Abstract

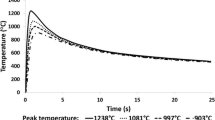

Subregions of CA6NM (ASTM 743) heat-affected zones—HAZ, were investigated in a microstructural and mechanical perspective. Those subregions suffer microstructural changes in welded joints, being considered the most critical regions in welded components. As the HAZ subregions possess very small volume, base metal was submitted to a welding simulation in the physical Gleeble simulator, which allows to reproduce the same microstructures found in real welding, allowing characterization of the different subregions in HAZ. Simulated samples were analyzed by optical microscopy (OM), scanning electron microscopy and X-ray diffraction measurements. For mechanical properties, evaluation samples were submitted to impact and hardness measurements. Microstructural and mechanical analysis for the experiments showed that δ-ferrite is found in all HAZ subregions, being related to higher microhardness and higher absorbed energy in impact. Higher heat inputs promoted higher hardness levels and higher δ-phase amounts.

Similar content being viewed by others

References

Thibault D, Bocher P, Thomas M (2009) Residual stress and microstructure in welds of 13%Cr-4%Ni martensitic stainless steel. J Mater Process Technol 209(4):2195–2202

Gracioso JFF (2003) Efeito das condições de têmperas na microestrutura e propriedades mecânicas de um aço inoxidável martensítico fundido CA6NM. Universidade Federal de Santa Catarina, Florianópolis

Sung HK, Shin SY, Cha W, Oh K, Lee S, Kim NJ (2011) Effects of acicular ferrite on charpy impact properties in heat affected zones of oxide-containing API X80 linepipe steels. Mater Sci Eng Struct Mater Prop Microstruct Process 528(9):3350–3357

Tabatabae BA, Ashrafizadeh F, Hassanli AM (2011) Influence of retained austenite on the mechanical properties of low carbon martensitic stainless steel castings. ISIJ Int 51(3):471–475

Song YY, Li XY, Rong LJ, Li YY (2010) Anomalous phase transformation from martensite to austenite in Fe-13%Cr-4%Ni-Mo martensitic stainless steel. J Mater Sci Technol 26(9):823–826

Gonçalves BHB (2007) Estudo comparativo da resistência à erosão por cavitação do metal de solda depositado por um arame tubular do tipo 13%Cr-4%Ni-0.4%Mo e do aço fundido ASTM A743 CA6NM, Departamento de Engenharia Mecânica, UFMG, Belo Horizonte, p 100

Li CW, Wang Y, Chen YH (2011) Influence of peak temperature during in-service welding of API X70 pipeline steels on microstructure and fracture energy of the reheated coarse grain heat-affected zones. J Mater Sci 46(19):6424–6431

Bilmes PD, Solari M, Llorente CL (2001) Characteristics and effects of austenite resulting from tempering of 13Cr-NiMo martensitic steel weld metals. Mater Charact 46(4):285–296

Zaayman JJJ, Van Rooyen GT (1992) The toughness of the heat-affected zone of welds in 11.5 Per Cent chromium steels proceedings of the 1st international chromium steels and alloys congress, 26

Schafer L (1998) Influence of delta ferrite and dendritic carbides on the impact and tensile properties of a martensitic chromium steel. J Nucl Mater 258:1336–1339

Wang QF, Shang CJ, Fu RD, Yang YN, Chen W (2005) Physical simulation and metallurgical evaluation of heat-affected zone during laser welding of ultrafine grain steel, Pricm 5: the Fifth Pacific rim international conference on advanced materials and processing, Pts 1–5 475–479: 2717–2720

Mirakhorli F, Cao XJ, Pham XT, Wanjara P, Fihey JL (2016) Hybrid laser-arc welding of 10-mm-thick cast martensitic stainless steel CA6NM: as-welded microstructure and mechanical properties. Metall Mater Trans B-Process Metall Mater Process Sci 47A(7):3545–3563

Mirakhorli F, Cao XJ, Pham XT, Wanjara P, Fihey JL (2016) Post-weld tempered microstructure and mechanical properties of hybrid laser-arc welded cast martensitic stainless steel CA6NM. Metall Mater Trans B-Process Metall Mater Process Sci 47(6):3245–3256

Mirakhorli F, Cao X, Pham XT, Wanjara P, Fihey JL (2017) Phase structures and morphologies of tempered CA6NM stainless steel welded by hybrid laser-arc process. Mater Charact 123:264–274

Silva R, de Almeida LFCB, Faria MIST, Nunes CA, Vieira D, Borges W Jr (2017) Microstructure and mechanical properties of ASTM A743 steel welded by FCAW process. Mater Res 20(6):1622–1629

Poorhaydari K, Patchett BM, Ivey DG (2005) Estimation of cooling rate in the welding of plates with intermediate thickness. Weld J 84(10):149S–155S

Acknowledgement

The authors acknowledge FAPESP (The Scientific Research Foundation of the State of São Paulo, Brazil) for financial support and also CNPEM/LNNano laboratories and University of São Paulo for technological and instrumental support. Finally, authors acknowledge Dedini for material supply.

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Márcio Bacci da Silva.

Rights and permissions

About this article

Cite this article

Lima, B.G., Lourenço, J.C., Nunes, C.A. et al. CA6NM stainless steel submitted to different thermal cycles in the Gleeble weld simulator. J Braz. Soc. Mech. Sci. Eng. 40, 453 (2018). https://doi.org/10.1007/s40430-018-1375-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-018-1375-2