Abstract

There is no consensus in the literature on the need to remove preprocessing layers from the material prior to the measurement of residual stresses by X-ray diffractometer. Thus, the purpose of this work was to evaluate the residual stresses induced by material preprocessing and its evolution during the preparation of the surface by electrolytic removal. Sample surfaces were pre-processed by grinding and sandblasting and the resulting residual stresses were measured by X-ray diffractometry. At each removal stage, the evolution of residual stresses, hardness and microstructure of the surface were verified. It was concluded that different preprocessing methods can induce surface residual stresses of either tension or compression, reaching different depths. Removal by electrolytic method of the modified layer has shown itself capable of reducing significantly the magnitude of the residual stresses induced by preprocessing. On the other hand, the depth of deformed grains or surface hardness proved to be incapable of predicting the depth of induced residual stresses. Finally, it was discussed whether or not the layers removed by this method reveal the subsurface stresses and if the removal should take place before or after a second processing.

Similar content being viewed by others

1 Introduction

Lachmann et al. [1] ranked measurement speed, portable equipment and safety as reasons for residual stress (RS) measurement through X-ray diffractometry (XRD) to be one of the most used techniques, both in research and in industrial applications. Still according to Lachmann et al., the main limitation of RS measurements by XRD is the limited penetration of the X-rays. Owing to this low penetration, the measurement result represents stresses state only at the surface. These authors, however, point out to the fact that the measurement results can be disguised by material preprocessing. As reported by Robinson et al. [2], Hatori et al. [3] and De Giorgi [4], RS due to preprocessing are concentrated on the workpiece surface and can have both tensile and compressive nature.

Robinson et al. [2] measured RS along the thickness of a cold-forged aluminum plate. On the plate surface, the measurement reached − 300 MPa, with a tendency of turning into tensile stresses at deeper layers. Hattori et al. [3] studied RS in cold rolled aluminum plates. The RS measured was of compressive nature on the surface and of tensile nature at deeper positions. De Giorgi [4] quantified RS on cold rolled plates of AISI 301. The difference between the RS values taken from the surface and from a 0.6-mm-deep layer reached up to − 150 MPa. Che-Haron and Jawaid [5] found a greater than 0.010-mm-thick plastically deformed surface after titanium alloy shaft turning. Nasr et al. [6] observed a deformed surface thickness of 0.140 mm after turning AISI 316 steel. Although in the last two cited papers RS were not measured, it can be deduced that the plastic deformation implies the presence of RS.

Prior to the welding operation, for instance, the plate region near the groove must be cleaned by grinding, machining or shot blasting. As a result, manufacturing related preprocessing superficial modifications can be eliminated in the region under cleaning, but a new surface change is imposed. AISI 316 steel plates blasted with Al2O3 or ZrO showed compressive stresses of 400 MPa in surface layers up to 0.080 mm deep, according to Multinger et al. [7]. Youssef et al. [8] indicated that grinding can induce tensile RS with a value close to the rupture stress of AISI 316L steel. Thus, it is important to know the RS induced by preprocessing and to find out whether it is necessary or not to eliminate them before XRD measurements.

When thermal stresses due to welding are generated on the material, the pre-existing stress field on the surface will certainly assume another value. This fact itself does not characterize a problem for RS measurement, because this is the real situation. However, as XRD measurement occurs on a thin surface, the resulting stress field may not accurately represent what it is desired to measure (which are the stresses that actually will influence on the mechanical behavior of the component). Nevertheless, when one wants to study the parameters that govern RS generation due to welding, unquestionably the pre-existing stress field on the surface will disguise the results of a XRD measurement. In these cases, to guarantee the quality of RS measurement by XRD, the pre-deformed surface is usually eliminated by electrolytic processes, which do not induce plastic deformations.

