Abstract

The paper presents selected issues of position-force control of electro-hydraulic servo system using adaptive methods. This kind of measure extends the capabilities of control system which uses only position measurements. Indirect adaptive control has allowed for the monitoring and updating the dynamic phenomena occurring in the drive.

Similar content being viewed by others

1 Introduction

Control of the position in connection with the compensation load force is required in many industrial tasks. With these problems dealt for several years. During this time many mutually different conceptually methods and algorithms arose [1–3]. Each of the proposed methods has determined advantages and disadvantages as well cannot be applied for to perform all tasks. In particular requiring coupling from the exerted force. It should be emphasize that methods of position-force control are characterized by a great computational complexity which enables control of the location and force at every position of the piston actuator. Impacts on the piston actuator transmit to the driving system, however any right to control using coupling from force must take dynamic relations into account between the deviation of the position and the reaction force. So the adjustment of force is integrally associated with the control of positioning. Simultaneously, the control right must ensure stable behavior of the system for changing sizes of load forces. Therefore it is hard to carry out the independent control system and insensitive to changes of the load parameters.

In control of position is followed by the constant measurement of the piston position. Control modules proportional control valve or servo valve are developed from the level of on-board electronics through the drive controller working along with the position transducer in closed system. Depending on the kind of control valve a force or tension coupling is applied. In the control valve card there is a module cooperating with the inductive system of the measurement position of slider of the control valve (position control) or module where value of the tension (pressure control) is controlled. Such a card usually contains conventionally classical proportional controllers P, PD or PID, arrangements of the nonlinearity correction, limitations of the hysteresis control valve, steepness of falling and growing control signal [4]. However, control system of the drive responsible for positioning and controls of the speed, realizes the algorithm of control and cooperates with the measurement systems and potential communication modules.

In the case where the technological load force and pressures in chambers of the actuator it is possible to describe as variables of the state, then the control is applied which in the form of servomechanism is similar to position control [3, 5]. The difference consists in change of the position sensor to forces. Constant measurement of the technological burden force takes place. Necessary condition to maintain stable position of the actuator at the changeable external load is to keep permanent pressure in the chamber, which decides about its move. The automatic compensation occurs when a value of burdening force is known and on this base the controller determines the normal flow through the control valve[10].

In basic methods of force control the signal from the force sensor is converted into the position signals (velocity) by modifying the control algorithm. It consists on proper correction set values of position (velocity) based on changeable values of force. Such an approach causes the external control loop of force closed around the position of control system. In control theory implemented the concept of admittance control and impedance control, which were led on the principle of mechanical systems analogy to the electrical systems. This distinction regards the fundamental difference between the admittance and impedance approach in force controlling. About the admittance type we say when dynamic force at the input generates a flow (velocity) on the output. The impedance object is one in which the flow at the input generates force on the output. Impedance control is not carrying the direct control of force, however ensures the dynamic relations between position and force. This relation “involves” not only absolute position, but offset position with regard to the set value and force incurred as a result of this movement. In consequence of such impedance approach is lack of direct link from force in the control system, which is necessary in the admittance approach [3, 6].

2 Construction of the test stand

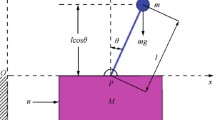

In the algorithms research of control electro-hydraulic servo drive is used the test stand. In the Fig. 1 presented a view of the test stand consisting of the electro-hydraulic servomechanism controlled by the proportional flow valve (2).

The load of working actuator as the technological resistance force is achieved by weights installed on the linear guide support (5). Servomechanism control systems is using the card of C/A converters. Displacement of the linear guide block is measured relatively to the corps test stand with the converter position Novotechnik Company (4). Velocity of the linear guide block is calculated by the differentiation piston position of the actuator (1). In the system there is also possible measurement of the technological resistance force using the force sensor (3). Placing proportional valve directly on the receiver reduced the volume of oil between the distributor and receiver which improved the dynamics of control system [7]. Hydraulic power supply is also included in the test stand \((P_{max} = 31.5\,\hbox {MPa})\), along with the proportioned pressure valve (DBETR-10/315G24K4M-381). The test stand also includes computer system in the superior control system equipped with the Matlab/Simulink (xPC Target) software. The microcomputer has cards of converters C/A and A/C of the PCI type-DAS1602/16 Measurement Computing Corporation. Card along with the converter of position and force creates the measurement system [2, 8].

