Abstract

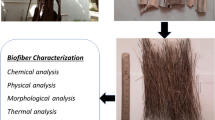

Bio-based materials with high-performance are being explored extensively at the moment for improving the specific properties of reinforced polymer composites and thereby to extend the life-span of composite-based goods. Bio-fillers are one of the sought materials in the polymer composite industry for use in a wide range of matrix systems. At the same time, the annoying release of various agro-wastes into the environment prompt many researchers or scientists to utilize such wastes effectively for sustainable development by aiming zero-waste concepts. Since the current study was intended to utilize an agro-industrial waste from mustard (Brassica juncea) seed oil cake for the extraction cellulosic micro fillers and its characterization for understanding the applicability of it for polymer composite formulation, along with reducing environmental pollution. The isolation of micro cellulose was accomplished by chemical treatments and its characterization was done through physico-chemical (density, FT-IR, XRD, UV-visible spectroscopy), morphological (SEM, EDX, AFM), and thermal (TGA) means. Relatively low density (1.572 g/cm3) revealed its aptness against synthetic reinforcements for light-weight polymer composites. Likewise, high cellulose content (93.49%) with very less hemicellulose (4.97%) and lignin (0.83%) contents offers good mechanical properties to the fillers. The functional group examination revealed the presence of chemical moieties as hydroxyl, carbonyl, methyl, carboxyl, and alkene groups that confirmed the occurrence of high-functionality cellulose. Although, high crystallinity index (79.3%), desired thermal stability (206 °C), significant surface roughness (23.570 nm), and agreeable particle size (20.02 μm) make the material as a superior reinforcing one. Moreover, the extracted organic material is mainly composed of carbon (45.73 wt.%) and oxygen (41.11 wt.%) with a total yield percentage of 41±1.10 wt.%. Despite of these specific properties, the obtained micro-cellulose could be a viable alternative for synthetic or other bio-based reinforcements in synthesizing eco-friendly polymer composites.

Similar content being viewed by others

Data availability

The data that support the findings of this study are available on request from the corresponding author. The data are not publicly available due to privacy or ethical restrictions.

References

McCormick K, Kautto N (2013) The bioeconomy in Europe: an overview. Sustain 5:2589–2608 5:2589–2608. https://doi.org/10.3390/SU5062589

Sunesh NPNP, Indran S, Divya D, Suchart S (2022) Isolation and characterization of novel agrowaste-based cellulosic micro fillers from Borassus flabellifer flower for polymer composite reinforcement. Polym Compos 43:6476–6488. https://doi.org/10.1002/pc.26960

Sanjay MR, Madhu P, Jawaid M et al (2018) Characterization and properties of natural fiber polymer composites: a comprehensive review. Elsevier B.V

Haldar D, Purkait MK (2020) Micro and nanocrystalline cellulose derivatives of lignocellulosic biomass: a review on synthesis, applications and advancements. Carbohydr Polym 250:116937

Haafiz MKM, Hassan A, Zakaria Z et al (2013) Properties of polylactic acid composites reinforced with oil palm biomass microcrystalline cellulose. Carbohydr Polym 98:139–145

Cataldi A, Dorigato A, Deflorian F, Pegoretti A (2015) Innovative microcrystalline cellulose composites as lining adhesives for canvas. Polym Eng Sci 55:1349–1354

Xiao X, Lu S, Qi B et al (2014) Enhancing the thermal and mechanical properties of epoxy resins by addition of a hyperbranched aromatic polyamide grown on microcrystalline cellulose fibers. RSC Adv 4:14928–14935

Rafiee Z, Keshavarz V (2015) Synthesis and characterization of polyurethane/microcrystalline cellulose bionanocomposites. Prog Org Coatings 86:190–193

Cataldi A, Deflorian F, Pegoretti A (2015) Poly 2-ethyl-2-oxazoline/microcrystalline cellulose composites for cultural heritage conservation: mechanical characterization in dry and wet state and application as lining adhesives of canvas. Int J Adhes Adhes 62:92–100

