Abstract

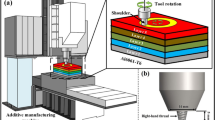

Friction stir additive manufacturing (FSAM) is a solid-state sheet-based metal additive manufacturing (MAM) process that utilizes the classical friction stir welding (FSW) process to join the layers. So far, FSAM has been explored for fabricating thin to thick metallic walls. However, to realize large-scale defect-free dense structures, FSAM demands multiple welding tracks in each layer with a suitable overlap. Therefore, this work investigates the effect of overlapping percentages (0%, 25%, 50%, and 75%) in joining two layers of AA6061-T6 alloy by a concave shouldered tool and a cylindrical taper pin. The multi-track FSAM strategy is incorporated to join the two layers with a raster pattern toolpath. The joined layer's cross-sectional micrographs showed the absence of the half-ellipse-shaped banded patterns and a high degree of plasticized material mixing with an increase in overlapping percentage. It has been noticed that the successive overlapping weld tracks act as a post-heat treatment process for pre-scanned tracks, leading to more heat exposure time and grain re-growth. High magnification images and energy dispersion spectroscopy (EDS) revealed the homogeneous distribution of secondary precipitates into the samples prepared by 50% overlap, resulting in relatively higher tensile strength and uniform hardness. As 50% overlap exhibited better mechanical and microstructural properties, it has been further implemented as a toolpath stepover to join multiple sheets of AA6061-T6 material to create a block. The outcomes showed a dense microstructure in the processed zones and good interlayer bonding with increased tensile strength (maximum UTS 258 MPa) and hardness (maximum value 102 HV0.1) along the building direction. Moreover, a spur gear has been realized by machining from the block created by multi-layered multi-track FSAM.

Graphical Abstract

Similar content being viewed by others

Data availability

Data related to any results in this article will be available upon request.

References

Ngo TD, Kashani A, Imbalzano G, Nguyen KT, Hui D (2018) Additive manufacturing (3D printing): a review of materials, methods, applications and challenges. Compos B Eng 143:172–196. https://doi.org/10.1016/j.compositesb.2018.02.012

Fayazfar H, Salarian M, Rogalsky A, Sarker D, Russo P, Paserin V, Toyserkani E (2018) A critical review of powder-based additive manufacturing of ferrous alloys: Process parameters, microstructure and mechanical properties. Mater Des 144:98–128. https://doi.org/10.1016/j.matdes.2018.02.018

Javidani M, Arreguin-Zavala J, Danovitch J, Tian Y, Brochu M (2017) Additive manufacturing of AlSi10Mg alloy using direct energy deposition: microstructure and hardness characterization. J Therm Spray Technol 26(4):587–597. https://doi.org/10.1007/s11666-016-0495-4

Yi S, Liu F, Zhang J, Xiong S (2004) Study of the key technologies of LOM for functional metal parts. J Mater Process Technol 150(1–2):175–181. https://doi.org/10.1016/j.jmatprotec.2004.01.035

Liu HJ, Hou JC, Guo H (2013) Effect of welding speed on microstructure and mechanical properties of self-reacting friction stir welded 6061–T6 aluminum alloy. Mater Des 50:872–878. https://doi.org/10.1016/j.matdes.2013.03.105

Vijayananth, S., Jayaseelan, V., & Kumar, N. M. High temperature superplasticity and its deformation mechanism of AA6063/SiCp. Case Studies in Thermal Engineering, 2019; 14, 100479. https://doi.org/10.1016/j.csite.2019.100479

Chen, Z., Li, S., & Hihara, L. H. Microstructure, mechanical properties and corrosion of friction stir welded 6061 Aluminum Alloy. arXiv preprint arXiv:2015;1511.05507. https://doi.org/10.48550/arXiv.1511.05507

Nezhadfar, P. D., Thompson, S., Saharan, A., Phan, N., & Shamsaei, N. Structural integrity of additively manufactured aluminum alloys: Effects of build orientation on microstructure, porosity, and fatigue behavior. Additive Manufacturing, 2021; 47, 102292. https://doi.org/10.1016/j.addma.2021.102292

Olakanmi EO (2013) Selective laser sintering/melting (SLS/SLM) of pure Al, Al–Mg, and Al–Si powders: Effect of processing conditions and powder properties. J Mater Process Technol 213(8):1387–1405. https://doi.org/10.1016/j.jmatprotec.2013.03.009

