Abstract

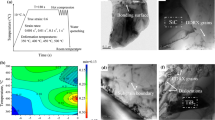

Aluminium-matrix composites containing thermally oxidized and unoxidized SiC particles featuring four average particle diameters ranging from 3 to 40 μm were produced by vacuum assisted high pressure infiltration. Their thermal expansion coefficient (CTE) was measured between 25 and 500°C. Oxidation of the SiC particles in air produces the formation at their surface of silicon oxide in quantities sufficient to bond the particles together, and confer strength to preforms. After infiltration with pure aluminium, the composites produced showed no sign of significant interfacial reaction. The CTE of the composite reinforced with unoxidized SiC particles featured an abrupt upward deviation upon heat-up near 200°C, and a second abrupt decrease near 400°C. The first transition is attributed to an inversion of stress across particle contact points. When composites are produced with oxidized SiC particles, these two transitions were removed, their CTE varying smoothly and gradually from the lower elastic bound to the upper elastic bound as temperature increases. With both composite types, the CTE decreased as the average particle size decreased. This work illustrates the benefits of three-dimensional reinforcement continuity for the production of low-CTE metal matrix composites, and shows a simple method for producing such composites.

Similar content being viewed by others

References

D. J. LLOYD, Inter. Mater. Rev. 39 (1994) 1.

S. ELOMARI, R. BOUKHILI, M. D. SKIBO and J. MASOUNAVE, J. Mater. Sci. 30 (1995) 3037.

R. J. ARSENAULT, Scripta Metall. 22 (1988) 767.

Y. FLOM and R. J. ARSENAULT, J. Metals 38 (1986) 31.

F. A. GIROT, J. M. QUENISSET and R. NASLAIN, Comp. Sci. Tech. 30 (1987) 155.

R. H. JONES, C. A. LAVENDER and M. T. SMITH, Scripta Metall. 21 (1987) 1565.

H. J. HEINE, Founy Mgmt Tech. 116 (1988) 25.

V. C. NARDONE and J. R. STRIFE, Metall. Trans. 18 (1987) 109.

K. S. RAVICHANDRAN and E. S. DWARKADASA, J. Metals 39 (1987) 28.

Duralcan composites casting guidelines, "Duralcan composites-mechanical and physical property, Wrought composites, SI Units", 1992, Duralcan USA, San Diego, CA, USA.

M. J. KOCZAK, S. C. KHATRI, J. E. ALLISON and M. G. BADER, in “Fundamentals of metal matrix composites”, edited by S. Suresh, A. Mortensen and A. Needleman (Butterworth-Heinemann, Boston, 1993) p. 297.

C. ZWEBEN, JOM 44 (1992) 15.

D. K. BALCH, T. J. FITZGERALD, V. J. MICHAUD, A. MORTENSEN, Y.-L. SHEN, and S. SURESH, Metall. Trans. accepted.

A. BRANDES, Smithells Metals Reference Book (6th edn. Butterworths, London, 1983) p. 14.

F. A. HUMMEL “Phase equilibria in ceramic systems” (Marcel Dekker, New York, 1984) p. 32.

N. EUSTATHOPOULOS and A. MORTENSEN, in “Fundamentals of metal matrix composites”, edited by S. Suresh, A. Mortensen and A. Needleman (Butterworth-Heinemann, Boston, 1993) p. 42.

J. NARCISO, A. ALONSO, A. PAMIES, C. G. CORDOVILLA and A. LOUIS, Metall. Trans. 26A (1995) p. 983.

R. J. VAIDYA and K. K. CHAWLA, Comp. Sci.Tech. 50 (1994) p. 13.

E. SIDERIDIS, ibid. (1994) 301.

T. H. HAHN, in “Metal matrix composites: mechanisms and properties”, edited by R. K. Everett and R. J. Arsenault (Academic Press, Boston, 1991) p. 329.

R. A. SCHAPERY, J. Comp. Mater. 2 (1968) 380.

M. OLSSON, A. E. GIANNAKOPOULOS, and S. SURESH, J. Mech. Phys. Solids 43 (1995) 1639.

Z. LI and R. C. BRADT, Int. J. High Technology Ceramics 4 (1988) 1.

Z. R. XU, K. K. CHAWLA, R. MITRA and M. E. FINE, Scripta Metall. Mater. 31 (1994) 1525.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

ELOMARI, S., BOUKHILI, R., SAN MARCHI, C. et al. Thermal expansion responses of pressure infiltrated SiC/Al metal-matrix composites. Journal of Materials Science 32, 2131–2140 (1997). https://doi.org/10.1023/A:1018535108269

Published:

Issue Date:

DOI: https://doi.org/10.1023/A:1018535108269