Sun X, Lu C, Liu Y et al (2014) Melt-processed poly (vinyl alcohol) composites filled with microcrystalline cellulose from waste cotton fabrics. Carbohydr Polym 101:642–649

Hoyos CG, Cristia E, Vázquez A (2013) Effect of cellulose microcrystalline particles on properties of cement based composites. Mater Des 51:810–818

Cataldi A, Dorigato A, Deflorian F, Pegoretti A (2014) Thermo-mechanical properties of innovative microcrystalline cellulose filled composites for art protection and restoration. J Mater Sci 49:2035–2044

Zulkifli NI, Samat N, Anuar H, Zainuddin N (2015) Mechanical properties and failure modes of recycled polypropylene/microcrystalline cellulose composites. Mater Des 69:114–123

Rantheesh J, Indran S, Raja S, Siengchin S (2022) Isolation and characterization of novel micro cellulose from Azadirachta indica A. Juss agro-industrial residual waste oil cake for futuristic applications. Biomass Convers Biorefin 13(5):4393–4411. https://doi.org/10.1007/S13399-022-03467-0

Jagadeesan R, Suyambulingam I, Somasundaram R et al (2023) Isolation and characterization of novel microcellulose from Sesamum indicum agro-industrial residual waste oil cake: conversion of biowaste to wealth approach. Biomass Convers Biorefin 1:1–15. https://doi.org/10.1007/S13399-022-03690-9

Bai W, Li K (2009) Partial replacement of silica with microcrystalline cellulose in rubber composites. Compos Part A Appl Sci Manuf 40:1597–1605

Kong Q, Lu H, Chen Z, Fan W (2005) Synthesis and properties of polystyrene/Fe-montmorillonite nanocomposites using synthetic Fe-montmorillonite by bulk polymerization. J Mater Sci 40:4505–4509

Krishnasamy P, Rajamurugan G, Aravindraj S, Sudhagar PE (2020) Vibration and wear characteristics of aloevera/flax/hemp woven fiber epoxy composite reinforced with wire mesh and BaSO4. J Nat Fibers 19:2885–2901. https://doi.org/10.1080/15440478.2020.1835782

Rizkiansyah RR, Mardiyati S, Suratman R (2016) Crystallinity and thermal resistance of microcrystalline cellulose prepared from manau rattan (Calamusmanan). In: AIP Conference Proceedings. American Institute of Physics Inc.

Szcześniak L, Rachocki A, Tritt-Goc J (2008) Glass transition temperature and thermal decomposition of cellulose powder. Cellulose 15:445–451. https://doi.org/10.1007/s10570-007-9192-2

Paes SS, Sun S, MacNaughtan W et al (2010) The glass transition and crystallization of ball milled cellulose. Cellulose 17:693–709. https://doi.org/10.1007/s10570-010-9425-7

Tarchoun AF, Trache D, Klapötke TM (2019) Microcrystalline cellulose from Posidonia oceanica brown algae: extraction and characterization. Int J Biol Macromol 138:837–845. https://doi.org/10.1016/j.ijbiomac.2019.07.176

Kuthi FA, Norzali NR, Badri KH (2016) Sifat terma mikrokristal selulosa daripada biojisim tandan kosong sawit. Malaysian J Anal Sci 20:1112–1122. https://doi.org/10.17576/mjas-2016-2005-17

Yohana Chaerunisaa A, Sriwidodo S, Abdassah M (2020) Microcrystalline cellulose as pharmaceutical excipient. In: Pharmaceutical Formulation Design - Recent Practices. IntechOpen

Susi S, Ainuri M, Wagiman W, Falah MAF (2022) Effect of delignification and bleaching stages on cellulose purity of oil palm empty fruit bunches. In: IOP Conference Series: Earth and Environmental Science. Institute of Physics

Mohanty A, Rout PR, Dubey B, Meena SS, Pal P, Goel M (2021) A critical review on biogas production from edible and non-edible oil cakes. Biomass Convers Biorefin 2021:1–8. https://doi.org/10.1007/s13399-021-01292-5