3 Model reference of the adaptive control

To design electro-hydraulic servo-system control algorithms the parametric modelling ARMA (Auto-Regressive Moving-Averange) was used Jelali and Kroll [6]:

and ARX (Auto-Regressive with eXternal input):

where \(y_{t},\,u_{t}\), output and input signals in discrete time \(t\); \(d\) discrete delay and number of sampling periods \(T_{p}\); \(\xi _{t}\), controlled system interferences; \(q\), backward shift (delay) operator; \(A(q^{-1}),\,B(q^{-1})\), polynomial in the back shift operator \(q^{-1}\).

For nA, nB polynomials the model was parameterized by the vector:

The recursive identification enables to determine the parameters of controlled system on-line, within one sampling period:

in which regressive variable is present:

where \(\varphi _{t}\) is the vector of known regressive variables which are delayed samples of control and output signals the controlled system:

The model parameters estimators were determined by standard least squares algorithm:

where:

For the electro-hydraulic servo-system presented in Fig. 1 the estimates algorithm was used according to block diagram in Fig. 2.

The \(\varphi _{t}\) vector contains values of parameters measured in t-1 time, but covariance matrix \(P_{t}\) depends upon the values of all measurements \(\varphi _{t},\,i=1,..,t\). Figure 3 presents the estimated parameters of \(A(q^{-1}),\,B(q^{-1}),\,n=3\) polynomials of the electro-hydraulic servo-system model to ramp input function. The estimates determined by conventional methods are based upon the whole history of observation process and are the averaged values obtained in full registration period. The iterative algorithm does not keep up with the changes of the controlled system parameters “overloaded” with random interferences. Additionally, the control system is overloaded with substantial number of measurements as an increased dimensions result of \({{\varvec{P}}}_{{{\varvec{t}}}}\) matrix and \(\varphi _{t}\) vector.

4 Position-force control system

The control of force and position is carried out as two separate controllers, which parameters are selected individually. Designed in this way control system performs the task consisting in keeping up the driving system according to the set trajectory with the compensation force load from the technological resistance [7, 9]. However, for set position of carriage the control system of force enables to adapt the driving system to identified load conditions. Servo drive controllers in the terminus of force and positional loop were isolated from the PID controller [3].

For the controller of PD position,

where \(y_{ref},\,y_{k}\)—signals: set and initial of the system.

For the controller of the PI force,

where \(e_{k} =F_{ref} -F_{k}\)

Coupling PI type in the force loop causes that offend forces will be zero in the situation of appearance resistance force, even when the set speed of the servo drive will be non-zero. From the ordinary system with feedback, the used adaptive system distinguishes information in the form of defined reference model [9]. Therefore, in order to select controller parameters for the control systems in constant way parameters of models are identified for the position and force. When replacing \(q^{-1}\) (1) with \(z^{-1}\) we obtain:

\(A(z^{-1}),\,B(z^{-1})\)—polynomials model of the identified control objects, \(d\)—discrete delay determined by the number of sampling periods \(T_{p}\).

Parameters estimation for the mathematical model are appointed in the result of implementation identification algorithm, which describes how should be processed results of measurements in order to appoint values rates of the model [1, 2]. Polynomial model rates of identified control objects are a base for the update controllers set PI (forces) and PD (position). Figure 4 presents an architecture of position-force control system. For controlling digital cards and teams of regulators, amplifiers cards as well as sensors and units are used.

In deliberations concerning algorithms of the control electro-hydraulic servo drive in most cases the selection of control system parameters are carried out assuming that the properties of the system do not change over time. Adopted theoretical description does not change during the operation of the system. In this assumption it is only needed to accept once adequate theoretical description and to select parameters of the controller in the course of forcing drive move. As a result the disadvantage of presented solution is that it is very sensitive to errors in the description of controlled object. Lack of the resistance system to interferences appears. Additionally all variables of the state must be available measurement. Because the values of many parameters are not possible to be determined by direct measurements, they must be appointed as a result of parametric identification by building mathematical model of tested object. It is difficult and laborious process, often burdened with a large degree of uncertainty. As a result, to the control right are accepted approximate values of rates, which try to compensate nonlinearities appearing in the arrangement. In contemporary control systems such an approach is insufficient. To ensure appropriate quality for the control during the work system should be still tune up, which means to adapt parameters process of the control.

