Abstract

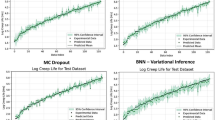

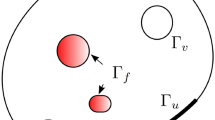

This paper presents an uncertainty quantification (UQ) framework for the physics-based model prediction of material response with a large number of parameters. The application problem presented in this work is that of predicting creep in Grade 91 steel at 600 °C. The material response is defined with a physically based microstructural model with constitutive equations emulating several observed phenomena in Grade 91 and embodied into an explicit geometry mesoscale finite element model for prior austenite grains and grain boundaries. Creep within the grains and in grain boundaries are represented by crystal plasticity for dislocation motion and a physics-based model for cavity growth and nucleation, respectively. The creep behavior of this material is influenced by several parameters, some of which have a wide range of variation based on experimental data. UQ combined with microstructural modeling can discover the core microstructural causes of experimental variability, leading to improved materials with lower variability in critical long-term material properties. In this study, we investigate the model's uncertainty to identify material properties that may be modified during production to increase creep life and analyze different components of the crystal plasticity model for improvements. For this purpose, a quantity of interest is defined as time to minimum creep rate, which correlates well to the creep failure of the material. A deep neural network model was trained and validated to be used as a surrogate for the finite element model. Then, a variance-based sensitivity analysis is performed on the surrogate model to find the Sobol indices of the input parameters in respect to the output quantity of interest. The Sobol indices are used to reduce the dimensionality of the model. Generalized polynomial chaos expansion is used on the reduced basis models to propagate the uncertainty from the input parameters to the quantity of interest using the deep neural network surrogate model. These results are benchmarked against uncertainty propagation using Monte Carlo simulations. The UQ performed through the reduced basis model captures almost all the uncertainty in the model with significantly fewer simulations, making it possible to perform the UQ directly via simulations with the finite element model rather than surrogate machine-learned models.

Similar content being viewed by others

References

Charit I, Murty KL (2010) Structural materials issues for the next generation fission reactors. JOM 62:67–74. https://doi.org/10.1007/s11837-010-0142-3

Wilshire B, Scharning PJ (2008) A new methodology for analysis of creep and creep fracture data for 9–12% chromium steels. Int Mater Rev 53:91–104. https://doi.org/10.1179/174328008X254349

Kloc L, Sklenička V (1997) Transition from power-law to viscous creep behaviour of p-91 type heat-resistant steel. Mater Sci Eng A 234:962–965. https://doi.org/10.1016/S0921-5093(97)00364-X

Panait CG, Bendick W, Fuchsmann A et al (2010) Study of the microstructure of the Grade 91 steel after more than 100,000 h of creep exposure at 600 °C. Int J Press Vessels Pip 87:326–335. https://doi.org/10.1016/j.ijpvp.2010.03.017

Shrestha T, Basirat M, Charit I et al (2012) Creep deformation mechanisms in modified 9Cr–1Mo steel. J Nucl Mater 423:110–119. https://doi.org/10.1016/j.jnucmat.2012.01.005

Moosbrugger JC (1992) Nonisothermal constitutive model for the small strain behavior of 9Cr-1 Mo-V-Nb pressure vessel steel. J Eng Mater Technol 114:354–361. https://doi.org/10.1115/1.2904185

Chaboche JL (1988) Continuum damage mechanics: part II—damage growth, crack initiation, and crack growth. J Appl Mech 55:65–72. https://doi.org/10.1115/1.3173662

Chaboche JL (1989) Constitutive equations for cyclic plasticity and cyclic viscoplasticity. Int J Plast 5:247–302. https://doi.org/10.1016/0749-6419(89)90015-6

Panait CG, Zielińska-Lipiec A, Koziel T et al (2010) Evolution of dislocation density, size of subgrains and MX-type precipitates in a P91 steel during creep and during thermal ageing at 600 C for more than 100,000 h. Mater Sci Eng, A 527:4062–4069. https://doi.org/10.1016/j.msea.2010.03.010

Sawada K, Kushima H, Hara T et al (2014) Heat-to-heat variation of creep strength and long-term stability of microstructure in Grade 91 steels. Mater Sci Eng, A 597:164–170. https://doi.org/10.1016/j.msea.2013.12.088

