Abstract

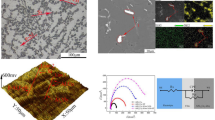

This study investigated the effect of Nb-content on the corrosion behavior of the \({\text{Al}}_{7}{{\text{Cr}}}_{20}{{\text{Fe}}}_{\text{35} - {{x}}}{\text{Ni}}_{35}{{\text{Mo}}}_{3}{{\text{Nb}}}_{{x}}\) (x = 0, 1 and 2) high-entropy alloys in a Cl− environment. The results indicated that only the face centered cubic phase existed in the Nb0 and Nb1 alloys, while the emergence of Laves phase was observed when Nb-content reached 2 at.%. The Nb0 and Nb1 alloys exhibited pitting corrosion, while the NiAl-rich phase experienced localized preferential corrosion in the Nb2 alloy. The electrochemical results revealed that the corrosion current density of the \({\text{Nb}}_{{x}}\) (x = 0, 1 and 2) alloys fell within the range of 10−8–10−7 A·cm−2, with a pitting corrosion potential exceeding 700 mVSCE. Notably, the Nb1 alloy exhibited the most impressive corrosion resistance, as its corrosion current density (7 × 10−8 A·cm−2) was merely half that of 316LN stainless steel. This is attributed to its rapid passivation process, resulting in the development of a protective film characterized by an increased \({\text{Cr}}_{2}{{\text{O}}}_{3}{\text{/Al}}_{2}{{\text{O}}}_{3}{\text{+Cr(OH)}}_{3}\) ratio. This study highlighted that the addition of Nb contributed to grain refinement, decreased corrosion current density, and elevated pitting potential, favoring passivation and improving corrosion resistance. However, excessive Nb-content resulted in the emergence of the Laves phase, inducing galvanic corrosion and diminishing resistance to corrosion.

Similar content being viewed by others

Data availability

The data generated during and/or analyzed in this article are available from the corresponding author on reasonable request.

References

Hou BR, Li XG, Ma XM, Du CW, Zhang DW, Zheng M, Xu WC, Lu DZ, Ma FB. The cost of corrosion in China. Npj Mater Degrad. 2017;1(1):4. https://doi.org/10.1038/s41529-017-0005-2.

Ahmed N, Barsoum I, Haidemenopoulos G, Al-Rub RKA. Process parameter selection and optimization of laser powder bed fusion for 316L stainless steel: a review. J Manuf Process. 2022;75:415. https://doi.org/10.1016/j.jmapro.2021.12.064.

Wang L, Liu F, Cheng JJ, Zuo Q, Chen CF. Hot deformation characteristics and processing map analysis for nickel-based corrosion resistant alloy. J Alloys Compd. 2015;623:69. https://doi.org/10.1016/j.jallcom.2014.10.034.

Zhang LC, Chen LY. A review on biomedical titanium alloys: recent progress and prospect. Adv Eng Mater. 2019;21(4):1801215. https://doi.org/10.1002/adem.201801215.

Azuma S, Kudo T, Miyuki H, Yamashita M, Uchida H. Effect of nickel alloying on crevice corrosion resistance of stainless steels. Corros Sci. 2004;46(9):2265. https://doi.org/10.1016/j.corsci.2004.01.003.

Gupta RK, Birbilis N. The influence of nanocrystalline structure and processing route on corrosion of stainless steel: a review. Corros Sci. 2015;92:1. https://doi.org/10.1016/j.corsci.2014.11.041.

Du XH, Li WP, Chang HT, Yang T, Duan GS, Wu BL, Huang JC, Chen FR, Liu CT, Chuang WS, Lu Y, Sui ML, Huang EW. Dual heterogeneous structures lead to ultrahigh strength and uniform ductility in a Co-Cr-Ni medium-entropy alloy. Nat Commun. 2020;11(1):2390. https://doi.org/10.1038/s41467-020-16085-z.

Fan L, Yang T, Zhao Y, Luan J, Zhou G, Wang H, Jiao Z, Liu CT. Ultrahigh strength and ductility in newly developed materials with coherent nanolamellar architectures. Nat Commun. 2020;11(1):6240. https://doi.org/10.1038/s41467-020-20109-z.

