Abstract

Tribological testing using twin disc equipment is widely used in railway research as it allows for a simulation of the complex wheel/rail tribological system. In this study, an extensive systematic bibliographic review was carried out, seeking to understand, synthesize, organize the knowledge developed and the methodological strategies adopted in research in the last 12 years that used twin disc tribometers to simulate relevant railway themes. For this, 440 articles present in the main scientific databases had their abstracts read and evaluated. After the evaluation, 133 articles were selected for extraction, data synthesis and scientific mapping using the Bibliometrix tool. The results allowed us to identify where the main active research groups and the main formed research networks that address this subject are located. As for the importance of using the twin disc, the great versatility of the test to simulate events of interest in the railway is evidenced, identifying studies on friction management, simulation of different operating and environmental conditions, evaluation of the behavior of new materials and surface treatments of wheel and rail among other themes. A detailed description of the main methodological strategies is also provided in this review.

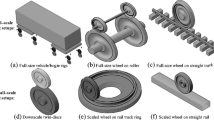

Source: Authors

Similar content being viewed by others

References

Merritt HE (1935) Worm gear performance. Proc Inst Mech Eng 129:127–194. https://doi.org/10.1243/PIME_PROC_1935_129_011_02

Petersen D, Link R, Fletcher D, Beynon J (2000) Development of a machine for closely controlled rolling contact fatigue and wear testing. J Test Eval 28:267. https://doi.org/10.1520/JTE12104J

Meneghetti G, Terrin A, Giacometti S (2016) A twin disc test rig for contact fatigue characterization of gear materials. Procedia Struct Integr 2:3185–3193. https://doi.org/10.1016/j.prostr.2016.06.397

Moder J, Grün F, Stoschka M, Gódor I (2017) A novel two-disc machine for high precision friction assessment. Adv Tribol 2017:1–16. https://doi.org/10.1155/2017/8901907

Ramalho A (2015) Wear modelling in rail–wheel contact. Wear 330–331:524–532. https://doi.org/10.1016/j.wear.2015.01.067

Bolton PJ, Clayton P (1984) Rolling—sliding wear damage in rail and tyre steels. Wear 93:145–165. https://doi.org/10.1016/0043-1648(84)90066-8

Miranda RS, Rezende AB, Fonseca ST, Fernandes FM, Sinatora A, Mei PR (2022) Fatigue and wear behavior of pearlitic and bainitic microstructures with the same chemical composition and hardness using twin-disc tests. Wear 494–495:204253. https://doi.org/10.1016/j.wear.2022.204253

Santa JF, Cuervo P, Christoforou P, Harmon M, Beagles A, Toro A, Lewis R (2019) Twin disc assessment of wear regime transitions and rolling contact fatigue in R400HT–E8 pairs. Wear 432–433:102916. https://doi.org/10.1016/j.wear.2019.05.031

Harmon M, Santa JF, Jaramillo JA, Toro A, Beagles A, Lewis R (2020) Evaluation of the coefficient of friction of rail in the field and laboratory using several devices. Tribol Mater Surf Interfaces 14:119–129. https://doi.org/10.1080/17515831.2020.1712111

Zhao XJ, Guo J, Liu QY, Butini E, Marini L, Meli E, Rindi A, Wang WJ (2018) Effect of spherical dents on microstructure evolution and rolling contact fatigue of wheel/rail materials. Tribol Int 127:520–532. https://doi.org/10.1016/j.triboint.2018.07.001

Gallardo EA, Lewis R (2009) Coating and treatment solutions for rolling/sliding component contacts. Wear 267:1009–1021. https://doi.org/10.1016/j.wear.2009.01.021

Mercado-Solis RD, Talamantes-Silva J, Beynon JH, Hernandez-Rodriguez MAL (2007) Modelling surface thermal damage to hot mill rolls. Wear 263:1560–1567. https://doi.org/10.1016/j.wear.2006.12.062

Liu H, Liu H, Zhu C, Parker RG (2020) Effects of lubrication on gear performance: a review. Mech Mach Theory 145:103701. https://doi.org/10.1016/j.mechmachtheory.2019.103701

Chen H, Namura A, Ishida M, Nakahara T (2016) Influence of axle load on wheel/rail adhesion under wet conditions in consideration of running speed and surface roughness. Wear 366–367:303–309. https://doi.org/10.1016/j.wear.2016.05.012

Zhou Y, Peng JF, Wang WJ, Jin XS, Zhu MH (2016) Slippage effect on rolling contact wear and damage behavior of pearlitic steels. Wear 362–363:78–86. https://doi.org/10.1016/j.wear.2016.05.001

Wang WJ, Lewis SR, Lewis R, Beagles A, He CG, Liu QY (2017) The role of slip ratio in rolling contact fatigue of rail materials under wet conditions. Wear 376–377:1892–1900. https://doi.org/10.1016/j.wear.2016.12.049

He CG, Guo J, Liu QY, Wang WJ (2016) Experimental investigation on the effect of operating speeds on wear and rolling contact fatigue damage of wheel materials. Wear 364–365:257–269. https://doi.org/10.1016/j.wear.2016.08.006

Lee H, Namgung H-G, Kwon S-B (2018) Effect of train velocity on the amount of airborne wear particles generated from wheel–rail contacts. Wear 414–415:296–302. https://doi.org/10.1016/j.wear.2018.08.023

