Abstract

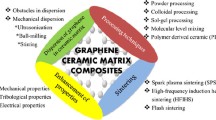

The unique physical and mechanical properties of SiC ceramics have led to extensive activities in recent years to improve these properties. The use of various additives can not only reduce the sintering temperature and improve the sinterability but also can change the properties of this ceramic. Graphene is one of these additives that has recently been paid attention by researchers. In this research, an attempt has been made to review the most important studies performed on the fabrication of SiC-graphene composites and the effect of parameters such as graphene type, size and amount, sintering temperature and time, and post-sintering heat treatment on the microstructure, crack propagation, densification, and mechanical properties such as hardness and fracture toughness and other important properties of this ceramic are discussed.

Similar content being viewed by others

Notes

SPS.

HIP.

References

Chi, W., et al.: Sintering behavior of porous SiC ceramics. Ceram. Int. 30(6), 869–874 (2004)

Negita, Keishi: Effective sintering aids for silicon carbide ceramics: reactivities of silicon carbide with various additives. J. Am. Ceram. Soc. 69(12), C–308 (1986)

Song, N., et al.: Effects of SiC whiskers on the mechanical properties and microstructure of SiC ceramics by reactive sintering. Ceram. Int. 43(9), 6786–6790 (2017)

Zhang, T., et al.: Preparation of SiC ceramics by aqueous gelcasting and pressureless sintering. Mater. Sci. Eng., A 443(1–2), 257–261 (2007)

Jang, B.-K., Sakka, Y.: Thermophysical properties of porous SiC ceramics fabricated by pressureless sintering. Sci. Technol. Adv. Mater. 8(7–8), 655 (2007)

Liang, H., et al.: Low temperature pressureless sintering of α-SiC with Al2O3 and CeO2 as additives. J. Eur. Ceram. Soc. 34(3), 831–835 (2014)

Kumar, B.V.M., et al.: Influence of small amount of sintering additives on unlubricated sliding wear properties of SiC ceramics. Ceram. Int. 37(8), 3599–3608 (2011)

Li, C., et al.: Microstructure and mechanical properties of spark plasma sintered SiC ceramics aided by B4C. Ceram. Int. 46(8), 10142–10146 (2020)

Kultayeva, S., et al.: Effects of porosity on electrical and thermal conductivities of porous SiC ceramics. J. Eur. Ceram. Soc. 40(4), 996–1004 (2020)

Xu, T.-T., et al.: High-temperature flexural strength of SiC ceramics prepared by additive manufacturing. Int. J. Appl. Ceram. Technol. 17(2), 438–448 (2020)

Koyanagi, Takaaki, et al.: Recent progress in the development of SiC composites for nuclear fusion applications. J. Nucl. Mater. 511, 544–555 (2018)

Das, Jiten, et al.: Microstructure and mechanical properties of a SiC containing advanced structural ceramics. Int. J. Refract Metal Hard Mater. 84, 105030 (2019)

Lopez-Robledo, M.J., et al.: Sliding wear resistance of porous biomorphic sic ceramics. Int. J. Refract Metal Hard Mater. 59, 26–31 (2016)

Bondioli, M.J., et al.: Oxidation behavior of LPS-SiC ceramics sintered with AlN/Y2O3 as additive. Int. J. Refract Metal Hard Mater. 42, 246–254 (2014)

Kovalčíková, Alexandra, et al.: Effect of the counterpart material on wear characteristics of silicon carbide ceramics. Int. J. Refract Metal Hard Mater. 44, 12–18 (2014)

Zhang, J., et al.: Properties of silicon carbide ceramics from gelcasting and pressureless sintering. Mater. Des. (1980–2015) 65, 12–16 (2015)

Kim, Y.-H., Kim, Y.-W., Kim, K.J.: Electrically conductive SiC ceramics processed by pressureless sintering. Int. J. Appl. Ceram. Technol. 16(2), 843–849 (2019)

