Abstract

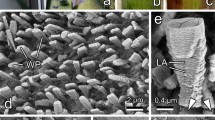

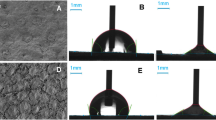

The leaf of lotus (Nelumbo nucifera) exhibits exceptional ability to maintain the opening status even under adverse weather conditions, but the mechanism behind this phenomenon is less investigated. In this paper, lotus leaves were investigated using environmental scanning electron microscopy in order to illustrate this mechanism. The macro-observations show that the primary veins are oriented symmetrically from leaf center and then develop into fractal distribution, with net-shaped arrangement of the side veins. Further micro-observations show that all the veins are composed of honeycomb micro-tubes viewed from cross section, the inner of micro-tubes are patterned with extended closed-hexagons from vertical section. Different positions of leaf possess diverse mechanical properties by size variation of diameter and inner hexagons of veins, which is theoretically analyzed by building a regular honeycomb model. Specifically, the central area of lotus tends to be stiffer while its margin be softer. These special distribution and composition of the veins mainly account for the distinct behavior of lotus.

Similar content being viewed by others

References

Barthlott W, Neinhuis C. Purity of the sacred lotus, or escape from contamination in biological surfaces. Planta, 1997, 202, 1–8.

Bhushan B, Jung Y C. Natural and biomimetic artificial surfaces for superhydrophobicity, self-cleaning, low adhesion, and drag reduction. Progress in Materials Science, 2011, 56, 101–108.

Gao N, Yan Y Y. Modeling Superhydrophobic contact angles and wetting transition. Journal of Bionic Engineering, 2009, 6, 335–340.

Zhang Y F, Yu X Q, Zhou Q H, Chen F, Li K N. Fabrication of superhydrophobic copper surface with ultra-low water roll angle. Applied Surface Science, 2010, 256, 1883–1887.

Zhang Y F, Wu J, Yu X Q, Wu H. Low-cost one-step fabrication of superhydrophobic surface on Al alloy. Applied Surface Science, 2011, 257, 7928–7931.

Zhang X, Tan S, Zhao N, Guo X, Zhang X, Zhang Y, Xu J. Evaporation of sessile water droplets on superhydrophobic natural lotus and biomimetic polymer surfaces. ChemPhysChem, 2006, 7, 2067–2670.

Wang J, Chen H, Sui T, Li A, Chen D. Investigation on hydrophobicity of lotus leaf: Experiment and theory. Plant Science. 2009, 176, 687–695.

Cheng Y T, Rodak D E, Wong C A, Hayden C A. Effects of micro- and nano-structures on the self-cleaning behavior of lotus leaves. Nanotechnology, 2006, 17, 1359–1362.

Zhang J, Sheng X, Jiang L. The dewetting properties of lotus leaves. Langmuir, 2009, 25, 1371–1376.

Yin L, Wang Q, Xue J, Ding J, Chen Q. Stability of superhydrophobicity of lotus leaf under extreme humidity. Chemistry Letter, 2010, 39, 816–817.

Boreyko J B, Chen C H. Restoring superhydrophobicity of lotus leaves with vibration-induced dewetting. Physics Review Letter, 2009, 103, 174502.

Merlen A, Brunet P. Impact of drops on non-wetting biomimetic surfaces. Journal of Bionic Engineering, 2009, 6, 330–334.

Zhang J, Wang J, Zhao Y, Xu L, Gao X, Zheng Y, Jiang L. How does the leaf margin make the lotus surface dry as the lotus leaf floats on water? Soft Matter, 2008, 4, 2232–2237.

Guo Z G, Liu W M, Su B L. Why so strong for the lotus leaf? Applied Physics Letter, 2008, 93, 201909.

Yu Y, Zhao Z H, Zheng Q S. Mechanical and superhydrophobic stabilities of two-Scale surfacial structure of lotus leaves. Langmuir, 2007, 23, 8212–8216.

Balani K, Batista R G, Lahiri D, Agarwal A. The hydrophobicity of a lotus leaf: A nanomechanical and computational approach. Nanotechnology, 2009, 20, 305707.

Mandelbrot B B. The Fractal Geometry of Nature, W H Freeman, San Francisco, USA 1982.

Andrews E W, Gibson L J. The influence of cracks, notches and holes on the tensile strength of cellular solids. Acta Materials, 2001, 49, 2975–2979.

Dierking I. Fractal and non-fractal structure-property relationships of polymer-stabilized liquid crystals. Advanced Functional Materials, 2004, 14, 883–890.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, Y., Wu, H., Yu, X. et al. Microscopic Observations of the Lotus Leaf for Explaining the Outstanding Mechanical Properties. J Bionic Eng 9, 84–90 (2012). https://doi.org/10.1016/S1672-6529(11)60100-5

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1672-6529(11)60100-5