Abstract

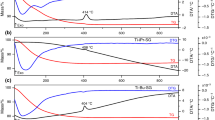

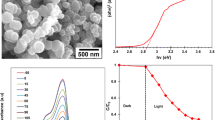

The photocatalytic characteristics of nanostructured TiO2 ultrafine powder with rutile phase produced using the homogeneous precipitation process at low temperatures (HPPLT) were compared with those of commercial P-25 TiO2 powder by flame hydrolysis. The TiO2 powder by the HPPLT showed much higher photoactivity in the removal rate, showing lower pH values in the solution than the P-25 powder when eliminating metal ions such as Pb and Cu from the aqueous metal-EDTA solutions. This can be inferred as the more rapid photo-oxidation or -reduction of metal ions from the aqueous solution, together with relatively higher efficiencies in the use of an electron-hole pair formed on the surface of the TiO2 particles under UV light irradiation. Also, in the view of the TiO2 particle morphology, compared to the well-dispersed spherical P-25 particles, the agglomerated TiO2 secondary particles by the HPPLT consist of acicular typed primary particles with a thickness in the range of 3–7 nm and the primary particles radialize in all directions, which would be more effective to photocatalytic reactions without the large electron-hole recombination on the surface of the TiO2 particle under UV light irradiation. It can be, therefore, thought that the higher photoactivity of the rutile TiO2 powder by the HPPLT in the aqueous solutions results mainly from having a larger surface area by the acicular shaped primary particles with very thin thickness and radialization in all directions.

Similar content being viewed by others

References

Y. Argaman and C.W. Weddle, AlChE Symp. 70(136), 400 (1972).

L.M. Ottosen, H.K. Hansen, and A. Villumsen, Environ. Sci. Technol. 31, 1711 (1997).

J.D. Way, R.D. Noble, and E.D. Sloam, J. Memb. Sci. 12, 239 (1982).

J.E. Hoffman and I.C. Gundiler, Precious and Rare Earths Technologies (Elsevier, Amsterdam, 1989), p. 391.

L.Y. Chang, Env. Prog. 15, 28 (1996).

A. Fujishima and K. Honda, Nature (London) 238, 37 (1972).

A.L. Pruden and D.F. Ollis, J. Catal. 82, 404 (1983).

M.A. Fox and M.T. Dulay, Chem. Rev. 93, 341 (1993).

M.R. Hoffmann, S.T. Martin, W.Y. Choi, and D.W. Bahnemann, Chem. Rev. 95, 69 (1995).

S.E. Pratsinis, H. Bai, and P. Biswas, J. Am. Ceram. Soc. 73(7), 2158 (1990).

E. Narita, H. Takeuchi, N. Horiguchi, and T. Okabe, Bull. Chem. Soc. Jpn. 57, 1388 (1984).

E. Reck and M. Richards, Pigment & Resin Technology 28(3), 149 (1999).

A. Tsevis, N. Spanos, P.G. Koutsoukos, Ab J. van der Linde, and J. Lyklema, J. Chem. Soc., Faraday Trans. 94(2), 295 (1998).

J. Augustynski, J. Electrochem. Acta 38, 43 (1993).

B. Ohtani and S.-I. Nishimoto, J. Phys. Chem. 97, 920 (1993).

K.-M. Schindler and M. Kunst, J. Phys. Chem. 94, 8222 (1990).

G.A. Somorjai, Chemistry in Two Dimensions: Surface (Cornel University Press, Ithaca, USA, 1981), p. 551.

A. Mills, R.H. Davies, and D. Worley, Chemical Society Reviews, pp. 417–425 (1993).

A. Mills, S. Morris, and R. Davies, J. Photochem. Photobiol. A: Chem. 71, 285 (1993).

N. Serpone, J. Photochem. Photobiol. A 104, 1 (1997).

S.J. Kim, S.D. Park, Y.H. Jeong, and S. Park, J. Am. Ceram. Soc. 82(4), 927 (1999).

S.D. Park, Y.H. Cho, W.W. Kim, and S.J. Kim, J. Solid State Chem. 146(1), 230 (1999).

S.J. Kim, S.D. Park, K.H. Kim, Y.H. Jeong, and I.H. Kuk, US Patent No. 6001326.

Q. Zhang, L. Gao, and J. Guo, Applied Catalysis B: Environmental 26, 207 (2000).

J.A. Ayres, Decontamination of Nuclear Reactors and Equipment (Ronald Press, New York, 1970), p. 6.

L. Loy and E.E. Wolf, Solar Energy 34(6), 455 (1985).

M.Z. Hoffmann, D.R. Prasad, G. Jones II, and V. Malba, J. Am. Chem. Soc. 105, 6360 (1983).

K.-N.P. Kumar, Scripta Metallurgica et Materialia 32(6), 873 (1995).

K. Tanaka, K. Harada, and S. Murata, Sol. Energy 36(2), 159 (1986).

M.R. Prairie, I.R. Evans, B.M. Stange, and S.L. Martinez, Environ. Sci. Tech. 27, 1776 (1993).

R.R. Bacsa and J. Kiwi, Applied Catalysis B: Environmental 16, 19 (1998).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kim, SJ., Lee, E., Park, S. et al. Photocatalytic Effects of Rutile Phase TiO2 Ultrafine Powder with High Specific Surface Area Obtained by a Homogeneous Precipitation Process at Low Temperatures. Journal of Sol-Gel Science and Technology 22, 63–74 (2001). https://doi.org/10.1023/A:1011264320138

Issue Date:

DOI: https://doi.org/10.1023/A:1011264320138