Ma Y, Zhang Y, Zhang Z, Liu L, Sun L. Two novel Zr-rich refractory high-entropy alloys with excellent tensile mechanical properties. Intermetallics. 2023;157:107872. https://doi.org/10.1016/j.intermet.2023.107872.

Liu L, Zhang Y, Li J, Fan M, Wang X, Wu G, Yang Z, Luan J, Jiao Z, Liu CT, Liaw PK, Zhang Z. Enhanced strength-ductility synergy via novel bifunctional nano-precipitates in a high-entropy alloy. Int J Plasticity. 2022;153:103235. https://doi.org/10.1016/j.ijplas.2022.103235.

Lu C, Niu L, Chen N, Jin K, Yang T, Xiu P, Zhang Y, Gao F, Bei H, Shi S, He MR, Robertson IM, Weber WJ, Wang L. Enhancing radiation tolerance by controlling defect mobility and migration pathways in multicomponent single-phase alloys. Nat Commun. 2016;7(1):13564. https://doi.org/10.1038/ncomms13564.

Su Z, Ding J, Song M, Jiang L, Shi T, Li Z, Wang S, Gao F, Yun D, Ma E, Lu C. Enhancing the radiation tolerance of high-entropy alloys via solute-promoted chemical heterogeneities. Acta Mater. 2023;245:118662. https://doi.org/10.1016/j.actamat.2022.118662.

Su Z, Shi T, Yang J, Shen H, Li Z, Wang S, Ran G, Lu C. The effect of interstitial carbon atoms on defect evolution in high entropy alloys under helium irradiation. Acta Mater. 2022;233:117955. https://doi.org/10.1016/j.actamat.2022.117955.

Shi T, Lei PH, Yan X, Li J, Zhou YD, Wang YP, Su ZX, Dou YK, He XF, Yun D, Yang W, Lu CY. Current development of body-centered cubic high-entropy alloys for nuclear applications. Tungsten. 2021;3(2):197. https://doi.org/10.1007/s42864-021-00086-6.

He F, Wang Z, Shang X, Leng C, Li J, Wang J. Stability of lamellar structures in CoCrFeNiNbx eutectic high entropy alloys at elevated temperatures. Mater Des. 2016;104:259. https://doi.org/10.1016/j.matdes.2016.05.044.

Lim KR, Lee KS, Lee JS, Kim JY, Chang HJ, Na YS. Dual-phase high-entropy alloys for high-temperature structural applications. J Alloys Compd. 2017;728:1235. https://doi.org/10.1016/j.jallcom.2017.09.089.

Luo H, Li Z, Mingers AM, Raabe D. Corrosion behavior of an equiatomic CoCrFeMnNi high-entropy alloy compared with 304 stainless steel in sulfuric acid solution. Corros Sci. 2018;134:131. https://doi.org/10.1016/j.corsci.2018.02.031.

Nene SS, Frank M, Liu K, Sinha S, Mishra RS, McWilliams BA, Cho KC. Corrosion-resistant high entropy alloy with high strength and ductility. Scr Mater. 2019;166:168. https://doi.org/10.1016/j.scriptamat.2019.03.028.

Wu P, Gan K, Yan D, Fu Z, Li Z. A non-equiatomic FeNiCoCr high-entropy alloy with excellent anti-corrosion performance and strength-ductility synergy. Corros Sci. 2021;183:109341. https://doi.org/10.1016/j.corsci.2021.109341.

Yang J, Shi K, Zhang W, Chen Q, Ning Z, Zhu C, Liao J, Yang Y, Liu N, Zhang W, Yang J. A novel AlCrFeMoTi high-entropy alloy coating with a high corrosion-resistance in lead-bismuth eutectic alloy. Corros Sci. 2021;187:109524. https://doi.org/10.1016/j.corsci.2021.109524.

Yang J, Zhang F, Chen Q, Zhang W, Zhu C, Deng J, Zhong Y, Liao J, Yang Y, Liu N, Yang J. Effect of Au-ions irradiation on mechanical and LBE corrosion properties of amorphous AlCrFeMoTi HEA coating: enhanced or deteriorated? Corros Sci. 2021;192:109862. https://doi.org/10.1016/j.corsci.2021.109862.