Feng, D., et al.: Effect of oxygen content on the sintering behaviour and mechanical properties of SiC ceramics. Ceram. Int. 45(18), 23984–23992 (2019)

Moslemi, M., et al.: Effect of carbon fiber volume fraction on 6H to 4H-SiC polytype transformation. Phase Transitions 91(7), 733–741 (2018)

Wan, P., Wang, J.: Highly porous nano-SiC with very low thermal conductivity and excellent high temperature behavior. J. Eur. Ceram. Soc. 38(2), 463–467 (2018)

Dehghani, Hadi, et al. The effect of AlN-Y2O3 compound on properties of pressureless sintered SiC ceramics-a review. Int. J. Refract Metal Hard Mater. 105420 (2020)

Khodaei, Mahdi, et al.: Investigation of the effect of Al2O3–Y2O3–CaO (AYC) additives on sinterability, microstructure and mechanical properties of SiC matrix composites: a review. Int. J. Refract Metal Hard Mater. 78, 9–26 (2019)

Arena, Héléne., et al.: Effect of TiC incorporation on the optical properties and oxidation resistance of SiC ceramics. Sol. Energy Mater. Sol. Cells 213, 110536 (2020)

Pai, C.-H.: Thermoelectric properties of the reaction sintered n-type β-SiC. Journal of the Korea Academia-Industrial cooperation Society 20(3), 29–34 (2019)

Liu, M., et al.: Preparation of dense and high-purity SiC ceramics by pressureless solid-state-sintering. Ceram. Int. 45(16), 19771–19776 (2019)

Wang, F., et al.: Porous SiC ceramics fabricated by quick freeze casting and solid state sintering. Progress in Natural Science: Materials International 27(3), 380–384 (2017)

Xing, Yuanyuan, et al.: Aqueous gelcasting of solid-state-sintered SiC ceramics with the addition of the copolymer of isobutylene and maleic anhydride. J. Mater. Process. Technol. 271, 172–177 (2019)

Jana, D.C., Sundararajan, G., Chattopadhyay, K.: Effect of monomers content in enhancing solid-state densification of silicon carbide ceramics by aqueous gelcasting and pressureless sintering. Ceram. Int. 43(6), 4852–4857 (2017)

Wu, Haibo, et al.: Effects of particle grading on porous gelcasted and solid-state-sintered SiC ceramics with improved connectivity. J. Alloy. Compd. 732, 547–554 (2018)

Soto, C., García-Rosales, C., Echeberria, J.: Production of porous SiC by liquid phase sintering using graphite as sacrificial phase: influence of SiO2 and graphite on the sintering mechanisms. J. Eur. Ceram. Soc. 39(14), 3949–3958 (2019)

Malik, R., Kim, Y.-H., Kim, Y.-W.: Effect of additive content on the mechanical and thermal properties of pressureless liquid-phase sintered SiC. Journal of Asian Ceramic Societies 8(2), 448–459 (2020)

Candelario, V.M., et al.: Liquid-phase assisted flash sintering of SiC from powder mixtures prepared by aqueous colloidal processing. J. Eur. Ceram. Soc. 37(2), 485–498 (2017)

Khodaei, Mahdi, et al.: The effect of Cr2O3 additions on sinterability and mechanical properties of liquid-phase sintered SiC ceramics. J. Alloy. Compd. 829, 154501 (2020)

Li, Y., et al.: Microstructures and properties of porous liquid-phase-sintered SiC ceramic by hot press sintering. Materials 12(4), 639 (2019)

Khodaei, Mahdi, et al.: Effects of different sintering methods on the properties of SiC-TiC, SiC-TiB2 composites. Int. J. Refract Metal Hard Mater. 70, 19–31 (2018)

Bahaaddini, M., et al.: Pressureless sintering of LPS-SiC (SiC-Al2O3-Y2O3) composite in presence of the B4C additive. Ceram. Int. 45(10), 13536–13545 (2019)

