Abstract

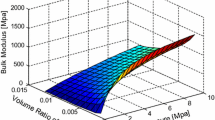

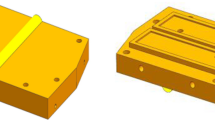

For a heavy hydrostatic bearing with a high linear velocity, the results of numerical calculations often differ from practical conditions if the viscosity is considered as constant. In this article, the influence of the oil cavity depth on the temperature field in the heavy hydrostatic bearing is discussed in the context of variable viscosity. The viscosity-temperature relations for the gap oil film are first established by fitting B-Spline curves, then, numerical calculations for the temperature field in the heavy hydrostatic bearing of different oil cavity depths are carried out based on Finite Volume Method (FVM) under the same rotating speed, and the influence of the oil cavity depth on the temperature distribution in the gap oil film of the hydrostatic bearing is discussed. The results of numerical calculations provide the temperature distribution state inside the hydrostatic bearing, which would help the selection and the design of hydrostatic bearings in engineering practice.

Similar content being viewed by others

References

CANBULUT F., YILDIRIM S. and SINANOĞLU C. Design of an artificial neural network for analysis of frictional power loss of hydrostatic slipper bearings[J]. Tribology Letters, 2004, 17(4): 887–899.

FU Yan-li, MA Xi-zhi and ZHU Jun. Study on the three-dimensional temperature field of circular journal bearing[J]. Mechanical Science and Technology, 2002, 21(5): 711–713(in Chinese).

WANG Chang-min. Analysis temperature field of hydrostatic bearing based on ANSYS[J]. Mechanical Management and Development, 2008, 23(5): 101–104(in Chinese).

AGRODZKI P., LAM K. Nonlinear transient behavior of a sliding system with frictionally excited thermoelastic instability[J]. Journal of Tribology, 2001, 123(5): 699–708.

MA Wen-qi, JIANG Ji-hai and ZHAO Ke-ding. Research on temperature rise of hydrostatic thrust bearing under variable viscosity[J]. China Mechanical Engineering, 2001, 12(8): 953–955(in Chinese).

JIANG Ji-hai, MA Wen-qi and ZHAO Ke-ding. Characteristic analysis of annular hydrostatic bearing based on variable viscosity[J]. Journal of Harbin Institute of Technology, 2000, 32(4): 19–25.

ZHANG Yan-qin, SHAO Jun-peng and NI Shi-qian. Numerical simulation of temperature field in large size hydrostatic bearing[J]. China Mechanical Engineering, 2008, 19(5): 563–565(in Chinese).

ZHANG Yan-qin, YU Xiao-dong. Viscosity influence research on load capacity of heavy hydrostatic bearing[J]. Key Engineering Materials, 2010, 450(9): 63–66.

ZHANG Yan-qin, YANG Xiao-dong. Research on influence of cavity depth on load capacity of heavy hydrostatic bearing in variable viscosity condition[J]. Advanced Materials Research, 2010, 129(9): 1181–1185.

ZHANG Xiao-feng, CUI Zhan-feng and LU Xin-hua. Simulation of sediment deposittion in a cavity with free surface[J]. Journal of Hydrodynamics, 2010, 22(5): 626–633.

SHAO Jun-peng, ZHANG Yan-qin and LI Peng-cheng. Static flow simulation of hydrostatic bearing ellipse and sector curve based on fluent[J]. Lubrication Engineering, 2007, 32(1): 93–95(in Chinese).

SHAO Jun-peng, ZHANG Yan-qin and YU Xiao-dong et al. Numerical simulation analysis of sector and circular oil recess temperature field of heavy hydrostatic[J]. Journal of Hydrodynamics, Ser. A, 2009, 24(1): 119–124(in Chinese).

ZHOU Jing-jun, YU Kai-ping and MIN Jin-xin et al. The comparative study of ventilated super cavity shape in water tunnel and infinite flow field[J]. Journal of Hydrodynamics, 2010, 22(5): 689–696.

PANG Zhi-cheng. Hydrostatic and pneumostatic tech-nology[M]. Harbin: Heilongjiang People’s Publishing House, 1981(in Chinese).

LI Zhi-wei, HUAI Wen-xin and QIAN Zhong-dong et al. Numerical study of flow and dilution behavior of radial wall jet[J]. Journal of Hydrodynamics, 2010, 22(5): 681–688.

DING Zhen-qian. Design of fluid hydrostatics support[M]. Shanghai: Shanghai Scientific and Tech-nological Publishers, 2004(in Chinese).

Author information

Authors and Affiliations

Corresponding author

Additional information

Project supported by the National Natural Science Foundation of China (Grant Nos. 50975066, 51075106), the National Natural Science Funds for Young Scholars of China (Grant No. 51005063).

Biography: SHAO Jun-peng (1957-), Male, Ph. D.

Rights and permissions

About this article

Cite this article

Shao, Jp., Dai, Cx., Zhang, Yq. et al. The Effect of Oil Cavity Depth on Temperature Field in Heavy Hydrostatic Thrust Bearing. J Hydrodyn 23, 676–680 (2011). https://doi.org/10.1016/S1001-6058(10)60164-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1001-6058(10)60164-3