Abstract

Achieving optical gain and/or lasing in silicon has been one of the most challenging goals in silicon-based photonics1,2,3 because bulk silicon is an indirect bandgap semiconductor and therefore has a very low light emission efficiency. Recently, stimulated Raman scattering has been used to demonstrate light amplification and lasing in silicon4,5,6,7,8,9. However, because of the nonlinear optical loss associated with two-photon absorption (TPA)-induced free carrier absorption (FCA)10,11,12, until now lasing has been limited to pulsed operation8,9. Here we demonstrate a continuous-wave silicon Raman laser. Specifically, we show that TPA-induced FCA in silicon can be significantly reduced by introducing a reverse-biased p-i-n diode embedded in a silicon waveguide. The laser cavity is formed by coating the facets of the silicon waveguide with multilayer dielectric films. We have demonstrated stable single mode laser output with side-mode suppression of over 55 dB and linewidth of less than 80 MHz. The lasing threshold depends on the p-i-n reverse bias voltage and the laser wavelength can be tuned by adjusting the wavelength of the pump laser. The demonstration of a continuous-wave silicon laser represents a significant milestone for silicon-based optoelectronic devices.

Similar content being viewed by others

Main

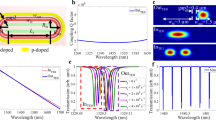

The continuous-wave (c.w.) silicon Raman laser is constructed from a low-loss silicon-on-insulator (SOI) rib waveguide whose facets are coated with multilayer dielectric films. The front facet coating is dichroic, having a reflectivity (Rf) of ∼71% for the Raman/Stokes wavelength of 1,686 nm and ∼24% for the pump wavelength of 1,550 nm. The back facet has a broadband high-reflectivity coating (Rb) of ∼90% for both pump and Raman wavelengths (Fig. 1a). These waveguide facet reflectivities were determined using a Fabry–Pérot resonance technique2.

The silicon rib waveguide is fabricated on the (100) surface of an undoped SOI substrate using standard photolithographic patterning and reactive ion etching techniques. We designed the waveguide dimensions with the goal of obtaining a small cross-section for minimizing the required optical power to achieve the lasing threshold, but not so small as to cause high transmission loss. A cross-section scanning electron microscope image of a typical p-i-n waveguide is shown in Fig. 1b. The rib waveguide dimensions are: rib width (W) ∼1.5 µm; height (H) ∼1.55 µm; and etch depth (h) ∼0.7 µm. The effective core area13 of the waveguide is calculated to be ∼1.6 µm2. The waveguide was formed in an S-shaped curve with a total length of 4.8 cm and a bend radius of 400 µm (Fig. 1a). The straight sections of the waveguide are oriented along the [011] crystallographic direction.

A p-i-n diode structure was designed to reduce the nonlinear optical loss due to the TPA-induced FCA. The p-i-n structure was formed by implanting boron and phosphorus in the slab on either side of the rib waveguide (Fig. 1a, b) with a doping concentration of ∼1 × 1020 cm-3. The separation between the p- and n-doped regions was designed to be ∼6 µm. Ohmic contacts were formed by depositing aluminium films on the surface of the p- and n-doped regions. This was followed by a SiO2 passivation layer deposition. The doped regions and the metal contacts at the designed separation had negligible effect on the propagation loss of the waveguide because the optical mode is tightly confined in the waveguide. This was verified experimentally. The linear optical transmission loss of the S-bend waveguide was measured to be 0.35 dB cm-1 using the Fabry–Pérot resonance technique2.

When a reverse bias voltage is applied to the p-i-n diode, the TPA-generated electron–hole pairs can be swept out of the silicon waveguide by the electric field between the p- and n-doped regions. Thus the effective carrier lifetime, representing the lifetime of the free carrier's interaction with the optical mode in the waveguide region, reduces with increased bias voltage. This has been experimentally verified by comparing the measured nonlinear transmission of a silicon waveguide with modelling9,14. The measured photocurrent in the reverse-biased p-i-n diode scales with the square of the light power inside the waveguide, indicating that the charge carriers are generated by the TPA process10. At a reverse-bias voltage of 25 V, the effective carrier lifetime is reduced to ∼1 ns compared to the free carrier lifetime of several tens of nanoseconds in ordinary silicon rib waveguides10,11. Before performing the lasing experiment, the single-pass c.w. Raman gain of a p-i-n silicon waveguide was measured in a pump–probe experiment14, showing a single-pass net gain of >3 dB at a reverse-bias voltage of 25 V and a pump power of ∼700 mW coupled into the waveguide.