Perevislov, S.N., et al.: Production of ceramic materials based on SiC with low-melting oxide additives. Glass Ceram. 75(9), 400–407 (2019)

Jana, D.C., Sundararajan, G., Chattopadhyay, K.: Effective activation energy for the solid-state sintering of silicon carbide ceramics. Metall. and Mater. Trans. A. 49(11), 5599–5606 (2018)

Santos, A.C., Ribeiro, S.: Liquid phase sintering and characterization of SiC ceramics. Ceram. Int. 44(10), 11048–11059 (2018)

Liang, H., et al.: Effect of sintering techniques on the microstructure of liquid-phase-sintered SiC ceramics. J. Eur. Ceram. Soc. 36(8), 1863–1871 (2016)

Chai, Zhenfei, et al. "Thermal conductivity of spark plasma sintered SiC ceramics with Alumina and Yttria." Journal of the European Ceramic Society (2020).

Strecker, K., et al.: Influence of microstructural variation on fracture toughness of LPS-SiC ceramics. Int. J. Refract Metal Hard Mater. 22(4–5), 169–175 (2004)

Falk, L.K.L.: Microstructural development during liquid phase sintering of silicon carbide ceramics. J. Eur. Ceram. Soc. 17(8), 983–994 (1997)

Zawrah, M.F., Shaw, L.: Liquid-phase sintering of SiC in presence of CaO. Ceram. Int. 30(5), 721–725 (2004)

Ribeiro, S., et al.: Effect of heating rate on the shrinkage and microstructure of liquid phase sintered SiC ceramics. Ceram. Int. 42(15), 17398–17404 (2016)

Izhevskyi, V.A., Bressiani, A.H.A., Bressiani, J.C.: Effect of liquid phase sintering on microstructure and mechanical properties of Yb2O3-AlN containing SiC-based ceramics. J. Am. Ceram. Soc. 88(5), 1115–1121 (2005)

Ortiz, A.L., et al.: A route for the pressureless liquid-phase sintering of SiC with low additive content for improved sliding-wear resistance. J. Eur. Ceram. Soc. 32(4), 965–973 (2012)

Liang, Hanqin, et al.: The effect of powder bed on the liquid phase sintering of α-SiC. Mater. Des. (1980–2015) 56, 1009–1013 (2014)

Hotta, M., Hojo, J.: Effect of AlN additive on densification, microstructure and strength of liquid-phase sintered SiC ceramics by spark plasma sintering. J. Ceram. Soc. Jpn. 117(1369), 1009–1012 (2009)

Taguchi, S.P., et al.: Wetting behaviour of SiC ceramics: part II—Y2O3/Al2O3 and Sm2O3/Al2O3. Mater. Lett. 58(22–23), 2810–2814 (2004)

Izhevskyi, V.A., Genova, L.A., Bressiani, J.C., Bressiani, A.H.A.: Liquid phase sintered SiC ceramics from starting materials of different grade. Cerâmica 50(315), 261–267 (2004)

Kim, Y.-W., et al.: Influence of powder characteristics on liquid phase sintering of silicon carbide. J. Ceram. Soc. Jpn. 103(1195), 257–261 (1995)

Borrero-López, O., et al.: Effect of liquid-phase content on the contact-mechanical properties of liquid-phase-sintered α-SiC. J. Eur. Ceram. Soc. 27(6), 2521–2527 (2007)

Balog, M., et al.: Nano-versus macro-hardness of liquid phase sintered SiC. J. Eur. Ceram. Soc. 25(4), 529–534 (2005)

Grande, T., et al.: Effect of weight loss on liquid-phase-sintered silicon carbide. J. Am. Ceram. Soc. 80(4), 1047–1052 (1997)

Liang, H., et al.: In situ toughening of pressureless liquid phase sintered α-SiC by using TiO2. Ceram. Int. 40(7), 10699–10704 (2014)