Wang Z, Wu W, Qian G, Sun L, Li X, Correia JA (2019) In-situ SEM investigation on fatigue behaviors of additive manufactured Al-Si10-Mg alloy at elevated temperature. Eng Fract Mech 214:149–163. https://doi.org/10.1016/j.engfracmech.2019.03.040

Tang M, Pistorius PC (2017) Oxides, porosity and fatigue performance of AlSi10Mg parts produced by selective laser melting. Int J Fatigue 94:192–201. https://doi.org/10.1016/j.ijfatigue.2016.06.002

Hang, Z. Y., Jones, M. E., Brady, G. W., Griffiths, R. J., Garcia, D., Rauch, H. A., ... & Hardwick, N. Non-beam-based metal additive manufacturing enabled by additive friction stir deposition. Scripta Materialia, 2018; 153, 122–130. https://doi.org/10.1016/j.scriptamat.2018.03.025

Tongne A, Desrayaud C, Jahazi M, Feulvarch E (2017) On material flow in friction stir welded Al alloys. J Mater Process Technol 239:284–296. https://doi.org/10.1016/j.jmatprotec.2016.08.030

Mishra RS, Haridas RS, Agrawal P (2022) Friction stir-based additive manufacturing. Sci Technol Weld Joining 27(3):141–165. https://doi.org/10.1080/13621718.2022.2027663

Rivera, O. G., Allison, P. G., Jordon, J. B., Rodriguez, O. L., Brewer, L. N., McClelland, Z., ... & Hardwick, N. Microstructures and mechanical behavior of Inconel 625 fabricated by solid-state additive manufacturing. Materials Science and Engineering: A, 2017; 694, 1–9. https://doi.org/10.1016/j.msea.2017.03.105

Griffths RJ, Petersen DT, Garcia D, Yu HZ (2019) Additive friction stir-enabled solid-state additive manufacturing for the repair of 7075 aluminum alloy. Appl Sci 9:3486. https://doi.org/10.3390/app9173486

Avery, D.Z., Phillips, B.J., Mason, C.J.T., Palermo, M., Williams, M.B., Cleek, C., Rodriguez, O.L., Allison, P.G., Jordon, J.B., Influence of grain refnement and microstructure on fatigue behavior for solid-state additively manufactured Al-ZnMg-Cu alloy. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2020; https://doi.org/10.1007/s11661-020-05746-9

Phillips, B.J., Avery, D.Z., Liu, T., Rodriguez, O.L., Mason, C.J.T., Jordon, J.B., Brewer, L. N., Allison, P.G., Microstructure-deformation relationship of additive friction stir-deposition Al–Mg–Si. Materialia 2019; 7. https://doi.org/10.1016/J.MTLA.2019.100387

Jordon, J.B., Allison, P.G., Phillips, B.J., Avery, D.Z., Kinser, R.P., Brewer, L.N., Cox, C., Doherty, K., Direct recycling of machine chips through a novel solid-state additive manufacturing process. Mater. Des. 2020; 193, 108850. https://doi.org/10.1016/j.matdes.2020.108850

Agrawal, P., Haridas, R. S., Yadav, S., Thapliyal, S., Gaddam, S., Verma, R., & Mishra, R. S. Processing-structure-property correlation in additive friction stir deposited Ti-6Al-4V alloy from recycled metal chips. Additive Manufacturing, 2021; 47, 102259. https://doi.org/10.1016/j.addma.2021.102259

Palanivel S, Sidhar H, Mishra RS (2015) Friction stir additive manufacturing: route to high structural performance. Jom 67(3):616–621. https://doi.org/10.1007/s11837-014-1271-x

Yuqing M, Liming K, Chunping H, Fencheng L, Qiang L (2016) Formation characteristic, microstructure, and mechanical performances of aluminum-based components by friction stir additive manufacturing. The International Journal of Advanced Manufacturing Technology 83(9–12):1637–1647. https://doi.org/10.1007/s00170-015-7695-9

He, C., Li, Y., Zhang, Z., Wei, J., & Zhao, X. Investigation on microstructural evolution and property variation along building direction in friction stir additive manufactured Al–Zn–Mg alloy. Materials Science and Engineering: 2020; A, 777, 139035. https://doi.org/10.1016/j.msea.2020.139035

Zhang, Z., Tan, Z. J., Li, J. Y., Zu, Y. F., Liu, W. W., & Sha, J. J. (2019). Experimental and numerical studies of re-stirring and re-heating effects on mechanical properties in friction stir additive manufacturing. The International Journal of Advanced Manufacturing Technology, 2019; 104(1–4), 767–784. https://doi.org/10.1007/s00170-019-03917-6