Wang WJ, Zhang HF, Wang HY, Liu QY, Zhu MH (2011) Study on the adhesion behavior of wheel/rail under oil, water and sanding conditions. Wear 271:2693–2698. https://doi.org/10.1016/j.wear.2010.12.019

Arias-Cuevas O, Li Z, Lewis R (2011) A laboratory investigation on the influence of the particle size and slip during sanding on the adhesion and wear in the wheel–rail contact. Wear 271:14–24. https://doi.org/10.1016/j.wear.2010.10.050

Wang WJ, Liu TF, Wang HY, Liu QY, Zhu MH, Jin XS (2014) Influence of friction modifiers on improving adhesion and surface damage of wheel/rail under low adhesion conditions. Tribol Int 75:16–23. https://doi.org/10.1016/j.triboint.2014.03.008

Seo J-W, Jun H-K, Kwon S-J, Lee D-H (2016) Rolling contact fatigue and wear of two different rail steels under rolling–sliding contact. Int J Fatigue 83:184–194. https://doi.org/10.1016/j.ijfatigue.2015.10.012

Rezende AB, Fonseca ST, Fernandes FM, Miranda RS, Grijalba FAF, Farina PFS, Mei PR (2020) Wear behavior of bainitic and pearlitic microstructures from microalloyed railway wheel steel. Wear 456–457:203377. https://doi.org/10.1016/j.wear.2020.203377

Zapata D, Jaramillo J, Toro A (2011) Rolling contact and adhesive wear of bainitic and pearlitic steels in low load regime. Wear 271:393–399. https://doi.org/10.1016/j.wear.2010.10.009

Wang WJ, Shen P, Song JH, Guo J, Liu QY, Jin XS (2011) Experimental study on adhesion behavior of wheel/rail under dry and water conditions. Wear 271:2699–2705. https://doi.org/10.1016/j.wear.2011.01.070

Wang WJ, Wang H, Wang HY, Guo J, Liu QY, Zhu MH, Jin XS (2013) Sub-scale simulation and measurement of railroad wheel/rail adhesion under dry and wet conditions. Wear 302:1461–1467. https://doi.org/10.1016/j.wear.2012.12.014

Faccoli M, Petrogalli C, Lancini M, Ghidini A, Mazzù A (2018) Effect of desert sand on wear and rolling contact fatigue behaviour of various railway wheel steels. Wear 396–397:146–161. https://doi.org/10.1016/j.wear.2017.05.012

Lewis SR, Lewis R, Fletcher DI (2015) Assessment of laser cladding as an option for repairing/enhancing rails. Wear 330–331:581–591. https://doi.org/10.1016/j.wear.2015.02.027

Lewis SR, Fretwell-Smith S, Goodwin PS, Smith L, Lewis R, Aslam M, Fletcher DI, Murray K, Lambert R (2016) Improving rail wear and RCF performance using laser cladding. Wear 366–367:268–278. https://doi.org/10.1016/j.wear.2016.05.011

Zeng D, Lu L, Li Z, Zhang J, Jin X, Zhu M (2014) Influence of laser dispersed treatment on rolling contact wear and fatigue behavior of railway wheel steel. Mater Des 54:137–143. https://doi.org/10.1016/j.matdes.2013.08.041

Jiang J, Luo Q, Wang L, Qiao L, Li M (2020) Review on logarithmic spiral bevel gear. J Braz Soc Mech Sci Eng 42:400. https://doi.org/10.1007/s40430-020-02488-y

Santos AVF, Silveira ZC (2021) Design for assistive technology oriented to design methodology: a systematic review on user-centered design and 3D printing approaches. J Braz Soc Mech Sci Eng 43:483. https://doi.org/10.1007/s40430-021-03184-1

Kumar S, Singh KK (2022) Tribological characteristics of glass/carbon fibre-reinforced thermosetting polymer composites: a critical review. J Braz Soc Mech Sci Eng 44:496. https://doi.org/10.1007/s40430-022-03817-z

Skipper W, Chalisey A, Lewis R (2020) A review of railway sanding system research: Wheel/rail isolation, damage, and particle application. Proc Inst Mech Eng Part F J Rail Rapid Transit 234:567–583. https://doi.org/10.1177/0954409719851634

Lewis R, Christoforou P, Wang WJ, Beagles A, Burstow M, Lewis SR (2019) Investigation of the influence of rail hardness on the wear of rail and wheel materials under dry conditions (ICRI wear mapping project). Wear 430–431:383–392. https://doi.org/10.1016/j.wear.2019.05.030

Zhu Y (2018) The influence of iron oxides on wheel–rail contact: a literature review. Proc Inst Mech Eng Part F J Rail Rapid Transit 232:734–743. https://doi.org/10.1177/0954409716689187

Harmon M, Lewis R (2016) Review of top of rail friction modifier tribology. Tribol Mater Surf Interfaces 10:150–162. https://doi.org/10.1080/17515831.2016.1216265

Tranfield D, Denyer D, Smart P (2003) Towards a methodology for developing evidence-informed management knowledge by means of systematic review. Br J Manag 14:207–222. https://doi.org/10.1111/1467-8551.00375

Pagani RN, Kovaleski JL, Resende LM (2015) Methodi ordinatio: a proposed methodology to select and rank relevant scientific papers encompassing the impact factor, number of citation, and year of publication. Scientometrics 105:2109–2135. https://doi.org/10.1007/s11192-015-1744-x

