Abstract

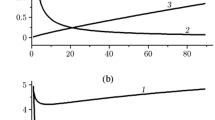

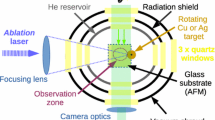

A theory is presented that includes capillary, hydrodynamic, and diffusion aspects. The main attention is devoted to capillary and hydrodynamic effects. The hydrodynamic process (bubble growth) is governed by a nonlinear integrodifferential equation, whose coefficients are dependent on the surface tension, density, and viscosity of the liquid, and also on the difference between the pressure in the gas within the bubble and that in the surrounding liquid. The gas pressure in the bubble is dependent on the rate of gas release from the inclusion (source). An expression is derived for the bubble radius as a function of time. The theory can be useful for developing the technology of powder materials and foam metals.

Similar content being viewed by others

REFERENCES

S. V. Gniloskurenko, A. I. Raichenko, T. Nakamura, et al., “Theory of initial microcavity growth in a liquid metal around a gas-releasing particle. I. Physical and mathematical models, ” Poroshk. Metall., Nos. 11-12, 78-84 (2001).

A. I. Raichenko, The Mathematical Theory of Diffusion in Applications [in Russian], Nauk. Dumka, Kiev (1981).

E. J. Barlow and W. E. Langlois, “Diffusion of gas from a liquid into expanding bubble, ” IBM J. Res. Devel., 6, No. 3, 329-337 (1962).

V. I. Nizhenko and A. I. Floka, Surface Tension in Liquid Metals and Alloys (One-Component and Two-Component Systems): Handbook [in Russian], Metallurgiya, Moscow (1981).

T. R. P. Gibb Jr., J. J. McSharry, and R. W. Bragdon, “The titanium-hydrogen system and titanium hydride. II. Studies at high pressure, ” J. Amer. Chem. Soc., 73, No. 4, 1751-1755 (1951).

W. M. Müller, “Titanium hydrides, ” in: Metal Hydrides, W. Müller, D. Blacklege, and J. Libowicz (eds.), [Russian translation], Atomizdat, Moscow (1973), pp. 278-309.

G. V. Samsonov (ed.), Properties of the Elements: Handbook. Part 1. Physical Properties [in Russian], Metallurgiya, Moscow (1976).

T. Utigard, J. M. Toguri, and T. Nakamura, “Interfacial tension and flotation characteristics of liquid metalsodium flux system, ” Metall. Transact., 17B, No. 6, 339-346 (1986).

V. V. Sobolev and N. A. Nesterov, “A numerical study of gas inclusion behavior in a solidifying liquid, ” Izv. VUZ, Chernaya Metallurgiya, No. 8, 1-4 (1984).

R. C. Atwood, S. Sridhar, W. Zhang, and P. Lee, “Diffusion-controlled growth of hydrogen pores in aluminium-silicon castings: In situ observation and modelling, ” Acta Mater., 48, 405-417 (2000).

H. Yin and J. N. Koster, “In-situ observed pore formation during solidification of aluminium, ” ISIJ International, 40, No. 4, 364-372 (2000).

J. Banhart and J. Baumeister, “Production methods for metallic foams, ” Mat. Res. Soc. Symp. Proc., 521, 121-132 (1998).

F. Simancik, J. Jerz, J. Kovacik, and P. Minar, “Aluminium foam: A new light-weight structural material, ” Kovove Materialy (Metallic Materials), 35, No. 4, 265-277 (1997).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Raichenko, A.I., Byakova, A.V. Theory of Initial Microcavity Growth in a Liquid Metal Around a Gas - Releasing Particle. Part 2. Bubble Initiation Conditions and Growth Kinetics. Powder Metallurgy and Metal Ceramics 41, 90–96 (2002). https://doi.org/10.1023/A:1016072817565

Issue Date:

DOI: https://doi.org/10.1023/A:1016072817565