However, some authors remove 0.100 mm of material before XRD appraisal, others apply a deeper removal. For example, Gou et al. [9] and Hilson et al. [10] made an electrolytic removal of 0.100 mm thick before measuring RS by means of XRD in arc welded tubes (although, none of the researching groups verified if the deformed surface was completely eliminated or not). Rai et al. [11], on the other hand, consider the removal of a 0.020 mm layer as sufficient to eliminate the oxide film effect on measurement results of RS in arc welded tubes. In addition, Brown et al. [12] and Tsuji et al. [13] used electrolytic polishing to prepare the surface before RS measurements. However, the thickness of the removed layer was not specified. Harati et al. [14] did not make any material removal and measured the RS in pieces as received. Furthermore, in all the cited papers, the authors did not take into account the type of manufacturing related preprocessing applied to the plate surface.

On the other hand, there are explicit recommendations upon the surface preparation prior to measuring given in standards, such as one from ASTM International [15], in which a 0.250 mm removal before the measurement of RS by XRD is recommended in section 8.1. Another standard, from British Standards Institution [16] also recommends removal of work-hardened surface, but in this case the thickness is not specified. Conversely, based on the results of literature review, the thickness of the surface deformed by several manufacturing processes varies greatly from one process to another and sometimes a recommended removal of 0.250 mm may be excessive (by removing this thickness, the RS of interest, as RS induced by welding process, may be altered). A relevant issue, also not usually observed by those who investigate or measure RS, is when the altered surface cleanliness must be done. It could be done before or after the stress-generating operation, for example, welding. All the cited papers did it afterward. The questionable would be: if the surface layer removal is done after applying a new RS generation processing (such as welding), would not the new stresses be removed together with the preprocessing stresses? Even when there is surface preparation before measurements, for example, as seen in Gou’s et al. [9] and Hilson’s et al. [10] papers, how can it be ensured that the entire surface changed by a given pre-processing was fully eliminated?

Finally, another phenomenon that apparently affects measurement results is the relaxation of RS over time. The relaxation of RS induced by welding process was recently reported by Estefen et al. [17], when they observed the continuous relaxation of RS during the first 14 days after restrictions removal.

As has been seen, there are antagonistic procedures and recommendations applied to surface preparation before the measurement of RS by XRD. It can be noticed a lack of information upon the alteration that a given type of surface processing can imply in measurement results. Therefore, this study’s aim was to evaluate the RS induced by preprocessing and the evolution of their intensities during the surface preparation by electrolytic removal, considering the potential temporal relaxation over a maturation period.

2 Methodology, equipment and materials

Three batches of plates (AISI 1020 carbon steel, 50 × 50 × 6.35 mm) were prepared. One of them was used for tests with a surface preparation by grinding, a second one for replication with the same preparation and a third one in which the surface preparation was sandblasted. To relieve pre-existing stresses and normalize the microstructure, the three batches of test plates were prior to grinding/sandblasting, individually heated at a temperature of 650 °C, at a rate of 865 °C/h, kept for 2 h and cooled at an average rate of 224 °C/h to room temperature. The average residual stresses measured on the first, second and third batches after the heat treatment were − 70 ± 32, − 8.7 ± 21 and 122 ± 3 MPa, respectively. The search for reasons for the plates to have not reached the same residual status after the heat treatment was not the focus of this work, because the heat treatment objective was to stress relieve and normalize the microstructure, as successfully reached. One could say that these variations could be due to different removal positions of them in relation to the “mother plate”, different removal positions inside the furnace (gradients of temperature), etc.

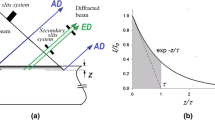

RS measurements were made only in one direction (Y, φ = 0°), as illustrated in Fig. 1, and following ASTM standard [15] recommendations. A commercial portable system was used for RS measurements, applying the technique sin2ψ. Measurements were made for index plane 211, at seven angles ψ [− 30°; − 20°; − 10°; 0°; 10°; 20°; 30°] using Cr, Kα (λ = 2.29 Å) radiation, 25 kV, 0.6 mA with a measurement time of approximately 480 s and a 4-mm-diameter collimator. The RS measurements were replicated (batch 2 of test plates) using another diffractometer, a stationary and benchtop equipment, using Cr Kα radiation, 30 kV, 55 mA, angles ψ [0°; 10°; 14°; 17°; 20°; 22°] with a measurement time of 651 s and a collimator with a 3 × 3 mm aperture and the same index 211 of the diffraction peak. Test plates for replication underwent the same procedure as the first batch. It is worth mentioning that the measurement results obtained represent the stresses of the family of planes <211> and, in this study, it was assumed that the distribution of residual stresses is isotropic among all the families of planes.