Kumar GA, Panwar VS, Yadav KR, Sihag S (2002) Mustard cake as a source of dietary protein for growing lambs. Small Ruminant Res 44(1):47–51

Ganesh Babu A, Saravanakumar SS (2022) Mechanical and physicochemical properties of green bio-films from poly(Vinyl Alcohol)/ nano rice hull fillers. Polym Bull 79:5365–5387. https://doi.org/10.1007/s00289-021-03757-z

Trache D, Hussin MH, Hui Chuin CT et al (2016) Microcrystalline cellulose: Isolation, characterization and bio-composites application—a review. Elsevier B.V

Kalita RD, Nath Y, Ochubiojo ME, Buragohain AK (2013) Extraction and characterization of microcrystalline cellulose from fodder grass; Setaria glauca (L) P. Beauv, and its potential as a drug delivery vehicle for isoniazid, a first line antituberculosis drug. Colloids Surf B 108:85–89. https://doi.org/10.1016/j.colsurfb.2013.02.016

Khatoon BHG, Khatoon H, Solanki P et al (2017) Role of microbes in organic carbon decomposition and maintenance of soil ecosystem. Int J Chem Stud 5:1648–1656

Pinto E, Aggrey WN, Boakye P, Amenuvor G, Sokama-Neuyam YA, Fokuo MK, Karimaie H, Sarkodie K, Adenutsi CD, Erzuah S, Rockson MA (2022) Cellulose processing from biomass and its derivatization into carboxymethylcellulose: A review. Sci African 1(15):e01078

Roy R, Rahman MS, Raynie DE (2020) Recent advances of greener pretreatment technologies of lignocellulose. Curr Opin Green Sustain Chem 1(3):100035

Ghaemi F, Abdullah LC, Ariffin H (2019) Lignocellulose structure and the effect on nanocellulose production. In: Lignocellulose for Future Bioeconomy, vol bll. Elsevier, pp 17–30

Martins MA, Teixeira EM, Corrêa AC et al (2011) Extraction and characterization of cellulose whiskers from commercial cotton fibers. J Mater Sci 46:7858–7864. https://doi.org/10.1007/s10853-011-5767-2

Rostami R, Zarrebini M, Mandegari M et al (2020) A review on performance of polyester fibers in alkaline and cementitious composites environments. Constr Build Mater 241:117998. https://doi.org/10.1016/j.conbuildmat.2020.117998

Megalingam A, Kumar M, Sriram B et al (2021) Borassus fruit fiber reinforced composite: a review. Mater Today Proc 45:723–728. https://doi.org/10.1016/j.matpr.2020.02.750

Balasubramanian K, Rajeswari N, Vaidheeswaran K (2019) Analysis of mechanical properties of natural fibre composites by experimental with FEA. Mater Today Proc 28:1149–1153. https://doi.org/10.1016/j.matpr.2020.01.098

Bruton K, Hazael R, Critchley R, Bloodworth-Race S (2020) Lignocellulosic natural fibers in polymer composite materials: benefits, challenges and applications. Ref Modul Mater Sci Mater Eng 13:1–17. https://doi.org/10.1016/b978-0-12-820352-1.00053-5

Narayanasamy P, Balasundar P, Senthil S et al (2020) Characterization of a novel natural cellulosic fiber from Calotropis gigantea fruit bunch for ecofriendly polymer composites. Int J Biol Macromol 150:793–801. https://doi.org/10.1016/j.ijbiomac.2020.02.134

Ramasamy M, Daniel AA, Nithya M et al (2020) Characterization of natural - synthetic fiber reinforced epoxy based composite - hybridization of kenaf fiber and kevlar fiber. Mater Today Proc 37:1699–1705. https://doi.org/10.1016/j.matpr.2020.07.243

Hadiji H, Assarar M, Zouari W, Pierre F, Behlouli K, Zouari B, Ayad R (2020) Damping analysis of nonwoven natural fibre-reinforced polypropylene composites used in automotive interior parts. Polymer Testing. 1(89):106692