Aria M, Cuccurullo C (2017) Bibliometrix: an R-tool for comprehensive science mapping analysis. J Informetr 11:959–975. https://doi.org/10.1016/j.joi.2017.08.007

Chen H, Zhang C, Liu W, Li Q, Chen H, Yang Z, Weng Y (2016) Microstructure evolution of a hypereutectoid pearlite steel under rolling-sliding contact loading. Mater Sci Eng A 655:50–59. https://doi.org/10.1016/j.msea.2015.12.082

Hu Y, Watson M, Maiorino M, Zhou L, Wang WJ, Ding HH, Lewis R, Meli E, Rindi A, Liu QY, Guo J (2021) Experimental study on wear properties of wheel and rail materials with different hardness values. Wear 477:203831. https://doi.org/10.1016/j.wear.2021.203831

Zhu WT, Guo LC, Shi LB, Cai ZB, Li QL, Liu QY, Wang WJ (2018) Wear and damage transitions of two kinds of wheel materials in the rolling-sliding contact. Wear 398–399:79–89. https://doi.org/10.1016/j.wear.2017.11.023

Li Q, Huang X, Huang W (2019) Fatigue property and microstructure deformation behavior of multiphase microstructure in a medium-carbon bainite steel under rolling contact condition. Int J Fatigue 125:381–393. https://doi.org/10.1016/j.ijfatigue.2019.04.019

Rezende AB, Fonseca ST, Miranda RS, Fernandes FM, Grijalba FAF, Farina PFS, Mei PR (2021) Effect of niobium and molybdenum addition on the wear resistance and the rolling contact fatigue of railway wheels. Wear 466–467:203571. https://doi.org/10.1016/j.wear.2020.203571

Pereira HB, Alves LHD, Rezende AB, Mei PR, Goldenstein H (2022) Influence of the microstructure on the rolling contact fatigue of rail steel: spheroidized pearlite and fully pearlitic microstructure analysis. Wear 498–499:204299. https://doi.org/10.1016/j.wear.2022.204299

Li Q, Guo J, Zhao A (2019) Effect of upper bainite on wear behaviour of high-speed wheel steel. Tribol Lett 67:121. https://doi.org/10.1007/s11249-019-1239-7

Seo J-W, Hur H-M, Kwon S-J (2022) Effect of mechanical properties of rail and wheel on wear and rolling contact fatigue. Metals (Basel) 12:630. https://doi.org/10.3390/met12040630

Li Q, Zhang C, Chen H, Chen H, Yang Z (2016) Microstructural evolution of a hypoeutectoid pearlite steel under rolling-sliding contact loading. J Iron Steel Res Int 23:1054–1060. https://doi.org/10.1016/S1006-706X(16)30157-1

Christoforou P, Fletcher DI, Lewis R (2019) Benchmarking of premium rail material wear. Wear 436–437:202990. https://doi.org/10.1016/j.wear.2019.202990

Zhou L, Wang WJ, Hu Y, Marconi S, Meli E, Ding HH, Liu QY, Guo J, Rindi A (2020) Study on the wear and damage behaviors of hypereutectoid rail steel in low temperature environment. Wear 456–457:203365. https://doi.org/10.1016/j.wear.2020.203365

Shi X, Yan Q, Zhang X, Diao G, Zhang C, Hong Z, Wen Z, Jin X (2019) Hardness matching of rail/wheel steels for high-speed-train based on wear rate and rolling contact fatigue performance. Mater Res Express 6:066501. https://doi.org/10.1088/2053-1591/ab072d

Solano-Alvarez W, Fernandez Gonzalez L, Bhadeshia HKDH (2019) The effect of vanadium alloying on the wear resistance of pearlitic rails. Wear 436–437:203004. https://doi.org/10.1016/j.wear.2019.203004

Liu C, Liu P, Pan J, Chen C, Ren R (2021) Effect of original microstructure on wear property of ER9 wheel steel. Ironmak Steelmak 48:133–141. https://doi.org/10.1080/03019233.2020.1741280

Rezende AB, Amorim GA, Minicucci DJ, Fonseca ST, Mei PR (2019) Effect of vanadium addition on the surface roughness and fatigue crack propagation in a railroad wheel using twin disc wear test. Defect Diffus Forum 391:66–73. https://doi.org/10.4028/www.scientific.net/DDF.391.66

Seo J, Kwon S, Jun H, Lee C (2019) Effects of wheel materials on wear and fatigue damage behaviors of wheels/rails. Tribol Trans 62:635–649. https://doi.org/10.1080/10402004.2019.1588446

Voltr P, Lata M (2015) Transient wheel–rail adhesion characteristics under the cleaning effect of sliding. Veh Syst Dyn 53:605–618. https://doi.org/10.1080/00423114.2014.961488

Huang YB, Shi LB, Zhao XJ, Cai ZB, Liu QY, Wang WJ (2018) On the formation and damage mechanism of rolling contact fatigue surface cracks of wheel/rail under the dry condition. Wear 400–401:62–73. https://doi.org/10.1016/j.wear.2017.12.020

Ishizaka K, Lewis SR, Lewis R (2017) The low adhesion problem due to leaf contamination in the wheel/rail contact: bonding and low adhesion mechanisms. Wear 378–379:183–197. https://doi.org/10.1016/j.wear.2017.02.044

Zhou L, Hu Y, Ding HH, Liu QY, Guo J, Wang WJ (2021) Experimental study on the wear and damage of wheel-rail steels under alternating temperature conditions. Wear 477:203829. https://doi.org/10.1016/j.wear.2021.203829