Hu Q, Ye CP, Zhang SC, Wang XZ, Du CF, Wang H. Mo content-depended competition between Cr2O3 enrichment and selective dissolution of CoCrFeNiMox high entropy alloys. Npj Mater Degrad. 2022;6(1):97. https://doi.org/10.1038/s41529-022-00313-6.

Fu J, Wang J, Li F, Cui K, Du X, Wu Y. Effect of Nb addition on the microstructure and corrosion resistance of ferritic stainless steel. Appl Phys A Mater Sci Process. 2020;126(3):194. https://doi.org/10.1007/s00339-020-3383-1.

Afonso CRM, Martinez-Orozco K, Amigó V, Della Rovere CA, Spinelli JE, Kiminami CS. Characterization, corrosion resistance and hardness of rapidly solidified Ni–Nb alloys. J Alloys Compd. 2020;829:154529. https://doi.org/10.1016/j.jallcom.2020.154529.

Liu C, Gao Y, Chong K, Guo F, Wu D, Zou Y. Effect of Nb content on the microstructure and corrosion resistance of FeCoCrNiNbx high-entropy alloys in chloride ion environment. J Alloys Compd. 2023;935:168013. https://doi.org/10.1016/j.jallcom.2022.168013.

Tanji A, Fan X, Sakidja R, Liaw PK, Hermawan H. Niobium addition improves the corrosion resistance of TiHfZrNbx high-entropy alloys in Hanks’ solution. Electrochim Acta. 2022;424:140651. https://doi.org/10.1016/j.electacta.2022.140651.

Tsau CH, Yeh CY, Tsai MC. The effect of Nb-content on the microstructures and corrosion properties of CrFeCoNiNbx high-entropy alloys. Materials. 2019. https://doi.org/10.3390/ma12223716.

Tong Y, Chen D, Han B, Wang J, Feng R, Yang T, Zhao C, Zhao YL, Guo W, Shimizu Y, Liu CT, Liaw PK, Inoue K, Nagai Y, Hu A, Kai JJ. Outstanding tensile properties of a precipitation-strengthened FeCoNiCrTi0.2 high-entropy alloy at room and cryogenic temperatures. Acta Mater. 2019;165:228. https://doi.org/10.1016/j.actamat.2018.11.049.

Li R, Ren J, Zhang GJ, He JY, Lu YP, Wang TM, Li TJ. Novel (CoFe2NiV0.5Mo0.2)100−xNbx eutectic high-entropy alloys with excellent combination of mechanical and corrosion properties. Acta Metallurgica Sinica (English Letters). 2020;33(8):1046. https://doi.org/10.1007/s40195-020-01072-6.

Zhao YL, Yang T, Zhu JH, Chen D, Yang Y, Hu A, Liu CT, Kai JJ. Development of high-strength Co-free high-entropy alloys hardened by nanosized precipitates. Scr Mater. 2018;148:51. https://doi.org/10.1016/j.scriptamat.2018.01.028.

Kumar NAPK, Li C, Leonard KJ, Bei H, Zinkle SJ. Microstructural stability and mechanical behavior of FeNiMnCr high entropy alloy under ion irradiation. Acta Mater. 2016;113:230. https://doi.org/10.1016/j.actamat.2016.05.007.

Li C, Hu X, Yang T, Kumar NAPK, Wirth BD, Zinkle SJ. Neutron irradiation response of a Co-free high entropy alloy. J Nucl Mater. 2019;527:151838. https://doi.org/10.1016/j.jnucmat.2019.151838.

Han J, Zhang Y, Zhang Z, Liu L, Li J, Yu Y, Sun L. Strength-plasticity regulation via nanoscale precipitation and coprecipitation in cobalt-free medium-entropy alloys. Mater Charact. 2022;193:112263. https://doi.org/10.1016/j.matchar.2022.112263.

Han HJ, Zhang Y, Sun Z, Zhang Y, Zhao Y, Sun L, Zhang Z. Enhanced irradiation tolerance of a medium entropy alloy via precipitation and dissolution of nanoprecipitates. J Nucl Mater. 2023;586:154693. https://doi.org/10.1016/j.jnucmat.2023.154693.