In this study, the superficial change of each test plate of the first and second batches was done by manual grinding with Al2O3 disc of grit size 24, at 11,000 rpm rotation, imposing a 15°–20° attack angle for approximately 30 s. To estimate the depth required to be achieved during the removal phase, a cross-section was prepared metallographically for analysis by optical microscopy. Figure 2 shows the difference between the plastically deformed grains on the plate surface and the inside grains, and this visual difference is the criterion to define the deformed surface thickness. Measurements of the plastically deformed thickness (e) were made at four equally spaced points along the 50-mm length of a sample (representing the whole batch). As the grinding process was manual, the repeatability of the process was also verified and at the same time if the RS would be at the same level regardless of the test plate. Therefore, RS was measured on several test plates and analysis of variance was applied. For this grinding process, the average thickness of the deformed surface was 0.066 ± 0.013 mm.

The plate surfaces of the third batch were processed by sandblasting (Fig. 3). The blasting and experimental procedure parameters were taken from Slatineau et al. [18]. Three plates were blasted with #40 granulation for 60 s at a 0.86 MPa pressure and with a 100-mm distance between the blasting gun and the plate surface. Slightly differentiated from the ground plates, RS was measured only after blasting and after removal of 0.140 mm (this depth was taken after Staia et al.’s findings [19], who used similar blasting and suppressed deformed material layers with this figure).

Schematic representation of the sandblasting test plate surface, where d is the distance between the pistol and the plate surface (adapted from Slatineau et al. [18])

The plastically deformed surfaces were removed by electrolytic etching with a solution of 19% H3PO4, 9% H2SO4 and 72% H2O. The removal procedure and electrolyte removal parameters were previously published elsewhere (Mishchenko et al. [20]). Briefly, the electrolyte process adjustments were to obtain approximately 0.020, 0.040, 0.060, 0.080, 0.100, 0.120 and 0.140 mm removals. For each target thickness of removal, two test plates were used, for repeatability control. One of the plates was used only for hardness and deformed thickness measurement. RS and removed thickness measurements were performed on both plates. After measuring the RS, the second plate was saved as an evidence.

Vickers Hardness measurements on the test plate surfaces were with a load of 2000 g. The measurements were carried out immediately after the grinding and after the removal of the work-hardened surface, in the area indicated in Fig. 1, always on five randomly selected points. The removed layer thickness was measured by a micrometer with 0.001 mm resolution. After electrolytic removals and RS measurements, cross sections were taken at the position as indicated in Fig. 4a, to assist in the quantification of the thickness removed. Figure 4b illustrates the electrolytic removal in the cross section.

This study has extended to evaluate the possible stresses relaxation over time, as suggested by Estefen et al. [17]. It is important to mention that the existence of this phenomenon in experimental conditions used in this study will potentially impact the analyzes described above. For this purpose, the value of RS was measured on a test plate ground on both sides, that is, to say on the top surface (face) and the bottom surface (back side). Even assuming that the present paper results would not have to match Estefen’s et al. (distinct RS source, material, experiment conditions, etc.), it was decided to monitor the RS temporal evolution in the ground plate. RS measurements were made for 18 days at an interval of 6 days and no surface removal was applied.

2.1 RS value correction as a function of the removed layer thickness

When layers are removed for residual stress analysis, it is important to consider the stress relaxation on the exposed surface due to subtraction of the mechanical constraint (Noyan and Cohen [21]). The procedure proposed by Moore and Evans [22] is suitable to make corrections owed to this relaxation in flat samples with low thickness, as in the present study. Therefore, Eq. 1 was used to correct the measured values in this work, where ΔZ is the removal thickness, H is the original thickness of the test plate, σm(H) is the RS value measured before surface layer removal, σm(Z) is the RS value measured after Z-mm-thick layer removal and σ(z) is the corrected stress.