Nakahara T, Baek K-S, Chen H, Ishida M (2011) Relationship between surface oxide layer and transient traction characteristics for two steel rollers under unlubricated and water lubricated conditions. Wear 271:25–31. https://doi.org/10.1016/j.wear.2010.10.030

Shi LB, Ma L, Guo J, Liu QY, Zhou ZR, Wang WJ (2018) Influence of low temperature environment on the adhesion characteristics of wheel-rail contact. Tribol Int 127:59–68. https://doi.org/10.1016/j.triboint.2018.05.037

Shen M, Qin Y, Ji D-H, Yu M, Li S, Huangfu L, Liu S (2022) Role of ambient temperature in the adhesion and damage characteristics of wheel/rail interface during rolling-sliding contact. Wear 506–507:204458. https://doi.org/10.1016/j.wear.2022.204458

Zani N, Petrogalli C (2022) Predictive maps for the rolling contact fatigue and wear interaction in railway wheel steels. Wear 510–511:204513. https://doi.org/10.1016/j.wear.2022.204513

Shu K, Ding HH, Mazzù A, Lin Q, Guo J, Meli E, Liu QY, Wang WJ (2022) Effect of dynamic windblown sand environments on the wear and damage of wheel-rail under different slip ratios. Wear 500–501:204349. https://doi.org/10.1016/j.wear.2022.204349

White B, Kempka R, Laity P, Holland C, Six K, Trummer G, Buckley-Johnstone L, Lewis R (2022) Iron oxide and water paste rheology and its effect on low adhesion in the wheel/rail interface. Tribol Lett 70:8. https://doi.org/10.1007/s11249-021-01549-0

White B, Lewis R (2019) Simulation and understanding the wet-rail phenomenon using twin disc testing. Tribol Int 136:475–486. https://doi.org/10.1016/j.triboint.2019.03.067

Lee H (2020) Generation of airborne wear particles from the wheel–rail contact under wet conditions using a twin-disk rig. Wear 448–449:203236. https://doi.org/10.1016/j.wear.2020.203236

Ishizaka K, White B, Watson M, Lewis SR, Lewis R (2020) Influence of temperature on adhesion coefficient and bonding strength of leaf films: a twin disc study. Wear 454–455:203330. https://doi.org/10.1016/j.wear.2020.203330

Chen H, Tanimoto H (2018) Experimental observation of temperature and surface roughness effects on wheel/rail adhesion in wet conditions. Int J Rail Transp 6:101–112. https://doi.org/10.1080/23248378.2017.1415772

Zhu Y, Yang H, Wang W (2016) Twin-disc tests of iron oxides in dry and wet wheel−rail contacts. Proc Inst Mech Eng Part F J Rail Rapid Transit 230:1066–1076. https://doi.org/10.1177/0954409715575093

Chen H, Ishida M, Namura A, Baek K-S, Nakahara T, Leban B, Pau M (2011) Estimation of wheel/rail adhesion coefficient under wet condition with measured boundary friction coefficient and real contact area. Wear 271:32–39. https://doi.org/10.1016/j.wear.2010.10.022

Zhou G, He C, Wen G, Liu Q (2015) Fatigue damage mechanism of railway wheels under lateral forces. Tribol Int 91:160–169. https://doi.org/10.1016/j.triboint.2015.07.008

Rodríguez-Arana B, San Emeterio A, Panera M, Montes A, Álvarez D (2022) Investigation of a relationship between twin-disc wear rates and the slipping contact area on R260 grade rail. Tribol. Int 168:107456. https://doi.org/10.1016/j.triboint.2022.107456

Leso TP, Siyasiya CW, Mostert RJ, Moema J (2022) Study of rolling contact fatigue, rolling and sliding wear of class B wheel steels against R350HT and R260 rail steels under dry contact conditions using the twin disc setup. Tribol Int 174:107711. https://doi.org/10.1016/j.triboint.2022.107711

Lee H (2021) Reducing the nanoparticles generated at the wheel–rail contact by applying tap water lubricant at subway train operational velocities. Sci Rep 11:23366. https://doi.org/10.1038/s41598-021-02037-0

Lee H (2020) The effect of water lubricant on reducing the generation of airborne wear particles from wheel–rail contacts under various train velocities. Tribol Int 150:106393. https://doi.org/10.1016/j.triboint.2020.106393

Vicente FS, Guillamón MP (2019) Use of the fatigue index to study rolling contact wear. Wear 436–437:203036. https://doi.org/10.1016/j.wear.2019.203036

Jetti YS, Dunn AC (2021) Shakedown analysis of evolving non-hertzian rolling contact using a semi-analytical numerical model. Tribol Lett 69:137. https://doi.org/10.1007/s11249-021-01506-x

Leso TP, Siyasia C, Mostert R, Moema J (2022) Effects of slip ratio on wear performance of class B wheel steels against softer R260 rail steels using the twin disc setup. S Afr J Ind Eng. https://doi.org/10.7166/33-3-2805

Lee H (2020) Generation characteristics of the airborne wear particles emitted from the wheel–rail contact for various train velocities and their generation relation with the train velocity. Atmos Environ X 5:100068. https://doi.org/10.1016/j.aeaoa.2020.100068

Hardwick C, Lewis R, Eadie DT (2014) Wheel and rail wear—understanding the effects of water and grease. Wear 314:198–204. https://doi.org/10.1016/j.wear.2013.11.020