Conejero O, Palacios M, Rivera S. Premature corrosion failure of a 316L stainless steel plate due to the presence of sigma phase. Eng Fail Anal. 2009;16(3):699. https://doi.org/10.1016/j.engfailanal.2008.06.022.

Shi YZ, Yang B, Xie X, Brechtl J, Dahmen KA, Liaw PK. Corrosion of AlxCoCrFeNi high-entropy alloys: Al-content and potential scan-rate dependent pitting behavior. Corros Sci. 2017;119:33. https://doi.org/10.1016/j.corsci.2017.02.019.

Duan XT, Han TZ, Guan X, Wang YN, Su HH, Ming KS, Wang J, Zheng SJ. Cooperative effect of Cr and Al elements on passivation enhancement of eutectic high-entropy alloy AlCoCrFeNi2.1 with precipitates. J Mater Sci Technol. 2023;136:97. https://doi.org/10.1016/j.jmst.2022.07.023.

McCafferty E. Validation of corrosion rates measured by the tafel extrapolation method. Corros Sci. 2005;47(12):3202. https://doi.org/10.1016/j.corsci.2005.05.046.

Chai WK, Lu T, Pan Y. Corrosion behaviors of FeCoNiCrx (x = 0, 0.5, 1.0) multi-principal element alloys: role of Cr-induced segregation. Intermetallics. 2020;116:106654. https://doi.org/10.1016/j.intermet.2019.106654.

Xu ZL, Zhang H, Du XJ, He YZ, Luo H, Song GS, Mao L, Zhou TW, Wang LL. Corrosion resistance enhancement of CoCrFeMnNi high-entropy alloy fabricated by additive manufacturing. Corros Sci. 2020;177:108954. https://doi.org/10.1016/j.corsci.2020.108954.

Shi YZ, Collins L, Feng R, Zhang C, Balke N, Liaw PK, Yang B. Homogenization of AlxCoCrFeNi high-entropy alloys with improved corrosion resistance. Corros Sci. 2018;133:120. https://doi.org/10.1016/j.corsci.2018.01.030.

Yi JZ, Hu HX, Wang ZB, Zheng YG. Comparison of critical flow velocity for erosion-corrosion of six stainless steels in 3.5 wt% NaCl solution containing 2 wt% silica sand particles. Wear. 2018;416-417:62. https://doi.org/10.1016/j.wear.2018.10.006.

Ming TY, Peng QJ, Han YL, Zhang T. Effect of water jet cavitation peening on electrochemical corrosion behavior of nickel-based alloy 600 in NaCl solution. Mater Chem Phys. 2023;295:127122. https://doi.org/10.1016/j.matchemphys.2022.127122.

Peng X, Zhang Y, Zhao J, Wang F. Electrochemical corrosion performance in 3.5% NaCl of the electrodeposited nanocrystalline Ni films with and without dispersions of Cr nanoparticles. Electrochim Acta. 2006;51(23):4922. https://doi.org/10.1016/j.electacta.2006.01.035.

Chen T, John H, Xu J, Lu QH, Hawk J, Liu XB. Influence of surface modifications on pitting corrosion behavior of nickel-base alloy 718. Part 1: effect of machine hammer peening. Corros Sci. 2013;77:230. https://doi.org/10.1016/j.corsci.2013.08.007.

Hemmasian Ettefagh A, Zeng C, Guo S, Raush J. Corrosion behavior of additively manufactured Ti-6Al-4V parts and the effect of post annealing. Addit Manuf. 2019;28:252. https://doi.org/10.1016/j.addma.2019.05.011.

Delgado-Alvarado C, Sundaram PA. A study of the corrosion behavior of gamma titanium aluminide in 3.5wt% NaCl solution and seawater. Corros Sci. 2007;49(9):3732. https://doi.org/10.1016/j.corsci.2007.04.001.

Pu J, Zhang YL, Zhang XG, Yuan XL, Ren PD, Jin ZM. Mapping the fretting corrosion behaviors of 6082 aluminum alloy in 3.5% NaCl solution. Wear. 2021;482–483:203975. https://doi.org/10.1016/j.wear.2021.203975.

Zhu M, Zhao BZ, Yuan YF, Guo SY, Pan J. Effect of solution temperature on the corrosion behavior of 6061–T6 aluminum alloy in NaCl Solution. J Mater Eng Perform. 2020;29(7):4725. https://doi.org/10.1007/s11665-020-04932-5.