It is important to point out that all RS values thereafter presented here are corrected using Eq. (1), except the ones (Sect. 3.1) on test plates without layer removal [by principle, Eq. (1) cannot be applied over results from a plate without material removal].

3 Results and discussion

3.1 Residual stresses temporal evolution and the experiment repeatability

Figure 5 presents the average measured values and their standard deviations of RS on both sides of the plates over 18 days after the surface change of the test plate. Applying analysis of variance (ANOVA) on the data, there was no statistically substantial variation amongst the values for a significance level of 0.05. Conversely, if only visual trends are taken into account, Fig. 5 shows a RS growth according to time, not relaxation. As this fact does not find theoretical justifications to happen, assuming no variation seems reasonable. However, it is important to note that, as seen in Fig. 5, the measured RS value after grinding approaches or exceeds the nominal rupture limit value for AISI 1020 steel. Nevertheless, it is not possible to draw hastened conclusions based on this fact, because the mechanical properties of the surface work-hardened by grinding were unknown, and both the yield and ultimate stress limits of the surface material may have increased. In addition, the observed RS value is in accordance with data found in literature. For example, Youssef et al. [8] studied the effect of manual grinding upon the RS distribution on AISI 316L steel surfaces. Although Youssef’s et al. experimental conditions (grinding material and processing) are different from those of the present study, tensile RS with values close to the material rupture stress were observed by these authors.

Analyzing now the repeatability aspect of the grinding process, Fig. 6 suggests, with the help of ANOVA, that there is no difference of the RS, considering 0.05 as a level of significance, in five randomly selected grinding plates. The RS average value is 460 MPa. Thus, the fact that grinding has been applied manually, it would not be responsible for significant variations in the RS measurement results.

3.2 Evolution of residual stresses and surface microstructure in relation to the layer removed thickness

Corrected RS values using the Moore and Evans methodology for tests and their repetitions are shown in Fig. 7. The corrected RS values were always lower than the measured values and in the present case the relative difference between the measured and corrected values was on average, 3%. The presentation of the measured values without correction application was omitted in Fig. 7 because of this small value of correction, avoiding making difficult the figure interpretation. In this figure, the RS value for zero thickness of the removed layer presents the measured value shortly after grinding. The successive layers removal by electrolytic process resulted in RS continuous relaxation until reaching the measured stress value before surface change. When the removed thickness of 0.120 mm was reached, the RS approached the measured value before surface change − 61 ± 13 MPa calculated after removal of 0.120 mm in contrast to − 70 ± 32 MPa measured before test plates grinding of the first batch. This means that the deformed layers by emery are virtually eliminated and the RS is approaching the measured value before surface change. The similar phenomenon was observed in replicate batch test plates (RS after 0.120 mm removal was ≈ 100 ± 21 versus 122 ± 3 MPa prior to grinding of second batch plates).

To assist in the achieved results analysis, in Fig. 8 are presented the micrograph sections taken from the plates at the electrolytic removal positions. Visually, it can be seen from the images that the deformed grains begin to disappear after 0.041 mm removed and at approximately 0.100 mm the visual difference between grain sizes is not observed anymore. On the other hand, as Fig. 7 indicates, the RS for 0.041-mm-surface removed is still above the RS measured before surface processing, which was − 70 ± 32 MPa. This means that the deformed layers by grinding have not been completely removed, showing the importance of using more than one criterion. This difference among criteria may be due to the impossibility of detecting a microscopic deformation inside the grains by optical microscopy, but it does not mean that they are not stressed. XRD would be a more sensitive criterion. From approximately 0.110 mm removed, the stress already begins to approach the measured initial value before changing the surface. It is noticed, by the micrographic images, an increase in grain size from 0.100 mm of removal thickness. Therefore, based on the measurement results mainly of the RS, it can be inferred that for the ground test plates the plastically deformed surface thickness was 0.100–0.120 mm.