Hota G, Barker W, Manalo A (2020) Degradation mechanism of glass fiber/vinylester-based composite materials under accelerated and natural aging. Constr Build Mater 256:119462. https://doi.org/10.1016/j.conbuildmat.2020.119462

Manimaran P, Senthamaraikannan P, Sanjay MRR et al (2018) Study on characterization of Furcraea foetida new natural fiber as composite reinforcement for lightweight applications. Carbohydr Polym 181:650–658. https://doi.org/10.1016/j.carbpol.2017.11.099

Sanjay MR, Arpitha GR, Senthamaraikannan P et al (2019) The hybrid effect of jute/kenaf/E-glass woven fabric epoxy composites for medium load applications: impact, inter-laminar strength, and failure surface characterization. J Nat Fibers 16:600–612. https://doi.org/10.1080/15440478.2018.1431828

Sathyaseelan P, Sellamuthu P, Palanimuthu L (2021) Dynamic mechanical analysis of areca/kenaf fiber reinforced epoxy hybrid composites fabricated in different stacking sequences. Mater Today Proc 39:1202–1205. https://doi.org/10.1016/j.matpr.2020.03.590

Bambach MR (2020) Durability of natural fibre epoxy composite structural columns: High cycle compression fatigue and moisture ingress. Compos Part C Open Access 2:100013. https://doi.org/10.1016/j.jcomc.2020.100013

Reddy RA, Yoganandam K, Mohanavel V (2020) Effect of chemical treatment on natural fiber for use in fiber reinforced composites - review. Mater Today Proc 33:2996–2999. https://doi.org/10.1016/j.matpr.2020.02.982

Shariff M, Nagamadhu M, Jaiprakash M et al (2019) Effect of drilling process parameters on natural fiber reinforced basket epoxy composites using grey relational analysis. Mater Today Proc 24:2255–2264. https://doi.org/10.1016/j.matpr.2020.03.753

Nadeem H, Malan P, Khan A et al (2021) New insights on the utilization of ultrasonicated mustard seed cake: chemical composition and antagonistic potential for root-knot nematode, Meloidogyne javanica. J Zhejiang Univ Sci B 22:563–574. https://doi.org/10.1631/jzus.B2000746

Suryadi H, Sutriyo AM, Murti MW (2018) Characterization of microcrystalline cellulose obtained from enzymatic hydrolysis of alpha-cellulose and its application. J Young Pharm 10:s87–s92. https://doi.org/10.5530/jyp.2018.2s.17

Picker KM, Hoag SW (2002) Characterization of the thermal properties of microcrystalline cellulose by modulated temperature differential scanning calorimetry. J Pharm Sci 91(2):342–349

Benkhaya S, M'rabet S, El Harfi A (2020) A review on classifications, recent synthesis and applications of textile dyes. Inorg Chem Commun 1(115):107891

Jagadeesan R, Suyambulingam I, Divakaran D, Siengchin S (2022) Novel sesame oil cake biomass waste derived cellulose micro-fillers reinforced with basalt/banana fibre-based hybrid polymeric composite for lightweight applications. Biomass Convers Biorefin 28:1–6. https://doi.org/10.1007/s13399-022-03570-2

Kallel F, Bettaieb F, Khiari R et al (2016) Isolation and structural characterization of cellulose nanocrystals extracted from garlic straw residues. Ind Crops Prod 87:287–296. https://doi.org/10.1016/j.indcrop.2016.04.060

Fareez IM, Ibrahim NA, Wan Yaacob WMH et al (2018) Characteristics of cellulose extracted from Josapine pineapple leaf fibre after alkali treatment followed by extensive bleaching. Cellulose 25:4407–4421. https://doi.org/10.1007/s10570-018-1878-0

Mercy JL, Velmurugan R, Sasipraba T, Jacob C (2020) Neurofuzzy modelling of moisture absorption kinetics and its effect on the mechanical properties of pineapple fibre-reinforced polypropylene composite. J Compos Mater 54:899–912. https://doi.org/10.1177/0021998319870581