Zhang Y, Xiao Z, Zhao YY, Li Z, Xing Y, Zhou KC. Effect of thermo-mechanical treatments on corrosion behavior of Cu-15Ni-8Sn alloy in 3.5 wt% NaCl solution. Mater Chem Phys. 2017;199:54. https://doi.org/10.1016/j.matchemphys.2017.06.041.

Song SL, Li DG, Chen DR, Liang P. The role of Ti in cavitation erosion and corrosion behaviours of NAB alloy in 3.5 % NaCl solution. J Alloys Compd. 2022. https://doi.org/10.1016/j.jallcom.2022.165728.

Cui PC, Bao ZJ, Liu Y, Zhou F, Lai ZH, Zhou Y, Zhu JC. Corrosion behavior and mechanism of dual phase Fe1.125Ni1.06CrAl high entropy alloy. Corros Sci. 2022;201:110276. https://doi.org/10.1016/j.corsci.2022.110276.

Zhao QC, Pan ZM, Wang XF, Luo H, Liu Y, Li XG. Corrosion and passive behavior of AlxCrFeNi3−x (x = 0.6, 0.8, 1.0) eutectic high entropy alloys in chloride environment. Corros Sci. 2022;208:110666. https://doi.org/10.1016/j.corsci.2022.110666.

Della Rovere CA, Alano JH, Silva R, Nascente PAP, Otubo J, Kuri SE. Characterization of passive films on shape memory stainless steels. Corros Sci. 2012;57:154. https://doi.org/10.1016/j.corsci.2011.12.022.

Zhang MD, Shi XL, Li ZY, Xu HQ, Li G. Corrosion behaviors and mechanism of CrFeNi2 based high-entropy alloys. Corros Sci. 2022;207:110562. https://doi.org/10.1016/j.corsci.2022.110562.

Kumar AM, Khan A, Khan MY, Suleiman RK, Jose J, Dafalla H. Hierarchical graphitic carbon nitride-ZnO nanocomposite: viable reinforcement for the improved corrosion resistant behavior of organic coatings. Mater Chem Phys. 2020;251:122987. https://doi.org/10.1016/j.matchemphys.2020.122987.

Luo H, Zou SW, Chen YH, Li ZM, Du CW, Li XG. Influence of carbon on the corrosion behaviour of interstitial equiatomic CoCrFeMnNi high-entropy alloys in a chlorinated concrete solution. Corros Sci. 2020;163:108287. https://doi.org/10.1016/j.corsci.2019.108287.

Zhang ZC, Lan AD, Zhang M, Qiao JW. Effect of Ce on the pitting corrosion resistance of non-equiatomic high-entropy alloy Fe40Mn20Cr20Ni20 in 3.5wt% NaCl solution. J Alloys Compd. 2022. https://doi.org/10.1016/j.jallcom.2022.164641.

Song LF, Wb Hu, Liao BK, Wan S, Kang L, Guo XP. Corrosion behavior of AlCoCrFeNi2.1 eutectic high-entropy alloy in Cl–containing solution. J Alloys Compd. 2023;938:168609. https://doi.org/10.1016/j.jallcom.2022.168609.

Luo H, Yu Q, Dong CF, Sha G, Liu ZB, Liang JX, Wang L, Han G, Li XG. Influence of the aging time on the microstructure and electrochemical behaviour of a 15–5PH ultra-high strength stainless steel. Corros Sci. 2018;139:185. https://doi.org/10.1016/j.corsci.2018.04.032.

Kissi M, Bouklah M, Hammouti B, Benkaddour M. Establishment of equivalent circuits from electrochemical impedance spectroscopy study of corrosion inhibition of steel by pyrazine in sulphuric acidic solution. Appl Surf Sci. 2006;252(12):4190. https://doi.org/10.1016/j.apsusc.2005.06.035.

Wei L, Liu Y, Li Q, Cheng YF. Effect of roughness on general corrosion and pitting of (FeCoCrNi)0.89(WC)0.11 high-entropy alloy composite in 3.5 wt.% NaCl solution. Corros Sci. 2019;146:44. https://doi.org/10.1016/j.corsci.2018.10.025.