Wang WJ, Lewis R, Yang B, Guo LC, Liu QY, Zhu MH (2016) Wear and damage transitions of wheel and rail materials under various contact conditions. Wear 362–363:146–152. https://doi.org/10.1016/j.wear.2016.05.021

Cao X, Huang WL, He CG, Peng JF, Guo J, Wang WJ, Liu QY, Zhu MH (2016) The effect of alumina particle on improving adhesion and wear damage of wheel/rail under wet conditions. Wear 348–349:98–115. https://doi.org/10.1016/j.wear.2015.12.004

Omasta M, Machatka M, Smejkal D, Hartl M, Křupka I (2015) Influence of sanding parameters on adhesion recovery in contaminated wheel–rail contact. Wear 322–323:218–225. https://doi.org/10.1016/j.wear.2014.11.017

Lewis SR, Lewis R, Evans G, Buckley-Johnstone LE (2014) Assessment of railway curve lubricant performance using a twin-disc tester. Wear 314:205–212. https://doi.org/10.1016/j.wear.2013.11.033

Maya-Johnson S, Santa JF, Toro A (2017) Dry and lubricated wear of rail steel under rolling contact fatigue—wear mechanisms and crack growth. Wear 380–381:240–250. https://doi.org/10.1016/j.wear.2017.03.025

Biazon L, Ferrer BP, Toro A, Cousseau T (2021) Correlations between rail grease formulation and friction, wear and RCF of a wheel/rail tribological pair. Tribol Int 153:106566. https://doi.org/10.1016/j.triboint.2020.106566

Hardwick C, Lewis R, Stock R (2017) The effects of friction management materials on rail with pre existing RCF surface damage. Wear 384–385:50–60. https://doi.org/10.1016/j.wear.2017.04.016

Wang WJ, Lewis R, Evans MD, Liu QY (2017) Influence of different application of lubricants on wear and pre-existing rolling contact fatigue cracks of rail materials. Tribol Lett 65:58. https://doi.org/10.1007/s11249-017-0841-9

Wang C, Shi LB, Ding HH, Wang WJ, Galas R, Guo J, Liu QY, Zhou ZR, Omasta M (2021) Adhesion and damage characteristics of wheel/rail using different mineral particles as adhesion enhancers. Wear 477:203796. https://doi.org/10.1016/j.wear.2021.203796

Lewis SR, Lewis R, Richards P, Buckley-Johnstone LE (2014) Investigation of the isolation and frictional properties of hydrophobic products on the rail head, when used to combat low adhesion. Wear 314:213–219. https://doi.org/10.1016/j.wear.2013.11.024

Shi LB, Wang C, Ding HH, Kvarda D, Galas R, Omasta M, Wang WJ, Liu QY, Hartl M (2020) Laboratory investigation on the particle-size effects in railway sanding: Comparisons between standard sand and its micro fragments. Tribol Int 146:106259. https://doi.org/10.1016/j.triboint.2020.106259

Shi LB, Li Q, Kvarda D, Galas R, Omasta M, Wang WJ, Guo J, Liu QY (2019) Study on the wheel/rail adhesion restoration and damage evolution in the single application of alumina particles. Wear 426–427:1807–1819. https://doi.org/10.1016/j.wear.2019.01.021

Huang W, Cao X, Wen Z, Wang W, Liu Q, Zhu M, Jin X (2017) A subscale experimental investigation on the influence of sanding on adhesion and rolling contact fatigue of wheel/rail under water condition. J Tribol. https://doi.org/10.1115/1.4033100

Leiva-Mateus JE, Santa-Marín JF, Buitrago-Sierra R, Mesa Grajales DH, Geffroy E (2022) Rheological and tribological evaluation of friction modifiers for wheel-rail applications. Lubr Sci 34:537–546. https://doi.org/10.1002/ls.1607

Messaadi M, Oomen M, Kumar A (2019) Friction modifiers effects on tribological behaviour of bainitic rail steels. Tribol Int 140:105857. https://doi.org/10.1016/j.triboint.2019.105857

Seo J-W, Jun H-K, Kwon S-J, Lee D-H (2018) Effect of friction modifier on rolling contact fatigue and wear of wheel and rail materials. Tribol Trans 61:19–30. https://doi.org/10.1080/10402004.2016.1271487

Pérez-de Brito AF, Ponce S, Pérez-Robles JF, Higuera-Ciapara I, Toro A, Esparza R, Medina DI, Villaseñor-Ortega F, Luna-Barcenas G (2020) Linseed and complex rosin ester oils additivated with MWCNTs and nanopearls for gears/wheel-rail systems. Eur J Lipid Sci Technol 122:1900331. https://doi.org/10.1002/ejlt.201900331

Navrátil V, Galas R, Klapka M, Kvarda D, Omasta M, Shi L, Ding H, Wang W-J, Krupka I, Hartl M (2022) Wheel squeal noise in rail transport: the effect of friction modifier composition. Tribol Ind 44:361–373. https://doi.org/10.24874/ti.1211.11.21.02

Gutsulyak DV, Stanlake LJE, Qi H (2021) Twin disc evaluation of third body materials in the wheel/rail interface. Tribol Mater Surf Interfaces 15:115–126. https://doi.org/10.1080/17515831.2020.1829878

Buckley-Johnstone L, Harmon M, Lewis R, Hardwick C, Stock R (2019) A comparison of friction modifier performance using two laboratory test scales. Proc Inst Mech Eng Part F J Rail Rapid Transit 233:201–210. https://doi.org/10.1177/0954409718787045