Figure 2 is a schematic of the Raman laser experiment. A c.w. external cavity diode laser (ECDL) at 1,550 nm is amplified by an erbium-doped fibre amplifier system to produce a pump beam of up to 3 W. The pump beam passes through a polarization controller followed by a thin-film-based wavelength de-multiplexer and is coupled into the waveguide cavity by a lensed fibre through the dichroic-coated front facet. The Raman laser output and the reflected pump beam are coupled back into the lensed fibre, and separated through the wavelength de-multiplexer. The extracted laser output from the reflection port of the de-multiplexer is further filtered by a long-wavelength pass filter before being detected by a power meter or optical spectrum analyser. The coupling loss between the lensed fibre and the waveguide was measured to be ∼4 dB and the insertion loss of the de-multiplexer and the long-wavelength pass filter is ∼0.6 dB. The silicon chip is mounted on a thermo electric cooler and kept at a constant temperature of 25 °C.

At the pump wavelength, a low finesse cavity is formed by the low reflectivity front facet and high reflectivity back facet. This configuration allows the cavity enhancement effect15,16,17 of the pump power to be used to lower the lasing threshold. When the pump laser is tuned to the resonance of the cavity, the circulating power inside the waveguide cavity is enhanced, and the effective mean internal power (Ieff) inside the cavity can be expressed as18:

where Ii is the incident pump power (less coupling loss), Rf and Rb are the reflectivity of the front and back facet respectively, α is the absorption coefficient, and L is the waveguide length. At low power, we can estimate the power enhancement factor M = Ieff/Ii to be ∼2.2, using our experimental parameters. At high power, however, the absorption coefficient α increases owing to the TPA-induced nonlinear absorption, and M reduces accordingly.

Figure 3 plots the Raman laser output power versus the input pump power (Ii) coupled into the laser cavity depicted in Fig. 1a, at two different reverse-bias voltages applied to the p-i-n diode. In the experiment, the pump beam polarization is adjusted with a polarization controller and its wavelength is fine-tuned to the cavity resonance to take advantage of the cavity enhancement of the pump and maximize the laser output. The Raman laser frequency is 15.6 THz lower than that of the pump laser. We see from Fig. 3 that the lasing threshold reduces with increasing reverse-bias voltage. The lasing threshold is ∼280 mW with a 5-V bias and ∼180 mW with a 25-V bias. The lower threshold and higher laser output power with higher reverse-bias voltage are expected because the effective carrier lifetime is shorter, resulting in lower nonlinear loss and higher gain14. For this waveguide cavity, the total loss of the feedback mirrors (Rf = 71% and Rb = 90%) at the lasing wavelength is ∼2 dB, so a ∼1-dB single-pass net gain is needed to reach lasing threshold. From previous measurements14, a ∼1-dB net c.w. gain is obtained at a pump power of ∼400 mW with 25-V reverse bias and ∼600 mW with 5-V reverse bias. Taking into account the cavity enhancement factor of ∼2.2, the lasing thresholds are expected to be ∼182 and ∼273 mW for reverse biases of 25 and 5 V, respectively, which is consistent with our measurements. The slope efficiency (single side output) above threshold is ∼4.3% with a reverse bias of 25 V, and 2% with a reverse bias of 5 V. Figure 3 also shows that the laser output power begins to saturate at a pump power of >400 mW with a 25-V bias and at a pump power of >500 mW with a 5-V bias. This is primarily due to the nonlinear loss caused by the TPA-induced FCA as a consequence of the non-zero carrier lifetime of the p-i-n waveguide, reducing the net gain at higher pump powers. In addition, the cavity enhancement factor M for the pump reduces with increasing nonlinear loss, lowering the effective pump power in the cavity.