Palanivel S, Nelaturu P, Glass B, Mishra RS (2015) Friction stir additive manufacturing for high structural performance through microstructural control in an Mg based WE43 alloy. Mater Des 65:934–952. https://doi.org/10.1016/j.matdes.2014.09.082

Zhao Z, Yang X, Li S, Li D (2019) Interfacial bonding features of friction stir additive manufactured build for 2195–T8 aluminum-lithium alloy. J Manuf Process 38:396–410. https://doi.org/10.1016/j.jmapro.2019.01.042

Aktarer, S. M., Sekban, D. M., Saray, O., Kucukomeroglu, T., Ma, Z. Y., & Purcek, G. Effect of two-pass friction stir processing on the microstructure and mechanical properties of as-cast binary Al–12Si alloy. Materials Science and Engineering: 2015; A, 636, 311–319. https://doi.org/10.1016/j.msea.2015.03.111

Nazari, M., Eskandari, H., & Khodabakhshi, F. Production and characterization of an advanced AA6061-Graphene-TiB2 hybrid surface nanocomposite by multi-pass friction stir processing. Surface and Coatings Technology, 2019; 377, 124914. https://doi.org/10.1016/j.surfcoat.2019.124914

Derazkola, H. A., Khodabakhshi, F., & Simchi, A. Evaluation of a polymer-steel laminated sheet composite structure produced by friction stir additive manufacturing (FSAM) technology. 2020; Polymer Testing, 90, 106690. https://doi.org/10.1016/j.polymertesting.2020.106690

He C, Li Y, Wei J, Zhang Z, Tian N, Qin G, Zhao X (2022) Enhancing the mechanical performance of Al–Zn–Mg alloy builds fabricated via underwater friction stir additive manufacturing and post-processing aging. J Mater Sci Technol 108:26–36. https://doi.org/10.1016/j.jmst.2021.08.050

Liu F, Zhang Y, Dong P (2022) Large area friction stir additive manufacturing of intermetallic-free aluminum-steel bimetallic components through interfacial amorphization. J Manuf Process 73:725–735. https://doi.org/10.1016/j.jmapro.2021.11.042

Zou S, Ma S, Liu C, Chen C, Ma L, Lu J, Guo J (2017) Multi-track friction stir lap welding of 2024 aluminum alloy: processing, microstructure and mechanical properties. Metals 7(1):1. https://doi.org/10.3390/met7010001

Zhao, Y., Luo, Y., Lu, Y., He, Y., Guo, X., Wang, S., ... & Wang, Z. Effect of welding parameters on the microstructures and mechanical properties of double-pass aluminum/magnesium dissimilar metal friction stir lap welding joint. Materials Today Communications, 2021; 26, 102132. https://doi.org/10.1016/j.mtcomm.2021.102132

Al-Fadhalah KJ, Almazrouee AI, Aloraier AS (2014) Microstructure and mechanical properties of multi-pass friction stir processed aluminum alloy 6063. Mater Des 53:550–560. https://doi.org/10.1016/j.matdes.2013.07.062

Leitao C, Arruti E, Aldanondo E, Rodrigues DM (2016) Aluminium-steel lap joining by multipass friction stir welding. Mater Des 106:153–160. https://doi.org/10.1016/j.matdes.2016.05.101

Kumar, K. S. V. K., & Kailas, S. V. The role of friction stir welding tool on material flow and weld formation. Materials Science and Engineering: 2008; A, 485(1–2), 367–374. https://doi.org/10.1016/j.msea.2007.08.013

Gratecap F, Girard M, Marya S, Racineux G (2012) Exploring material flow in friction stir welding: tool eccentricity and formation of banded structures. IntJ Mater Form 5(2):99–107. https://doi.org/10.1007/s12289-010-1008-5

Geyer, M., Vidal, V., Pottier, T., Boher, C., & Rézaï-Aria, F. Investigations on the material flow and the role of the resulting hooks on the mechanical behaviour of dissimilar friction stir welded Al2024-T3 to Ti-6Al-4V overlap joints. Journal of Materials Processing Technology, 2021; 292, 117057. https://doi.org/10.1016/j.jmatprotec.2021.117057

Zhou N, Song D, Qi W, Li X, Zou J, Attallah MM (2018) Influence of the kissing bond on the mechanical properties and fracture behaviour of AA5083-H112 friction stir welds. Mater Sci Eng, A 719:12–20. https://doi.org/10.1016/j.msea.2018.02.011