Kouadri I, Satha H (2018) Extraction and characterization of cellulose and cellulose nanofibers from Citrullus colocynthis seeds. Ind Crops Prod 124:787–796. https://doi.org/10.1016/j.indcrop.2018.08.051

Maryana R, Muryanto TE et al (2022) Extraction of cellulose acetate from cajuput (Melaleuca leucadendron) twigs and sugarcane (Saccharum officinarum) bagasse by environmentally friendly approach. Waste and Biomass Valorization 13:1535–1545. https://doi.org/10.1007/S12649-021-01610-Y/FIGURES/5

Bezazi A, Belaadi A, Bourchak M et al (2014) Novel extraction techniques, chemical and mechanical characterisation of Agave americana L. natural fibres. Compos Part B Eng 66:194–203. https://doi.org/10.1016/j.compositesb.2014.05.014

Shanmugam V, Mensah RA, Försth M et al (2021) Circular economy in biocomposite development: state-of-the-art, challenges and emerging trends. Compos Part C Open Access 5:100138. https://doi.org/10.1016/j.jcomc.2021.100138

Hao W, Wang M, Zhou F et al (2020) A review on nanocellulose as a lightweight filler of polyolefin composites. Carbohydr Polym 243:116466. https://doi.org/10.1016/j.carbpol.2020.116466

Harini K, Chandra Mohan C (2020) Isolation and characterization of micro and nanocrystalline cellulose fibers from the walnut shell, corncob and sugarcane bagasse. Int J Biol Macromol 163:1375–1383. https://doi.org/10.1016/j.ijbiomac.2020.07.239

Reddy N, Yang Y (2008) Characterizing natural cellulose fibers from velvet leaf (Abutilon theophrasti) stems. Bioresour Technol 99:2449–2454. https://doi.org/10.1016/j.biortech.2007.04.065

Collazo-Bigliardi S, Ortega-Toro R, Chiralt Boix A (2018) Isolation and characterisation of microcrystalline cellulose and cellulose nanocrystals from coffee husk and comparative study with rice husk. Carbohydr Polym 191:205–215. https://doi.org/10.1016/j.carbpol.2018.03.022

Ibrahim IK, Hussin SM, Al-Obaidi Y (2015) Extraction of cellulose nano crystalline from cotton by ultrasonic and its morphological and structural characterization. Int J Mater Chem Phys 1:99–109

Sanjay MR, Siengchin S, Parameswaranpillai J et al (2019) A comprehensive review of techniques for natural fibers as reinforcement in composites: preparation, processing and characterization. Carbohydr Polym 207:108–121. https://doi.org/10.1016/j.carbpol.2018.11.083

Sumesh KRK, Kanthavel K, Kavimani V (2020) Machinability of hybrid natural fiber reinforced composites with cellulose micro filler incorporation. J Compos Mater 54:3655–3671. https://doi.org/10.1177/0021998320918020

Dominic CDM, Joseph R, Sabura Begum PM et al (2020) Chitin nanowhiskers from shrimp shell waste as green filler in acrylonitrile-butadiene rubber: Processing and performance properties. Carbohydr Polym 245:116505. https://doi.org/10.1016/j.carbpol.2020.116505

Valášek P, Müller M (2014) Biocomposite based on epoxy resin and Jatropha curcas L. microparticles. In: Advanced Materials Research, vol bll. Trans Tech Publications Ltd, pp 446–449

Nagarajan KJ, Balaji AN, Kasi Rajan ST, Ramanujam NR (2020) Preparation of bio-eco based cellulose nanomaterials from used disposal paper cups through citric acid hydrolysis. Carbohydr Polym 235:115997. https://doi.org/10.1016/j.carbpol.2020.115997

Reddy KO, Uma Maheswari C, Muzenda E et al (2016) Extraction and characterization of cellulose from pretreated Ficus (Peepal Tree) leaf fibers. J Nat Fibers 13:54–64. https://doi.org/10.1080/15440478.2014.984055