Vélez JC, Cornelio JAC, Sierra RB, Santa JF, Hoyos-Palacio LM, Nevshupa R, Toro A (2020) Development of a composite friction modifier with carbon nanotubes for applications at the wheel–rail interface. Adv Compos Lett. https://doi.org/10.1177/2633366X20930019

Galas R, Omasta M, Klapka M, Kaewunruen S, Krupka I, Hartl M (2017) Case Study: the Influence of Oil-based Friction Modifier Quantity on Tram Braking Distance and Noise. Tribol Ind 39:198–206. https://doi.org/10.24874/ti.2017.39.02.06

Seo J, Kwon S, Jun H, Lee D (2011) Numerical stress analysis and rolling contact fatigue of white etching layer on rail steel. Int J Fatigue 33:203–211. https://doi.org/10.1016/j.ijfatigue.2010.08.007

Zhao XJ, Guo J, Wang HY, Wen ZF, Liu QY, Zhao GT, Wang WJ (2016) Effects of decarburization on the wear resistance and damage mechanisms of rail steels subject to contact fatigue. Wear 364–365:130–143. https://doi.org/10.1016/j.wear.2016.07.013

Zhang SY, Spiryagin M, Ding HH, Wu Q, Guo J, Liu QY, Wang WJ (2022) Rail rolling contact fatigue formation and evolution with surface defects. Int J Fatigue 158:106762. https://doi.org/10.1016/j.ijfatigue.2022.106762

Zhang S, Spiryagin M, Lin Q, Ding H, Wu Q, Guo J, Liu Q, Wang W (2022) Study on wear and rolling contact fatigue behaviours of defective rail under different slip ratio and contact stress conditions. Tribol Int 169:107491. https://doi.org/10.1016/j.triboint.2022.107491

Zhang SY, Zhao XJ, Ding HH, Spiryagin M, Guo J, Liu QY, Wang WJ, Zhou ZR (2021) Effects of dent size on the evolution process of rolling contact fatigue damage on defective rail. Wear 477:203894. https://doi.org/10.1016/j.wear.2021.203894

Zeng D, Lu L, Gong Y, Zhang Y, Zhang J (2017) Influence of solid solution strengthening on spalling behavior of railway wheel steel. Wear 372–373:158–168. https://doi.org/10.1016/j.wear.2016.12.025

Kato T, Sugeta A, Nakayama E (2011) Investigation of influence of white layer geometry on spalling property in railway wheel steel. Wear 271:400–407. https://doi.org/10.1016/j.wear.2010.10.024

Zhang SY, Liu QY, Wang WJ, Spiryagin M, Lin Q, Ding HH, Wu Q, Zhou ZR (2022) Implications of water medium for the evolution of rolling contact fatigue under rail surface defect conditions. Tribol Int 175:107870. https://doi.org/10.1016/j.triboint.2022.107870

Kanematsu Y, Uehigashi N, Matsui M, Noguchi S (2022) Influence of a decarburised layer on the formation of microcracks in railway rails: On-site investigation and twin-disc study. Wear 504–505:204427. https://doi.org/10.1016/j.wear.2022.204427

Vargolici O, Merino P, Saulot A, Cavoret J, Simon S, Ville F, Berthier Y (2016) Influence of the initial surface state of bodies in contact on the formation of white etching layers under dry sliding conditions. Wear 366–367:209–216. https://doi.org/10.1016/j.wear.2016.06.023

Zeng D, Xu T, Liu W, Lu L, Zhang J, Gong Y (2020) Investigation on rolling contact fatigue of railway wheel steel with surface defect. Wear 446–447:203207. https://doi.org/10.1016/j.wear.2020.203207

Zhao X, Wang Z, Wen Z, Wang H, Zeng D (2020) The initiation of local rolling contact fatigue on railway wheels: an experimental study. Int J Fatigue 132:105354. https://doi.org/10.1016/j.ijfatigue.2019.105354

He CG, Chen YZ, Huang YB, Liu QY, Zhu MH, Wang WJ (2017) On the surface scratch and thermal fatigue damage of wheel material under different braking speed conditions. Eng Fail Anal 79:889–901. https://doi.org/10.1016/j.engfailanal.2017.06.017

Kato T, Fujimura T, Hiramatsu S, Yamamoto Y (2021) Subsurface crack propagation from internal defect in rolling contact fatigue of railway wheel steel. Mater Trans 62:185–190. https://doi.org/10.2320/matertrans.Z-M2020860

Kato T, Kato H, Makino T (2016) Effect of elevated temperature on shelling property of railway wheel steel. Wear 366–367:359–367. https://doi.org/10.1016/j.wear.2016.04.015

Lewis SR, Lewis R, Cotter J, Lu X, Eadie DT (2016) A new method for the assessment of traction enhancers and the generation of organic layers in a twin-disc machine. Wear 366–367:258–267. https://doi.org/10.1016/j.wear.2016.04.030

Beaty P, Temple B, Marshall MB, Lewis R (2016) Experimental modelling of lipping in insulated rail joints and investigation of rail head material improvements. Proc Inst Mech Eng Part F J Rail Rapid Transit 230:1375–1387. https://doi.org/10.1177/0954409715600740

Lewis R, Gallardo EA, Cotter J, Eadie DT (2011) The effect of friction modifiers on wheel/rail isolation. Wear 271:71–77. https://doi.org/10.1016/j.wear.2010.10.036