Pabandi HK, Jashnani HR, Paidar M (2018) Effect of precipitation hardening heat treatment on mechanical and microstructure features of dissimilar friction stir welded AA2024-T6 and AA6061-T6 alloys. J Manuf Process 31:214–220. https://doi.org/10.1016/j.jmapro.2017.11.019

Jayaseelan V, Jayabalakrishnan D, Muthuramalingam T, Francis Xavier J (2022) Impact of the novel square wave tool path pattern on AA6061-T6 friction stir welding. Mater Manuf Processes 37(8):886–895. https://doi.org/10.1080/10426914.2021.1973028

Banik, A., Saha, A., Barma, J. D., Acharya, U., & Saha, S. C. Determination of best tool geometry for friction stir welding of AA 6061-T6 using hybrid PCA-TOPSIS optimization method. Measurement, 2021; 173, 108573. https://doi.org/10.1016/j.measurement.2020.108573

Kalinenko, A., Kim, K., Vysotskiy, I., Zuiko, I., Malopheyev, S., Mironov, S., & Kaibyshev, R. Microstructure-strength relationship in friction-stir welded 6061-T6 aluminum alloy. Materials Science and Engineering:2020; A, 793, 139858. https://doi.org/10.1016/j.msea.2020.139858

Banik A, Deb Barma J, Saha SC (2020) Effect of threaded pin tool for friction stir welding of AA6061-T6 at varying traverse speeds: torque and force analysis. Iranian Journal of Science and Technology, Transactions of Mechanical Engineering 44:749–764. https://doi.org/10.1007/s40997-019-00289-w

Nami H, Adgi H, Sharifitabar M, Shamabadi H (2011) Microstructure and mechanical properties of friction stir welded Al/Mg2Si metal matrix cast composite. Mater Des 32(2):976–983. https://doi.org/10.1016/j.matdes.2010.07.008

Hakem M, Lebaili S, Mathieu S, Miroud D, Lebaili A, Cheniti B (2019) Effect of microstructure and precipitation phenomena on the mechanical behavior of AA6061-T6 aluminum alloy weld. The International Journal of Advanced Manufacturing Technology 102(9):2907–2918. https://doi.org/10.1007/s00170-019-03401-1

Moharami, A., Razaghian, A., Babaei, B., Ojo, O. O., & Šlapáková, M. Role of Mg2Si particles on mechanical, wear, and corrosion behaviors of friction stir welding of AA6061-T6 and Al-Mg2Si composite. Journal of Composite Materials, 2020; 54(26), 4035–4057. https://doi.org/10.1177/2F0021998320925528

Maji P, Nath RK, Karmakar R, Paul P, Meitei RB, Ghosh SK (2021) Effect of post processing heat treatment on friction stir welded/processed aluminum based alloys and composites. CIRP J Manuf Sci Technol 35:96–105. https://doi.org/10.1016/j.cirpj.2021.05.014

Maisonnette D, Suery M, Nelias D, Chaudet P, Epicier T (2011) Effects of heat treatments on the microstructure and mechanical properties of a 6061 aluminium alloy. Mater Sci Eng, A 528(6):2718–2724. https://doi.org/10.1016/j.msea.2010.12.011

Sato YS, Park SHC, Kokawa H (2001) Microstructural factors governing hardness in friction-stir welds of solid-solution-hardened Al alloys. Metall and Mater Trans A 32(12):3033–3042. https://doi.org/10.1007/s11661-001-0178-7

Rajakumar S, Muralidharan C, Balasubramanian V (2011) Predicting tensile strength, hardness and corrosion rate of friction stir welded AA6061-T6 aluminium alloy joints. Mater Des 32(5):2878–2890. https://doi.org/10.1016/j.matdes.2010.12.025

Acknowledgements

We acknowledge Technology Innovation Hub (TIH), IIT Guwahati to provide experimental facilities. We also acknowledge Department of Science and Technology (DST), New Delhi, India, for financial support for project No. SR/FST/ET-II/2017/111 (C) under Fund for Improvement of S&T Infrastructure in Universities and Higher Educational Institutions (FIST) Program.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Das, A., Medhi, T., Kapil, S. et al. Multi-track multi-layer friction stir additive manufacturing of AA6061-T6 alloy. Prog Addit Manuf (2023). https://doi.org/10.1007/s40964-023-00485-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40964-023-00485-w