Manikandan KM, Yelilarasi A, Saravanakumar SS et al (2019) Effect of imidazole based polymer blend electrolytes for dye-sensitized solar cells in energy harvesting window glass applications. Chinese J Chem Eng 27:2807–2814. https://doi.org/10.1016/j.cjche.2019.03.034

Ganapathy T, Sathiskumar R, Senthamaraikannan P et al (2019) Characterization of raw and alkali treated new natural cellulosic fibres extracted from the aerial roots of banyan tree. Int J Biol Macromol 138:573–581. https://doi.org/10.1016/j.ijbiomac.2019.07.136

Merci A, Urbano A, Grossmann MVE et al (2015) Properties of microcrystalline cellulose extracted from soybean hulls by reactive extrusion. Food Res Int 73:38–43. https://doi.org/10.1016/j.foodres.2015.03.020

Chen Y, Zheng W, Xu S et al (2022) Characteristics of mineral fillers and their effects on mastic fracture resistance at intermediate temperature 20 °C. Constr Build Mater 323:126568. https://doi.org/10.1016/j.conbuildmat.2022.126568

Reddy KO, Maheswari CU, Dhlamini MS et al (2018) Extraction and characterization of cellulose single fibers from native african napier grass. Carbohydr Polym 188:85–91. https://doi.org/10.1016/j.carbpol.2018.01.110

Li M, He B, Zhao L (2019) Isolation and characterization of microcrystalline cellulose from Cotton Stalk Waste. BioResources 14:3231–3246. https://doi.org/10.15376/biores.14.2.3231-3246

Jittin V, Rithuparna R, Bahurudeen A, Pachiappan B (2021) Synergistic use of typical agricultural and industrial by-products for ternary cement: a pathway for locally available resource utilisation. J Clean Prod 279:123448. https://doi.org/10.1016/j.jclepro.2020.123448

Li J, Hu B, Hui K et al (2021) Effects of inorganic nanofibers and high char yield fillers on char layer structure and ablation resistance of ethylene propylene diene monomer composites. Compos Part A Appl Sci Manuf 150:106633. https://doi.org/10.1016/j.compositesa.2021.106633

Piah MRM, Baharum A, Abdullah I (2016) Mechanical properties of bio-composite natural rubber/high density polyethylene/ mengkuang fiber (NR/HDPE/MK). Polym Polym Compos 24:767–774. https://doi.org/10.1177/096739111602400913

Gabriel T, Belete A, Syrowatka F et al (2020) Extraction and characterization of celluloses from various plant byproducts. Int J Biol Macromol 158:1248–1258. https://doi.org/10.1016/j.ijbiomac.2020.04.264

Abu-Thabit NY, Judeh AA, Hakeem AS et al (2020) Isolation and characterization of microcrystalline cellulose from date seeds (Phoenix dactylifera L.). Int J Biol Macromol 155:730–739. https://doi.org/10.1016/j.ijbiomac.2020.03.255

Kassab Z, Abdellaoui Y, Salim MH, El Achaby M (2020) Cellulosic materials from pea (Pisum Sativum) and broad beans (Vicia Faba) pods agro-industrial residues. Mater Lett 280:128539. https://doi.org/10.1016/j.matlet.2020.128539

Zia KM, Akram N, Tabasum S, Noreen A, Akbar MU (2021) Processing Technology for Bio-Based Polymers: Advanced Strategies and Practical Aspects. Elsevier

Thomas SK, Parameswaranpillai J, Krishnasamy S et al (2021) A comprehensive review on cellulose, chitin, and starch as fillers in natural rubber biocomposites. Carbohydr Polym Technol Appl 2:100095. https://doi.org/10.1016/j.carpta.2021.100095

Arpitha GR, Verma A, Gorbatyuk S, Khan A, Sobahi TR, Asiri AM, Siengchin S (2022) Bio-composite film from corn starch based vetiver cellulose. J Nat Fibers 19(16):14634–14644. https://doi.org/10.1080/15440478.2022.2068174

