Abstract

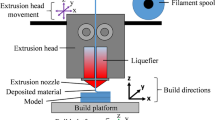

Recently, various additive manufacturing (AM) methods with a wide range of capabilities have been employed to produce metallic objects. Metals are a popular choice among AM materials due to their superior properties, despite being more challenging to print. Reduced product cost, the possibility for quick production and prototyping, and the capability of a produced component by high accuracy in a broad variety of shapes, geometrical complexity, size, and material are all advantages of metal AM technology. Metal fused deposition modeling (metal FDM) is a relatively new technique based on the widely used FDM process. It is a relatively low-cost competitor to other metal AM techniques such as selective laser melting (SLM). This review paper has explored the most recently issued publications in this extrusion-based metal additive manufacturing (EAM) technique. The main parameters in feedstock preparation, deposition and 3D printing, debinding, and sintering phases of the metal FDM process will be discussed and their influence on the mechanical and microstructural characteristics of the 3D-printed parts. Furthermore, the application of finite element modeling for metal FDM process analysis is explored. Finally, the challenges and gaps in the manufacturing of components and obtaining desired characteristics have been presented.

Similar content being viewed by others

Availability of data and materials

Not applicable.

Code availability

Not applicable.

Abbreviations

- ADAM:

-

Atomic diffusion additive manufacturing

- AM:

-

Additive manufacturing

- BJ:

-

Binder jetting

- BMD:

-

Bound metal deposition

- DIW:

-

Direct ink writing

- EAM:

-

Extrusion-based additive manufacturing

- EBM:

-

Electron beam melting

- FDM:

-

Fused deposition modeling

- FDMet:

-

Fused deposition of metals

- FEM:

-

Finite element modeling

- FFF:

-

Fused filament fabrication

- MF3:

-

Metal fused filament fabrication

- MIM:

-

Metal Injection Molding

- RWL:

-

Restaurant waste lipids

- SSMED:

-

Semi-solid metal extrusion and deposition

- SDS:

-

Shaping, debinding & sintering

- SLM:

-

Selective laser melting

- SLS:

-

Selective laser sintering

- SS:

-

Stainless steel

- TPE:

-

Thermoplastic elastomer

References

ISO/ASTM52900-15 (2015) Standard terminology for additive manufacturing—general principles—terminology, ASTM International, West Conshohocken, PA. www.astm.org

Shirazi SFS et al (2015) A review on powder-based additive manufacturing for tissue engineering: Selective laser sintering and inkjet 3D printing. Sci Technol Adv Mater 16:033502

Zadpoor AA (2018) Frontiers of additively manufactured metallic materials. Materials 11:1–10

Jabbari A, Abrinia K (2018) A metal additive manufacturing method: semi-solid metal extrusion and deposition. Int J Adv Manuf Technol 94:3819–3828

Pack RC, Compton BG (2021) Material extrusion additive manufacturing of metal powder-based inks enabled by Carrageenan rheology modifier. Adv Eng Mater 23:2000880

Roshchupkin SI, Golovin VI, Kolesov AG, Tarakhovskiy AY (2020) Extruder for the production of metal-polymer filament for additive technologies. IOP Conf Ser Mater Sci Eng 971:022009

Rane K, Strano M (2019) A comprehensive review of extrusion-based additive manufacturing processes for rapid production of metallic and ceramic parts. Adv Manuf 7:155–173

Rosnitschek T, Hueter F, Alber-Laukant B (2020) FEM-based modelling of elastic properties and anisotropic sinter Shrinkage of metal EAM. Int J Simul Model 19:197–208

Strano M, Rane K, Briatico Vangosa F, Di Landro L (2019) Extrusion of metal powder-polymer mixtures: Melt rheology and process stability. J Mater Process Technol 273:116250

Strano M, Rane K, Farid MA, Mussi V, Zaragoza V, Monno M (2021) Extrusion-based additive manufacturing of forming and molding tools,". Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-021-07162-8

Chávez FA, Quiñonez PA, Roberson DA (2019) Hybrid metal/thermoplastic composites for FDM-type additive manufacturing. J Thermoplast Comp Mater. https://doi.org/10.1177/0892705719864150

Çevik Ü, Kam M (2020) A review study on mechanical properties of obtained products by FDM method and metal/polymer composite filament production. J Nanomater. https://doi.org/10.1155/2020/6187149