Ribeiro, S., Ribeiro, G.C., Rego, M., de Oliveira,: Properties of SiC ceramics sintered via liquid phase using Al2O3+ Y2O3, Al2O3+ Yb2O3 and Al2O3+ Dy2O3 as additives: a comparative study. Mater. Res. 18(3), 525–529 (2015)

Kim, Y.-W., Mitomo, M., Nishimura, T.: High-temperature strength of liquid-phase-sintered SiC with AlN and Re2O3 (RE= Y, Yb). J. Am. Ceram. Soc. 85(4), 1007–1009 (2002)

Lan’er, W. U., et al.: Liquid phase sintering of SiC with AlN-Re2O3 additives. Journal of the Chinese Ceramic Society 36(5), 593–596 (2008)

Kim, Y.-W., Ando, K., Chu, M.C.: Crack-healing behavior of liquid-phase-sintered silicon carbide ceramics. J. Am. Ceram. Soc. 86(3), 465–470 (2003)

Rixecker, Georg, et al. "Liquid-phase sintered SiC ceramics with oxynitride additives." Proceedings of the Korea Association of Crystal Growth Conference. The Korea Association of Crystal Growth, 2000.

Cho, T.-Y., Kim, Y.-W.: Effect of grain growth on the thermal conductivity of liquid-phase sintered silicon carbide ceramics. J. Eur. Ceram. Soc. 37(11), 3475–3481 (2017)

Perevislov, S.N., Tomkovich, M.V., Lysenkov, A.S.: Silicon carbide liquid-phase sintering with various activating agents. Refract. Ind. Ceram 59(5), 522–527 (2019)

Khodaei, M., et al.: The effect of nano-TiO2 additions on the densification and mechanical properties of SiC-matrix composite. Ceram. Int. 46(5), 6477–6483 (2020)

Lee, Y.-I., Kim, Y.-W., Mitomo, M.: Effect of processing on densification of nanostructured SiC ceramics fabricated by two-step sintering. J. Mater. Sci. 39(11), 3801–3803 (2004)

Sciti, D., Bellosi, A.: Effects of additives on densification, microstructure and properties of liquid-phase sintered silicon carbide. J. Mater. Sci. 35(15), 3849–3855 (2000)

Jang, B.K., Sakka, Y.: Influence of microstructure on the thermophysical properties of sintered SiC ceramics. J. Alloy. Compd. 463(1–2), 493–497 (2008)

Rodríguez-Rojas, F., et al.: Effect of the sintering additive content on the non-protective oxidation behaviour of pressureless liquid-phase-sintered α-SiC in air. J. Eur. Ceram. Soc. 30(6), 1513–1518 (2010)

Khodaei, M., et al.: The effect of TiO2 additive on sinterability and properties of SiC-Al2O3-Y2O3 composite system. Ceram. Int. 44(14), 16535–16542 (2018)

Kim, Wonjoong, Young-Wook Kim, and Min-Hyung Choi. "Texture development and phase transformation in liquid-phase-sintered SiC ceramics." Materials Science Forum(Switzerland). Vol. 408. No. 2. 2002.

Ruh, Robert, Zangvil, Avigdor: Composition and properties of hot-pressed SiC-AIN solid solutions. Journal of the American Ceramic Society 65(5), 260–265 (1982)

Costello, J.A., Tressler, R.E.: Oxidation kinetics of hot-pressed and sintered α-SiC. J. Am. Ceram. Soc. 64(6), 327–331 (1981)

Endo, H., Ueki, M., Kubo, H.: Microstructure and mechanical properties of hot-pressed SiC-TiC composites. J. Mater. Sci. 26(14), 3769–3774 (1991)

Perevislov, S.N., et al.: Hot-pressed ceramic SiC–YAG materials. Inorg. Mater. 53(2), 220–225 (2017)

Kim, K.J., et al.: Effects of M2O3–Y2O3 (M= Sc and Al) additives on electrical conductivity of hot-pressed SiC ceramics. Ceram. Int. 46(4), 5454–5458 (2020)