Ding H, Mu X, Zhu Y, Yang W, Xiao Q, Wang W, Liu Q, Guo J, Zhou Z (2022) Effect of laser claddings of Fe-based alloy powder with different concentrations of WS2 on the mechanical and tribological properties of railway wheel. Wear 488–489:204174. https://doi.org/10.1016/j.wear.2021.204174

Wang WJ, Fu ZK, Cao X, Guo J, Liu QY, Zhu MH (2016) The role of lanthanum oxide on wear and contact fatigue damage resistance of laser cladding Fe-based alloy coating under oil lubrication condition. Tribol Int 94:470–478. https://doi.org/10.1016/j.triboint.2015.10.017

Zhu Y, Yang Y, Mu X, Wang W, Yao Z, Yang H (2019) Study on wear and RCF performance of repaired damage railway wheels: assessing laser cladding to repair local defects on wheels. Wear 430–431:126–136. https://doi.org/10.1016/j.wear.2019.04.028

Wang W-J, Fu Z-K, Guo J, Zhang Y-Q, Liu Q-Y, Zhu M-H (2016) Investigation on wear resistance and fatigue damage of laser cladding coating on wheel and rail materials under the oil lubrication condition. Tribol Trans 59:810–817. https://doi.org/10.1080/10402004.2015.1107926

Li Z, Xing X, Yang M, Yang B, Ren Z, Lin H (2014) Investigation on rolling sliding wear behavior of wheel steel by laser dispersed treatment. Wear 314:236–240. https://doi.org/10.1016/j.wear.2013.12.007

Lu P, Lewis SR, Fretwell-Smith S, Engelberg DL, Fletcher DI, Lewis R (2019) Laser cladding of rail; the effects of depositing material on lower rail grades. Wear 438–439:203045. https://doi.org/10.1016/j.wear.2019.203045

Seo J-W, Kim J, Kwon S-J, Jun H-K (2019) Effects of laser cladding for repairing and improving wear of rails. Int J Precis Eng Manuf 20:1207–1217. https://doi.org/10.1007/s12541-019-00115-y

Zhang Y, Lian Q, Wang X (2019) Enhancement of rolling contact fatigue performance of ferrite–pearlite steel with laser shock peening. Adv Mech Eng 11:168781401985094. https://doi.org/10.1177/1687814019850945

Donzella G, Faccoli M, Mazzù A, Petrogalli C, Roberti R (2011) Progressive damage assessment in the near-surface layer of railway wheel–rail couple under cyclic contact. Wear 271:408–416. https://doi.org/10.1016/j.wear.2010.10.042

Seo J-W, Kwon S-J, Lee D-H, Choi H-Y (2013) Analysis of contact fatigue crack growth using twin-disc tests and numerical evaluations. Int J Fatigue 55:54–63. https://doi.org/10.1016/j.ijfatigue.2013.05.005

Solano-Alvarez W, Peet MJ, Pickering EJ, Jaiswal J, Bevan A, Bhadeshia HKDH (2017) Synchrotron and neural network analysis of the influence of composition and heat treatment on the rolling contact fatigue of hypereutectoid pearlitic steels. Mater Sci Eng A 707:259–269. https://doi.org/10.1016/j.msea.2017.09.045

Trummer G, Lee ZS, Lewis R, Six K (2021) Modelling of frictional conditions in the wheel-rail interface due to application of top-of-rail products. Lubricants 9:100. https://doi.org/10.3390/lubricants9100100

Vasić G, Franklin FJ, Fletcher DI (2011) Influence of partial slip and direction of traction on wear rate in wheel-rail contact. Wear 270:163–171. https://doi.org/10.1016/j.wear.2010.10.012

da Nunhez RS, Neto AG (2021) Numerical investigation for creep curve evaluation on a twin-disc test scenario using finite elements. J Braz Soc Mech Sci Eng 43:339. https://doi.org/10.1007/s40430-021-03042-0

Lee H (2018) Estimation of adhesion coefficient using dynamic adhesion model. J Korean Soc Railw 21:331–341. https://doi.org/10.7782/JKSR.2018.21.4.331

Garnham JE, Davis CL (2011) Very early stage rolling contact fatigue crack growth in pearlitic rail steels. Wear 271:100–112. https://doi.org/10.1016/j.wear.2010.10.004

Zhu Y, Chen X, Wang W, Yang H (2015) A study on iron oxides and surface roughness in dry and wet wheel−rail contacts. Wear 328–329:241–248. https://doi.org/10.1016/j.wear.2015.02.025

Al-Maliki H, Meierhofer A, Trummer G, Lewis R, Six K (2021) A new approach for modelling mild and severe wear in wheel-rail contacts. Wear 476:203761. https://doi.org/10.1016/j.wear.2021.203761

Rong K, Xiao Y, Shen M, Zhao H, Wang W-J, Xiong G (2021) Influence of ambient humidity on the adhesion and damage behavior of wheel–rail interface under hot weather condition. Wear 486–487:204091. https://doi.org/10.1016/j.wear.2021.204091

Strey NF, Rezende AB, da Silva Miranda R, Tamara da Fonseca S, Mei PR, Scandian C (2021) Comparison of rolling contact fatigue damage between railway wheels and twin-disc test specimens. Tribol Int 160:107037. https://doi.org/10.1016/j.triboint.2021.107037

