Abstract

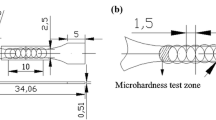

Surface microstructure and microhardness of (ferrite+cementite) microduplex structure of the ultrafine-grained high carbon steel after laser shock processing (LSP) with different impact times were investigated by means of scanning electron microscopy (SEM), transmission electron microscopy (TEM), X-ray diffraction (XRD) and microhardness measurements. Equiaxed ferrite grains were refined from 400 to 150 nm, and the cementite lamellae were fully spheroidized, with a decrease of the particle diameter from 150 to 100 nm as the impact times increased. The cementite dissolution was enhanced significantly. Correspondingly, the lattice parameter of α-Fe and microhardness increased with the impact times.

Similar content being viewed by others

References

C. S. Montross, T. Wei, L. Ye, G. Clark, Y. W. Mai, Int. J. Fatigue 24 (2002) 1021–1036.

C. Ye, S. Suslov, B. J. Kim, E. A. Stach, G. J. Cheng, Acta Mater. 59 (2011) 1014–1025.

R. Melookaran, A. Melaibari, C. Deng, P. Molian, Mater. Des. 35 (2012) 235–242.

Y. X. Hu, Z. Q. Yao, F. Wang, J. Hu, Surf. Eng. 13 (2007) 470–478.

J. Z. Lu, K. Y. Luo, Y. K. Zhang, C. Y. Cui, G. F. Sun, J. Z. Zhou, L. Zhang, J. You, K. M. Chen, J. W. Zhong, Acta Mater. 58 (2010) 3984–3994.

J. Z. Lu, K. Y. Luo, Y. K. Zhang, G. F. Sun, Y. Y. Gu, J. Z. Zhou, X. D. Ren, X. C. Zhang, L. F. Zhang, K.M. Chen, C. Y. Cui, Y. F. Jiang, A. X. Feng, L. Zhang, Acta Mater. 58 (2010) 5354–5362.

Y. K. Zhang, J. You, J. Z. Lu, C. Y. Cui, Y. F. Jiang, X. D. Ren, Surf. Coat. Technol. 204 (2010) 3947–3953.

B. Rouleau, P. Peyre, J. Breuils, H. Pelletier, T. Baudin, F. Brisset, Surf. Sci. 257 (2011) 7195–7203.

M. A. Meyers, F. Gregori, B. K. Kad, M. S. Schneider, D. H. Kalantar, B. A. Remington, G. Ravichandran, T. Boehly, J. S. Wark, Acta Mater. 51 (2003) 1211–1228.

Z. Zhou, S. Bhamare, G. Ramakrishnan, S. R. Mannava, K. Langer, Y. H. Wen, D. Qian, V. K. Vasudevan, Surf. Coat. Technol. 206 (2012) 4619–4627.

I. Nikitin, B. Sholtes, H. J. Maier, I. Altenberger, Scripta Mater. 50 (2004) 1345–1350.

I. Nikitin, I. Altenberger, Mater. Sci. Eng. A 465 (2007) 176–182.

Y. X. Hu, Z. Q. Yao, Surf. Coat. Technol. 202 (2008) 1517–1525.

J. P. Chu, J. M. Rigsbee, G. Bands, F. V. Lawrence, H. E. Elsayed-ali, Metall. Mater. Trans. A 26 (1995) 1507–1517.

Y. Xiong, T. T. He, Z. Q. Guo, H. Y. He, F. Z. Ren, A. A. Volinsky, Mater. Sci. Eng. A 570 (2013) 82–86.

Y. Xiong, T. T. He, Z. Q. Guo, H. Y. He, F. Z. Ren, A. A. Volinsky, Mater. Sci. Eng. A 563 (2013) 163–167.

T. T. He, Y. Xiong, F. Z. Ren, Z. Q. Guo, A. A. Volinsky, Mater. Sci. Eng. A 535 (2012) 306–310.

A. Belyakov, T. Sakai, H. Miura, R. Kaibyshev, K. Tsuzaki, Acta Mater. 50 (2002) 1547–1557.

J. Z. Lu, J. W. Zhong, K. Y. Luo, L. Zhang, F. Z. Dai, K. M. Chen, Q.W. Wang, J. S. Zhong, Y. K. Zhang, Mater. Sci. Eng. A 528 (2011) 6128–6133.

E. J. Fasiska, H. Wagenblas, Soc. AIME. 239 (1967) 1818–1820.

W. T. Fu, Y. Xiong, J. Zhao, Y. Li, T. Furuhara, T. Maki, J. Mater. Sci. Technol. 21 (2005) 25–27.

X. Scherpereel, P. Peyre, R. Fabbro, R. Fabbro, G. Lederer, N. Celatil, Proc. SPIE-Int. Soc. Opt. Eng. 3097 (1997) 546–557.

L. Chen, H. Zhou, Z. H. Zhang, L. Q. Ren, J. Iron Steel Res. Int. 16 (2009) No. 4, 39–43.

Author information

Authors and Affiliations

Additional information

Foundation Item: Item Sponsored by National Natural Science Foundation of China (50801021, 51201061); Program for Young Key Teachers in Henan Province of China (2011GGJS-070); Program for Henan Province for Science and Technology Innovation Excellent Talents of China (144200510001)

Rights and permissions

About this article

Cite this article

Xiong, Y., He, Tt., Ren, Fz. et al. Microstructure evolution and microhardness of ultrafine-grained high carbon steel during multiple laser shock processing. J. Iron Steel Res. Int. 22, 55–59 (2015). https://doi.org/10.1016/S1006-706X(15)60009-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(15)60009-7