Abstract

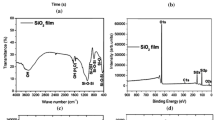

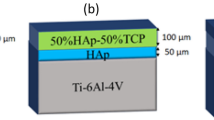

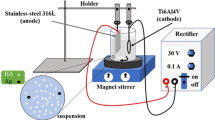

Ti6Al4V alloy, an α + β titanium alloy having good biocompatibility, low density, high strength and a better resistance to corrosion is an excellent candidate for bridges and implants. Hydroxyapatite (HA), a calcium phosphate (Ca10(PO4)6(OH)2) mineral having similar chemical composition with the hard tissues of human bones, was electrochemically deposited on Ti6Al4V alloy grade-5. The surface activity of substrate was increased by a uniform TiO2 film, achieved by grinding, polishing, pretreatment with anodization and alkali treatment. Electrochemical deposition was done by HA powder-ethanol suspension with an antibacterial binder called chitosan at set parameters of 20 V for 1 h at pH 4. The adhesion ability and polarization behavior of HA-coated Ti6Al4V alloy was observed. The anodized, HA-coated, and a bare substrate alloy samples were examined in a bio-simulated solution of ringer’s lactate for polarization testing. SEM and EDAX analysis were performed for HA powder and HA-deposited sample to observe the surface morphology with elemental compositions. Adhesion test (Shimadzu AGS X series tensile testing machine at 25 °C and 60% relative humidity) was performed to check the coating adhesiveness with the metallic substrate, and the observed value was upto 30 MPa. Herein, the electrochemical-deposited HA-coated samples were more resistant to dissolution and showed 2 times better corrosion resistance than bare metal. The bonding strength achieved in this work was also 30 MPa which is greater than required for tooth fixation and root implants (20 MPa).

Similar content being viewed by others

References

Brown S A and J E Lemons. Medical Applications of Titanium and Its Alloys: The Material and Biological Issues (1996).

Williams D F. Biocompatibility of Clinical Implant Mtls. CRC-Press (1981).

Long M, and Rack H J, Biomaterials 19 (1998) 1621.

Fonseca C, and Barbosa M A, Corros Sci 43 (2001) 547.

Chen Q, and Thouas G A, Mater Sci Eng R Rep 87 (2015) 1.

Geetha M, Singh A K, Asokamani R, and Gogia A K Prog Mater Sci 54 (2009) 397

Gepreel MA-H, and Niinomi M, J Mech Behav Biomed Mater 20 (2013) 407.

Manivasagam G, Dhinasekaran D, and Rajamanickam A, Recent Patents Corros Sci 2 (2010) 1.

Taddei E B, Henriques V A R, Silva C R M, and Cairo C A A, Mater Sci Eng C 24 (2004) 683.

Nasab M B, Hassan M R, and Sahari B B, Trends Biomater Artif Organs 24 (2010) 69.

Patel N R, and Gohil P P, Int J Emerg Technol Adv Eng 2 (2012) 91.

Mu Y, Kobayashi T, Tsuji K, Sumita M, and Hanawa T, J Mater Sci Mater Med 13 (2002) 583.

Thull, R. and M. Schaldach, Corrosion of highly stressed orthopedic joint replacements, in Engineering in medicine. 1976, Springer. p. 242-256.

Hoeppner D W, and Chandrasekaran V, Wear 173 (1994) 189.

Rabbe L M, Rieu J, Lopez A, and Combrade P, Clin Mater 15 (1994) 221.

Thull R and Schaldach M, Corrosion of Highly Stressed Orthopedic Joint Replacements, in Engineering in Medicine: Volume 2: Advances in Artificial Hip and Knee Joint Technology, M. Schaldach and D. Hohmann, Editors. 1976, Springer: Berlin, Heidelberg. p. 242–256.

Rao S, Ushida T, Tateishi T, Okazaki Y, and Asao S, Bio-Med Mater Eng 6 (1996) 79.

Yumoto S, Ohashi H, Nagai H, Kakimi S, Ogawa Y, Iwata Y, Ishii K, et al., Int J PIXE 2 (1992) 493.

Wen H B, Wolke J G C, de Wijn J R, Liu Q, Cui F Z, and de Groot K, Biomaterials 18 (1997) 1471.