Boparai KS, Singh R, Singh H (2016) Experimental investigations for development of Nylon6-Al-Al2O3 alternative FDM filament. Rapid Prototyp J 22:217–224

Fu X, Zhang X, Huang Z (2021) Axial crushing of Nylon and Al/Nylon hybrid tubes by FDM 3D printing. Compos Struct 256:113055

Scheithauer U, Slawik T, Schwarzer E, Richter HJ, Moritz T, Michaelis A (2015) Additive manufacturing of metal-ceramic-composites by thermoplastic 3D-printing (3DTP). J Ceram Sci Technol 6:125–132

Lengauer W et al. (2018) Preparation and properties of extrusion-based 3D-printed hardmetal and cermet parts. Euro PM 2018 Congress and Exhibition

Vafadar A, Guzzomi F, Rassau A, Hayward K (2021) Advances in metal additive manufacturing: a review of common processes, industrial applications, and current challenges. Appl Sci 11:1–33

Ren X, Shao H, Lin T, Zheng H (2016) 3D gel-printing-An additive manufacturing method for producing complex shape parts. Mater Des 101:80–87

Li JP, de Wijn JR, Van Blitterswijk CA, de Groot K (2006) Porous Ti6Al4V scaffold directly fabricating by rapid prototyping: preparation and in vitro experiment. Biomaterials 27(8):1223–1235

Elsayed H et al (2019) "Direct ink writing of porous titanium (Ti6Al4V) lattice structures. Mater Sci Eng 103:109794

Nurhudan AI, Supriadi S, Whulanza Y, Saragih AS (2021) Additive manufacturing of metallic based on extrusion process: a review. J Manuf Process 66:228–237

Wohlers T (2017) Desktop metal: a rising star of metal AM targets speed, cost and high-volume production. Metal AM: 89–92

Campbell I, Wohlers T (2017) Markforged: taking a different approach to metal additive manufacturing

Kukla C, Gonzalez-Gutierrez J, Hampel S, Burkhardt C, Holzer C (2017) The SDS process: a viable way for the production of metal parts. 11th International Conference on Industrial Tools and Advanced Processing Technologies

Watson A, Belding J, Ellis BD (2020) Characterization of 17–4 PH processed via bound metal deposition (BMD). TMS 2020 149th Annual Meeting & Exhibition Supplemental Proceedings. Springer, Cham, Switzerland. pp 205–216

Galati M, Minetola P (2019) Analysis of density, roughness, and accuracy of the atomic diffusion additive manufacturing (ADAM) process for metal parts. Materials 12(24):4122

Kurose T et al (2020) Influence of the layer directions on the properties of 316l stainless steel parts fabricated through fused deposition of metals. Materials 13:2493

Hassan W, Farid MA, Tosi A, Rane K, Strano M (2021) The effect of printing parameters on sintered properties of extrusion-based additively manufactured stainless steel 316L parts. Int J Adv Manuf Technol 114(9):3057–3067

Singh P, Balla VK, Tofangchi A, Atre SV, Kate KH (2020) Printability studies of Ti-6Al-4V by metal fused filament fabrication (MF3). Int J Refract Metals Hard Mater 91:15249

Gong H, Snelling D, Kardel K, Carrano A (2019) Comparison of stainless steel 316L parts made by FDM- and SLM-based additive manufacturing processes. JOM 71:880–885

Capus J (2020) Making steel powders for PM and AM. Metal Powder Rep 75:148–150

Korotchenko AY, Khilkov DE, Tverskoy MV, Khilkova AA (2020) Use of additive technologies for metal injection molding. Eng Solid Mech 8:143–150

Wu G, Langrana NA, Sadanji R, Danforth S (2002) Solid freeform fabrication of metal components using fused deposition of metals. Mater Des 23:97–105

Kukla C, Cano S, Kaylani D, Schuschnigg S, Holzer C, Gonzalez-Gutierrez J (2019) Debinding behaviour of feedstock for material extrusion additive manufacturing of zirconia. Powder Met 62:196–204

Amin AM, Ibrahim MHI, Asmawi R, Mustaffa N, Hashim MY (2017) Thermal debinding and sintering of water atomised SS316L metal injection moulding process. IOP Conf Series Mater Sci Eng 226:12155

