-SiO2 systems. Metal Trans B 24(5):807–816

Wang H, Qin R, He G (2016) SiO2 and CaF2 behavior during shielded metal arc welding and their effect on slag detachability of the CaO-CaF2-SiO2 type ENiCrFe-7-covered electrode. Metall Mater Trans A Phys Metall Mater Sci. 47(9):4530–4542

Burck PA, Indacochea JE, Olson DL (1990) Effects of welding flux additions on 4340 steel weld metal composition. Weld J (Miami, Fla) 69(3)

Mills KC, Su Y, Fox AB, Li Z, Thackray RP, Tsai HT (2005) A review of slag splashing. ISIJ Int 45(5):619–633

Sham K, Liu S (2014) Flux-coating development for SMAW consumable electrode of high-nickel alloys. Weld J 93(8):271s–281s

Elaiyarasan U, Kumar VS, Senthilkumar C (2021) Effect of parameters on microstructure of electrical discharge coated ZE41A magnesium alloy with tungsten carbide-copper composite electrode. Surf Topogr: Metrol Prop 9:025006. https://doi.org/10.1088/2051-672X/abf326

Elaiyarasan U, Vinod B, Nallathambi K Response surface methodology study on electrical discharge deposition of AZ31B magnesium alloy with powder composite electrode, Int J Interact Des Manuf, https://doi.org/10.1007/s12008-022-00923-z

Ananthi N, Elaiyarasan U, Satheeshkumar V, Senthilkumar C, Sathiyamurthy S. Effect of wc–cu composite electrodes on material deposition rate, microhardness and microstructure of electrical discharge coated magnesium alloy, https://doi.org/10.1142/S0218625X22500500

Mahajan S, Chhibber R (2020) Investigation on slags of CaO-CaF2-SiO2-Al2O3 based electrode coatings developed for power plant welds. Ceram Int 46(7):8774–8786

Sharma L, Chhibber R (2019) Design of TiO2-SiO2-MgO and SiO2-MgO-Al2O3-based submerged arc fluxes for a multipass bead on plate pipeline steel welds. Journal of Pressure Vessel Technology, Transactions of the ASME 141(4)

Sharma L, Chhibber R (2019) Investigating the physicochemical and thermophysical properties of submerged arc welding fluxes designed using TiO2-SiO2-MgO and SiO2-MgO-Al2O3 flux systems for linepipe steels. Ceram Int 45(2):1569–1587

Kumar V, Kumar J, Chhibber R, Sharma L (2022) Experimental study on wettability at high-temperature using TiO2-SiO2-CaO-Na3AlF6 based electrode coating for AUSC thermal power plant. Silicon. https://doi.org/10.1007/s12633-022-01824-2

McLean RA, Anderson VL (1966) Extreme vertices design of mixture experiments. Technometrics 8(3):447–454

Mukerji J (1965) Phase Equilibrium Diagram CaO-CaF2-2CaO.SiO2. J Am Ceram Soc 48(4):210–213

Garai M, Sasmal N, Molla AR, Karmakar B (2015) Structural effects of Zn+2/mg+2 ratios on crystallization characteristics and microstructure of fluorophlogopite mica-containing glass-ceramics. Solid State Sci 44:10–21

Kaur G, Kumar M, Arora A, Pandey OP, Singh K (2011) Influence of Y2O3 on structural and optical properties of SiO2-BaO-ZnO-xB2O3-(10-x) Y2O3 glasses and glass ceramics. J Non-Cryst Solids 357(3):858–863

Sowmya T, Sankaranarayanan SR (2004) Spectroscopic analysis of slags- preliminaryobservations. VII Int Conf on Molten Slags Fluxes and Salts, The South African Institute of Mining and Metallurgy

Garai M, Sasmal N, Molla AR, Singh SP, Tarafder A, Karmakar B (2014) Effects of nucleating agents on crystallization and microstructure of fluorophlogopite mica-containing glass-ceramics. J Mater Sci 49(4):1612–1623

Kerstan M, Muller M, Russel C (2011) Binary, ternary and quaternary silicates of CaO, BaO and ZnO in high thermal expansion seals for solid oxide fuel cells studied by high-temperature X-ray diffraction (HT-XRD). Mater Res Bull 46(12):2456–2463

Acknowledgements

It is requested to editorial board to please acknowledge the present research for possible publication in Silicon journal. The content is new and unpublished.

Funding

It is certified on behalf of corresponding author (Vijay Kumar) that present research is not funded by any external agency.

Author information

Authors and Affiliations

Contributions

It is certified on behalf of corresponding author (Vijay Kumar) that corresponding authors are contributed in the present manuscript.

Corresponding author

Ethics declarations

Ethical Approval

I Vijay Kumar (Corresponding Author) on behalf of other co-authors certified that I have taken the ethical approval to publish the data presented in the manuscript. Also the data used in this manuscript (such as figures) has been cited in this paper.

Consent to Participate

NA.

Consent of Publication

I Vijay Kumar (Corresponding Author) on behalf of other coauthors certified that I have taken the permission to publish the present content.

Research Involving Human Participants and/or Animals

The present research is involved for human participants.

Conflict of Interest

It is certified on behalf of corresponding author (Vijay Kumar) that present research is not funded by any external agency and authors declared that there is no conflicts of interest in the present research.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kumar, V., Chhibber, R. & Sharma, L. Investigation on Thermophysical and Physicochemical Properties of CaO-SiO2-CaF2-22.5%TiO2 Silica Based Electrode Coating System. Silicon 15, 739–753 (2023). https://doi.org/10.1007/s12633-022-02037-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-022-02037-3