Guillard, F., et al.: Densification of SiC by SPS-effects of time, temperature and pressure. J. Eur. Ceram. Soc. 27(7), 2725–2728 (2007)

Luo, Y., et al.: Fabrication and mechanical evaluation of SiC–TiC nanocomposites by SPS. Mater. Lett. 58(1–2), 150–153 (2004)

Hayun, S., et al.: Microstructure and mechanical properties of silicon carbide processed by Spark Plasma Sintering (SPS). Ceram. Int. 38(8), 6335–6340 (2012)

Wang, L., Jiang, W., Chen, L.: Rapidly sintering nanosized SiC particle reinforced TiC composites by the spark plasma sintering (SPS) technique. J. Mater. Sci. 39(14), 4515–4519 (2004)

Yamamoto, T., et al.: Consolidation of nanostructured β-SiC by spark plasma sintering. J. Am. Ceram. Soc. 87(8), 1436–1441 (2004)

Wu, C., et al.: High-speed grinding of HIP-SiC ceramics on transformation of microscopic features. The International Journal of Advanced Manufacturing Technology 102(5), 1913–1921 (2019)

Jensen, R.P., et al.: High-temperature properties of liquid-phase-sintered α-SiC. Mater. Sci. Eng., A 282(1–2), 109–114 (2000)

Tani, T.: Processing, microstructure and properties of in-situ reinforced SiC matrix composites. Compos. A Appl. Sci. Manuf. 30(4), 419–423 (1999)

Khodaei, Mahdi, et al.: The effect of TiO2 additive on the electrical resistivity and mechanical properties of pressureless sintered SiC ceramics with Al2O3-Y2O3. Int. J. Refract Metal Hard Mater. 76, 141–148 (2018)

Lee, S.K., Kim, Y.C., Kim, C.H.: Microstructural development and mechanical properties of pressureless-sintered SiC with plate-like grains using Al 2 O 3-Y 2 O 3 additives. J. Mater. Sci. 29(20), 5321–5326 (1994)

Cho, T.-Y., et al.: Electrical and mechanical properties of pressureless sintered SiC-Ti2CN composites. J. Eur. Ceram. Soc. 38(9), 3064–3072 (2018)

Mulla, M.A., Krstic, V.D.: Mechanical properties of β-SiC pressureless sintered with Al2O3 additions. Acta Metall. Mater. 42(1), 303–308 (1994)

Gubernat, A., Stobierski, L., Łabaj, P.: Microstructure and mechanical properties of silicon carbide pressureless sintered with oxide additives. J. Eur. Ceram. Soc. 27(2–3), 781–789 (2007)

Magnani, G., Beaulardi, L., Pilotti, L.: Properties of liquid phase pressureless sintered silicon carbide obtained without sintering bed. J. Eur. Ceram. Soc. 25(9), 1619–1627 (2005)

Cho, T.-Y., Kim, Y.-W., Kim, K.J.: Thermal, electrical, and mechanical properties of pressureless sintered silicon carbide ceramics with yttria-scandia-aluminum nitride. J. Eur. Ceram. Soc. 36(11), 2659–2665 (2016)

Khodaei, M., Yaghobizadeh, O., Alhosseini, S.H., Naghavi, E., S and Seyyed Rasool Mousavi,: The effect of oxide, carbide, nitride and boride additives on properties of pressureless sintered SiC: a review. J. Eur. Ceram. Soc. 39(7), 2215–2231 (2019)

Khodaei, M., et al.: The effect of TiC additive with Al2O3-Y2O3 on the microstructure and mechanical properties of SiC matrix composites. Advanced Ceramics Progress 6(3), 15–24 (2020)

Akin, I., Kaya, O.: Microstructures and properties of silicon carbide-and graphene nanoplatelet-reinforced titanium diboride composites. J. Alloy. Compd. 729, 949–959 (2017)

Zhang, W., et al.: Effect of mechanochemically functionalized multilayer graphene on the tribological properties of silicon carbide/graphene nanocomposites in aqueous environment. Tribol. Lett. 66(4), 1–12 (2018)

dos Santos Tonello, Karolina Pereira, et al. "Fabrication and characterization of laminated SiC composites reinforced with graphene nanoplatelets." Materials Science and Engineering: A 659 (2016): 158–164.