Abe F (2004) Coarsening behavior of lath and its effect on creep rates in tempered martensitic 9Cr–W steels. Mater Sci Eng, A 387–389:565–569. https://doi.org/10.1016/j.msea.2004.01.057

Abe F (2016) Progress in creep-resistant steels for high efficiency coal-fired power plants. J Pressure Vessel Technol 138:040804–040804. https://doi.org/10.1115/1.4032372

Dyson BF (2009) Microstructure based creep constitutive model for precipitation strengthened alloys: theory and application. Mater Sci Technol 25:213–220. https://doi.org/10.1179/174328408X369348

Christopher J, Choudhary BK (2014) Dislocation-density-based constitutive modelling of tensile flow and work-hardening behaviour of P92 steel. Phil Mag 94:2992–3016. https://doi.org/10.1080/14786435.2014.944608

Christopher J, Choudhary B (2019) Prediction of long-term creep behaviour of Grade 91 steel at 873 K in the framework of microstructure-based creep damage mechanics approach. Int J Damage Mech 28:105678951879611. https://doi.org/10.1177/1056789518796118

Oruganti R, Karadge M, Swaminathan S (2013) A comprehensive creep model for advanced 9–10% Cr ferritic steels. Procedia Engineering 55:727–734. https://doi.org/10.1016/j.proeng.2013.03.322

Basirat M, Shrestha T, Potirniche GP et al (2012) A study of the creep behavior of modified 9Cr–1Mo steel using continuum-damage modeling. Int J Plast 37:95–107. https://doi.org/10.1016/j.ijplas.2012.04.004

Li M, Pham M-S, Peng Z et al (2018) Creep deformation mechanisms and CPFE modelling of a nickel-base superalloy. Mater Sci Eng, A 718:147–156. https://doi.org/10.1016/j.msea.2018.01.100

Zhao J, Gong J, Saboo A et al (2018) Dislocation-based modeling of long-term creep behaviors of Grade 91 steels. Acta Mater 149:19–28. https://doi.org/10.1016/j.actamat.2018.02.001

McHugh PE, Mohrmann R (1997) Modelling of creep in a Ni base superalloy using a single crystal plasticity model. Comput Mater Sci 9:134–140. https://doi.org/10.1016/S0927-0256(97)00067-0

Ma A, Dye D, Reed RC (2008) A model for the creep deformation behaviour of single-crystal superalloy CMSX-4. Acta Mater 56:1657–1670. https://doi.org/10.1016/j.actamat.2007.11.031

Wu R, Sandström R (1996) Strain dependence of creep cavity nucleation in low alloy and 12%Cr steels. Mater Sci Technol 12:405–415. https://doi.org/10.1179/026708396790165858

Gaffard V (2004) Experimental study and modelling of high temperature creep flow and damage behaviour of 9Cr1Mo-NbV. Ecole Des Mines De Paris

Gupta C, Toda H, Schlacher C et al (2013) Study of creep cavitation behavior in tempered martensitic steel using synchrotron micro-tomography and serial sectioning techniques. Mater Sci Eng, A 564:525–538. https://doi.org/10.1016/j.msea.2012.12.002

Shrestha T, Basirat M, Charit I et al (2013) Creep rupture behavior of Grade 91 steel. Mater Sci Eng, A 565:382–391. https://doi.org/10.1016/j.msea.2012.12.031

Wang X, Wang X, Luo B, Guo J (2018) Analysis of cavity evolution in 9%Cr heat-resistant steel welded joint during creep. Eng Fract Mech. https://doi.org/10.1016/j.engfracmech.2018.08.006

McClintock FA (1968) A criterion for ductile fracture by the growth of holes. J Appl Mech 35:363–371. https://doi.org/10.1115/1.3601204

Rice JR, Tracey DM (1969) On the ductile enlargement of voids in triaxial stress fields. J Mech Phys Solids 17:201–217. https://doi.org/10.1016/0022-5096(69)90033-7

Gurson AL (1977) Continuum theory of ductile rupture by void nucleation and growth: part I—yield criteria and flow rules for porous ductile media. J Eng Mater Technol 99:2–15. https://doi.org/10.1115/1.3443401

Van Der Giessen E, Van Der Burg MWD, Needleman A, Tvergaard V (1995) Void growth due to creep and grain boundary diffusion at high triaxialities. J Mech Phys Solids 43:123–165. https://doi.org/10.1016/0022-5096(94)00059-E