The spectrum of the laser output is measured with a confocal scanning Fabry–Pérot spectrum analyser with a free spectral range of 8 GHz and finesse of 100. Figure 4a shows the Raman laser spectrum measured at a pump power of ∼400 mW and a reverse bias of 25 V. As shown, the laser has single-mode output, that is, no other cavity modes with expected mode spacing of 0.9 GHz for a 4.8-cm-long silicon waveguide cavity appear within the free spectral range (8 GHz) of the spectrum analyser. The measured linewidth of 80 MHz is limited by the resolution of the spectrum analyser. This was verified by recording the spectrum of a narrow-band laser of linewidth <1 MHz with the same spectrum analyser.

a, Measured with a confocal scanning Fabry–Pérot spectrum analyser. Displayed is a scan over one free spectral range of 8 GHz showing single-mode operation of the laser. The measured linewidth of 80 MHz is limited by the resolution of the spectrum analyser. b, Measured with a grating-based optical spectrum analyser at different pump wavelengths from 1,548 nm to 1,558 nm in 2-nm steps, showing a side mode suppression of >55 dB.

Figure 4b is a plot of the laser output spectrum measured with a grating-based optical spectrum analyser with 0.07-nm resolution at various pump wavelengths. The spectra shown were obtained by changing the wavelength of the pump laser seed (ECDL) from 1,548 to 1,558 nm in 2-nm steps. The input pump power was ∼400 mW and a reverse bias of 25 V was applied to the p-i-n diode. The Raman laser output has side-mode suppression of over 55 dB and its centre wavelength corresponds to the appropriate Stokes shift for each pump wavelength. The displayed linewidth is limited by the resolution of the spectrum analyser. The small fluctuation in output power is due to the wavelength dependence of the insertion loss of the de-multiplexer, the long-wavelength pass filter, and the gain of erbium-doped fibre amplifiers.

This first demonstration of c.w. Raman lasing in silicon represents a significant milestone towards producing fully integrated monolithic photonic chips. The performance of this silicon Raman laser could be further improved by optimizing cavity mirror and cavity length design. The threshold power could be reduced by using a waveguide with smaller cross-sectional dimensions and/or by introducing a larger cavity enhancement for the pump beam. The fibre to waveguide coupling efficiency could be improved by adding a mode converter in the waveguide19. In addition, with optimization of the p-i-n diode design, it may be possible to further reduce the effective carrier lifetime to below 1 ns. This would reduce the saturation effect and thus increase the laser output power. The multilayer coating approach used to form the cavity mirrors could also be replaced with waveguide Bragg reflectors20,21, ring or microdisk resonator architectures22,23,24,25; this could provide a platform for monolithic integration of silicon-based optoelectronics.

References

Pavesi, L. & Gaponenko, S. (eds) Towards the First Silicon Laser (NATO Science Series, Kluwer, Dordrecht, 2003)

Reed, G. T. & Knights, A. P. Silicon Photonics: An Introduction (John Wiley, Chichester, UK, 2004)

Pavesi, L. & Lockwood, D. J. (eds) Silicon Photonics (Springer, Berlin, 2004)

Liu, A., Rong, H., Paniccia, M., Cohen, O. & Hak, D. Net optical gain in a low loss silicon-on-insulator waveguide by stimulated Raman scattering. Opt. Expr. 12, 4261–4267 (2004)

Xu, Q., Almeida, V. & Lipson, M. Time-resolved study of Raman gain in highly confined silicon-on-insulator waveguides. Opt. Expr. 12, 4437–4442 (2004)

Liang, T. K. & Tsang, H. K. Efficient Raman amplification in silicon-on-insulator waveguides. Appl. Phys. Lett. 85, 3343–3345 (2004)

Boyraz, O. & Jalali, B. Demonstration of 11 dB fiber-to-fiber gain in a silicon Raman amplifier. IEICE Elect. Expr. 1, 429–434 (2004)

Boyraz, O. & Jalali, B. Demonstration of a silicon Raman laser. Opt. Expr. 12, 5269–5273 (2004)

Rong, H. et al. An all-silicon Raman laser. Nature 433, 292–294 (2005)

Liang, T. K. & Tsang, H. K. Role of free carriers from two-photon absorption in Raman amplification in silicon-on-insulator waveguides. Appl. Phys. Lett. 84, 2745–2747 (2004)

