Abstract

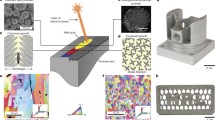

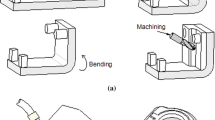

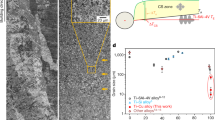

Freeform fabrication methods allow the direct formation of parts built layer by layer, under the control of a CAD drawing. Most of these methods form parts in thermoplastic or thermoset polymers, but there would be many applications for freeform fabrication of fully functional metal or ceramic parts. We describe here the freeforming of sinterable aluminium alloys. In addition, the building approach allows different materials to be positioned within a monolithic part for an optimal combination of properties. This is illustrated here with the formation of an aluminium gear with a metal-matrix composite wear surface.

Similar content being viewed by others

References

P. Calvert and R. Crockett, Chemistry of Materials 9 (1997) 650.

K. Stuffle et al., in Proceedings of the Solid Freeform Fabrication Symposium, edited by H. L. Marcus et al. (Austin, Texas, 1993) p. 60.

R. S. Crockett et al., in Proceedings of the Solid Freeform Fabrication Symposium, edited by H. L. Marcus et al. (Austin, Texas, 1995) p. 17.

P. Calvert et al., Chemistry of Materials 8 (1996) 1298.

J. Lombardi et al., Polymer Preprints 37 (1996) 221.

M. Greul et al., Computers in Industry 28 (1995) 23.

M. Greul, Materials Technology 11 (1996) 131.

M. Greul et al., Metal Powder Report 52 (1997) 24.

L. S. Darken and R. W. Gurry, in “Physical Chemistry of Metals” (McGraw Hill, New York, 1953).

C. Lall, Int. J. Powder Metall. 27 (1991) 315.

R. N. Lumley et al., Metallurgical Transactions A 30A (1999) 457.

T. B. Sercombe and G. B. Schaffer, in Advances in Powder Metallurgy and Particulate Materials: Proceedings of the 1997 Conference on Powder Metallurgy and Particulate Material, 1997.

H. Meher, in “Landolt Bornstein Numerical Data and Functional Relationships in Science and Technology,” Vol. III/26 (Springer-Verlag, Berlin, 1991), p. 151.

Y. Nakao et al., US Patent no. 5.525.292 (1996).

I. Kovacs et al., Materials Science and Engineering 21 (1975) 169.

H. Danninger, Metal Powder Report (UK) 48 (1993) 46.

A. K. Jha et al., Powder Metallurgy 32 (1989) 209.

G. H. Borhani et al., ibid. 36 (1993) 67.

R. Q. Guo et al., J. of Mater. Sci. 32 (1997) 3971.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Sercombe, T.B., Schaffer, G.B. & Calvert, P. Freeform fabrication of functional aluminium prototypes using powder metallurgy. Journal of Materials Science 34, 4245–4251 (1999). https://doi.org/10.1023/A:1004602819393

Issue Date:

DOI: https://doi.org/10.1023/A:1004602819393