Cerri E, Evangelista E, Spigarelli S, Bianchi P (1998) Evolution of microstructure in a modified 9Cr–1Mo steel during short term creep. Mater Sci Eng, A 245:285–292. https://doi.org/10.1016/S0921-5093(97)00717-X

Goyal S, Laha K, Das CR et al (2013) Finite element analysis of effect of triaxial state of stress on creep cavitation and rupture behaviour of 2.25Cr–1Mo steel. Int J Mech Sci 75:233–243. https://doi.org/10.1016/j.ijmecsci.2013.07.005

Choudhary BK, Isaac Samuel E (2011) Creep behaviour of modified 9Cr–1Mo ferritic steel. J Nucl Mater 412:82–89. https://doi.org/10.1016/j.jnucmat.2011.02.024

Eggeler G, Tato W, Jemmely P, deMestral B (1992) Creep rupture of circular notched P91-specimens: influence of heat treatment and notch geometry. Scr Metall Mater 27:1091–1096. https://doi.org/10.1016/0956-716X(92)90479-X

Fournier B, Sauzay M, Barcelo F et al (2009) Creep-fatigue Interactions in a 9 Pct Cr-1 Pct Mo martensitic steel: part II. Microstructural evolutions. Metall Mater Trans A 40:330–341. https://doi.org/10.1007/s11661-008-9687-y

Gieseke BG, Brinkman CR, Maziasz PJ (1993) The influence of thermal aging on the microstructure and fatigue properties of modified 9Cr-1Mo steel. Oak Ridge National Lab, Oak Ridge

Westwood C, Pan J, Crocombe AD (2004) Nucleation, growth and coalescence of multiple cavities at a grain-boundary. Eur J Mech A Solids 23:579–597. https://doi.org/10.1016/j.euromechsol.2004.02.001

Anderson PM, Rice JR (1985) Constrained creep cavitation of grain boundary facets. Acta Metall 33:409–422. https://doi.org/10.1016/0001-6160(85)90083-5

Mahesh S, Alur KC, Mathew MD (2011) A creep model for austenitic stainless steels incorporating cavitation and wedge cracking. Model Simul Mater Sci Eng 19:015005. https://doi.org/10.1088/0965-0393/19/1/015005

Nassif O, Truster TJ, Ma R et al (2019) Combined crystal plasticity and grain boundary modeling of creep in ferritic-martensitic steels: I. Theory and implementation. Model Simul Mater Sci Eng 27:075009. https://doi.org/10.1088/1361-651X/ab359c

Van Der Giessen E, Tvergaard V (1996) Micromechanics of intergranular creep failure under cyclic loading. Acta Mater 44:2697–2710. https://doi.org/10.1016/1359-6454(95)00399-1

Sham T-L, Needleman A (1983) Effects of triaxial stressing on creep cavitation of grain boundaries. Acta Metall 31:919–926. https://doi.org/10.1016/0001-6160(83)90120-7

Wang R, JIANG S, (2015) Mathematical methods for uncertainty quantification in nonlinear multi-physics systems and their numerical simulations. Sci Sin Math 45:723–738. https://doi.org/10.1360/N012014-00115

Liang X, Wang R (2017) Sensitivity analysis and validation of detonation CFD model. Acta Phys Sin 109:114–121. https://doi.org/10.7498/aps.66.116401

Oberkampf WL, Roy CJ (2010) Verification and validation in scientific computing. Cambridge University Press, Cambridge

Aeschliman DP, Oberkampf WL (1998) Experimental methodology for computational fluid dynamics code validation. AIAA J 36:733–741. https://doi.org/10.2514/2.461

Kozmenkov Y, Kliem S, Rohde U (2015) Validation and verification of the coupled neutron kinetic/thermal hydraulic system code DYN3D/ATHLET. Ann Nucl Energy 84:153–165. https://doi.org/10.1016/j.anucene.2014.12.012

Scovel CA, Menikoff R (2011) High explosive verification and validation: systematic and methodical approach (u). Los Alamos National Lab, Los Alamos

Ghanem RG, Spanos PD (2003) Stochastic finite elements: a spectral approach. Courier Corporation, Chelmsford

Soize C, Ghanem R (2004) Physical systems with random uncertainties: chaos representations with arbitrary probability measure. SIAM J Sci Comput 26:395–410. https://doi.org/10.1137/S1064827503424505