It was expected that, after grinding, the hardness in the surface layers increased (work hardening), decreasing accordingly to the material removal. However, the hardness measurement result had an oscillatory behavior, as seen in Fig. 9. Immediately after grinding, there was an increase in hardness compared to non-ground plate. This result was an expected consequence of the plastic deformation introduced by mechanical work. The highest standard deviation for the measurement right after ground is due to the large surface irregularity because of grinding process and difficulty of measuring the indentation. But in general, the measurement results do not indicate any correlation between the residual stress and the hardness of the test plate material. And, similar to optical microscopy, hardness also revealed not to be a safe method to evaluate the removal of treated surface.

3.3 Residual stresses in test plates with surface treated by sandblasting

It is noticeable, the difference between the surface layer after sandblasting and after the electrolytic removal, as emphasized in Fig. 10. This behavior agrees with the one found by Staia et al. [19], whose, in sandblasting of plain carbon steel surface, obtained approximately same thickness of deformed layers, from 0.080 to 0.100 mm. The residual stress measured after sandblasting was compressive of − 233 ± 29 MPa, reducing after removal of about 0.140 mm to − 138 ± 11 MPa (corrected value according to Sect. 2.1). It is important to remember that the residual stress measured on this test plate batch after the heat treatment was − 70 ± 32 MPa, indicating that, even after 0.137 mm removal, not all RS was eliminated due to sandblasting processing. It is suggested that different types of surface processing may alter the test plate surface in different ways, in both intensity (more or less deeply) and mode (tensile and compressive RS). It should be noted that, according to the micrographic image taken in the removal region and presented in Fig. 10, there was complete absence of the deformed grains after this removal magnitude. These results corroborate those of the previous section, which show that the plastic deformation criterion visible by optical microscopy does not represent the RS depth induced by surface processing.

4 Discussion

The fact that grinding has presented on its surface RS tensile values above the material yield stress and close to or higher than the material rupture limit (in agreement with literature) suggests that the depth of RS induction by grinding is close to 0.140 mm for a non-alloy carbon steel (other values can be reached for alloyed steels, with higher ultimate stress limits). Sandblasting, because it exerts compressive deformation, may even reach greater depth, but the high values of RS reached indicate the saturation point proximity. It is determined that the recommendation in section 8.1 of the ASTM standard [15], that is to say, a 0.250 mm removal before RS measurement by XRD, is well consistent, but depending on the application may be exaggerated, considering the relaxation that can be introduced due to excessive material removal. However, a temporal quantification of RS values along the removal would be the correct way to know if the RS due to preprocessing would have already been removed, at the expense of long time and increasing costs.

Still by the present results, it is suggested that the surfaces layers removal by electrolytic methods would be a way of measuring the RS field in the material thickness, overcoming a XRD technique limitation. Nevertheless, this paper’s authors believe that more studies must be done on this topic. For instance, it is not clear whether the reduction of reached RS as the removed depth is raised (regardless of being tensile or compressive), mean the existent stresses or just the reflex of restriction removal, which was avoiding the stress mechanical relaxation.

On the contrary, this study is able to support a reasoning about either material removal prior to RS measurements should be happen before or after another material processing. For instance, in welding case, the process will generate a particular stress field close to and at the weld bead. If the electrolytic removal is done after welding and before measured by XRD, it may happen that the own stresses generated by the welding process are being removed (therefore, not measured). It may be better to remove the pre-existing surface stresses (in the case of measurements close to the weld bead, not on the bead surface) prior to welding, so that they do not disguise the stresses generated by the weld. In contrast, the argument could be that the correct thing would be to never remove a surface layer before applying XRD, because the final stress is what matters (and the preexisting is part of it). It seems that the removal before welding, not after, is the most correct method to study the welding parameter effect upon the RS generation, since in this case it is necessary to eliminate sources of noise. However, if quantification of RS of an in-service component after a processing is the target, no surface removal should be applied besides the normal cleaning employed before the processing (groove grinding in welding, for instance).