P Andreazza, M.I De Barros, C Andreazza-Vignolle, D Rats, L Vandenbulcke (1998) Thin Solid Films. 319: 62.

Uchida M, Nihira N, Mitsuo A, Toyoda K, Kubota K, and Aizawa T, Surf Coat Technol 177178 (2004) 627.

X Nie, E.I Meletis, J.C Jiang, A Leyland, A.L Yerokhin, A Matthews (2002) Surf Coat Technol 149: 245.

Güleryüz H, and Çimenoğlu H, Biomaterials 25 (2004) 3325.

Kweh S W K, Khor K A, and Cheang P, Biomaterials 23 (2002) 775.

Brendel T, Engel A, and Rüssel C, J Mater Sci Mater Med 3 (1992) 175.

Hanawa T, Kamiura Y, Yamamoto S, Kohgo T, Amemiya A, Ukai H, Murakami K, and Asaoka K, J Biomed Mater Res 36 (1997) 131.

Sathishkumar S, Louis K, lShinyjoy E, Gopi (2016) Industrial & Engineering Chemistry Research 55: 6331.

Chai C, and Ben-Nissan B, J Mater Sci Mater Med 10 (1999) 465.

D’Antonio J A, Capello W N, Manley M T, Geesink R G T, and Jaffe W L, Hydroxyapatite femoral stems for total hip arthroplasty: 10–14 year follow-up. in Fifteen Years of Clinical Experience with Hydroxyapatite Coatings in Joint Arthroplasty, Springer (2004), pp 235–241.

Gross K A, Chai C S, Kannangara G S, Ben-Nissan B, and Hanley L, J Mater Sci Mater Med 9 (1998) 839.

Mediaswanti K, Wen C, Ivanova E P, Berndt C C, and Wang J, Titanium Alloys Adv Propert Control 21 (2013) 23.

Fernández-Pradas J M, Clèries L, Martı́nez E, Sardin G, Esteve J, and Morenza J L, Biomaterials 22 (2001) 2171.

Guo L, and Li H, Surf Coat Technol 185 (2004) 268.

Liu D, Savino K, and Yates M Z, Surf Coat Technol 205 (2011) 3975.

Song Y, Shan D, and Han E, Mater Lett 62 (2008) 3276.

Ramakrishna S, Mayer J, Wintermantel E, and Leong K W, Compos Sci Technol 61 (2001) 1189.

Sridhar T, Mudali U K, and Subbaiyan M, Corros Sci 45 (2003) 2337.

Staiger M P, Pietak A M, Huadmai J, and Dias G, Biomaterials 27 (2006) 1728.

Zhong Z, Qin J, and Ma J, Mater Sci Eng C 49 (2015) 251.

Yang Y, Kim K-H, and Ong J L, Biomaterials 26 (2005) 327.

Asri R I M, Harun W S W, Hassan M A, Ghani S A C, and Buyong Z, J Mech Behav Biomed Mater 57 (2016) 95.

He D, Wang P, Liu P, Liu X, Ma F, Li W, Chen X, Zhao J and Ye H, J Wuhan Univ Technol Mater Sci Ed 31 (2016) 461.

Zhang S, Wang Y S, Zeng X T, Khor K A, Weng W, and Sun D E, Thin Solid Films 516 (2008) 5162.

Guan K, Zhang L, Zhu F, Li H, Sheng H, and Guo Y, J Alloys Compd 821 (2020) 153543

Martin J Y, Schwartz Z, Hummert T W, Schraub D M, Simpson J, Lankford J, Dean D D, Cochran D L, and Boyan B D, J Biomed Mater Res 29 (1995) 389.

Schwartz Z, Martin JY, Dean DD, Simpson J, Cochran DL and Boyan BD, Journal of Biomedical Materials Research: An Official Journal of The Society for Biomaterials and The Japanese Society for. Biomaterials 30 (1996) 145.

Chehroudi B, McDonnell D, and Brunette D, J Biomed Mater Res Off J Soc Biomater Jpn Soc Biomater 34 (1997) 279.

Brunette D, Int J Oral Maxillofac Implants 3 (1988) 4.

Qiu D, Wang A, and Yin Y, Appl Surf Sci 257 (2010) 1774.