Ghanem R, Red-Horse J (2017) Polynomial chaos: modeling, estimation, and approximation. In: Ghanem R, Higdon D, Owhadi H (eds) Handbook of uncertainty quantification. Springer, Cham. https://doi.org/10.1007/978-3-319-12385-1_13

Doostan A, Ghanem RG, Red-Horse J (2007) Stochastic model reduction for chaos representations. Comput Methods Appl Mech Eng 196:3951–3966. https://doi.org/10.1016/j.cma.2006.10.047

Tipireddy R, Ghanem R (2014) Basis adaptation in homogeneous chaos spaces. J Comput Phys 259:304–317. https://doi.org/10.1016/j.jcp.2013.12.009

Tsilifis P, Ghanem RG (2017) Reduced Wiener Chaos representation of random fields via basis adaptation and projection. J Comput Phys 341:102–120. https://doi.org/10.1016/j.jcp.2017.04.009

Huan X, Geraci G, Safta C, et al (2018) Multifidelity statistical analysis of large eddy simulations in scramjet computations. In: 2018 AIAA non-deterministic approaches conference, p 1180. https://doi.org/10.2514/6.2018-1180

Huan X, Safta C, Sargsyan K et al (2018) Compressive sensing with cross-validation and stop-sampling for sparse polynomial chaos expansions. SIAM/ASA J Uncertain Quantif 6:907–936. https://doi.org/10.1137/17M1141096

Doostan A, Owhadi H (2011) A non-adapted sparse approximation of PDEs with stochastic inputs. J Comput Phys 230:3015–3034. https://doi.org/10.1016/j.jcp.2011.01.002

Ozturk D, Kotha S, Ghosh S (2021) An uncertainty quantification framework for multiscale parametrically homogenized constitutive models (PHCMs) of polycrystalline Ti alloys. J Mech Phys Solids 148:104294. https://doi.org/10.1016/j.jmps.2021.104294

Bandyopadhyay R, Prithivirajan V, Sangid MD (2019) Uncertainty quantification in the mechanical response of crystal plasticity simulations. JOM 71:2612–2624. https://doi.org/10.1007/s11837-019-03551-3

Zhang X, Oskay C (2021) Uncertainty quantification for fatigue nucleation in titanium alloy microstructures. In: AIAA Scitech 2021 Forum. American Institute of Aeronautics and Astronautics, Virtual Event. https://arc.aiaa.org/doi/abs/10.2514/6.2021-1904

Fong JT, Heckert NA, Filliben JJ, Cohn MJ (2018) Uncertainty in multi-scale creep rupture life modeling and a new approach to estimating frequency of in-service inspection of components at elevated temperatures. In: Pressure technology. American Society of Mechanical Engineers, p V001T04A002. https://doi.org/10.1115/ETAM2018-6711

Hossain MA (2020) A probabilistic creep constitutive model for creep deformation, damage, and rupture. PhD Dissertation, University of Texas at El Paso. https://scholarworks.utep.edu/open_etd/3097

Wallace J, Wang R, Mavris D (2003) Creep life uncertainty assessment of a gas turbine airfoil. In: 44th AIAA/ASME/ASCE/AHS/ASC structures, structural dynamics, and materials conference. p 1484. https://doi.org/10.2514/6.2003-1484

Boyce L, CHAMIS C (1991) Quantification of uncertainties in coupled material degradation processes-high temperature, fatigue and creep. In: 32nd structures, structural dynamics, and materials conference, p 977. https://doi.org/10.2514/6.1991-977

Tripathy RK, Bilionis I (2018) Deep UQ: Learning deep neural network surrogate models for high dimensional uncertainty quantification. J Comput Phys 375:565–588. https://doi.org/10.1016/j.jcp.2018.08.036

Naphon P, Wiriyasart S, Arisariyawong T, Nakharintr L (2019) ANN, numerical and experimental analysis on the jet impingement nanofluids flow and heat transfer characteristics in the micro-channel heat sink. Int J Heat Mass Transf 131:329–340. https://doi.org/10.1016/j.ijheatmasstransfer.2018.11.073

Karumuri S, Tripathy R, Bilionis I, Panchal J (2020) Simulator-free solution of high-dimensional stochastic elliptic partial differential equations using deep neural networks. J Comput Phys 404:109120. https://doi.org/10.1016/j.jcp.2019.109120

Madsen HO, Bazant ZP (1983) Uncertainty analysis of creep and shrinkage effects in concrete structures. ACI J 80:116–127