5 Experimental verification

The research work of the control algorithms was conducted using the following methods of transferring the piston of hydraulic actuator:

-

displacement of the actuator piston according to sinusoidal trajectory about the amplitude \(y_{ref}\) and \(T_{ref}\) period

-

displacement of the actuator piston from the initial situation \(y_{start}\) to set \(y_{ref}\) and the occurrence of pressure force \(F_{ref}\).

In experimental research the measuring signals were taken from sensors: position \(y_{p}\) (TMI 0250 Novotechnik), \(F\) forces (KT1101-K-10kN-2410-D Megatron) as continuous signals, and then after the discretization of signals \((y,\,F)\) registered in the digital way. The whole process of retrieving signals from sensors consists from mechanical transformation studied signals to the electric size, which is the electrical voltage proportional to the measured values. These figures using the data acquisition card and computer system as well as measurement shall be transformed to the digital figure [2]. Figure 5 presents courses of the regulation process using the adaptive algorithm of PD controller for chosen frequencies of the piston motion (0.16, 0.48 and 1.59 Hz).

Figure 6 presents courses of the regulation process of the adjustment force using the adaptive algorithm of the controller PI for chosen frequencies extortions of the pressure force. The correct work of the control system force appears for relatively slight force pulsations (up to 3 rad/s). At high frequencies there was a degradation of keeping up to set force.

6 Conclusions

Progress and development of new techniques point new objectives in front of electro-hydraulic drives. Developed position-force parallel control is a universal solution for single-axis electro-hydraulic servo drive. Depending on applications the controlled system can perform the following tasks:

-

free move of the bracket without contact with obstacles,

-

contact and exerting set force on the obstacle.

An example of such behavior is processes where the initial phase of bracket (actuator, the end effector of robot, processing slot) moves without contact with the environment. Only when a contact takes place, further movement occurs with the specific set force which is supposed to be exerted on the environment. Then applies only force control, in which is used interfering from the force. The first task is performed by the controller position, where the important parameter is the relevant accuracy of keeping up at displacement the actuator piston, however the second task performs the adjustment of force and adaptation of the servo drive to identified load conditions. Both controllers use the adaptive control technique which expands the area of the system application for non-stationary behaviors, that is where the change of dynamic properties takes place during the work.

References

Wos P, Dindorf R (2012) Adaptive control of a parallel manipulator driven by electro-hydraulic cylinders. Int J Appl Mech Eng 17(3):1061–1071

Wos P, Dindorf R (2008) Problems of the adaptive control for electro-hydraulic servo-system. In: Proceedings of the 5th Fluid Power Net International PhD Symposium, pp 153–162

Wos P, Dindorf R, Wołkow J (2008) Experimental studies of the electro-hydraulic servo system with adaptive controller. Monograph Library CYLINDER, KOMAG Gliwice (Poland), pp 111–119. http://komag.eu/wydawnictwa/monografie/komeko-cylinder-komtech/637-cylinder-2008

Katalog Bosch Rexroth AG (2012) Industrial hydraulics, hydraulic and electronic components

Rahmat MF, Rozali Md (2010) Modeling and controller design of the electro-hydraulic actuator system. Am J Appl Sci 7:1100–1108

Jelali M, Kroll A (2003) Hydraulic servo systems—modelling, identification & control. Springer, New York

Dindorf R, Wos P (2010) Adaptive control of an electro-hydraulic servo-system. Int J Appl Mech Eng 15(3):657–666

Dindorf R, Wos P (2011) Distributed real-time control system for fluid power drives. Hydraulika a Pneumatika 1:1–4; Slovakia

Wos P, Dindorf R (2013) Adaptive control of the electro-hydraulic servo-system with external disturbances. Asian J Control 15(4):1–16

Yao B (2002) Adaptive robust motion control of the single-rod hydraulic actuators: theory and experiments. IEEE ASME Trans Mechatron 5(1):79–91

Acknowledgments

This work was conducted in Kielce University of Technology and presented at the 12th Conference on Dynamical Systems Theory and Applications, December 2–5, 2013, Lodz, Poland.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Wos, P., Dindorf, R. Practical parallel position-force controller for electro-hydraulic servo drive using on-line identification. Int. J. Dynam. Control 4, 52–58 (2016). https://doi.org/10.1007/s40435-014-0092-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40435-014-0092-7