Liu HC, Zhang BB, Bader N, Venner CH, Poll G (2021) Scale and contact geometry effects on friction in thermal EHL: twin-disc versus ball-on-disc. Tribol Int 154:106694. https://doi.org/10.1016/j.triboint.2020.106694

Liu C, Liu P, Pan J, Chen C, Ren R (2020) Effect of pre-wear on the rolling contact fatigue property of D2 wheel steel. Wear 442–443:203154. https://doi.org/10.1016/j.wear.2019.203154

Philippon D, Martinie L, Vergne P (2021) Discussion on “scale and contact geometry effects on friction in thermal EHL: twin-disc versus ball-on-disc” by Liu, Zhang, Bader, Venner, Poll. Tribol Int 154: 106694, Tribol Int 157: 106877. https://doi.org/10.1016/j.triboint.2021.106877

Liu C, Ren R, Liu D, Zhao X, Chen C (2020) An EBSD investigation on the evolution of the surface microstructure of D2 wheel steel during rolling contact fatigue. Tribol Lett 68:47. https://doi.org/10.1007/s11249-020-1277-1

Mesaritis M, Shamsa M, Cuervo P, Santa JF, Toro A, Marshall MB, Lewis R (2020) A laboratory demonstration of rail grinding and analysis of running roughness and wear. Wear 456–457:203379. https://doi.org/10.1016/j.wear.2020.203379

Luccidi Y, Rezende AB, Fonseca ST, Mei PR (2022) Study of the running-in period in the twin-disc wear test using steel from a class C forged railway wheel. J Tribol. https://doi.org/10.1115/1.4054758

Hiensch M, Burgelman N (2019) Rolling contact fatigue: damage function development from two-disc test data. Wear 430–431:376–382. https://doi.org/10.1016/j.wear.2019.05.028

Liu P, Quan Y, Wan J, Yu L (2020) Experimental investigation on the wear and damage characteristics of machined wheel/rail materials under dry rolling-sliding condition. Metals (Basel) 10:472. https://doi.org/10.3390/met10040472

Jaramillo JAA, Sánchez JC, Santa JF, Palacio ME, Toro A (2022) Roughness evolution of wheel surface in a simulated wheel–rail contact. Tribol Mater Surf Interfaces 16:188–201. https://doi.org/10.1080/17515831.2021.1964876

Wang W, Zhang H, Liu Q, Zhu M, Jin X (2016) Investigation on adhesion characteristic of wheel/rail under the magnetic field condition. Proc Inst Mech Eng Part J J Eng Tribol 230:611–617. https://doi.org/10.1177/1350650115606480

Adams J (2012) The rise of research networks. Nature 490:335–336. https://doi.org/10.1038/490335a

Lewis R, Magel E, Wang W-J, Olofsson U, Lewis S, Slatter T, Beagles A (2017) Towards a standard approach for the wear testing of wheel and rail materials. Proc Inst Mech Eng Part F J Rail Rapid Transit 231:760–774. https://doi.org/10.1177/0954409717700531

Stock R, Stanlake L, Hardwick C, Yu M, Eadie D, Lewis R (2016) Material concepts for top of rail friction management—classification, characterisation and application. Wear 366–367:225–232. https://doi.org/10.1016/j.wear.2016.05.028

Lundén R, Paulsson B (2009) Introduction to wheel–rail interface research. Wheel-rail interface handbook. Elsevier, pp 3–33. https://doi.org/10.1533/9781845696788.1.3

Lewis R, Olofsson U (2009) Basic tribology of the wheel–rail contact. Wheel-rail interface handbook. Elsevier, pp 34–57. https://doi.org/10.1533/9781845696788.1.34

Lewis R, Dwyer-Joyce RS, Lewis J (2003) Disc machine study of contact isolation during railway track sanding. Proc Inst Mech Eng Part F J Rail Rapid Transit 217:11–24. https://doi.org/10.1243/095440903762727311

Tomberger C, Dietmaier P, Sextro W, Six K (2011) Friction in wheel–rail contact: a model comprising interfacial fluids, surface roughness and temperature. Wear 271:2–12. https://doi.org/10.1016/j.wear.2010.10.025

Lewis R, Olofsson U (2004) Mapping rail wear regimes and transitions. Wear 257:721–729. https://doi.org/10.1016/j.wear.2004.03.019

Acknowledgements

The authors would like to thank Vale S.A. through the Coordinator of the Project Wheel/Rail—Engineer Edilson Jun Kina, as well as the Brazilian National Council for Scientific and Technological Development (CNPQ) and Coordination for the Improvement of Higher Education Personnel—Brazil (CAPES) for financial support.

Funding

This study was funded by Brazilian National Council for Scientific and Technological Development (CNPQ), Coordination for the Improvement of Higher Education Personnel—Brazil (CAPES) and Vale Technological Institute (ITV).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

As corresponding author, I, Renan Carreiro Rocha, hereby confirm on behalf of all authors that: The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper. The paper has not been published previously, that it is not under consideration for publication elsewhere, and that if accepted it will not be published elsewhere in the same form, in English or in any other language, without the written consent of the publisher.

Additional information

Technical Editor: Zilda de Castro Silveira.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rocha, R.C., Ewald, H., Rezende, A.B. et al. Using twin disc for applications in the railway: a systematic review. J Braz. Soc. Mech. Sci. Eng. 45, 191 (2023). https://doi.org/10.1007/s40430-023-04104-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-023-04104-1