Rong, H. et al. Raman gain and nonlinear optical absorption measurement in a low loss silicon waveguide. Appl. Phys. Lett. 85, 2196–2198 (2004)

Claps, R., Raghunathan, V., Dimitropoulos, D. & Jalali, B. Role of nonlinear absorption on Raman amplification in Silicon waveguides. Opt. Expr. 12, 2774–2780 (2004)

Agrawal, G. P. Nonlinear Fiber Optics 2nd edn, 42–43 (Academic, New York, 1995)

Jones, R. et al. Net continuous wave optical gain in a low loss silicon-on-insulator waveguide by stimulated Raman scattering. Opt. Expr. 13, 519–525 (2005)

Siegman, A. E. Lasers 413–418 (University Science Books, Mill Valley, 1986)

Suto, K., Kimura, T. & Nishizawa, J. Semiconductor Raman laser pumped with a fundamental mode. IEE Proc. J. 139, 407–412 (1992)

Brasseur, J. K., Repasky, K. S. & Carlsten, J. L. Continuous-wave Raman laser in H2 . Opt. Lett. 23, 367–369 (1998)

Garmire, E. Criteria for optical bistability in a lossy saturating Fabry-Perot. IEEE J. Quant. Electron. QE-25, 289–295 (1989)

Salib, M. et al. Silicon photonics. Intel Technol. J. 8, 143–160 (2004)

Liu, M. Y. & Chou, S. Y. High-modulation-depth and short-cavity-length silicon Fabry–Perot modulator with two grating Bragg reflectors. Appl. Phys. Lett. 68, 170–172 (1996)

Barrios, C. A., Almeida, V. R., Panepucci, R. R., Schmidt, B. S. & Lipson, M. Compact silicon tunable Fabry-Perot resonator with low power consumption. IEEE Photon. Technol. Lett. 16, 506–508 (2004)

Headley, W. R., Reed, G. T., Liu, A., Paniccia, M. & Howe, S. Polarization independent optical racetrack resonators using rib waveguide on silicon on insulator. Appl. Phys. Lett. 85, 5523–5525 (2004)

Lee, M.-C. M. & Wu, M. C. in IEEE/LEOS Int. Conf. on Optical MEMS and Their Applications (Hawaii, 18–21 August 2003) Paper MC3 28–29 (IEEE, Piscataway, NJ, 2003).

Koonath, P., Indukuri, T. & Jalali, B. Vertically coupled micro-resonators realized using three-dimensional sculpting in silicon. Appl. Phys. Lett. 85, 1018–1020 (2004)

Kippenberg, T. J., Spillane, S. M., Armani, D. K. & Vahala, K. J. Ultralow-threshold microcavity Raman laser on a microelectronic chip. Opt. Lett. 29, 1224–1227 (2004)

Acknowledgements

We thank R. Nicolaescu for initiating and developing this research through the early stages; A. Alduino, D. Tran, J. Tseng, A. Barkai and D. Hodge, for assistance in device fabrication and sample preparation; S. Koehl for software development; L. Peremislov for scanning electron microscope images; M. Morse, H. Liu, M. Salib, D. Samararubio, L. Liao, R. Li and G. Ding, for technical discussions; G. T. Reed and I. P. Kaminow for helpful conversations.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no competing financial interests.

Rights and permissions

About this article

Cite this article

Rong, H., Jones, R., Liu, A. et al. A continuous-wave Raman silicon laser. Nature 433, 725–728 (2005). https://doi.org/10.1038/nature03346

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1038/nature03346

This article is cited by

-

Hyper spectral resolution stimulated Raman spectroscopy with amplified fs pulse bursts

Light: Science & Applications (2024)

-

Raman amplification at 2.2 μm in silicon core fibers with prospects for extended mid-infrared source generation

Light: Science & Applications (2023)

-

Widely-tunable, multi-band Raman laser based on dispersion-managed thin-film lithium niobate microring resonators

Communications Physics (2023)

-

Broadband high-Q multimode silicon concentric racetrack resonators for widely tunable Raman lasers

Nature Communications (2022)

-

Room-temperature continuous-wave indirect-bandgap transition lasing in an ultra-thin WS2 disk

Nature Photonics (2022)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.