Rane K, Farid MA, Hassan W, Strano M (2021) Effect of printing parameters on mechanical properties of extrusion-based additively manufactured ceramic parts. Ceram Int 47:12189–12198

Ahn S, Park SJ, Lee S, Atre SV, German RM (2009) Effect of powders and binders on material properties and molding parameters in iron and stainless steel powder injection molding process. Powder Technol 193:162–169

Quinard C, Barriere T, Gelin JC (2009) Development and property identification of 316L stainless steel feedstock for PIM and μPIM. Powder Technol 190:123–128

Momeni V, Alaei MH, Askari A, Rahimi AH, Nekouee K (2020) Effect of the fraction of steel 4605 powder in the load in injection molding with the use of a polymer-based binder. Metal Sci Heat Treat 61:777–781

Virdhian S, Doloksaribu M, Supriadi S, Balfas NM, Suharno B, Shieddieque AD (2020) Characterization of 17–4 PH stainless steel metal injection molding feedstock using mixing torque data. IOP Conf Ser Mater Sci Eng 980:20

Toropkov N, Lerner M, Mironov E (2019) Feedstock investigation based on SAE 316L steel bimodal powders and PLA/PMMA for injection molding: an experimental study. AIP Conf Proc 2167:20367

Park DY et al (2017) Investigation of powder size effects on sintering of powder injection moulded 17–4PH stainless steel. Powder Metal 60:139–148

Rane K et al. (2018) Rapid production of hollow SS316 profiles by extrusion based additive manufacturing. AIP Conference Proceedings 1960

Kassym K, Perveen A (2019) Atomization processes of metal powders for 3D printing. Mater Today Proc 26:1727–1733

Ren L et al (2017) Process parameter optimization of extrusion-based 3D metal printing utilizing PW-LDPE-SA binder system. Materials 10:305

Annoni M, Giberti H, Strano M (2016) Feasibility study of an extrusion-based direct metal additive manufacturing technique. Procedia Manuf 5:916–927

Lu Z, Ayeni OI, Yang X, Park HY, Jung YG, Zhang J (2020) Microstructure and phase analysis of 3D-printed components using bronze metal filament. J Mater Eng Perform 29:1650–1656

Li JP, De Wijn JR, Van Blitterswijk CA, De Groot K (2006) Porous Ti6Al4V scaffold directly fabricating by rapid prototyping: preparation and in vitro experiment. Biomaterials 27:1223–1235

Kang H, Kitsomboonloha R, Jang J, Subramanian V (2012) High-performance printed transistors realized using femtoliter gravure-printed sub-10 μm metallic nanoparticle patterns and highly uniform polymer dielectric and semiconductor layers. Adv Mater 24:3065–3069

Li J, Xie Z, Zhang X, Zeng Q, Liu H (2010) Study of metal powder extrusion and accumulating rapid prototyping. Key Eng Mater 443:81–86

Rane K, Di Landro L, Strano M (2019) Processability of SS316L powder—binder mixtures for vertical extrusion and deposition on table tests. Powder Technol 345:553–562

Liu B, Wang Y, Lin Z, Zhang T (2020) Creating metal parts by fused deposition modeling and sintering. Mater Lett 263:127252

Gonzalez-Gutierrez J, Arbeiter F, Schlauf T, Kukla C, Holzer C (2019) Tensile properties of sintered 17–4PH stainless steel fabricated by material extrusion additive manufacturing. Mater Lett 248:165–168

Gonzalez-Gutierrez J, Guráň R, Spoerk M, Holzer C, Godec D, Kukla C (2018) 3D printing conditions determination for feedstock used in fused filament fabrication (FFF) of 17-4PH stainless steel parts. Metalurgija 57:117–120

Godec D, Cano S, Holzer C, Gonzalez-Gutierrez J (2020) Optimization of the 3D printing parameters for tensile properties of specimens produced by fused filament fabrication of 17–4PH stainless steel. Materials 13:774

Yan X, Hao L, Xiong W, Tang D (2017) Research on influencing factors and its optimization of metal powder injection molding without mold via an innovative 3D printing method. RSC Adv 7:55232–55239

Yan X, Wang C, Xiong W, Hou T, Hao L, Tang D (2018) Thermal debinding mass transfer mechanism and dynamics of copper green parts fabricated by an innovative 3D printing method. RSC Adv 8:10355–10360

