Abstract

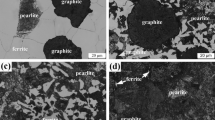

Spheroidal graphite (SG) irons with a variety of matrix-structure have been produced. The correlation between tensile properties, impact toughness, hardness and pearlite content is investigated. The pearlite content is varied from 0 to about 95 per cent by the use of different heat treatment processes. The apparent variation in the properties with the pearlite level reveals the remarkable consistency in the relationships between mechanical properties and pearlite content. The study of the tensile properties showed that the yield and ultimate tensile strengths are increased with increasing pearlite level in the matrix structure. For matrix structure with 94.6% pearlite, the increases are about 91% and 98%, respectively, compared with those of the ferritic matrix material. The impact toughness of SG-iron is influenced significantly by matrix microstructure. Energy of about 230 × 103J/m2 is required to fracture a ferritic matrix SG-iron. On the other hand, when the matrix structure approaches a fully pearlitic matrix the fracture energy is decreased by an amount of 75.5%. The Brinell hardness value is found to increase with increasing pearlite content in the matrix structure of the present material. It increases from about 128 for a fully ferritic matrix to about 258 as the matrix structure approaches a fully pearlitic condition. This change in the hardness value reflects the change in the mechanical properties presented in this study.

Similar content being viewed by others

References

J. Gayet and J. C. Margerie, AFS International Cast Metals Journal 6(6) (1981) 47.

J. E. Bevan and W. G. Scholz, AFS Trans. 85 (1977) 271.

X. P. Shen, S. J. Harris and B. Nobel, Materials Science and Technology 11 (1995) 893.

L. Guerin and M. Gagne, Foundryman 8, 9 (1987) 336.

N. Fatahalla, T. Gomaa, S. Bahi and M. Negm, Z. Metallkde 89(7) (1998) 507.

S. K. Yu, C. R. Loper, Jr. and H. H. Cornell, AFS Trans. 94 (1986) 557.

D. R. Askeland and S. S. Gupta, ibid. 83 (1975) 313.

H. Bayati and R. Elliott, Materials Science and Technology 11 (1995) 284.

S. C. Lin, T. S. Lui and L. H. Chen, AFS Trans. 105 (1997) 753.

P. Dierickx, C. Verda, A. Reynaud and R. Fougeres, Scripta Mater. 34(2) (1996) 261.

J. O. T. Adewara and C. R. Loper, Jr, AFS Trans. 84 (1976) 513.

A. G. Fuller, ibid. 85 (1977) 527.

ASM, “Metals Handbook-Metallography and Microstructures,” Vol. 9, 9th ed. (American Society of Metals, Metal Park, Ohio, USA, 1985).

ASM, “Metals Handbook,” Vol. 15, 9th ed. (American Society of Metals, Metal Park, Ohio, USA, 1992).

S. Karsay, “Ductile Iron-the Production Practices,” 2nd ed. (American Foundrymen's Society for Metals, USA, 1979).

J. Hwang, J. Doong and H. Chen, J. Mater. Sci. Letters 2 (1983) 737.

R. C. Voigt and L. M. Eldoky, AFS Trans. 94 (1986) 637.

L. M. Eldoky and R. C. Voigt, ibid. 93 (1985) 621.

J. O. T. Adewara and C. R. Loper, Jr, ibid. 84 (1976) 527.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Hafiz, M. Mechanical properties of SG-iron with different matrix structure. Journal of Materials Science 36, 1293–1300 (2001). https://doi.org/10.1023/A:1004866817049

Issue Date:

DOI: https://doi.org/10.1023/A:1004866817049