Catauro M, Papale F, and Bollino F, J Non-Crystal Solids 415 (2015) 9.

Farrokhi-Rad M, Khosrowshahi Y B, Hassannejad H, Nouri A, and Hosseini M, Mater Res Express 5 (2018) 115004

Qiu D, Yang L, Yin Y, and Wang A, Surf Coat Technol 205 (2011) 3280.

Yusoff M F M, Rafiq M, Kadir A, Iqbal N, Hassan, M A, and Hussain R, Surf Coat Technol 245 (2014) 102.

Huang Y, Han S, Pang X, Ding Q, and Yan Y, Appl Surf Sci 271 (2013) 299.

Zhong Z, Qin J, and Ma J, Ceram Int 41 (2015) 8878.

Zhang X, Li Q, Li L, Zhang P, Wang Z, and Chen F, Mater Lett 88 (2012) 76.

Vahabzadeh S, Roy M, Bandyopadhyay A, and Bose S, Acta Biomater 17 (2015) 47.

Janković A, Eraković S, Vukašinović-Sekulić M, Mišković-Stanković V, Park S J, and Rhee K Y, Prog Organ Coat 83 (2015) 1.

Kokubo T, and Yamaguchi S, Open Biomed Eng J 9 (2015) 29. https://doi.org/10.2174/1874120701509010029

Ravelingien M, Mullens S, Luyten J, Meynen V, Vinck E, Vervaet C and Remon JP, Ceramics-Silikaty 54 (2010) 3.

Suzan B, Saber Y, Maximilian M, Edward V, and Amir Z, Materials 8 (2015) 1612.

Takadama H, Kim HM, Kokubo T and Nakamura T, J Biomed Mater Res Off J Soc Biomater Jpn Soc Biomater Aust Soc Biomater Korean Soc Biomater 57 (2001) 441.

Ravelingien M, Mullens S, Luyten J, Meynen V, Vinck E, Vervaet C, and Remon J P, Appl Surf Sci 255 (2009) 9539.

Harun W S W, Asri R I M, Alias J, Zulkifli F H, Kadirgama K, Ghani S A C, and Shariffuddin J H M, Ceram Int 44 (2018) 1250.

Kokubo T, and Yamaguchi S, Open Biomed Eng J 9 (2015) 29.

Kim H-M, Miyaji F, Kokubo T, and Nakamura T, J Biomed Mater Res 32 (1996) 409.

Yang Z, Xia L, Li W and Han J, J Adv Biomed Eng Technol 2 (2015) 13.

Williams D F, Bioactive Mater 10 (2022) 306.

Zhu L, Luo D, and Liu Y, Int J Oral Sci 12 (2020) 1.

Woesz A, and Best S, Cellular response to bioceramics. in Cellular Response to Biomaterials, Elsevier (2009), pp 136–155.

Ducheyne P, J Biomed Mater Res 21 (1987) 219.

Kwok C T, Wong P K, Cheng F T, and Man H C, Appl Surf Sci 255 (2009) 6736.

STANDARD, I., Implants for surgery-hydroxyapatite (2008).

Avcu E, Baştan F E, Abdullah H Z, Ur Rehman M A, Avcu, Y Y, and Boccaccini A R, Prog Mater Sci 103 (2019) 69.

Nie X, Leyland A, and Matthews A, Surf Coat Technol 125 (2000) 407.

Wang L-N, and Luo J-L, Mater Charact 62 (2011) 1076.

Pei X, Zeng Y, He R, Li Z, Tian L, Wang J, Wan Q, Li X, and Bao H, Appl Surf Sci 295 (2014) 71.

Zhang Y-y, Tao J, Pang Y-c, Wang W, and W Tao, Trans Nonferrous Met Soc China 16 (2006) 633.

Albayrak O, El-Atwani O, and Altintas S, Surf Coat Technol 202 (2008) 2482.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors report that there is no competing interest to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Awan, N.M., Manzoor, M.U., Hussain, F. et al. A Feasible Route to Produce 30 MPa Adhesion Strength of Electrochemically Deposited Hydroxyapatite (HA) on Titanium (Ti6Al4V) Alloy. Trans Indian Inst Met 76, 1653–1660 (2023). https://doi.org/10.1007/s12666-023-02876-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-023-02876-7