5 Conclusions

In experimental conditions of this paper, which sought to evaluate the residual stresses (RS) using X-ray diffractometer (RXD), which, in turn, are induced by preprocessing, and the evolution of their intensities during surface preparation (work-hardened surface removal by electrolytic process), it was concluded that:

-

(a)

Different preprocessing methods can induce residual stresses in the metal surfaces RS with distinct modes (tensile or compressive) and depth;

-

(b)

Surface treatment with layer removal by electrolytic method has shown itself capable to eliminate the RS induced by preprocessing and a removal layer of about 0.200 mm would be safe to suppress the RS induced by grinding of unalloyed carbon steels;

-

(c)

Deformed grains depth visualized by optical microscopy or surface hardness proved to be incapable of predicting the induced RS depth.

A second purpose of this study, which was to evaluate the potential temporal relaxation during a maturation period of the material prior to the RS measurements, led to the deduction that relaxations does not happen if the material is left resting long time before XRD measurement, at least to reasonably small and non-restrained materials.

Finally, if the intention is to assess the effect of welding parameters on RS generation in a weld joint, surface removal should be applied before welding, not after it. However, if the aim is to quantify the residual stress of a component under service, surface removal dedicated to XRD measurements should not be employed.

Therefore, it is believed to have produced subsidies for the RS measurement procedures in metal plates that undergo pre or post processing prior to RS measurement by XRD. Nevertheless, for future studies, it remains that the task of classifying whether the removed layers through this method reveal or not the subsurface stresses and to demonstrate that removal should take place before or after a second processing.

References

Lachmann C, Nitschke-Pagel T, Wohlfahrt H (1999) Non-destructive characterization of fatigue processes in cyclically loaded welded joints by the Barkhausen noise method. In: 2nd int. workshop on structural health monitoring, Stanford university, Stanford, pp 327–332

Robinson JS, Hossain S, Truman CE, Oliver EC, Hughes DJ, Fox ME (2009) Influence of cold compression on the residual stresses in 7449 forgings. In: 59th Denver X ray conference on application of X ray diffraction, Colorado Springs, pp 667–674

Hattori N, Matsumoto R, Utsunomiya H (2014) Residual stress distribution through thickness in cold-rolled aluminum sheet. Key Eng Mater 622–623:1000–1007. https://doi.org/10.4028/www.scientific.net/KEM.622-623.1000

De Giorgi M (2011) Residual stress evolution in cold-rolled steels. Int J Fatigue 33:507–512. https://doi.org/10.1016/j.ijfatigue.2010.10.006

Che-Haron CH, Jawaid A (2005) The effect of machining on surface integrity of titanium alloy Ti–6% Al–4% V. J Mater Process Technol 166:188–192. https://doi.org/10.1016/j.jmatprotec.2004.08.012

Nasr MNA, Ng EG (2007) Elbestawi MA modelling the effects of tool-edge radius on residual stresses when orthogonal cutting AISI 316L. Int J Mach Tools Manuf 47:401–411. https://doi.org/10.1016/j.ijmachtools.2006.03.004

Multinger M, Ferreira-Barragáns S, Frutos E, Jaafar M, Ibanez J, Marin P, Perez-Prado MT, Gonzales-Doncel G, Ansejo A, Gonzalez-Carrasco J (2010) Superficial severe plastic deformation of 316 LVM stainless steel through grit blasting: effects on its microstructure and subsurface mechanical properties. Surf Coat Technol 205:1830–1837. https://doi.org/10.1016/j.surfcoat.2010.07.126

Youssef S, Calonne O, Feulvarch E, Hedi H (2011) Analysis of residual stress induced by hand grinding process. Mater Sci Forum 681:327–331. https://doi.org/10.4028/www.scientific.net/MSF.681.327