Nguyen, T.P., et al.: Characterization of spark plasma sintered TiC ceramics reinforced with graphene nano-platelets. Ceram. Int. 46(11), 18742–18749 (2020)

Ahmad, I., Parvez, S., Saeed, K.: Interfacial investigation, mechanical performance and thermal permanence of the inductively hot-pressed alumina ceramic hybrid nanocomposites reinforced by silicon carbide and multilayer graphene. Int. J. Refract Metal Hard Mater. 81, 49–57 (2019)

Aristov, V.Y., et al.: Layer-by-layer graphene growth on β-SiC/Si (001). ACS Nano 13(1), 526–535 (2018)

Lin, S., et al.: RGO-supported β-SiC nanoparticles by a facile solvothermal route and their enhanced adsorption and photocatalytic activity. Mater. Lett. 132, 380–383 (2014)

Asl, Mehdi Shahedi, and Mahdi Ghassemi Kakroudi. "Characterization of hot-pressed graphene reinforced ZrB2–SiC composite." Materials Science and Engineering: A 625 (2015): 385–392.

Wang, Y., et al.: Enhanced photocatalytic performance of chemically bonded SiC-graphene composites for visible-light-driven overall water splitting. Int. J. Hydrogen Energy 38(29), 12733–12738 (2013)

Hanzel, O., et al.: Anisotropy of functional properties of SiC composites with GNPs, GO and in-situ formed graphene. J. Eur. Ceram. Soc. 37(12), 3731–3739 (2017)

Wang, K., et al.: Preparation of graphene nanosheet/alumina composites by spark plasma sintering. Mater. Res. Bull. 46(2), 315–318 (2011)

Walker, L.S., et al.: Toughening in graphene ceramic composites. ACS Nano 5(4), 3182–3190 (2011)

Porwal, H., et al.: Tribological properties of silica–graphene nano-platelet composites. Ceram. Int. 40(8), 12067–12074 (2014)

Ramirez, C., et al.: Electrical conductivity maps in graphene nanoplatelet/silicon nitride composites using conducting scanning force microscopy. Carbon 49(12), 3873–3880 (2011)

Sedlák, R., et al.: Fracture characteristics of SiC/graphene platelet composites. J. Eur. Ceram. Soc. 37(14), 4307–4314 (2017)

Belmonte, Manuel, et al. "Toughened and strengthened silicon carbide ceramics by adding graphene-based fillers." Scripta Materialia 113 (2016): 127–130.

Petrus, M., et al.: The effect of the morphology of carbon used as a sintering aid on the sinterability of silicon carbide. Ceram. Int. 44(6), 7020–7025 (2018)

Li, Q., et al.: Effects of graphene on the thermal conductivity of pressureless-sintered SiC ceramics. Ceram. Int. 41(10), 13547–13552 (2015)

Guo, X., et al.: Pressureless sintering of multilayer graphene reinforced silicon carbide ceramics for mechanical seals. Adv. Appl. Ceram. 118(7), 409–417 (2019)

Li, Q., et al.: Enhanced fracture toughness of pressureless-sintered SiC ceramics by addition of graphene. J. Mater. Sci. Technol. 32(7), 633–638 (2016)

Huang, Y., et al.: Enhancing toughness and strength of SiC ceramics with reduced graphene oxide by HP sintering. J. Eur. Ceram. Soc. 38(13), 4329–4337 (2018)

Tapasztó, O., et al.: High orientation degree of graphene nanoplatelets in silicon nitride composites prepared by spark plasma sintering. Ceram. Int. 42(1), 1002–1006 (2016)

