Abstract

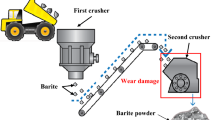

Wear properties of two different crushers used for grinding raw materials of cement industry are compared using pin-on-disk wear test. The wear test was carried out with different loads on a pin. Abrasive wear behavior of two alloys was evaluated by comparing mass loss, wear resistance, microhardness and friction coefficient. The mi-crostructure of the specimens was detected using optical microscope. The results showed that abrasive wear of high chromium cast iron is lower than that of Hadfield steel. Due to the presence of M7C3 carbides on the high chromium cast iron matrix, impact crushers exhibited higher friction coefficient.

Similar content being viewed by others

References

Reich H. Optimized Crusher Selection for the Cement Industry [C]//ThyssenKrupp Fordertechnik GmbH Processing. Magdeburg: [s. n.], 2000: 1.

Gundlach R, Janowak B J. Process Overview/Wear and Abrasion Testing [C]//2nd International Conference on Austem-pered Ductile Iron; Your Means to Improved Performance, Productivity and Cost. New York: ASME, 1986: 23.

Yuri N P, Valentin G G, Hans B, et al. Surface Structure of Stainless and Hadfield Steel after Impact Wear [J]. Wear, 2006, 260(6): 687.

Fucheng Z, Tingquan L. A Study of Friction-Induced Marten-sitic Transformation for Austenitic Manganese Steel [J]. Wear, 1997, 212(2): 195.

Yan W, Fang L, Sun K, et al. Effect of Surface Work Hardening on Wear Behavior of Hadfield Steel [J]. Materials Science and Engineering, 2007, 460–461A(6): 542.

Dastur Y N, Leslie W C. Mechanism of Work Hardening in Hadfield Manganese Steel [J]. Metallurgical and Materials Transactions, 1981, 12A(5): 749.

Mosbah A Y, Wexler D, Calka A. Abrasive Wear of WC-FeAl Composites [J]. Wear, 2005, 258(9): 1337.

Tianfu J, Fucheng Z. The Work-Hardening Behavior of Medium Manganese Steel Under Impact Abrasive Wear Condition [J]. Materials Letters, 1997, 31(5): 275.

Zhang G S, Xing J D, Gao Y M. Impact Wear Resistance of WC/Hadfield Steel Composite and its Interfacial Characteristics [J]. Wear, 2006, 260(7–8): 728.

Li D, Liu L, Zhang Y, et al. Phase Diagram Calculation of High Chromium Cast Irons and Influence of Its Chemical Composition [J]. Materials and Design, 2009, 30(2): 340.

Fernandez I, Belzunce F J. Wear and Oxidation Behavior of High Chromium Cast Iron [J]. Materials Characterization, 2008, 58(6): 669.

Bhushan B. Modern Tribology Handbook [M]. Florida: CRC Press, 2001.

Schon C L, Sinatora A. Simulation of Solidification Path in High Chromium White Cast Irons for Wear Applications [J]. Calphad, 1998, 22(4): 437.

Berns H. Comparison of Wear Resistant MMC and White Cast Iron [J]. Wear, 2003, 254(1/2): 47.

Pintaude G, Tschiptschin A P, Tanaka D K, et al. The Particle Size Effect on Abrasive Wear of High-Chromium White Cast Iron Mill Balls [J]. Wear, 2001, 250(1–12): 66.

Al-Rubaie K S. Equivalent Hardness Concept and Two-Body Abrasion of Iron Base Alloys [J]. Wear, 2000, 243(1–2): 92.

Abbasi M, Kheirandish S, Kharrazi Y, et al. The Fracture and Plastic Deformation of Aluminum Alloyed Hadfield Steels [J]. Materials Science and Engineering, 2009, 513–514A(7): 72.

Abbasi M, Kheirandish S, Kharrazi Y, et al. On the Comparison of the Abrasive Wear Behavior of Aluminum Alloyed and Standard Hadfield Steels [J]. Wear, 2010, 268(1–2): 202.

Remy L. The Interaction between Slip and Twinning Systems and the Influence of Twinning on the Mechanical Behavior of Face Centered Cubic Metals and Alloys [J]. Metall Trans, 1981, 12A(3): 387.

Moore M A. The Relationship Between the Abrasion Wear Resistance, Hardness and Microstructure of Ferritic Materials [J]. Wear, 1974, 28(1): 59.

Das S, Prasad B K, Jha A K, et al. Three-Body Abrasive Wear of 0.98% Carbon Steel [J], Wear, 1993, 162–164(B4): 802.

Garzino-Demo G A, Lama F L. Friction and Wear Uncoated or Si-Coated 329 Stainless Steel and of Uncoated or ALN-Coa-ted Aluminium Surfaces [J], Surface and Coating Technology, 1994, 68–69(12): 507.

Garzino-Demo G A, Lama F L. Friction and Wear of Metallic and Non-Metallic Surfaces [J]. Surface and Coating Technology, 1995, 76–77(12): 487.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Atabaki, M., Jafari, S. & Abdollah-pour, H. Abrasive Wear Behavior of High Chromium Cast Iron and Hadfield Steel—A Comparison. J. Iron Steel Res. Int. 19, 43–50 (2012). https://doi.org/10.1016/S1006-706X(12)60086-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(12)60086-7