Abstract

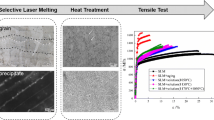

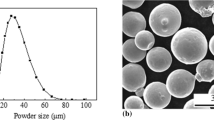

The potential of spray forming for microstructural refining can be attractive to the production of superal-loys. A #200 mm spray formed FGH95 superalloy round billet that was produced using a single atomizer has considerably homogeneous, small, equiaxed grains. The measured oxygen content is 2 × 10−5, and the measured porosity is only 0. 6%. The achieved yield of deposit is in a good range of about 73. 6%. The microstructure and tensile properties of nickel-based spray formed FGH95 superalloy are analyzed. Also, effects of heat treatment on microstructure were discussed. The results show that the spray formed FGH95 superalloy has higher isotropy in tensile property due to its γ′ phase homogeneous distribution and less defects in the microstructure. Regarding processing procedures, the different heat treatment processes affect the microstructure and γ′ phase homogeneous distribution of spray formed FGH95 superalloy.

Similar content being viewed by others

References

Bianchi L M. Argon Atomized Superalloys for Jet Engine Discs [C] // European Powder Metallurgy Conference on Meeting the Challenges of a Changing Market Place. Valencia, Spain: Maney Publisher, 2003: 328.

ZHANG Yi-wen, YANG Shi-zhong, LI Li, et al. Current Status of Research on PM Superalloy in China [J]. Materials Review, 2002, 16(5): 14.

YIN Fa-zhang, HU Ben-fu, JIN Kai-sheng, et al. Effect of Hot Extrusion and Heat Treatment on the γ’ Phase Precipitation in FGH95 Alloy [J]. Journal of Materials Engineering, 2005, 10: 52.

GUO Wei-min, WU Jian-tao, ZHANG Feng-ge. Microstructure, Properties and Heat Treatment Process of Powder Metallurgy Superalloy FGH95 [J]. Journal of Iron and Steel Research, International, 2006, 13(5): 65.

Lu Z Z, Liu C L, Yue Z F, et al. Probabilistic Safe Analysis of the Working Life of a Powder Metallurgical Turbine Disc [J]. Materials Science and Engineering, 2005, 395A: 153.

Manson-Whitton E D, Stone I C, Jones J R, et al. Isothermal Grain Coarsening of Spray Formed Alloys in the Semi-Solid State [J]. Acta Materialia, 2002, 50(10): 2517.

Alwin Schulz, Volker Uhlenwinkel, Christoph Escher, et al. Opportunities and Challenges of Spray Forming High-Alloyed Steels [J]. Materials Science and Engineering, 2008, 477A: 69.

Chaudhury S K, Sivaramakrishnan C S, Panigrahi S C. A New Spray Forming Technique for the Preparation of Aluminium Rutile (TiO2) ex Situ Particle Composite [J]. Journal of Materials Processing Technology, 2004, 145: 385.

MAO Jian, CHANG Ke-min, YANG Wan-hong, et al. Cooling Precipitation and Strengthening Study in Powder Metallurgy Superalloy Rene 88DT [J]. Matearials Science and Engineering, 2002, 332A: 318.

Rafael Agnelli Mesquita, Celso Antonio Barbosa. Spray Forming High Speed Steel—Properties and Processing [J]. Materials Science and Engineering, 2004, 383A: 87.

Li Z, Zhang G Q, Zhang Z H, et al. Investigation Into Hot Deformation Behavior of Spray Formed Superalloy GH742 [J]. Acta Metallurgica Sinica (English Letters), 2004, 17(2): 205.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item:Item Sponsored by National High Technology Research and Development Program (863 Program) of China (2007AA03Z502)

Rights and permissions

About this article

Cite this article

Xu, Y., Ge, Cc. & Shu, Q. Microstructure, Tensile Properties and Heat Treatment Process of Spray Formed FGH95 Superalloy. J. Iron Steel Res. Int. 20, 59–63 (2013). https://doi.org/10.1016/S1006-706X(13)60083-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(13)60083-7