Dusza, J., et al.: Microstructure and fracture toughness of Si3N4+ graphene platelet composites. J. Eur. Ceram. Soc. 32(12), 3389–3397 (2012)

Llorente, J., et al.: Tribological performance under dry sliding conditions of graphene/silicon carbide composites. J. Eur. Ceram. Soc. 36(3), 429–435 (2016)

Chen, C., et al.: Preferentially oriented SiC/graphene composites for enhanced mechanical and thermal properties. Ceram. Int. 46(14), 23173–23179 (2020)

Rahman, Arif, et al. "Graphene reinforced silicon carbide nanocomposites: processing and properties." Composite, Hybrid, and Multifunctional Materials, Volume 4. Springer, Cham, 2015. 165–176.

Rahman, Arif, et al. "Spark plasma sintering and characterization of graphene reinforced silicon carbide nanocomposites." Composite Materials and Joining Technologies for Composites, Volume 7. Springer, New York, NY, 2013. 139–146.

Chu, Ke, et al. "Anisotropic mechanical properties of graphene/copper composites with aligned graphene." Materials Science and Engineering: A 713 (2018): 269–277.

Porwal, Harshit, et al. (2013) "Toughened and machinable glass matrix composites reinforced with graphene and graphene-oxide nano platelets." Science and technology of advanced materials 14(5): 055007.

Chu, Ke, et al. "Thermal properties of graphene/metal composites with aligned graphene." Materials & Design 140 (2018): 85–94.

Yan, H., et al.: Enhanced thermal conductivity in polymer composites with aligned graphene nanosheets. J. Mater. Sci. 49(15), 5256–5264 (2014)

Balandin, A.A., et al.: Superior thermal conductivity of single-layer graphene. Nano Lett. 8(3), 902–907 (2008)

Petrus, M., et al.: The effect of the morphology of carbon used as a sintering aid on the mechanical properties of silicon carbide. Ceram. Int. 45(2), 1820–1824 (2019)

Bódis, E., et al.: Spark plasma sintering of graphene reinforced silicon carbide ceramics. Ceram. Int. 43(12), 9005–9011 (2017)

Petrus, M., et al.: Sintering behaviour of silicon carbide matrix composites reinforced with multilayer graphene. Ceram. Int. 43(6), 5007–5013 (2017)

Nader, M., Aldinger, F., Hoffmann, M.J.: Influence of the α/β-SiC phase transformation on microstructural development and mechanical properties of liquid phase sintered silicon carbide. J. Mater. Sci. 34(6), 1197–1204 (1999)

Cygan, Tomasz, et al.: Influence of graphene addition and sintering temperature on physical properties of Si3N4 matrix composites. Int. J. Refract Metal Hard Mater. 57, 19–23 (2016)

Kaźmierczak-Bałata, A., Mazur, J.: Effect of carbon nanoparticle reinforcement on mechanical and thermal properties of silicon carbide ceramics. Ceram. Int. 44(9), 10273–10280 (2018)

Roman-Manso, B., et al.: Enhanced electrical conductivity of silicon carbide ceramics by addition of graphene nanoplatelets. J. Eur. Ceram. Soc. 35(10), 2723–2731 (2015)

Chen, C., et al.: Enhanced electromagnetic interference shielding properties of silicon carbide composites with aligned graphene nanoplatelets. J. Eur. Ceram. Soc. 38(16), 5615–5619 (2018)

Miranzo, Pilar, et al. "Process for production of graphene/silicon carbide ceramic composites." U.S. Patent No. 9,988,313. 5 Jun. 2018.

Liu, Fu., et al.: Mechanical properties and microstructure of reaction sintering SiC ceramics reinforced with graphene-based fillers. Appl. Phys. A 125(10), 1–7 (2019)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Razmjoo, A., Baharvandi, H.R. & Ehsani, N. The effect of graphene addition on the properties of SiC ceramics—a review. J Aust Ceram Soc 58, 437–460 (2022). https://doi.org/10.1007/s41779-022-00701-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41779-022-00701-w