Singh G, Missiaen JM, Bouvard D, Chaix JM (2021) Copper additive manufacturing using MIM feedstock: adjustment of printing, debinding, and sintering parameters for processing dense and defectless parts. Int J Adv Manuf Technol 115:449–462

Hong S, Sanchez C, Du H, Kim N (2015) Fabrication of 3D printed metal structures by use of high-viscosity cu paste and a screw extruder. J Electron Mater 44:836–841

Gibson I, Rosen D, Stucker B, Khorasani M (2021) Additive manufacturing technologies. Gewerbestrasse 11, 6330 Cham, Switzerland. 685

Antony LVM, Reddy RG (2003) Processes for production of high-purity metal powders. JOM 55:14–18

Miranda R (2013) Handbook of metal injection molding. Int J Environ Stud 70:165–165

Liu L, Loh NH, Tay BY, Tor SB, Murakoshi Y, Maeda R (2005) Mixing and characterisation of 316L stainless steel feedstock for micro powder injection molding. Mater Charact 54:230–238

Weston NS, Thomas B, Jackson M (2019) Processing metal powders via field assisted sintering technology (FAST): a critical review. Mater Sci Technol 35:1306–1328

Thompson Y, Gonzalez-Gutierrez J, Kukla C, Felfer P (2019) Fused filament fabrication, debinding and sintering as a low cost additive manufacturing method of 316L stainless steel. Addit Manuf 30:100861

Gonzalez-Gutierrez J, Cano S, Schuschnigg S, Kukla C, Sapkota J, Holzer C (2018) Additive manufacturing of metallic and ceramic components by the material extrusion of highly-filled polymers: a review and future perspectives. Materials 11:840

Rane K, Castelli K, Strano M (2019) Rapid surface quality assessment of green 3D printed metal-binder parts. J Manuf Process 38:290–297

Giberti H, Sbaglia L, Silvestri M (2017) Mechatronic design for an extrusion-based additive manufacturing machine. Machines 5:29

Tosto C, Tirillò J, Sarasini F, Cicala G (2021) Hybrid metal/polymer filaments for fused filament fabrication (FFF) to print metal parts. Appl Sci 11:1

Rane K, Barriere T, Strano M (2020) Role of elongational viscosity of feedstock in extrusion-based additive manufacturing of powder-binder mixtures. Int J Adv Manuf Technol 107:4389–4402

Ait-Mansour I, Kretzschmar N, Chekurov S, Salmi M, Rech J (2020) Design-dependent shrinkage compensation modeling and mechanical property targeting of metal FFF. Prog Addit Manuf 5:51–57

Raza MR et al (2017) Effects of debinding and sintering atmosphere on properties and corrosion resistance of powder injection molded 316 L—stainless steel. JSM 46:285–293

Rosnitschek T, Glamsch J, Lange C, Alber-Laukant B, Rieg F (2021) An automated open-source approach for debinding simulation in metal extrusion additive manufacturing. Designs 5:1–15

Parenti P, Cataldo S, Annoni M (2018) Shape deposition manufacturing of 316L parts via feedstock extrusion and green-state milling. Manuf Letters 18:6–11

Gong P, Yan X, Xiong W, Hao L, Tang D, Li Y (2020) Design of a debinding process for polymetallic material green parts fabricatedviametal paste injection 3D printing with dual nozzles. RSC Adv 10:18000–18007

Gonzalez-Gutierrez J, Godec D, Kukla C, Schlauf T, Burkhardt C, Holzer C (2017) Shaping, debinding and sintering of steel components via fused filament fabrication. 16th International Scientific Conference on Production Engineering—CIM2017; 99–104

Tuncer N, Bose A (2020) Solid-state metal additive manufacturing: a review. JOM 72:3090–3111

Mirzababaei S, Pasebani S (2019) A review on binder jet additive manufacturing of 316L stainless steel. J Manuf Mater Process 3:82

Lieberwirth C, Sarhan M, Seitz H (2018) Mechanical properties of stainless-steel structures fabricated by composite extrusion modelling. Metals 8(2):84

Zhang Y, Bai S, Riede M, Garratt E, Roch A (2020) A comprehensive study on fused filament fabrication of Ti-6Al-4V structures. Addit Manuf 34:101256

