Abstract

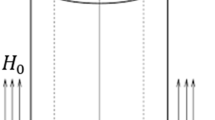

According to recent research, the theoretical consequences of viscoelastic materials may be adequately described using fractional calculus. A novel model for the fractional time derivative of the Kelvin-Voigt type of viscoelastic semiconductor material has been provided in this study. The Atangana and Baleanu (AB) fractional derivatives operator is utilized, which employs the generalized Mittag–Leffler function as a nonlocal and non-singular kernel and respects all features of fractional derivatives. The Moore–Gibson–Thompson (MGT) photothermal heat transfer model has also been considered to explain the mechanism of photosensitive heat transfer and the interplay between plasma, elastic, and heat signals. This fractional model is used to explore thermal and photoacoustic interactions when an infinite viscoelastic rotating material with a circular cylindrical hole is exposed to a time-dependent variable heat in the presence of an axial constant magnetic field. The solutions of photothermal field variables are obtained using Laplace transform methods, and the technique of Fourier series expansions is applied to obtain the inversions. Results have been listed to examine how the fractional-order and mechanical viscoelastic relaxation parameters affect different photo-thermoelastic variables that have physical meaning.

Similar content being viewed by others

Abbreviations

- \(\lambda_{0} ,\mu_{0}\) :

-

Lam´e’s constants

- \(\alpha_{t}\) :

-

Thermal expansion coefficient

- \(C_{E}\) :

-

Specific heat

- \(\gamma_{0} = \left( {3\lambda_{0} + 2\mu_{0} } \right)\alpha_{t}\) :

-

Thermal coupling parameter

- \(T_{0}\) :

-

Reference temperature

- \(\theta = T - T_{0}\) :

-

Temperature increment

- T :

-

Absolute temperature

- \(\overrightarrow {{\text{u}}}\) :

-

Displacement vector

- \(e = {\text{div}}\overrightarrow {{\text{u}}}\) :

-

Cubical dilatation

- \(\sigma_{ij}\) :

-

Stress tensor

- \(e_{ij}\) :

-

Strain tensor

- \(\delta_{ij}\) :

-

Kronecker’s delta function

- \(n_{0}\) :

-

Equilibrium carrier concentration

- \(\vec{H}\) :

-

Magnetic field

- \(\vec{h}\) :

-

Induced magnetic field

- \(d_{0} = \left( {3\lambda_{0} + 2\mu_{0} } \right)d_{n}\) :

-

Diffusion coupling parameter

- \(\mu_{v} ,\lambda_{v} ,\gamma_{v} ,d_{v}\) :

-

Viscoelastic relaxation times

- K :

-

Thermal conductivity

- \(\rho\) :

-

Material density

- \(\alpha\) :

-

Fractional order

- \(D_{t}^{\alpha }\) :

-

Fractional operator

- \(\vec{E}\) :

-

Induced electric field

- N :

-

Carrier density

- \(\tau_{0}\) :

-

Relaxation time

- \(\tau_{ij}\) :

-

Maxwell stress

- \(E_{g}\) :

-

Semiconducting energy gap

- \( d_{n}\) :

-

Electronic deformation coefficient

- \(D_{E}\) :

-

Diffusion coefficient

- \(\vec{q}\) :

-

Heat flux vector

- \(\kappa\) :

-

Thermal activation coupling parameter

- \(\tau\) :

-

Ifetime of photogenerated electron

- \(\vec{J}\) :

-

Current density

- \(\mu_{0}\) :

-

Magnetic permeability

- G :

-

Carrier photogeneration source

References

A M Freudenthal J. Appl. Phys. 25 1110 (1954)

N W Tschegl Mech. Time Depend. Mater. 1 3 (1997)

B Gross Mathematical structure of the theories of viscoelasticity, Hermann (1953)

R S Lakes Viscoelastic Solids, CRC Press (1998)

A Ilioushin, B Pobedria Fundamentals of the mathematical theory of thermal viscoelasticity, Nauka (1970) (In Russian)

R Tanner Engineering rheology, Oxford University Press (1988)

R Quintanilla Eur. J. Mech. A Solids 24 311 (2005)

D Iesan and L Nappa Math. Mech. Solids. 13 55 (2008)

Y Zhao, Y Zhang, F Liu and I Turner Math. Appl. 73 1087 (2017)

R L Bagley and P J Torvik AIAA J. 21 741 (1983)

Caputo and M Fabrizio Progr. Fract. Differ. Appl. 1 73 (2015)

M Zhang Meth. Part. Differ. Equ. 35 1588 (2019)

J Losada and J Nieto Progr. Fract. Differ. Appl. 1 87 (2015)

F Ali Eur. Phys. J. Plus 131 377 (2016)

L Wei and W Li Math. Comput. Simul. 188 280 (2021)

A Atangana and B S T Alkahtani Adv. Mech. Eng. 7 871 (2015)

T M Atanacković Calc Appl Anal. 21 29 (2018)

M I Abbas Asian Eur. J. Math. 14 2150073 (2021)

A Atangana and D Baleanu Therm. Sci. 20 763 (2016)

A Atangana and D Baleanu J. Eng. Mech. D4016005 (2016)

A Atangana and I Koca Chaos Solitons Fract. 1 (2016)

A M A El-Sayed J. Fract. Calc. Appl. 6 101 (2015)

G S F Frederico and D F M Torres Int. Math. Forum 3 1 (2008)

H W Lord and Y Shulman J. Mech. Phys. Solids 15 299 (1967)