Rastogi S, Verma A, Singh VK (2020) Experimental response of nonwoven waste cellulose fabric–reinforced epoxy composites for high toughness and coating applications. Mater Perform Charact 9(1):151–172. https://doi.org/10.1520/MPC20190251

Chaturvedi S, Kataria A, Chaudhary V, Verma A, Jain N, Sanjay MR, Siengchin S (2023) Bionanocomposites reinforced with cellulose fibers and agro-industrial wastes. In: Cellulose Fibre Reinforced Composites. Woodhead Publishing, pp 317–342. https://doi.org/10.1016/B978-0-323-90125-3.00017-3

Kataria A, Chaturvedi S, Chaudhary V, Verma A, Jain N, Sanjay MR, Siengchin S (2023) Cellulose fiber-reinforced composites—history of evolution, chemistry, and structure. In: Cellulose Fibre Reinforced Composites. Woodhead Publishing, pp 1–22. https://doi.org/10.1016/B978-0-323-90125-3.00012-4

Maran M, Kumar R, Senthamaraikannan P et al (2020) Suitability evaluation of Sida mysorensis plant fiber as reinforcement in polymer composite. J Nat Fibers 00:1–11. https://doi.org/10.1080/15440478.2020.1787920

Munagapati VS, Wen HY, Wen JC et al (2022) Adsorption of Reactive Red 195 from aqueous medium using Lotus (Nelumbo nucifera) leaf powder chemically modified with dimethylamine: characterization, isotherms, kinetics, thermodynamics, and mechanism assessment. Int J Phytoremediation 24:131–144. https://doi.org/10.1080/15226514.2021.1929060

Indran S, Raj REE, Daniel BSSSS, Saravanakumar SSS (2016) Cellulose powder treatment on Cissus quadrangularis stem fiber-reinforcement in unsaturated polyester matrix composites. J Reinf Plast Compos 35:212–227. https://doi.org/10.1177/0731684415611756

Wang S, Peng X, Zhong L et al (2015) Choline chloride/urea as an effective plasticizer for production of cellulose films. Carbohydr Polym 117:133–139. https://doi.org/10.1016/j.carbpol.2014.08.113

Mtibe A, Linganiso LZ, Mathew AP et al (2015) A comparative study on properties of micro and nanopapers produced from cellulose and cellulose nanofibres. Carbohydr Polym 118:1–8. https://doi.org/10.1016/j.carbpol.2014.10.007

Qing Y, Sabo R, Zhu JY et al (2013) A comparative study of cellulose nanofibrils disintegrated via multiple processing approaches. Carbohydr Polym 97:226–234. https://doi.org/10.1016/j.carbpol.2013.04.086

Manikandan KM, Yelilarasi A, Senthamaraikannan P et al (2019) A study on optical limiting properties of Eosin-Y and Eriochrome Black-T dye-doped poly (vinyl alcohol) composite film. Int J Polym Anal Charact 24:326–333. https://doi.org/10.1080/1023666X.2019.1596366

Chung C, Lee M, Choe EK (2004) Characterization of cotton fabric scouring by FT-IR ATR spectroscopy. Carbohydr Polym 58:417–420. https://doi.org/10.1016/j.carbpol.2004.08.005

Song YR, Han AR, Lim TG et al (2019) Isolation, purification, and characterization of novel polysaccharides from lotus (Nelumbo nucifera) leaves and their immunostimulatory effects. Int J Biol Macromol 128:546–555. https://doi.org/10.1016/j.ijbiomac.2019.01.131

Funding

This research was fully supported by King Mongkut’s University of Technology North Bangkok under grant no. KMUTNB-Post-66-08.

Author information

Authors and Affiliations

Contributions

All authors equally contributed to conceptualization, methodology, writing—original draft, and writing—review & editing.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Divakaran, D., Sriariyanun, M., Jagadeesan, R. et al. Isolation and characterization of an agro-industrial waste-based novel cellulosic micro fillers from mustard (Brassica juncea) seed oil cake: A waste to wealth approach. Biomass Conv. Bioref. (2023). https://doi.org/10.1007/s13399-023-04346-y

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-04346-y