Kimura K, Kushima H, Sawada K (2009) Long-term creep deformation property of modified 9Cr–1Mo steel. Mater Sci Eng, A 510–511:58–63. https://doi.org/10.1016/j.msea.2008.04.095

Messner MC, Nassif O, Ma R et al (2019) Combined crystal plasticity and grain boundary modeling of creep in ferritic-martensitic steels: II. The effect of stress and temperature on engineering and microstructural properties. Model Simul Mater Sci Eng 27:075010. https://doi.org/10.1088/1361-651X/ab359f

Cunha A, Nasser R, Sampaio R et al (2014) Uncertainty quantification through the Monte Carlo method in a cloud computing setting. Comput Phys Commun 185:1355–1363. https://doi.org/10.1016/j.cpc.2014.01.006

Ernst OG, Mugler A, Starkloff H-J, Ullmann E (2012) On the convergence of generalized polynomial chaos expansions. ESAIM: M2AN 46:317–339. https://doi.org/10.1051/m2an/2011045

Genz A, Keister BD (1996) Fully symmetric interpolatory rules for multiple integrals over infinite regions with Gaussian weight. J Comput Appl Math 71:299–309. https://doi.org/10.1016/0377-0427(95)00232-4

Feinberg J, Eck VG, Langtangen HP (2018) Multivariate polynomial chaos expansions with dependent variables. SIAM J Sci Comput 40:A199–A223. https://doi.org/10.1137/15M1020447

Feinberg J, Langtangen HP (2015) Chaospy: an open source tool for designing methods of uncertainty quantification. J Comput Sci 11:46–57. https://doi.org/10.1016/j.jocs.2015.08.008

Adams B, Bohnhoff W, Dalbey K et al (2020) Dakota, A multilevel parallel object-oriented framework for design optimization, parameter estimation, uncertainty quantification, and sensitivity analysis: version 6.13 User’s Manual. Sandia National Lab, Albuquerque

Eldred MS, Dalbey KR, Bohnhoff WJ et al (2010) DAKOTA: a multilevel parallel object-oriented framework for design optimization, parameter estimation, uncertainty quantification, and sensitivity analysis. Version 5.0, user’s manual. Sandia National Laboratories, Albuquerque

Ferretti F, Saltelli A, Tarantola S (2016) Trends in sensitivity analysis practice in the last decade. Sci Total Environ 568:666–670. https://doi.org/10.1016/j.scitotenv.2016.02.133

Messner MC, Truster TJ, Cochran KB et al (2017) Fy17 status report on the micromechanical finite element modeling of creep fracture of grade 91 steel. Argonne National Lab, Argonne. https://doi.org/10.2172/1401966

Lo Piano S, Ferretti F, Puy A et al (2021) Variance-based sensitivity analysis: the quest for better estimators and designs between explorativity and economy. Reliab Eng Syst Saf 206:107300. https://doi.org/10.1016/j.ress.2020.107300

Vojdani A, Farrahi GH, Mehmanparast A, Wang B (2018) Probabilistic assessment of creep-fatigue crack propagation in austenitic stainless steel cracked plates. Eng Fract Mech 200:50–63. https://doi.org/10.1016/j.engfracmech.2018.07.022

Mao H, Mahadevan S (2000) Reliability analysis of creep–fatigue failure. Int J Fatigue 22:789–797. https://doi.org/10.1016/S0142-1123(00)00046-3

Dodds RH, Darwin D, Leibengood LD (1984) Stress controlled smeared cracking in R/C beams. J Struct Eng 110:1959–1976. https://doi.org/10.1061/(ASCE)0733-9445(1984)110:9(1959)

Acknowledgements

The work of MCM was sponsored by the U.S. Department of Energy, under Contract No. DEAC02-06CH11357 with Argonne National Laboratory, managed and operated by UChicago Argonne LLC with funding provided by the U. S. Department of Energy, Office of Nuclear Energy.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Behnam, A., Truster, T.J., Tipireddy, R. et al. Uncertainty Quantification Framework for Predicting Material Response with Large Number of Parameters: Application to Creep Prediction in Ferritic-Martensitic Steels Using Combined Crystal Plasticity and Grain Boundary Models. Integr Mater Manuf Innov 11, 516–531 (2022). https://doi.org/10.1007/s40192-022-00277-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40192-022-00277-0