A E Green and K A Lindsay J. Elast. 2 1 (1972)

A E Green and P M Naghdi Proc. R Soc. A Math. Phys. Eng. Sci. 432 171 (1991)

A E Green and P M Naghdi J. Therm. Stresses 15 253 (1992)

A E Green and P M Naghdi J. Elast. 31 189 (1993)

A E Abouelregal, H M Sedighi, S A Faghidian and A H Shirazi Facta Un., Series: Mech. Eng. 19 633 (2021)

A E Abouelregal, W W Mohammed and H M Sedighi Arch. Appl. Mech. 91 2127 (2021)

A E Abouelregal J. Appl. Comput. Mech. 6 445 (2020)

A E Abouelregal Multidiscip. Model. Mater. Struct. 16 689 (2019)

A E Abouelregal Indian J. Phys. 94 1949 (2020)

A E Abouelregal Mech. Based Des. Struct. Mach. (2020)

M Malikan and V A Eremeyev Arch. Appl. Mech. (2022). https://doi.org/10.1007/s00419-022-02149-7

I Lasiecka and X Wang J. Diff. Eqns. 259 7610 (2015)

R Quintanilla Math. Mech. Solids 24 4020 (2019)

R Quintanilla Appl. Eng. Sci. 1 100006 (2020)

A E Abouelregal, I E Ahmed, M E Nasr, K M Khalil, A Zakria and F A Mohammed Mater. 13 4463 (2020)

A E Abouelregal and H M Sedighi Appl. Phys. A 127 582 (2021)

A E Aboueregal and H M Sedighi Proc. Inst. Mech. Eng. Part L J. Mater. Design Appl. 5 1004 (2021)

A E Aboueregal, H M Sedighi, A H Shirazi, M Malikan and V A Eremeyev Continuum Mech. Thermodyn. (2021)

A E Abouelregal, H Ersoy and O Civalek Mathematics 9 1536 (2021)

A Raza, T Thumma, K Al-Khaled, S U Khan, K Ghachem, M Alhadri and L Kolsi Waves Rand Compl. Media. (2022) https://doi.org/10.1080/17455030.2022.2067379

L Kolsi, A Raza, K Al-Khaled, K Ghachem, S U Khan and A Ul Haq Waves Rand Compl. Media. (2022) https://doi.org/10.1080/17455030.2022.2038816

J P Gordon, R C C Leite, R S Moore, S P S Porto and J W Whinnery Bull. Am. Phys. Soc. 119 501 (1964)

D M Todorovic, P M Nikolic and A I Bojicic J. Appl. Phys. 85 7716 (1999)

S Rekhi Sci. Instrum. 74 3820 (2003)

S Anzellini and S Boccato Crystals 10 459 (2020)

S Pasternak, G Aquilanti, S Pascarelli, R Poloni, B Canny, M V Coulet and L Zhang Rev. Sci. Instrum. 79 085103 (2008).

B S Yilbas, A Y Al-Dweik, N Al-Aqeeli and H M Al-Qahtani Laser Pulse Heating of Surfaces and Thermal Stress Analysis, Springer International Publishing (2014)

R Bagley Fract. Calcul. Appl. Anal. 10 123 (2007)

R L Bagley and P J Torvik J. Rheol. 27 201 (1983)

A Soleiman, A E Abouelregal and K M Khalil Phys. J. Plus 135 851 (2020)

M Caputo and F Mauro Prog. Fract. Differ. Appl. 1 1 (2015)

M Caputo and M Fabrizio Meccanica 52 3043 (2017)

C Cattaneo Compt. Rend. 247 431 (1958)

P Vernotte Compt. Rend. 246 3154 (1958)

P Vernotte Compt. Rend. 252 2190 (1961)

A E Abouelregal Mater. Res. Express 6 116535 (2019)

G Honig and U Hirdes J. Comp. Appl. Math. 10 113 (1984)

D Y Tzou, Macro-To Micro-Scale Heat Transfer: The Lagging Behavior, Taylor & Francis (1997)

Y Q Song J. Thermophys. 33 1270 (2012)

A E Abouelregal Appl. Math. Mech. Engl. Ed. 42 39 (2021)

A E Abouelregal Silicon 12 2837 (2020)

T R Mahapatra Adv. Mater. Struct. 23 1343 (2016)

T R Mahapatra J. Comput. Methods 13 1650015 (2016)

C K Hirwani, P K Mishra and S K Panda Compos. Struct. 265 113768 (2021)

V Kumar and H C Dewangan J. Appl. Mech. 13 2150086 (2021)

K Mehar J. Press. Vessel. Tech. 143 061301 (2021)

V Kumar and H C Dewangan Syst. Signal Process. 170 108883 (2022)

F Selimefendigil and H F Oztop Heat Mass Transfer 129 265 (2019).

V Kumar and H C Dewangan Struct. 293 115709 (2022)

Author information

Authors and Affiliations

Contributions

All authors discussed the findings, and the final version of the manuscript was reviewed and approved by all.

Corresponding author

Ethics declarations

Conflict of interest

Concerning this paper's research, writing, and publication, the authors reported no potential conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Alfadil, H., Abouelregal, A.E., Civalek, Ö. et al. Effect of the photothermal Moore–Gibson–Thomson model on a rotating viscoelastic continuum body with a cylindrical hole due to the fractional Kelvin-Voigt model. Indian J Phys 97, 829–843 (2023). https://doi.org/10.1007/s12648-022-02434-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12648-022-02434-9