Cerejo F, Gatões D, Vieira MT (2021) Optimization of metallic powder filaments for additive manufacturing extrusion (MEX). Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-021-07043-0

Ye H, Liu XY, Hong H (2008) Sintering of 17–4PH stainless steel feedstock for metal injection molding. Mater Lett 62:3334–3336

Várez A, Levenfeld B, Torralba JM, Matula G, Dobrzanski LA (2004) Sintering in different atmospheres of T15 and M2 high speed steels produced by a modified metal injection moulding process. Mater Sci Eng A 366:318–324

Dourandish M, Simchi A (2009) Study the sintering behavior of nanocrystalline 3Y-TZP/430L stainless-steel composite layers for co-powder injection molding. J Mater Sci 44(5):1264–1274

Olevsky EA, Dudina DV (2018) Field-assisted sintering: science and applications. Field-Assisted Sintering: Science and Applications. Gewerbestrasse 11, 6330 Cham, Switzerland. 1–425

Anklekar RM, Agrawal DK, Roy R (2001) Microwave sintering and mechanical properties of PM copper steel. Powder Metal 44:355–362

Panda SS, Singh V, Upadhyaya A, Agrawal D (2006) Sintering response of austenitic (316L) and ferritic (434L) stainless steel consolidated in conventional and microwave furnaces. Scripta Mater 54:2179–2183

Ertugrul O, Park HS, Onel K, Willert-Porada M (2014) Effect of particle size and heating rate in microwave sintering of 316L stainless steel. Powder Technol 253:703–709

Mousapour M, Salmi M, Klemettinen L, Partanen J (2021) Feasibility study of producing multi-metal parts by Fused Filament Fabrication (FFF) technique. J Manuf Process 67:438–446

ASTM F3122-14 (2014) Standard guide for evaluating mechanical properties of metal materials made via additive manufacturing processes, ASTM International, West Conshohocken. http://www.astm.org

Cooke S, Ahmadi K, Willerth S, Herring R (2020) Metal additive manufacturing: Technology, metallurgy and modelling. J Manuf Process 57:978–1003

Markforged (2020) Material datasheet 17-4 PH stainless steel: 1–2

ASM (2014) AISI Type 316L Stainless Steel ASM: 1–2

Verlee B, Dormal T, Lecomte-Beckers J (2012) Density and porosity control of sintered 316L stainless steel parts produced by additive manufacturing. Powder Metall 55(4):260–267

Lou JK et al (2020) Investigation of decarburization behaviour during the sintering of metal injection moulded 420 stainless steel. Metals 10:211

Torralba JM (2012) Metal injection molding (MIM) of stainless steel. In: Donald FH (ed) Woodhead Publishing, Handbook of Metal Injection Molding: 393–414

Shang F, Wang Z, Chen X, Ji Z, Ren S, Qu X (2021) UNS S32707 hyper-duplex stainless steel processed by powder injection molding and supersolidus liquid-phase sintering in nitrogen sintering atmosphere. Vacuum 184:109910

Mishra DK, Pandey PM (2020) Effect of sintering parameters on the microstructure and compressive mechanical properties of porous Fe scaffold fabricated using 3D printing and pressure less microwave sintering. Proc Inst Mech Eng C J Mech Eng Sci 234:4305–4320

Zhang Z, Femi-Oyetoro J, Fidan I, Ismail M, Allen M (2021) Prediction of dimensional changes of low-cost metal material extrusion fabricated parts using machine learning techniques. Metals 11:690

Acknowledgements

The authors wish to express their gratitude to Dr. Hasan Abdoos (Department of Nanotechnology, Faculty of New Sciences and Technologies, Semnan University, Semnan) for reading the manuscript and providing helpful suggestions for article improvement. The authors also would like to thank the numerous researchers whose work has been represented in this review paper.

Funding

No funding was received for conducting this study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflicts of interest to declare that are relevant to the content of this article.

Ethical approval

Not applicable because this article does not contain any studies with human or animal subjects.

Consent to participate

Not applicable.

Consent to publish

Not applicable.

Rights and permissions

About this article

Cite this article

Ramazani, H., Kami, A. Metal FDM, a new extrusion-based additive manufacturing technology for manufacturing of metallic parts: a review. Prog Addit Manuf 7, 609–626 (2022). https://doi.org/10.1007/s40964-021-00250-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40964-021-00250-x