Gou R, Zhang Y, Xu X, Sun L, Yang Y (2011) Residual stress measurement of new and in-service X70 pipelines by X-ray diffraction method. NDT Int 44:387–393. https://doi.org/10.1016/j.ndteint.2011.03.003

Hilson G, Simandjuntak S, Flewitt P, Hallam K, Pavier M, Smith D (2009) Spatial variation of residual stresses in a welded pipe for high temperature applications. Int J Press Vessels Pip 86:748–756. https://doi.org/10.1016/j.ijpvp.2009.07.003

Rai S, Jayakumar T, Rao CB, Bhattachayara DK, Raj B (1998) Residual stress measurement in ferritic steel tube welds using X-ray diffraction. Sci Technol Weld Join 3(204):204–207. https://doi.org/10.1179/stw.1998.3.4.204

Brown TB, Dauda TA, Truman CE, Smith DJ, MemhardD Pfeiffer W (2006) Predictions and measurements of residual stress in repair welds in plates. Int J Press Vessels Pip 83(11–12):809–818. https://doi.org/10.1016/j.ijpvp.2006.08.012

Tsuji A, Okano S, Mochizuki M (2015) Method of X-ray residual stress measurement for phase transformed welds. Weld World 59:577–583. https://doi.org/10.1007/s40194-015-0232-5

Harati E, Karlsson L, Svensson LE, Kamellia D (2015) The relative effects of residual stresses and weld toe geometry on fatigue life of weldments. Int J Fatigue 77:160–165. https://doi.org/10.1016/j.ijfatigue.2015.03.023

ASTM International (2012) ASTM E2860-12 standard test method for residual stress measurement by X-ray diffraction for bearing steels. https://doi.org/10.1520/e2860-12

British Standards Institution (2008) BS EN 15305/2008: non-destructive testing: test method for residual stress analysis by X-ray diffraction

Estefen SF, Gurova T, Werneck D, Leontiev A (2012) Welding stress relaxation effect in butt-jointed steel plates. Mar Struct 29(1):211–225. https://doi.org/10.1016/j.marstruc.2012.06.002

Slatineau L, Potarniche S, Coteata M, Grigoras I, Gherman L, Negoescu F (2011) Surface roughness of aluminium parts sand blasting. Proc Manuf Syst 6(2):69–74

Staia MH, Ramos E, Carrasquero A, Roman A, Lesage J, Chicot D, Mesmacque G (2000) Effect of substrate roughness induced by grit blasting upon adhesion of WC-17% Co thermal sprayed coatings. Thin Solid Films 377–378:657–664. https://doi.org/10.1016/S0040-6090(00)01447-4

Mishchenko A, Oliveira BJ, Scotti A (2016) Surface preparation for XRD residual stress measurements. Soldagem e Inspeção 21(4):497–507. https://doi.org/10.1590/0104-9224/si2104.09

Noyan IC, Cohen JB (1987) Residual stress. Measurement by diffraction and interpretation. Springer Science and Business Media, New York. https://doi.org/10.1007/978-1-4613-9570-6

Moore M, Evans W (1958) Mathematical correction for stress in removed layers in X-ray diffraction residual stress analysis SAE Technical Paper No. 580035. https://doi.org/10.4271/580035

Acknowledgements

The authors would like to thank the Center for Research and Development of Welding Processes (Laprosolda) of Federal University of Uberlandia and the Brazilian Nanotechnology National Laboratory—LNNano, for the laboratorial infrastructures. The authors also would like to acknowledge the financial support provided by the Brazilian National Council for Scientific and Technological Development (CNPq), through Grants number 302863/2016-8 and 149308/2014-0, and from the Minas Gerais State Agency for Research and Development (FAPEMIG), through Project number TEC—APQ-01992-15.

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Márcio Bacci da Silva.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Mishchenko, A., Wu, L., da Silva, V.K. et al. Analysis of residual stresses resulting from the surface preparation for X-ray diffraction measurement. J Braz. Soc. Mech. Sci. Eng. 40, 94 (2018). https://doi.org/10.1007/s40430-018-1036-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-018-1036-5