Du YF, Yang GM, Chen SY, Ren YS. Research on the erosion-corrosion mechanism of 304 stainless steel pipeline of mine water in falling film flow. Corros Sci. 2022;206:110531. https://doi.org/10.1016/j.corsci.2022.110531.

Jin J, Zhang JZ, Hu M, Li LX. Investigation of high potential corrosion protection with titanium carbonitride coating on 316L stainless steel bipolar plates. Corros Sci. 2021;191:109757. https://doi.org/10.1016/j.corsci.2021.109757.

Wang JM, Jiang H, Chang XX, Zhang LJ, Wang HX, Zhu L, Qin SX. Effect of Cu content on the microstructure and corrosion resistance of AlCrFeNi3Cux high entropy alloys. Corros Sci. 2023;221:111313. https://doi.org/10.1016/j.corsci.2023.111313.

Carmezim MJ, Simões AM, Montemor MF, Cunha Belo MD. Capacitance behaviour of passive films on ferritic and austenitic stainless steel. Corros Sci. 2005;47(3):581. https://doi.org/10.1016/j.corsci.2004.07.002.

Macdonald DD. The history of the point defect model for the passive state: a brief review of film growth aspects. Electrochim Acta. 2011;56(4):1761. https://doi.org/10.1016/j.electacta.2010.11.005.

Gao J, Ma QC, Sun Y, Wang KN, Song Q, Wang CM. Effect of Nb content on microstructure and corrosion resistance of Inconel 625 coating formed by laser cladding. Surf Coat Technol. 2023;458:129311. https://doi.org/10.1016/j.surfcoat.2023.129311.

Zheng ZJ, Gao Y, Gui Y, Zhu M. Corrosion behaviour of nanocrystalline 304 stainless steel prepared by equal channel angular pressing. Corros Sci. 2012;54:60. https://doi.org/10.1016/j.corsci.2011.08.049.

Gu XY, Zhuang YX, Huang D. Corrosion behaviors related to the microstructural evolutions of as-cast Al0.3CoCrFeNi high entropy alloy with addition of Si and Ti elements. Intermetallics. 2022. https://doi.org/10.1016/j.intermet.2022.107600.

Wang WR, Wang JQ, Sun ZH, Li JT, Li LF, Song X, Wen XD, Xie L, Yang X. Effect of Mo and aging temperature on corrosion behavior of (CoCrFeNi)100-xMox high-entropy alloys. J Alloys Compd. 2020;812:152139. https://doi.org/10.1016/j.jallcom.2019.152139.

Hirschorn B, Orazem ME, Tribollet B, Vivier V, Frateur I, Musiani M. Determination of effective capacitance and film thickness from constant-phase-element parameters. Electrochim Acta. 2010;55(21):6218. https://doi.org/10.1016/j.electacta.2009.10.065.

Liu CT, Wu JK. Influence of pH on the passivation behavior of 254SMO stainless steel in 3.5% NaCl solution. Corros Sci. 2007;49(5):2198. https://doi.org/10.1016/j.corsci.2006.10.032.

Khireche S, Boughrara D, Kadri A, Hamadou L, Benbrahim N. Corrosion mechanism of Al, Al–Zn and Al–Zn–Sn alloys in 3 wt.% NaCl solution. Corros Sci. 2014. https://doi.org/10.1016/j.corsci.2014.07.018.

Acknowledgements

The present work was supported by the National Natural Science Foundation of China (NSFC) (52001083, U2141207, 52171111), Natural Science Foundation of Heilongjiang (YQ2023E026).

Author information

Authors and Affiliations

Contributions

Peng-Fei Dai: investigation, methodology, data curation, formal analysis, and writing original draft. Yang Zhang: writing—review and editing, visualization, supervision, and funding acquisition. Ji-Hong Han: analyzing and discussing data. Shu-Wen Li: analyzing and discussing data. Zhong-Wu Zhang: funding acquisition, supervision, writing—review and editing.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dai, PF., Zhang, Y., Rogozhkin, S. et al. Effect of Nb-content on the corrosion resistance of Co-free high entropy alloys in chloride environment. Tungsten (2024). https://doi.org/10.1007/s42864-024-00274-0

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42864-024-00274-0